Patents

Literature

92 results about "Sample fixation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

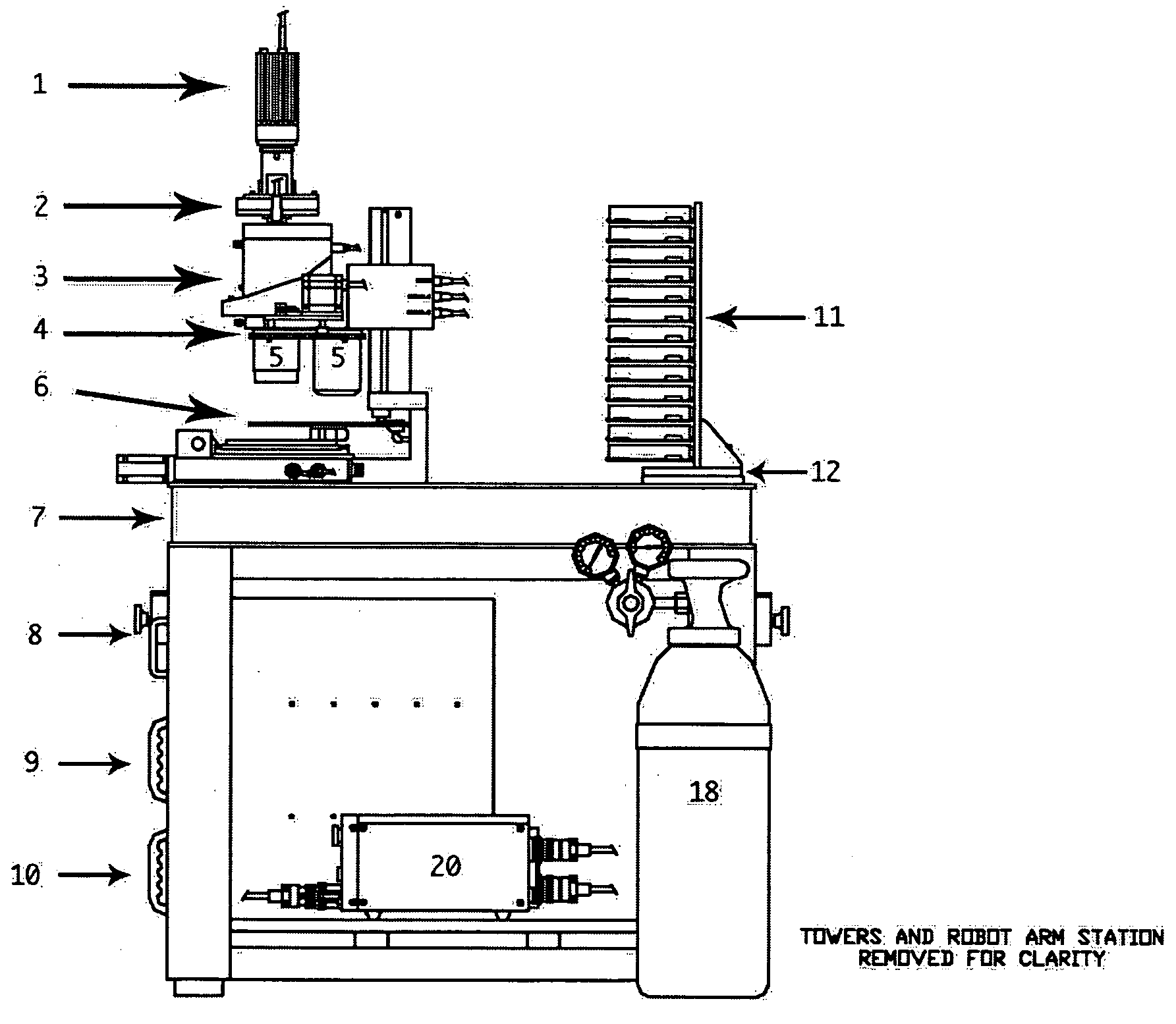

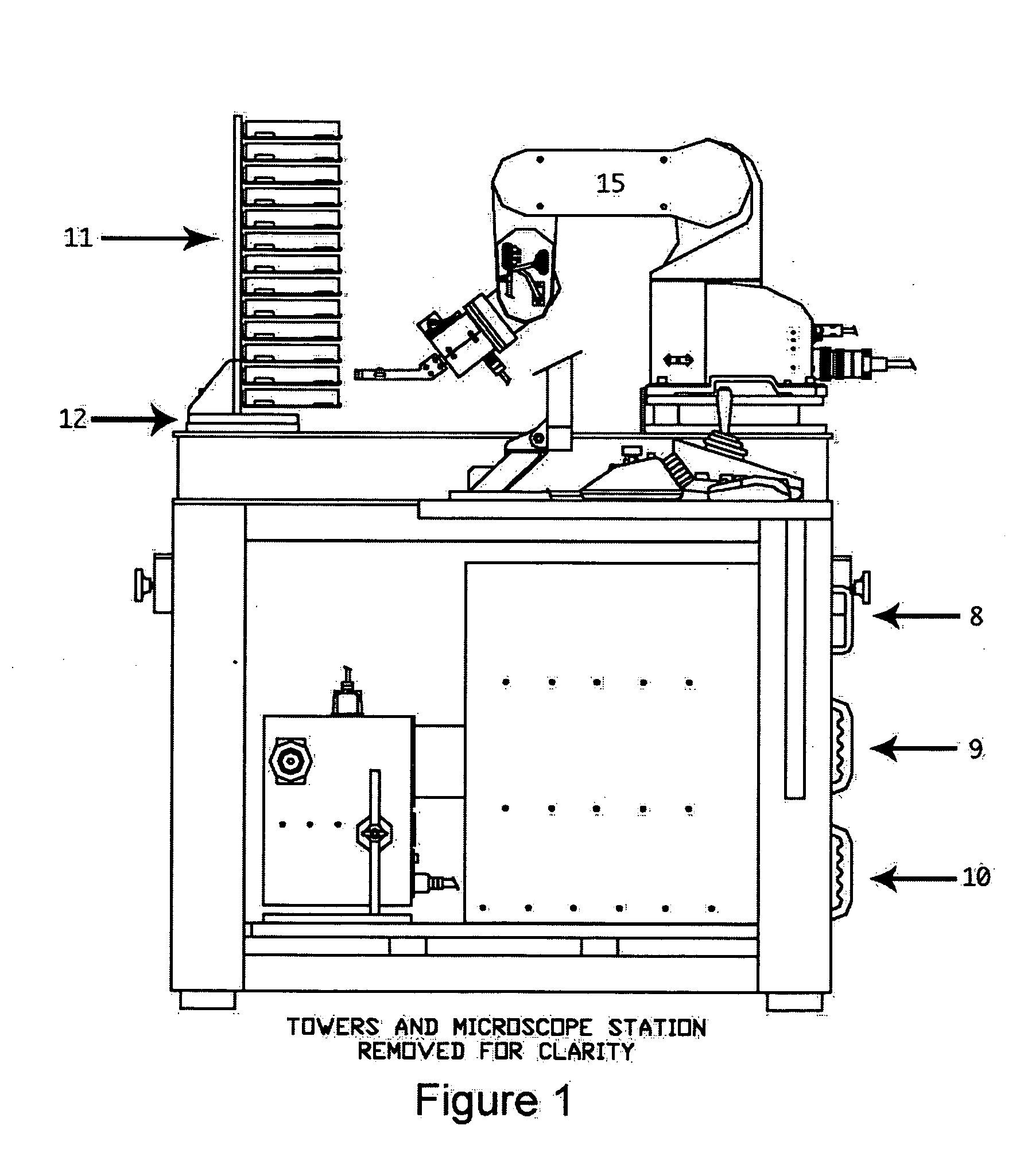

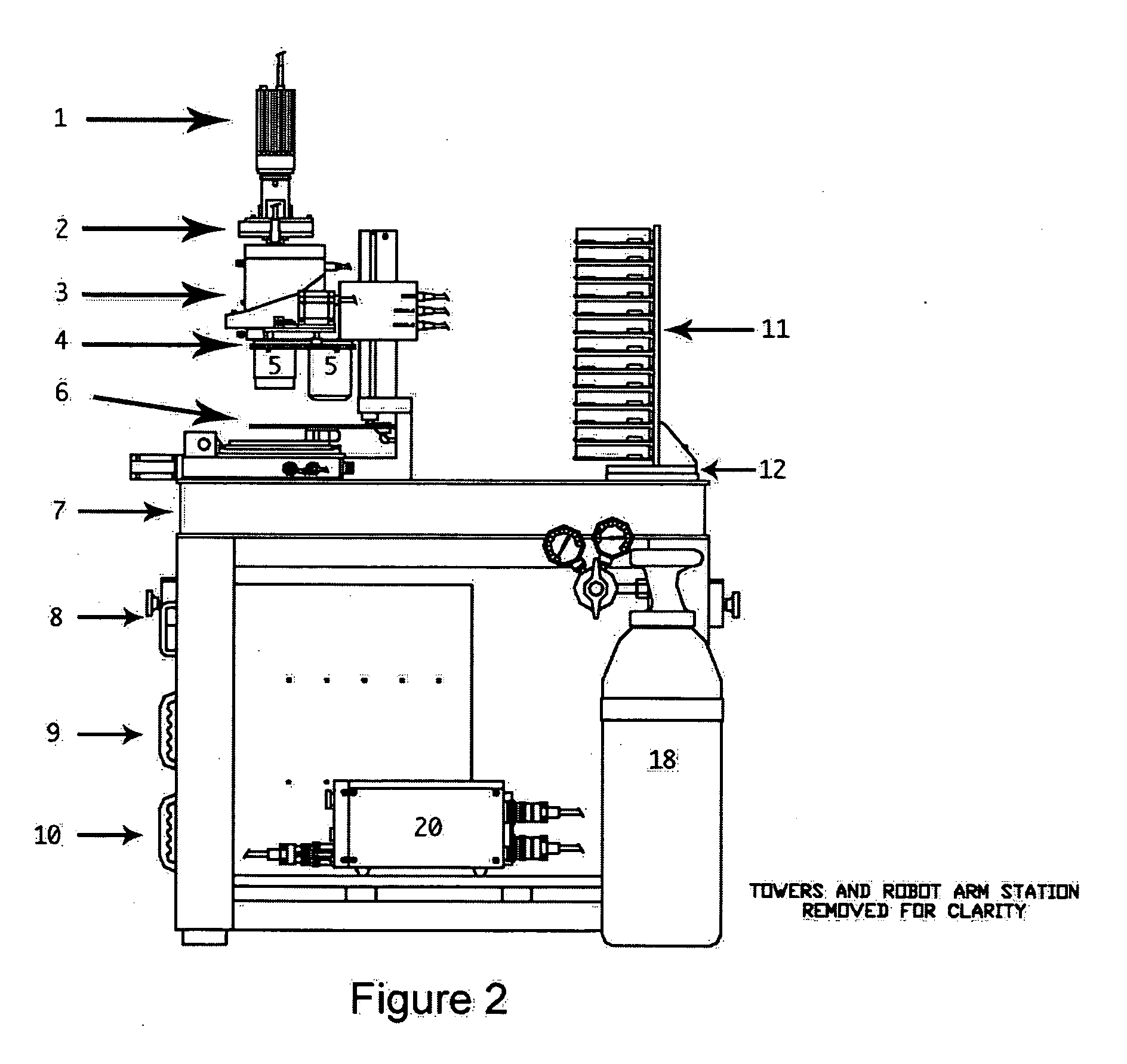

Robotic microscopy apparatus for high throughput observation of multicellular organisms

The present invention relates to a robotic microscopy apparatus that is able to screen, detect, count and image in an automated and high throughput fashion whole multicellular organisms, tissues, individual cells and groups of cells on or embedded within agar, collagen or other defined matrix. To achieve this, the robotic apparatus of the invention images the samples from the top using a microscope with a long working distance. The invention provides robotic systems for plate handling, biological sample immobilization and microscopic examination. The invention also provides for automatic image acquisition, image storage and display, and image analysis.

Owner:ELEGENICS

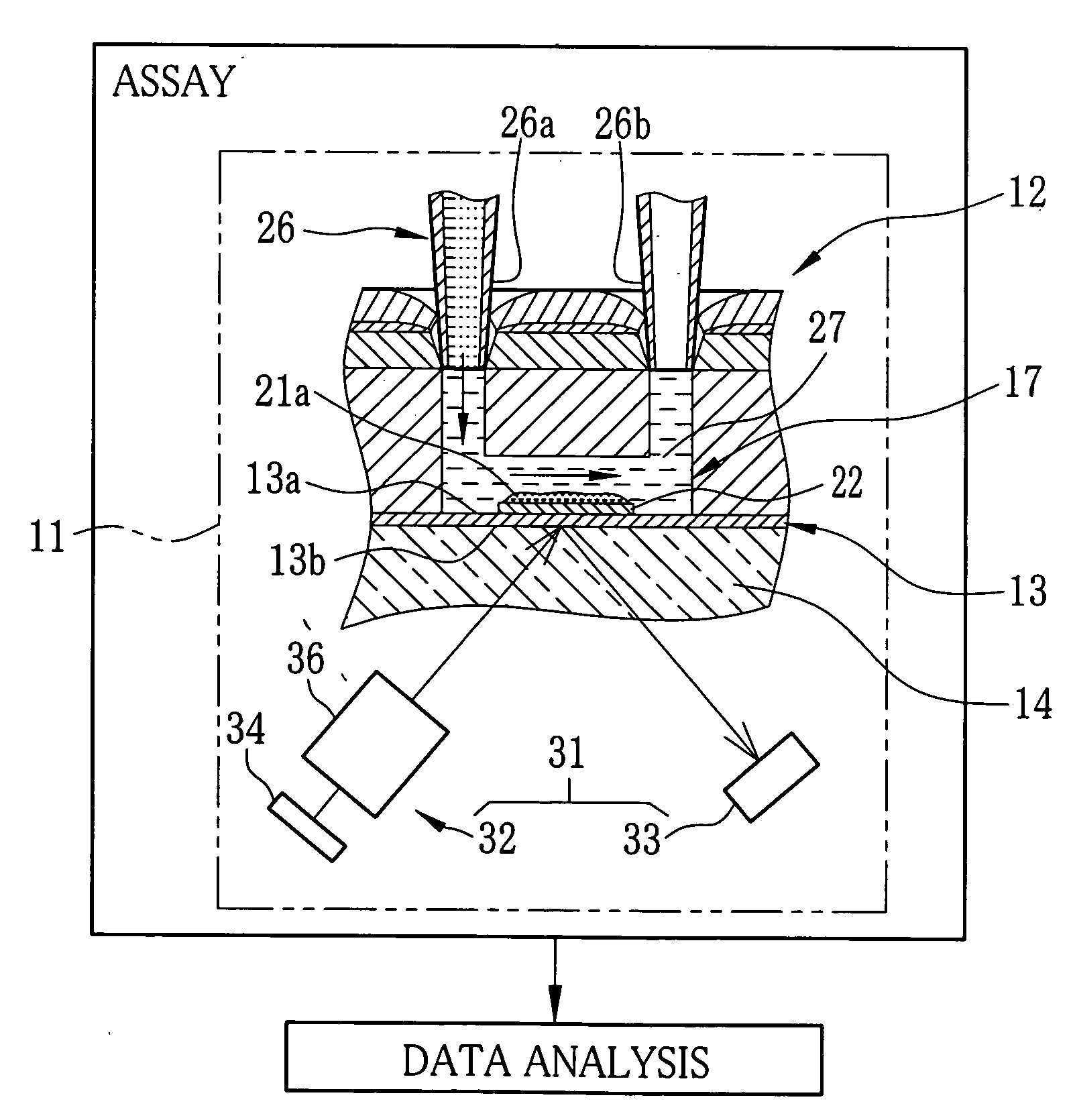

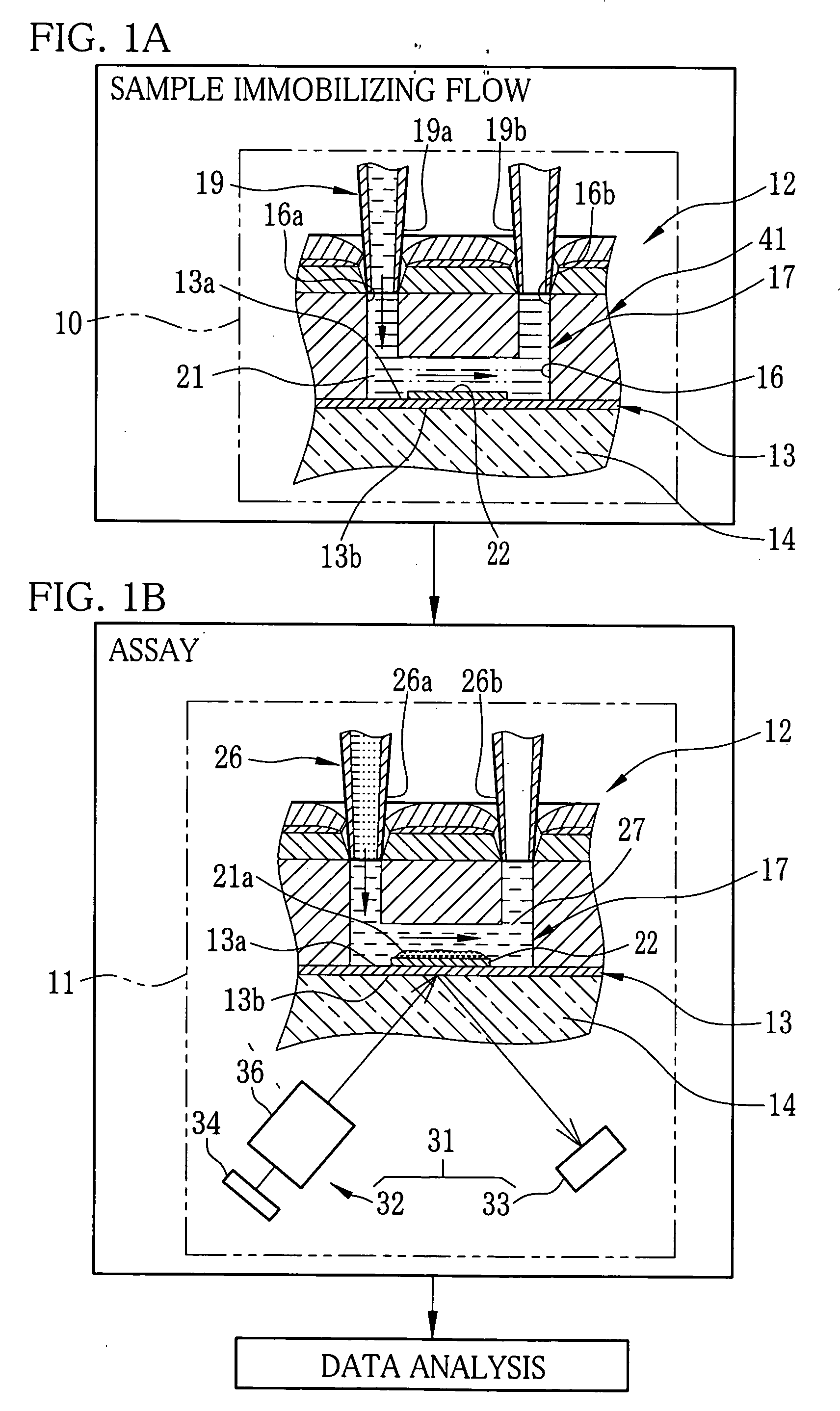

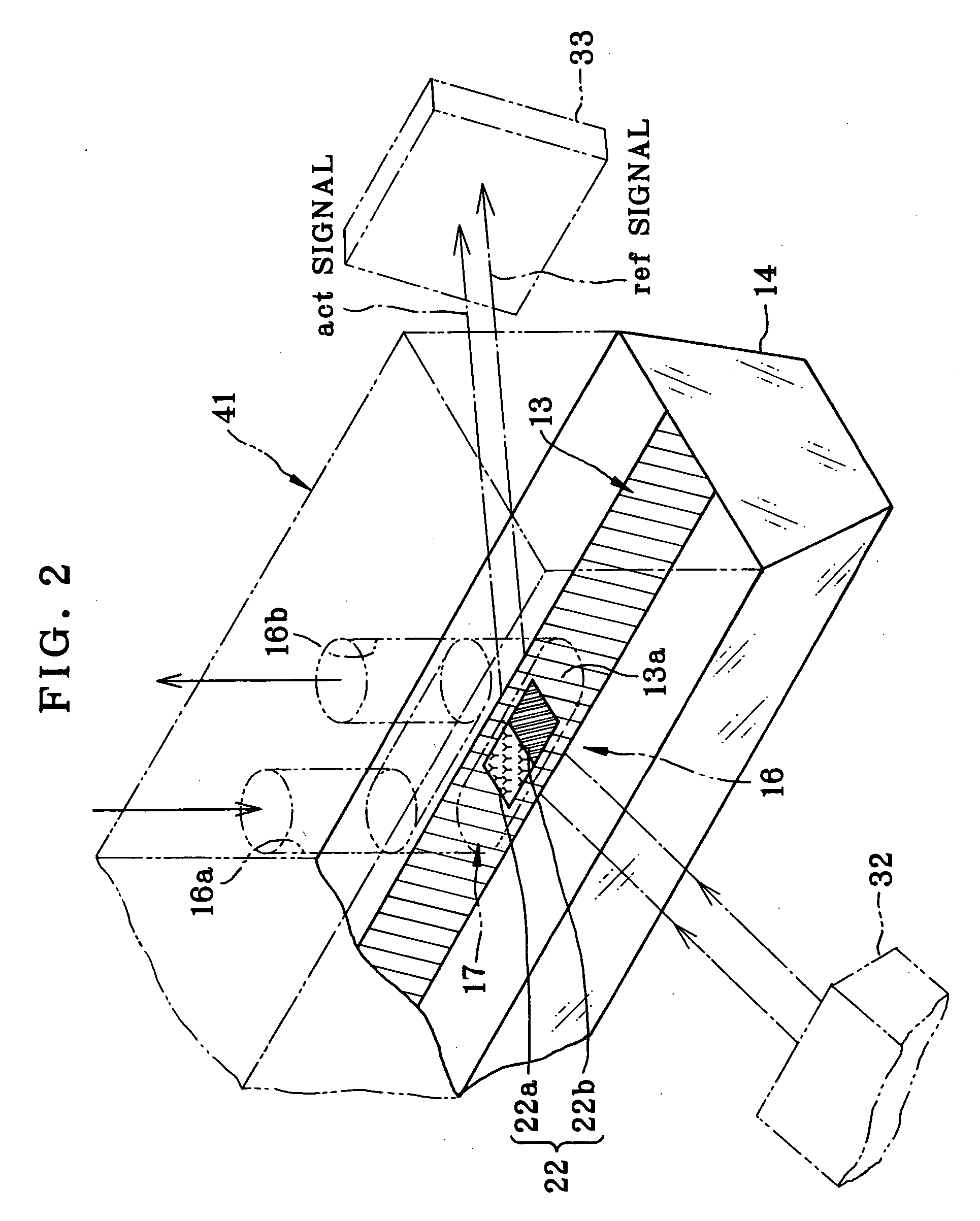

Fluid dispenser, fluid dispensing method and assay apparatus for assay in utilizing attenuated total reflection

InactiveUS20060257290A1Prevent liquid leakagePrevent leakageAnalysis using chemical indicatorsAnalysis by subjecting material to chemical reactionSample fixationPipette

A multiple pipette assembly is used for the purpose of sample immobilization for surface plasmon resonance (SPR) assay, and dispenses and introduces sample fluid of a sample to a sensing surface of a sensor unit. The sensor unit includes a flow channel having first and second orifices, and the sensing surface, positioned in the flow channel, for detecting the reaction of the sample. First and second pipette devices access the orifices. First and second pumps are connected with respectively the pipette devices, for pressurization to dispense the sample fluid through the pipette devices, or for decompression to aspirate the sample fluid through the pipette devices. The pumps are driven in a manner independent from one another. While the first and second pipette devices move away from the sensor unit, the pumps are caused to decompress a space in the first and second pipette devices and the flow channel.

Owner:FUJIFILM CORP +1

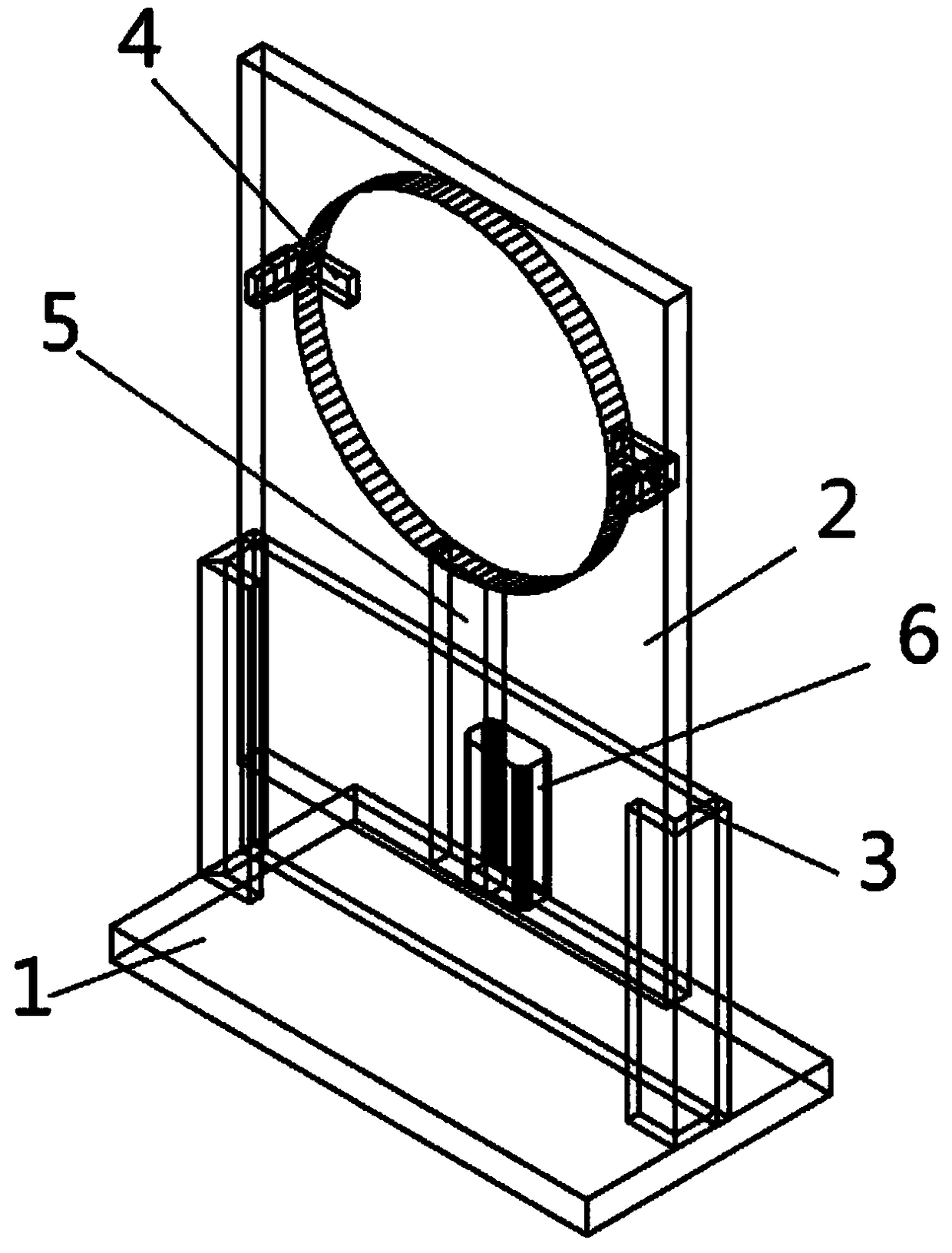

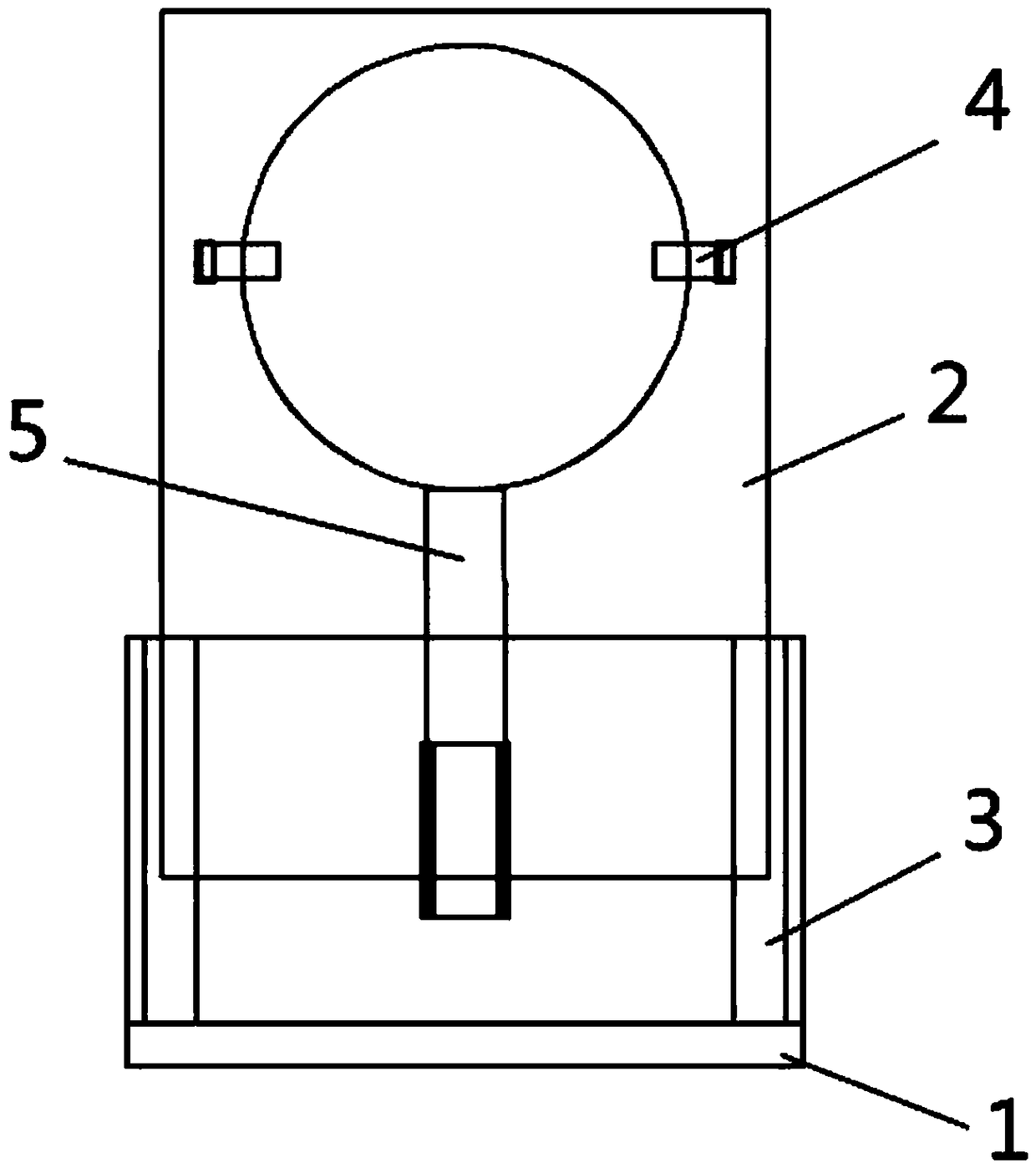

Thin film residual stress component analytical equipment

InactiveCN101285772AControl stressImprove the plating processPhase-affecting property measurementsUsing mechanical meansNon destructiveTemperature control

The invention discloses a device for analyzing compositions of residual stress of a film. The invention comprises a relay temperature control instrument, a heating plate driving circuit, a substrate fixture, an interferometer and a computer, wherein, the relay temperature control instrument is connected with the heating plate driving circuit, the substrate fixture, the interferometer and the computer in turn; the substrate fixture comprises a first copper sheet, a second copper sheet, an aluminum sheet, iron clamping pieces, a sample fixation circular orifice, a thermal resistance and MCH heating plates; the thermal resistance and two MCH heating pieces are fixed on the back of the first copper sheet; fixed grooves are arranged on both sides of the first copper sheet; the second copper sheet is inserted into the fixed grooves which are arranged on both sides of the first copper sheet; two iron clamping pieces are fixed on both sides of the upper end of the second copper sheet; the aluminum sheet is clamped on the two iron clamping pieces; and the sample fixation circular orifice is arranged on the aluminum sheet. The invention is a non-destructive detection method and has the advantages of convenient operation, quick measurement, high precision, capability of simultaneously determining a plurality of parameters and performing stress component analysis and so on.

Owner:ZHEJIANG UNIV

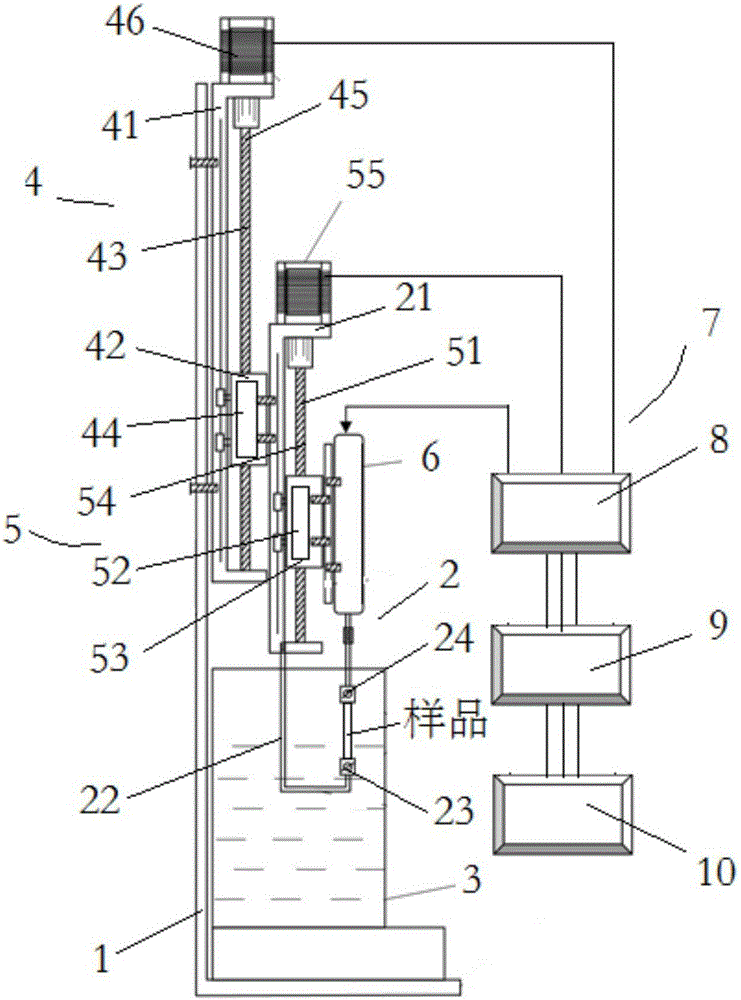

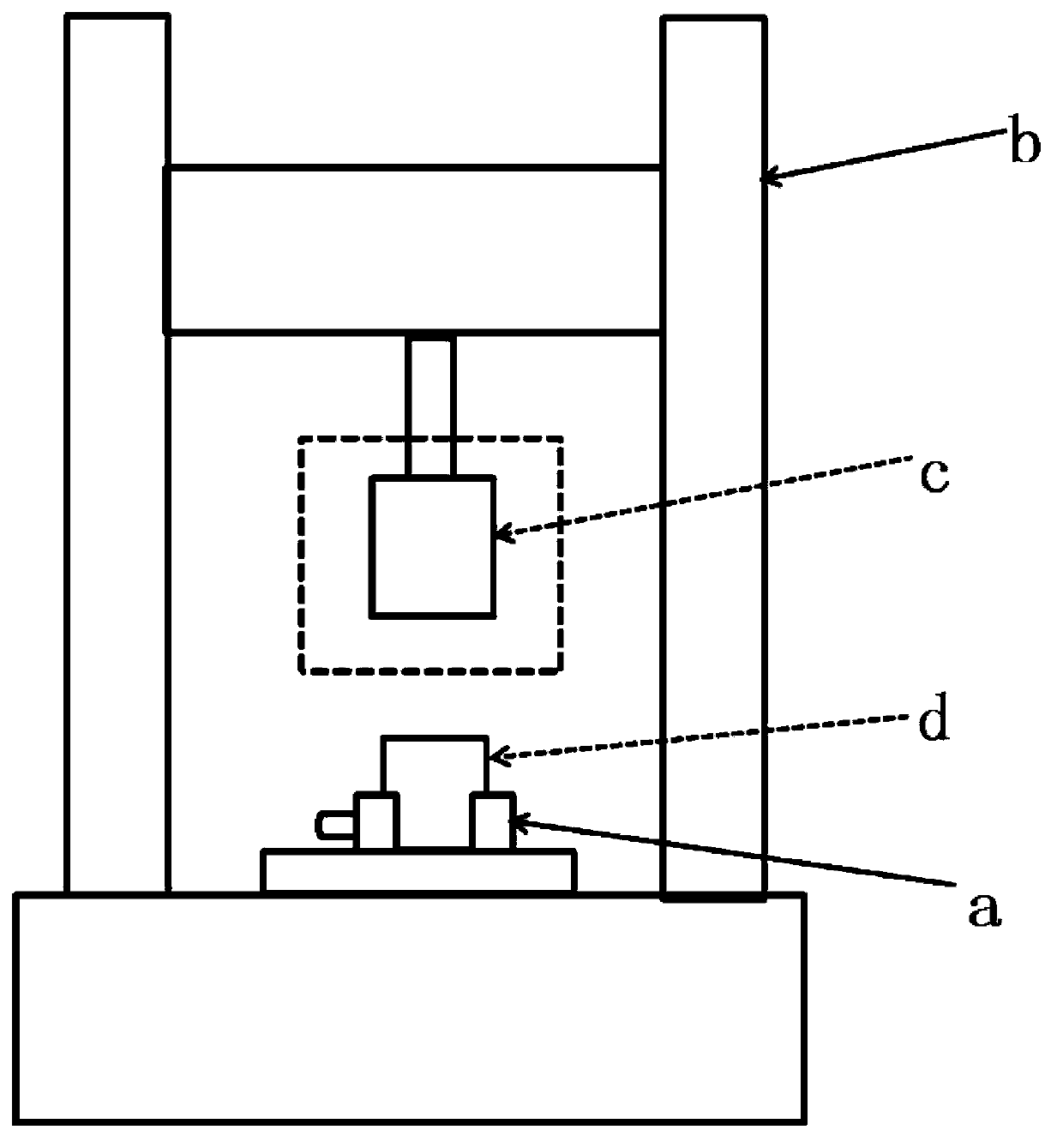

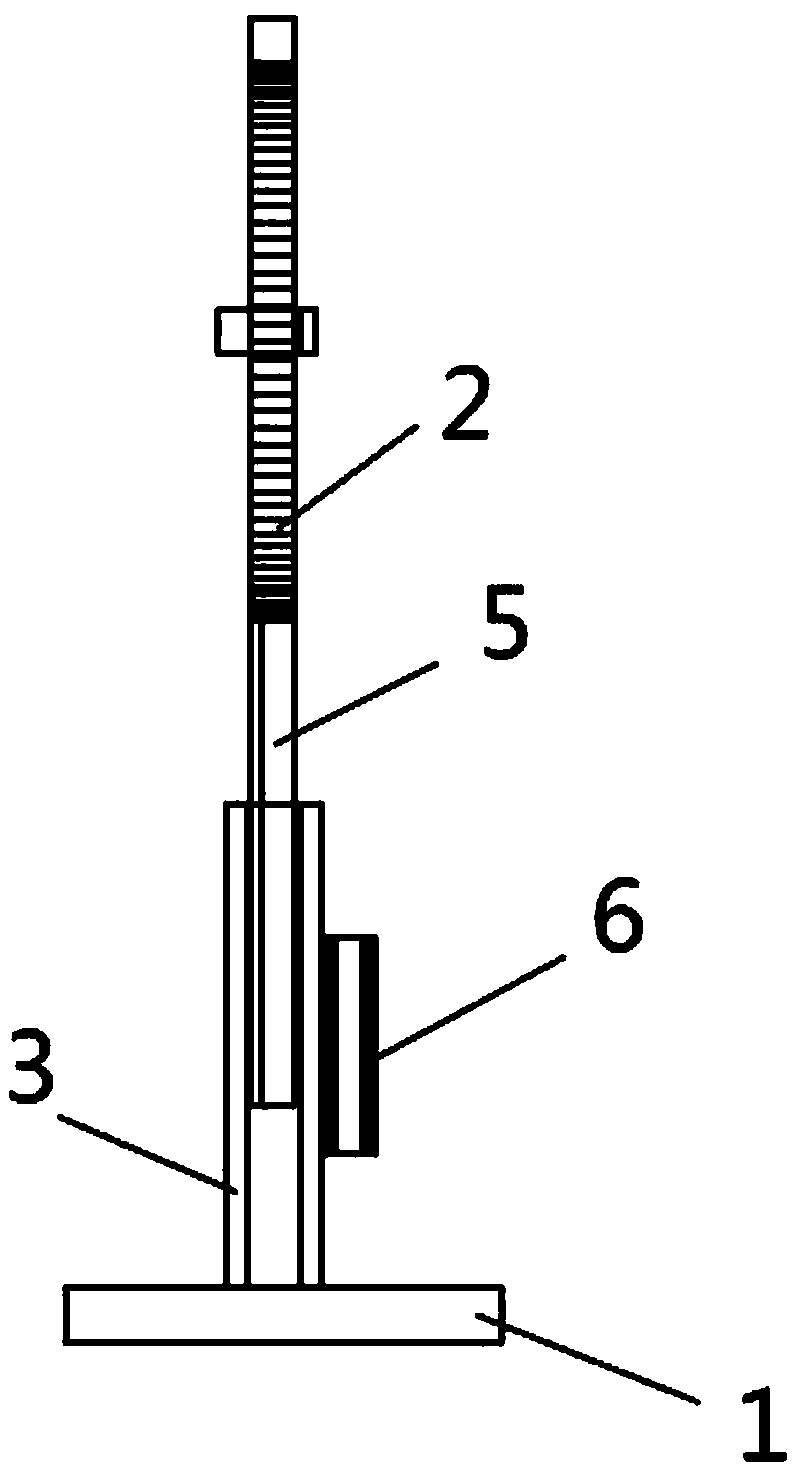

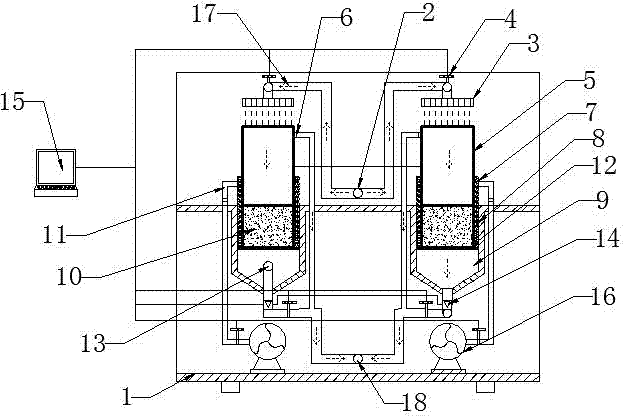

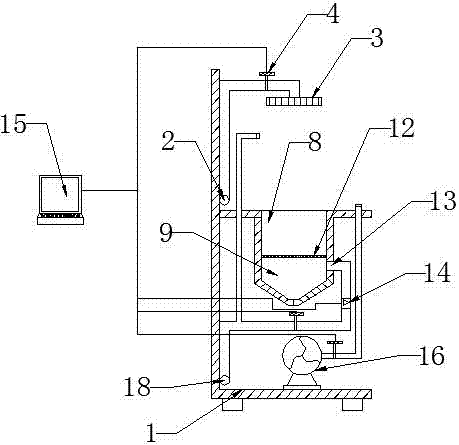

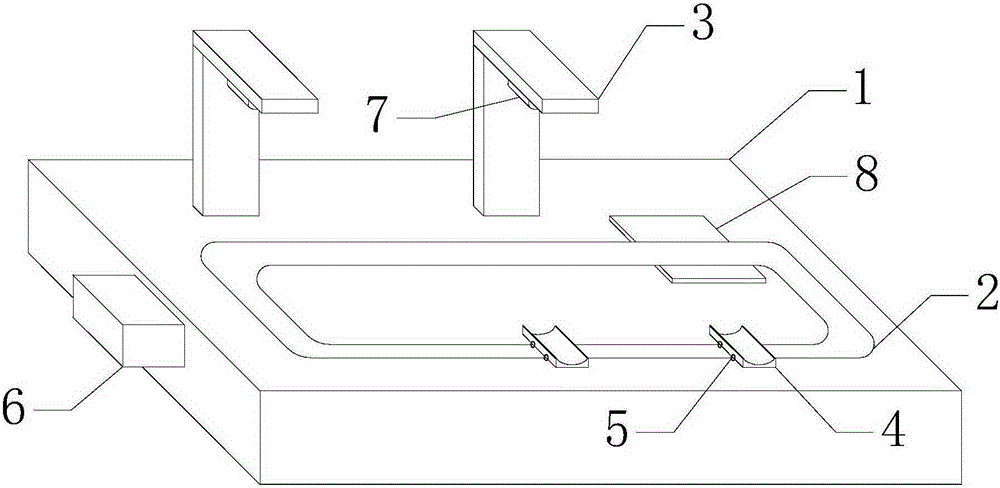

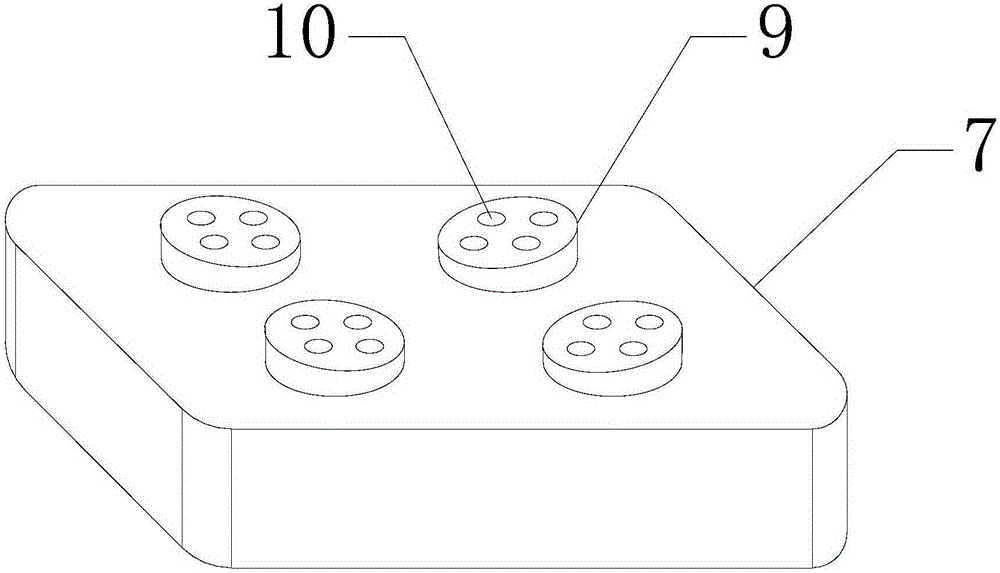

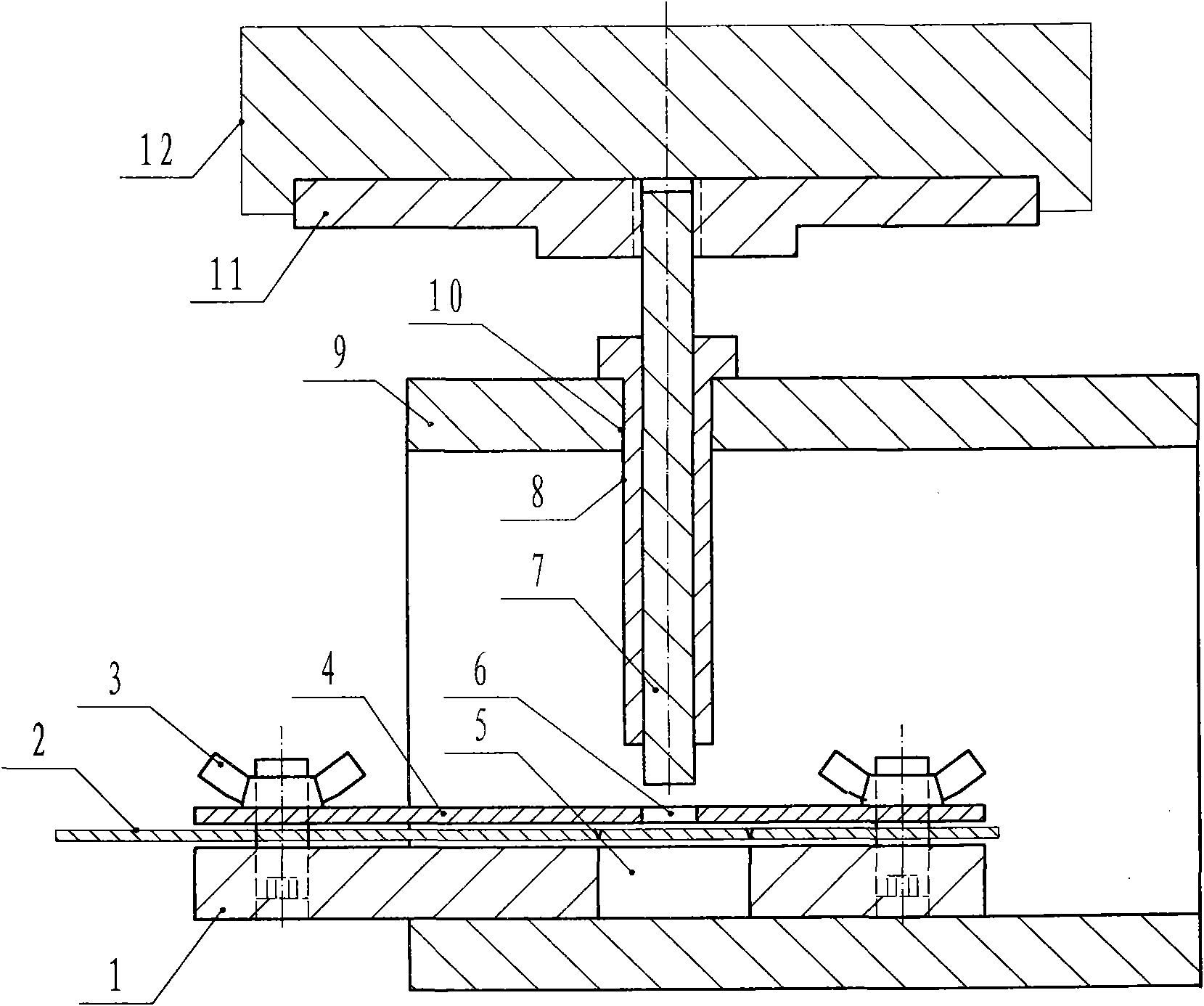

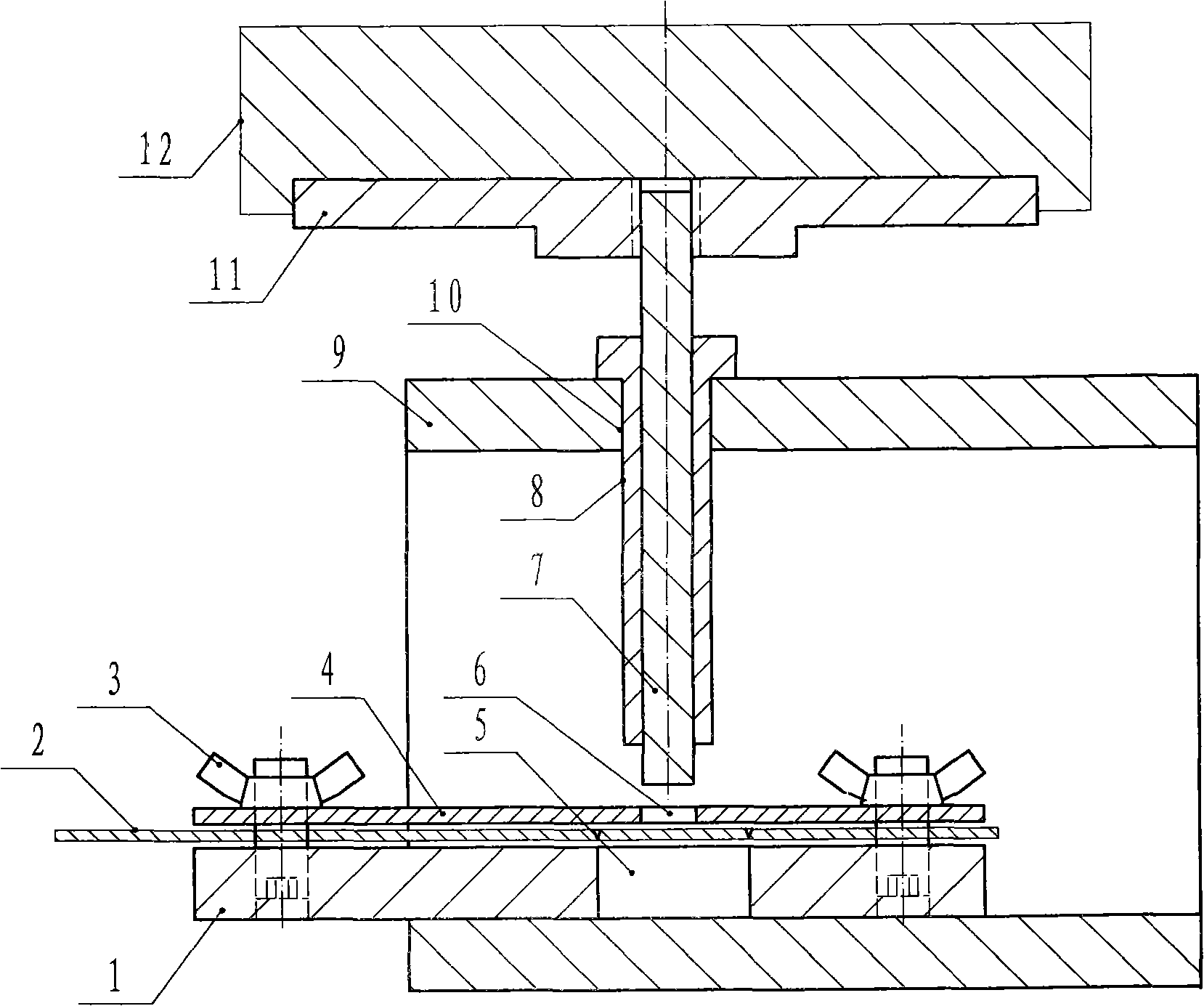

Determination apparatus and method for comprehensive properties of heat-shrinkage film

The invention discloses a determination apparatus and method for the comprehensive properties of a heat-shrinkage film, belonging to the field of testing technology. The determination apparatus comprises a base, sample clamps, a constant temperature control device, a sample length adjusting device and a control system. The determination method comprises the following steps: sample preparation; sample fixation; testing; etc. The determination apparatus and method provided by the invention are directed at the material characteristics of the heat-shrinkage film and particularity of a heat shrinkage force testing environment of the heat-shrinkage film, utilize constant-temperature water bath for heating to allow the heat-shrinkage film to be uniformly heated, and are stable and reliable in results; A lifting device is used for adjusting the working condition of a sample and the sample length adjusting device is used for adjusting distance between the sample clamps, so the determination apparatus and method can test the peeling strength of samples of different lengths and the heat shrinkage force of the samples of different lengths under different temperature conditions; meanwhile, cold shrinkage force can be tested during testing of the heat shrinkage force, so a testing scope is greatly broadened; moreover, the clamps can be replaced for testing of expansibility or restoring force, so testing of more properties of the heat-shrinkage film is realized.

Owner:CHONGQING UNIV

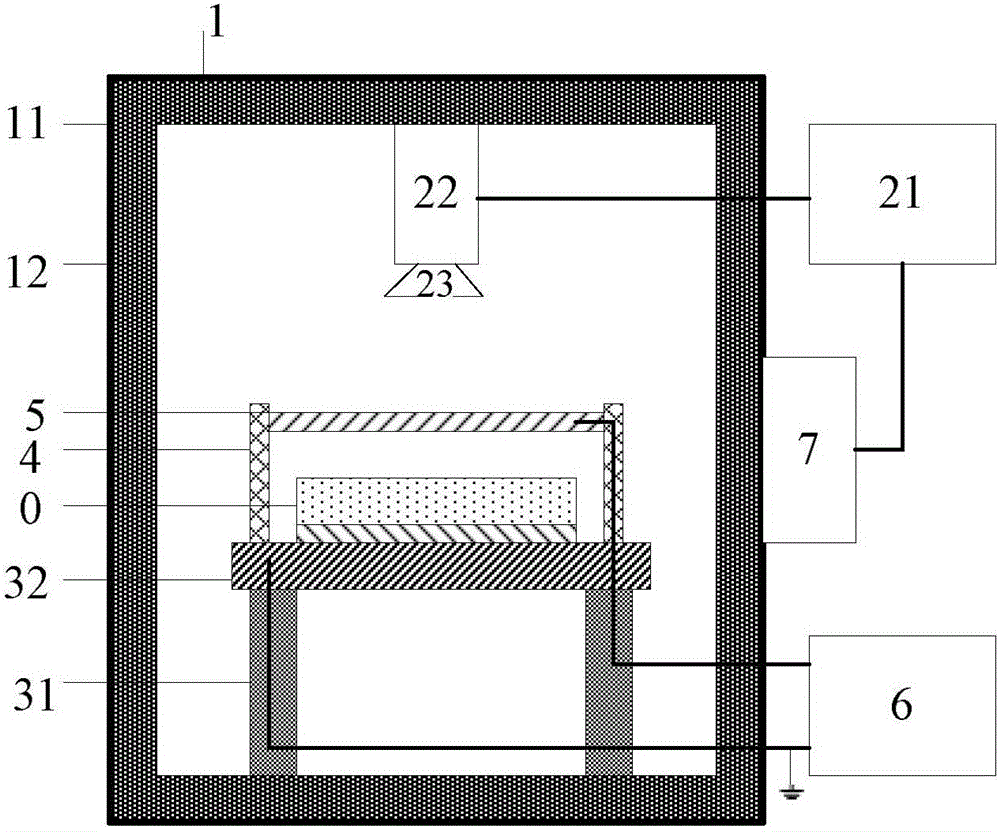

Ray based electret polarization device and method

ActiveCN105036065AFast polarizationSimple structureTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesHigh densitySample fixation

The invention discloses a ray based electret polarization device and method. The electret polarization device comprises a protective box body, a ray generator, a sample fixing component, a support rack, a metal film and a high voltage bias power supply. A space around the metal film, a to-be-polarized electret sample and a sample platform in a ray covered area is filled with high density plasma. A high voltage bias electric field is formed between the metal film connected with the high voltage end and a conductive sample platform connected with the grounded end. Under the action of the high voltage bias electric field, positive charge and negative charge in the plasma are separated and move toward the opposite directions, so that the charge of specific electric property can be adsorbed on the surface of the to-be-polarized electret sample. The device does not need a vacuum environment, has a simple structure, and is rapid and efficient. The polarization time can be shortened to 10 seconds magnitude from 5-20 minutes of the traditional corona polarization time. The electret in a packaging shell can be polarized rapidly.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

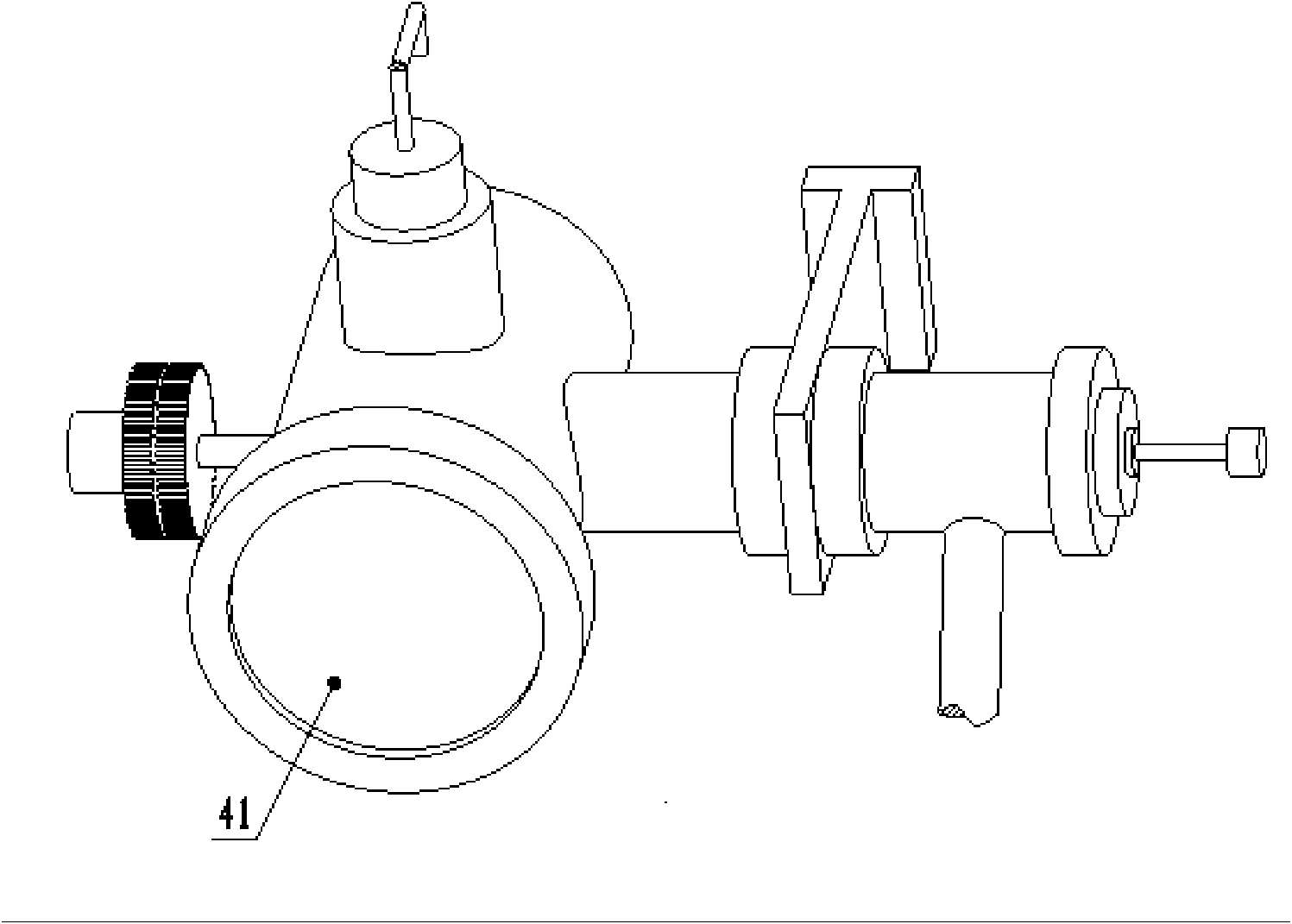

Light emission microscope opposite side sample fixer

InactiveCN101086553AAvoid pollutionEasy to useOptically investigating flaws/contaminationMicroscopesPhotoemission microscopySample fixation

The light transmitting microscope back sample fixture mainly comprises the sample bearing base plate, sample fixing pole and at least three movable threaded cushion, middle of the sample bearing plate embedded with transparent glass as the location for bearing sample. It does not need thermosol, without pollution, being material saving and convenient in use.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

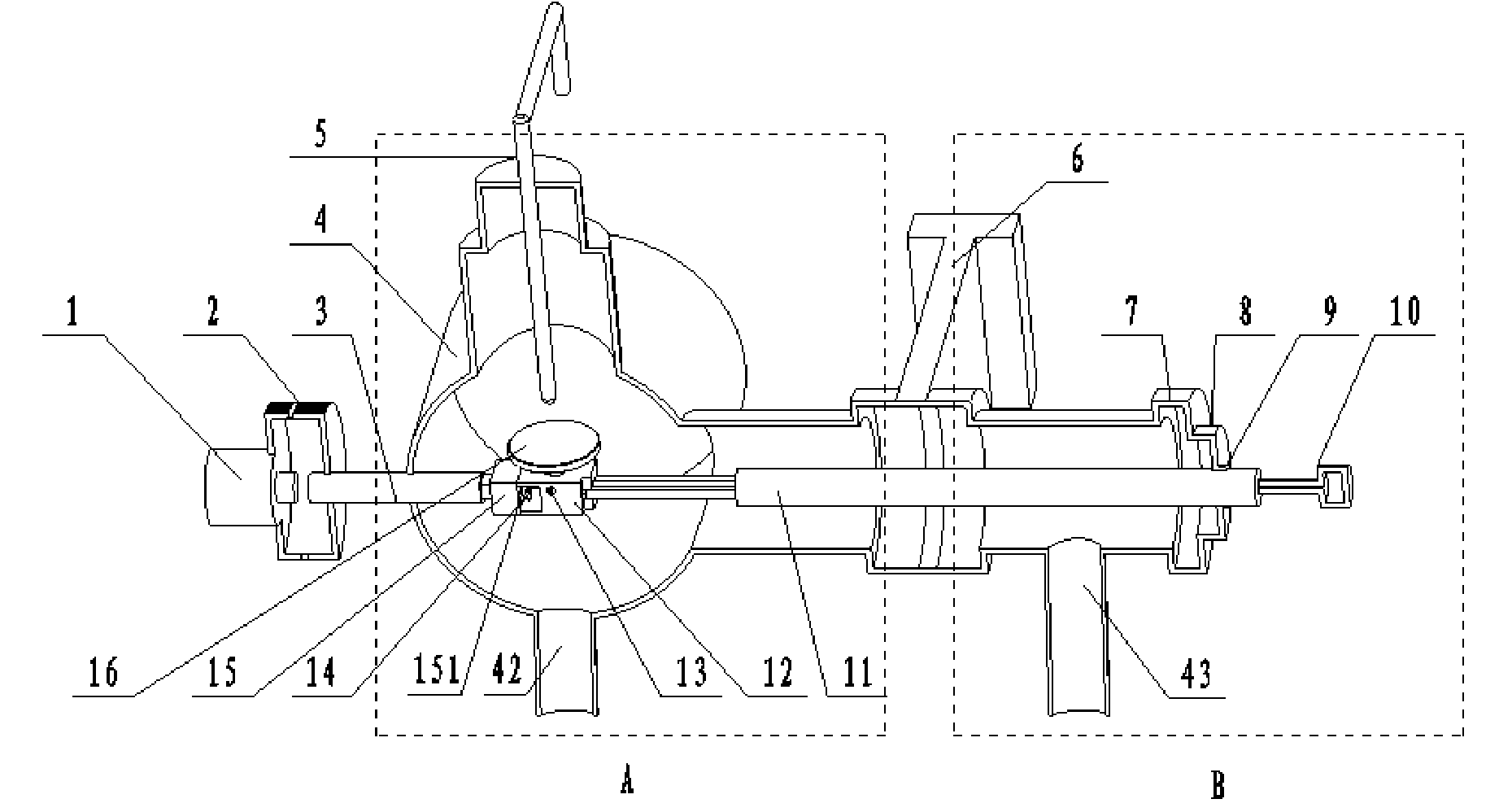

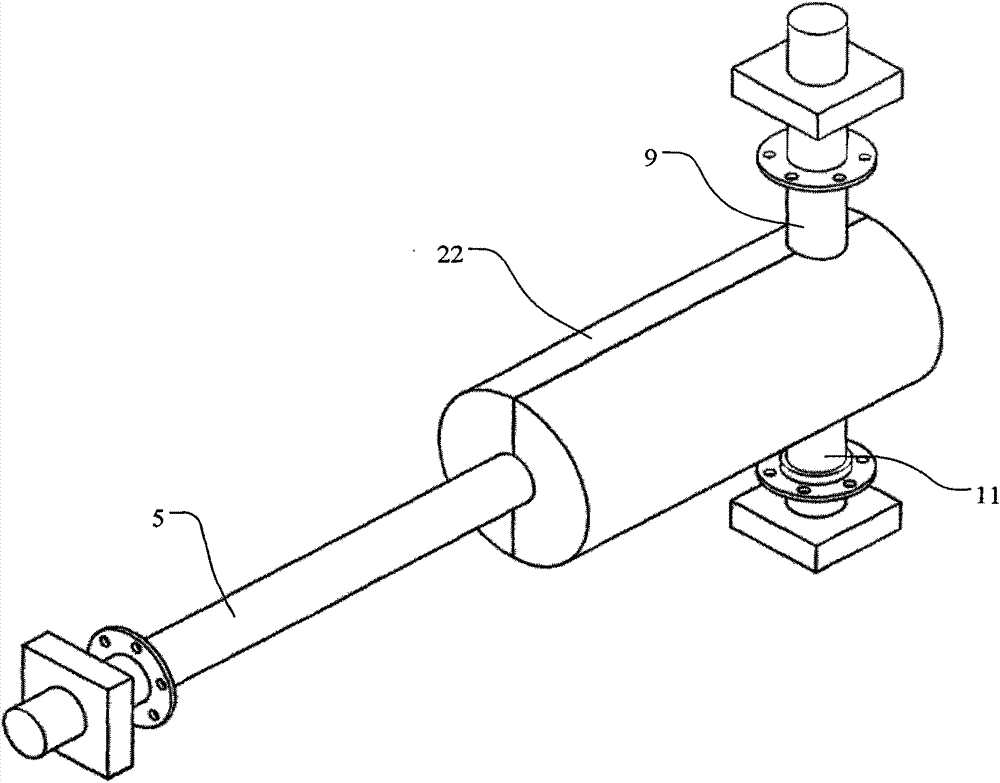

Sample feeding apparatus for ultra-high vacuum test

InactiveCN102809661ASimple structureAvoid multiple exposures to the atmospherePreparing sample for investigationSample fixationUltra-high vacuum

The invention discloses a sample feeding apparatus for an ultra-high vacuum test, and relates to a vacuum test technology. The apparatus comprises a vacuum tank, a sample seat, sample fixation pins, a sample feeding rod, a sample connection rod, connection screws, a sample connection head, and a gate valve. According to the apparatus, an axial end of the vacuum tank body is an observation window, a vertical cavity and a horizontal cavity are arranged in a radial direction, and the middle part of the horizontal cavity is provided with the gate valve. The left side of the gate valve is an ultra-high vacuum region, and the right side of the gate valve is a low vacuum region, wherein the two vacuum regions have air exhaust devices. A sample requiring detection is fixed on the upper surface of the sample seat through the fixation pin, the sample connection rod on the left side and the sample connection head form a separable fixation connection through the connection screw, and the sample seat and the sample connection head form a fixation connection so as to position inside a vacuum cavity. The sample connection rod, the sample connection head, the sample seat, and the sample feeding rod are horizontally and coaxially arranged in a line. The apparatus of the present invention has characteristics of simple structure, easy manufacturing and reliable sample feeding, and can be used for various vacuum tests and analysis equipment.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

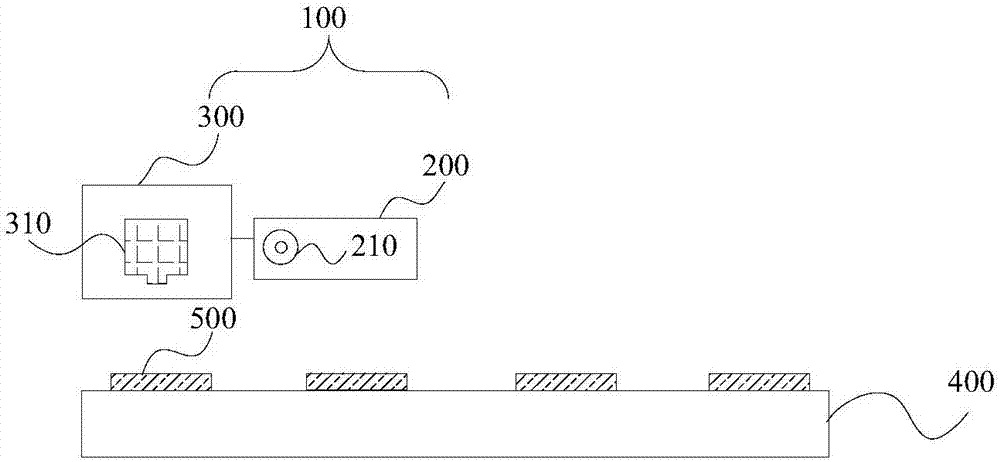

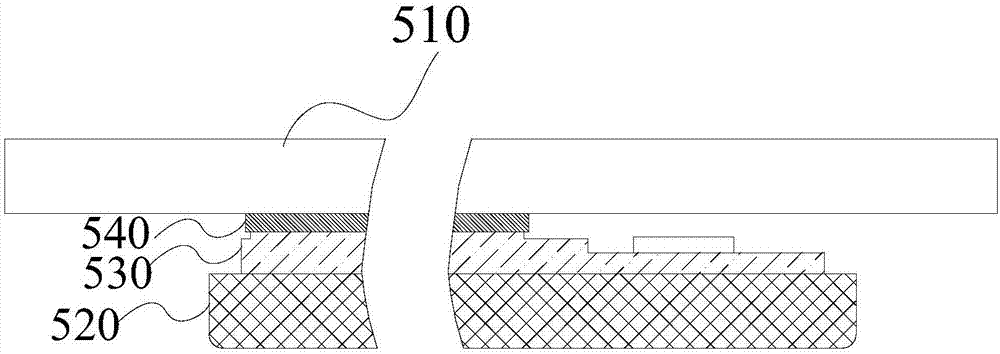

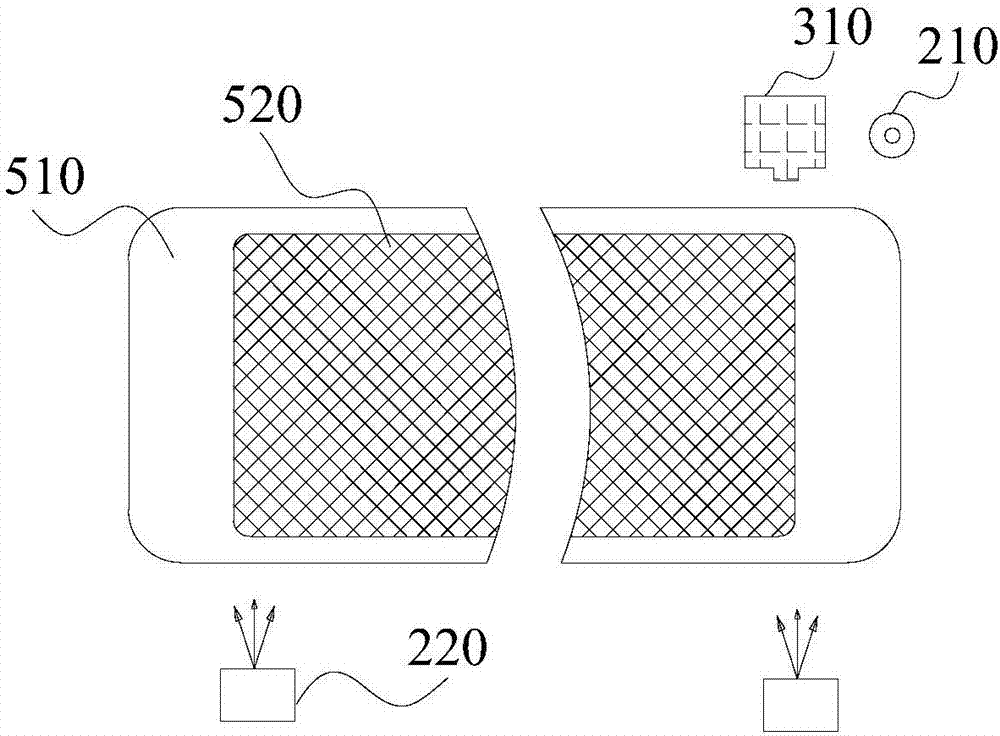

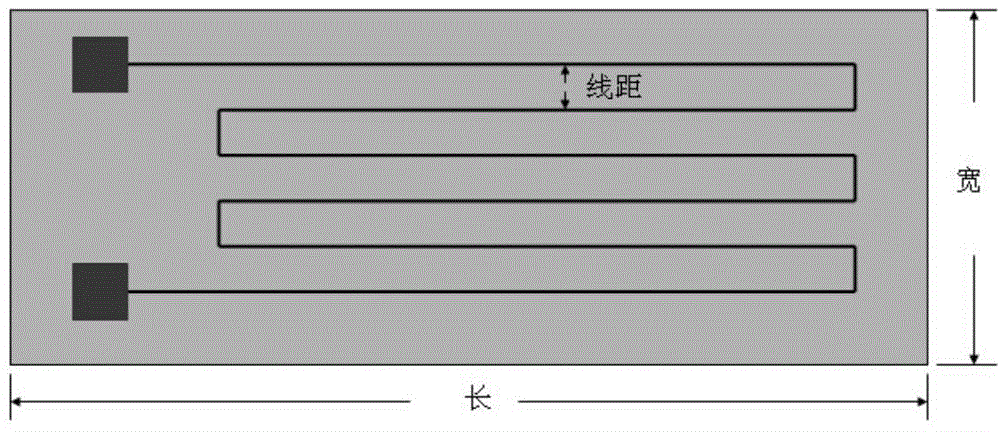

Dispensing system and method used for backlight module, display device and electronic equipment

The invention provides a dispensing system and method used for a backlight module, a display device and electronic equipment. The dispensing system comprises a sample fixing device and a dispensing device. The sample fixing device is internally provided with multiple sequentially-arranged samples to be subjected to dispensing. The dispensing device comprises a positioning unit and a dispensing unit. The positioning unit comprises a positioning camera which is used for determining the dispensing path according to positions of protection cover plates in the samples to be subjected to dispensing. The dispensing unit comprises a dispensing part which is arranged to be capable of conducting dispensing on the sample to be subjected to dispensing along the dispensing path, wherein the sample is adjacent to the positioning unit. The sample fixing device and the dispensing device are arranged to be capable of moving oppositely. The dispensing system has at least one of the following beneficial effects that the production efficiency is high, the dispensing path is accurate, and the production yield is high.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

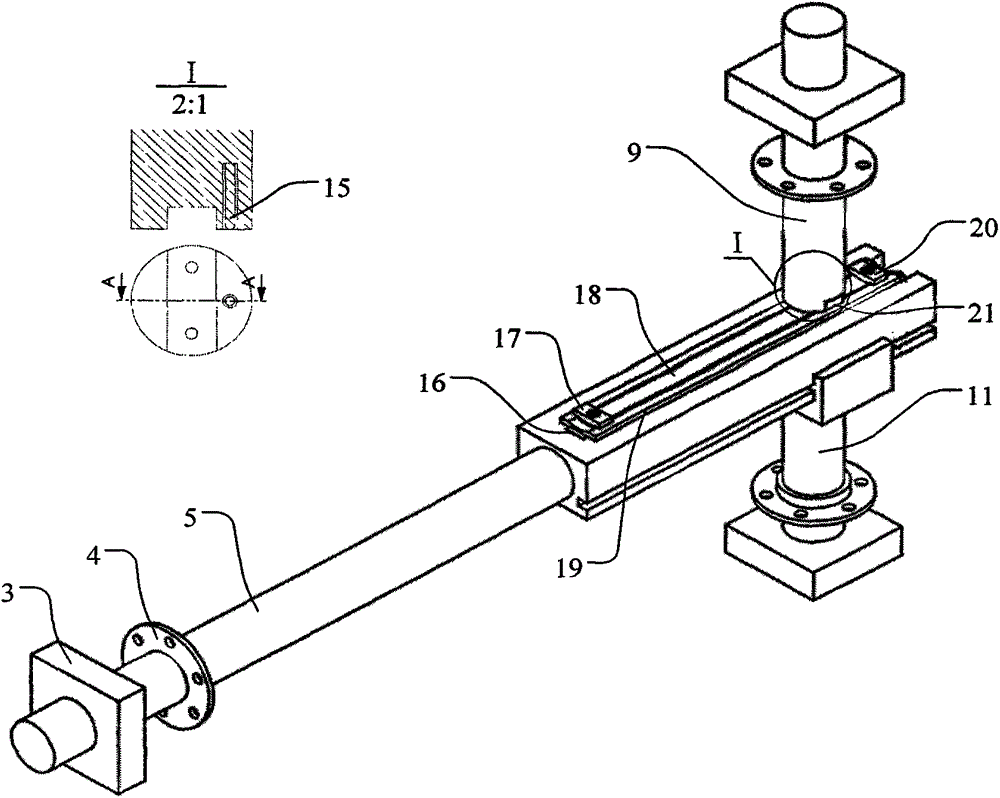

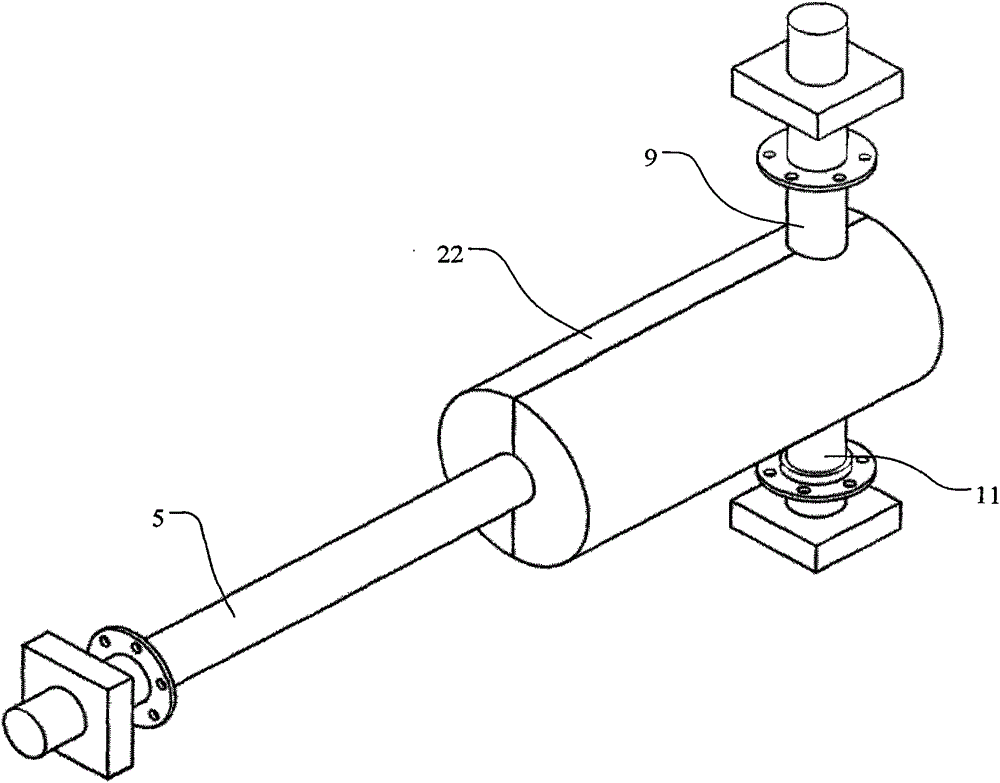

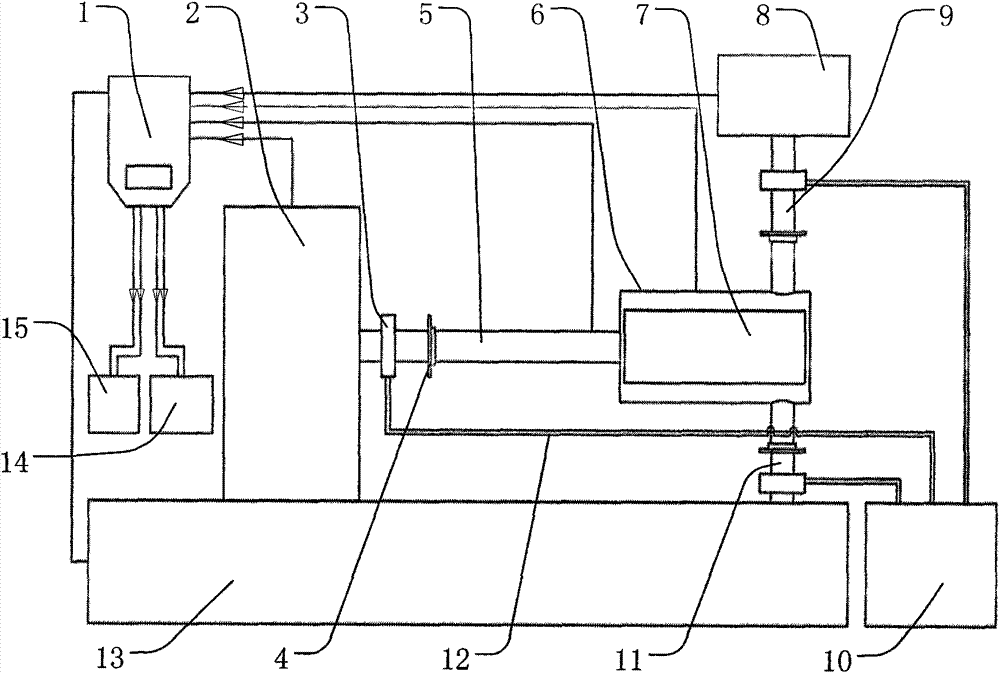

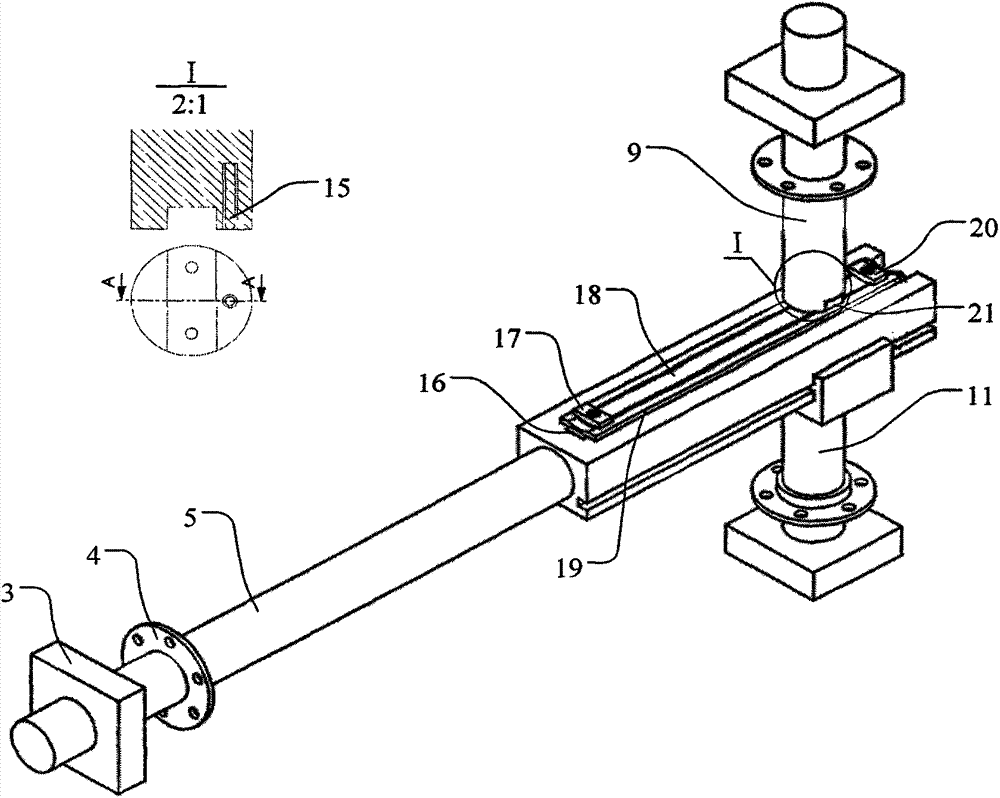

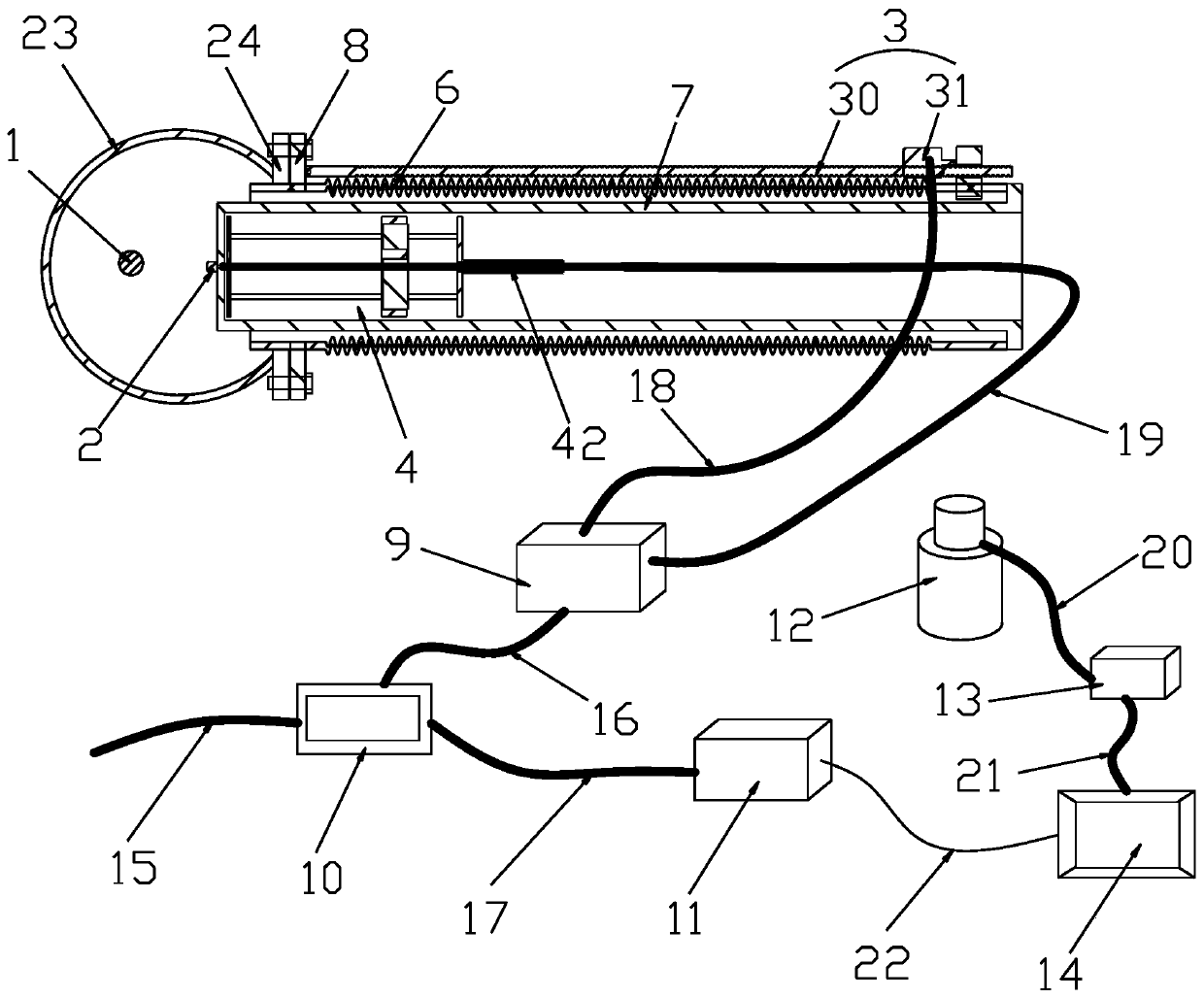

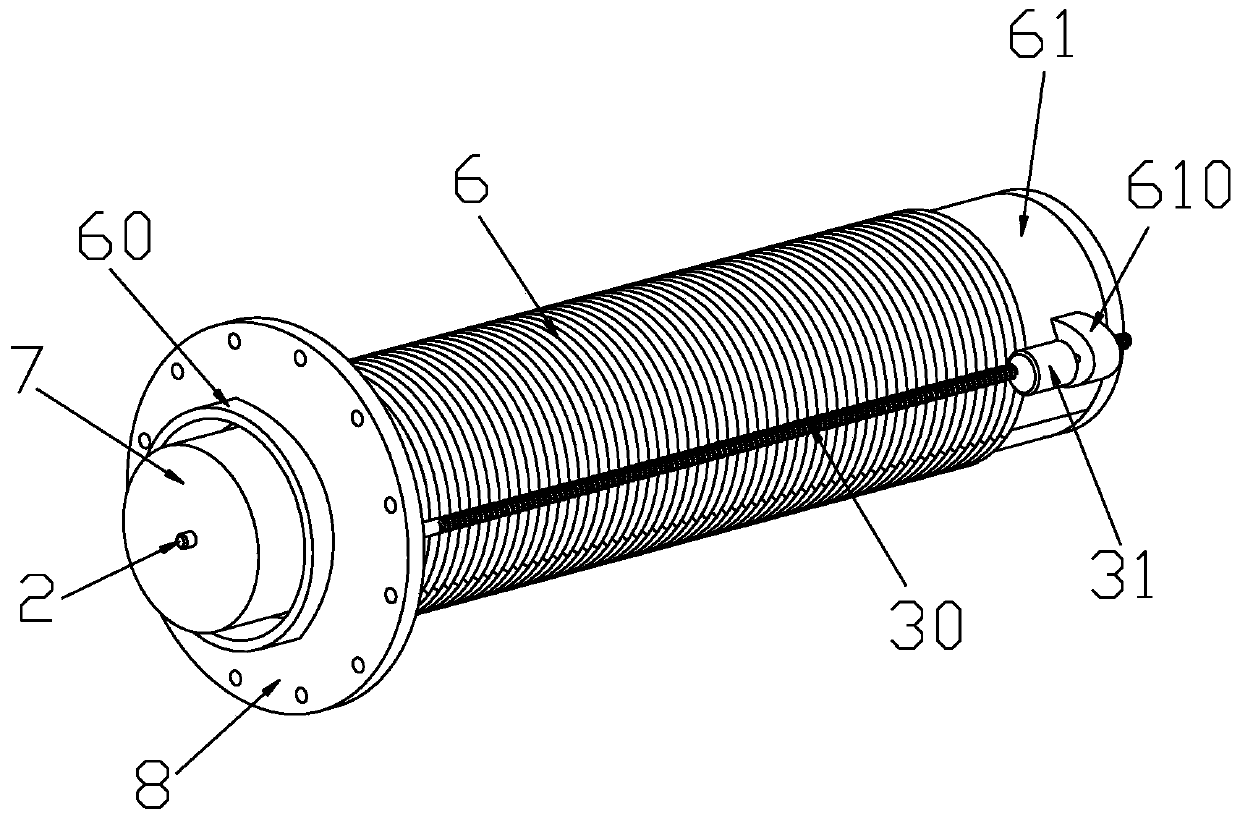

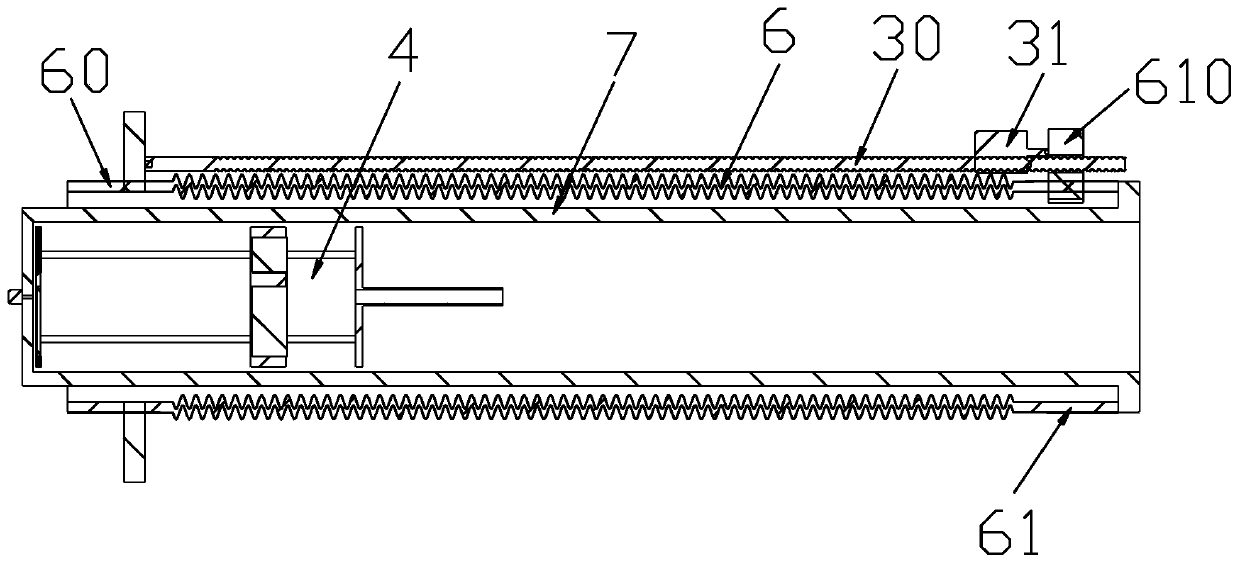

Device for measuring pipe/die friction coefficient during pipe bending forming

ActiveCN104132887AAvoid influenceReduce processing stepsUsing mechanical meansMaterial analysisHorizontal transmissionTemperature control

The invention relates to a device for measuring a pipe / die friction coefficient during pipe bending forming. The device includes: a horizontal transmission sensor platform, a hydraulic sensor platform, a cooling system, a friction pair instrument, a resistance heating furnace, a temperature sensor, a friction sensor, a charge amplifier, a temperature control instrument and an A / D acquisition computer. A horizontal transmission rod matches with a pipe die fixed station, a pipe sample is fixed on a sample fixation table, an upper die is fixed at the lower end of an upper die fixation rod, which is assembled with the hydraulic sensor platform, the cooling system is assembled with the horizontal transmission rod, the upper die fixation rod and a support seat, and the hydraulic sensor platform, the horizontal transmission sensor platform and all the sensors are respectively connected to the A / D acquisition computer through the charge amplifier. The device provided by the invention can accurately measure the friction coefficient between the pipe inner wall, outer wall and the die under different temperatures, pressures, lubrication states and other conditions, has the advantages of high degree of automation, simple operation and high measurement accuracy, and has a wide range of application for measurement of the pipe forming friction coefficient.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

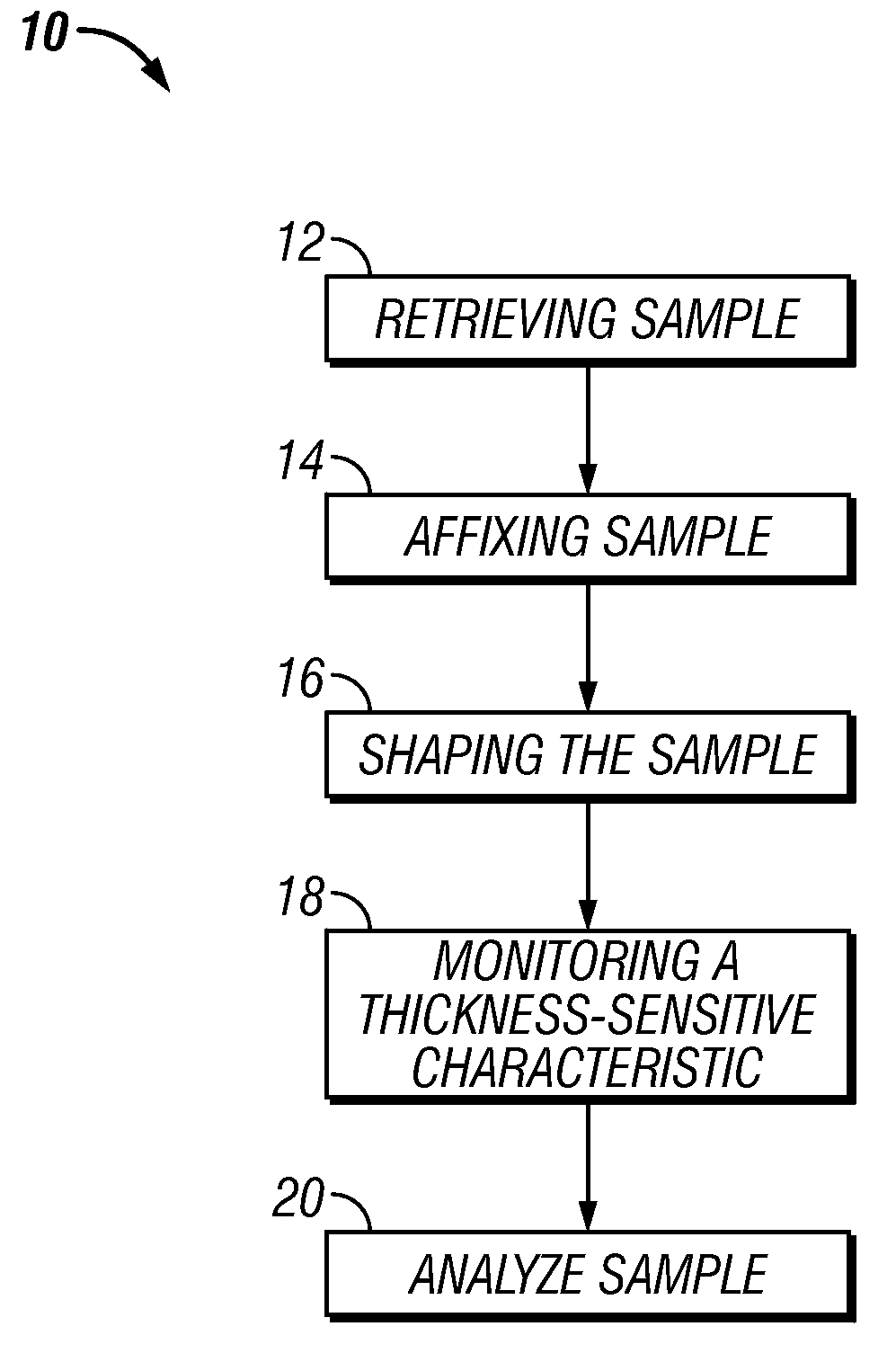

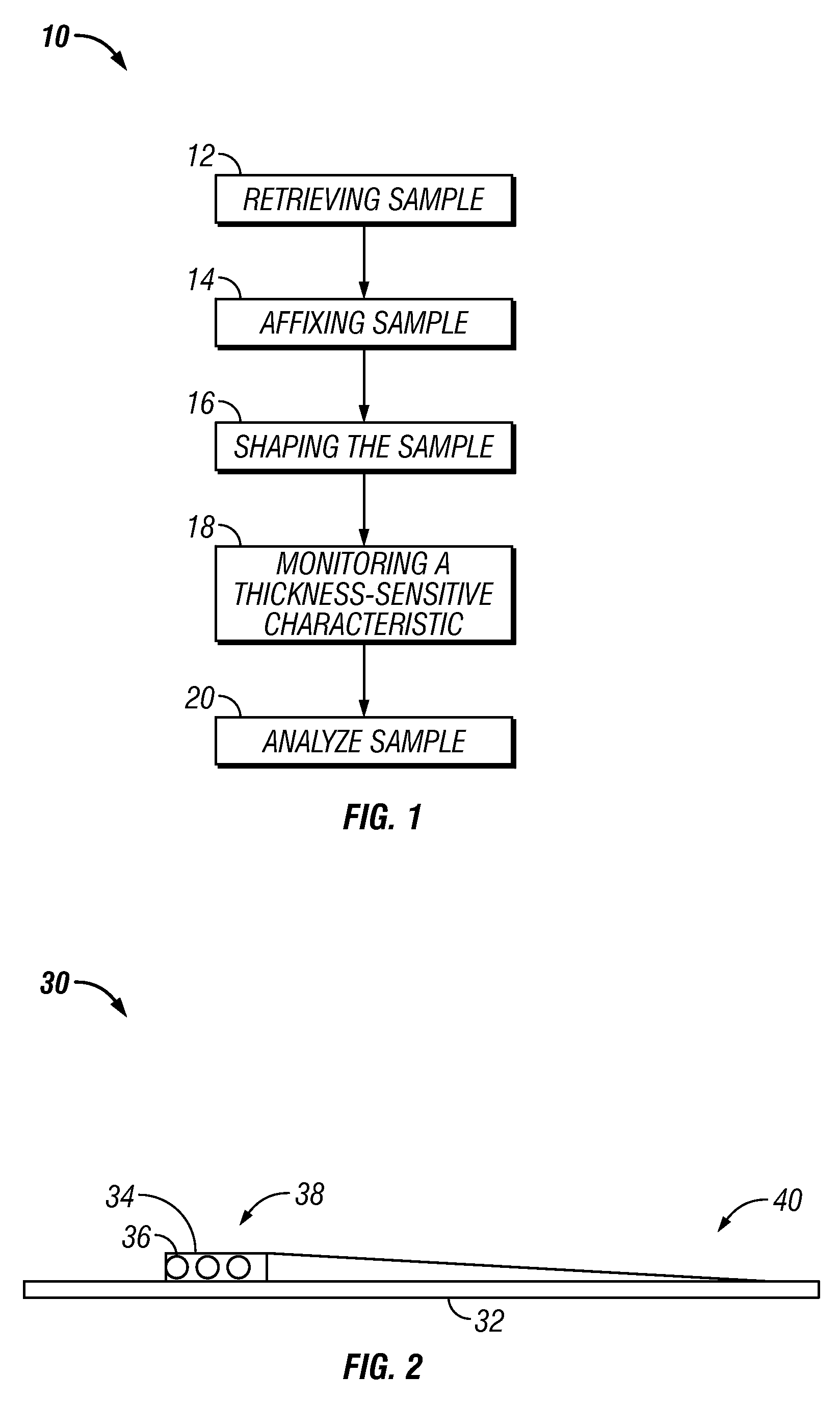

Enhanced process for preparing core sample thin sections

Owner:CORE LAB LP

Device and method for plating film on curved surface material

InactiveCN110607509ASimple device structureEase of mass productionVacuum evaporation coatingSputtering coatingEngineeringMultiple layer

The invention relates to a technology for plating a film on a curved surface material, in particular to a method for plating the film on the surface of the curved surface material by utilizing vacuumfilm plating equipment. According to the method for plating the film on the surface of the curved surface material by utilizing the vacuum film plating equipment, firstly, a plated sample is installedto a plated sample fixing rack, then vacuumizing is started, after vacuum is reached, a reactive inert gas is filled into a vacuum chamber, a target material is pre-sputtered, after pre-sputtering isfinished, the plated sample fixing rack fixed on a revolution turntable device is made to stop rotating after rotating to right ahead a target, then the plated sample fixing rack is made to start performing self-rotation, and then formal sputtering is started to start film plating. By means of the film plating device and method, an uniform thin film can be plated on a curved surface base material, multiple layers of thin films can be plated on the curved surface according to requirements, the film plating device is simple in structure, and large-scale production is easily realized.

Owner:JINLING INST OF TECH

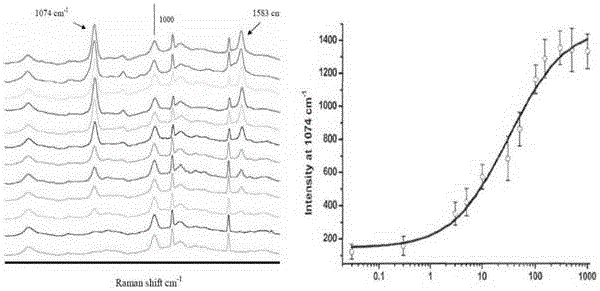

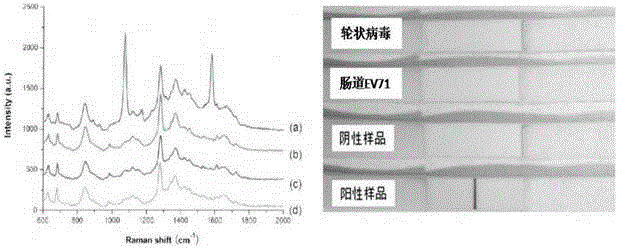

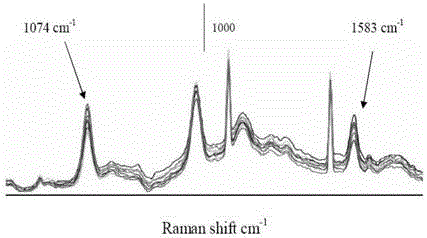

Immunochromatographic detection method of Norovirus Raman microprobe labeling

InactiveCN105759028AImprove detection efficiencyHigh sensitivityImmunoassaysSample fixationSurface-enhanced Raman spectroscopy

The invention relates to an immunochromatographic detection method of Norovirus Raman microprobe labeling.A principle of the detection method includes: using nitrocellulose membrane (NC) as an SERS substrate, labeling an immunoprobe by Raman labeling, constructing novel surface enhanced Raman spectroscopy and immunochromatographic assay (SERS-ICA) based on colloidal gold ICA, and detecting Norovirus by using the method.Detection includes sample fixation, colloidal gold penetration, antigen antibody reaction, detection and the like, detection results are used to read peaks under the band of 1074 cm<-1> through software on a detection instrument, some peaks are positive, and no peaks are negative.The method is suitable for quickly and sensitively detecting Norovirus and is simple to perform, it is possible to greatly improve detection efficiency for inspection and quarantine staff on the front line of entry and exit ports through the method, and the method is significant to controlling diarrhea due to Norovirus.

Owner:SHANGHAI ENTRY EXIT INSPECTION & QUARANTINE BUREAU OF P R C

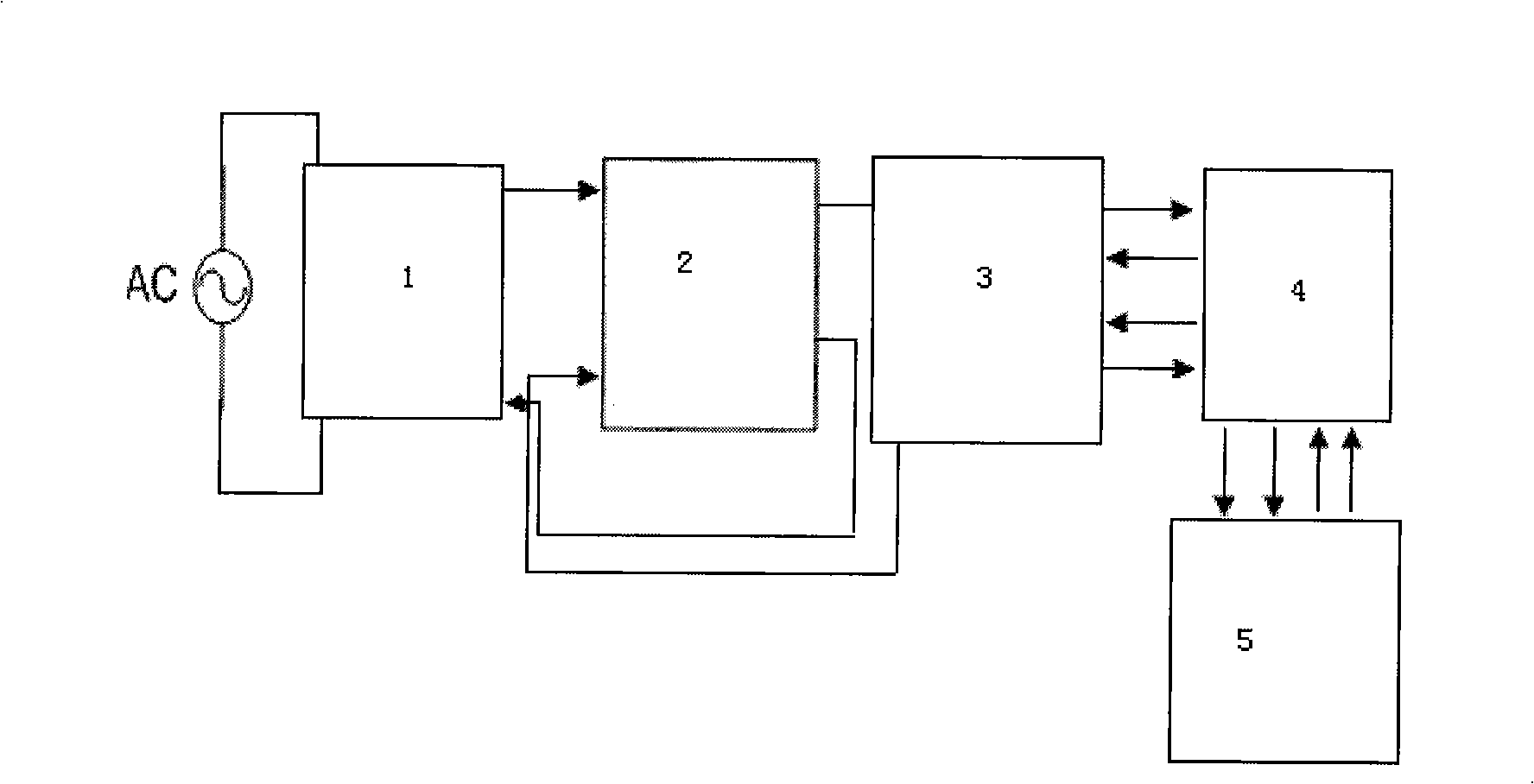

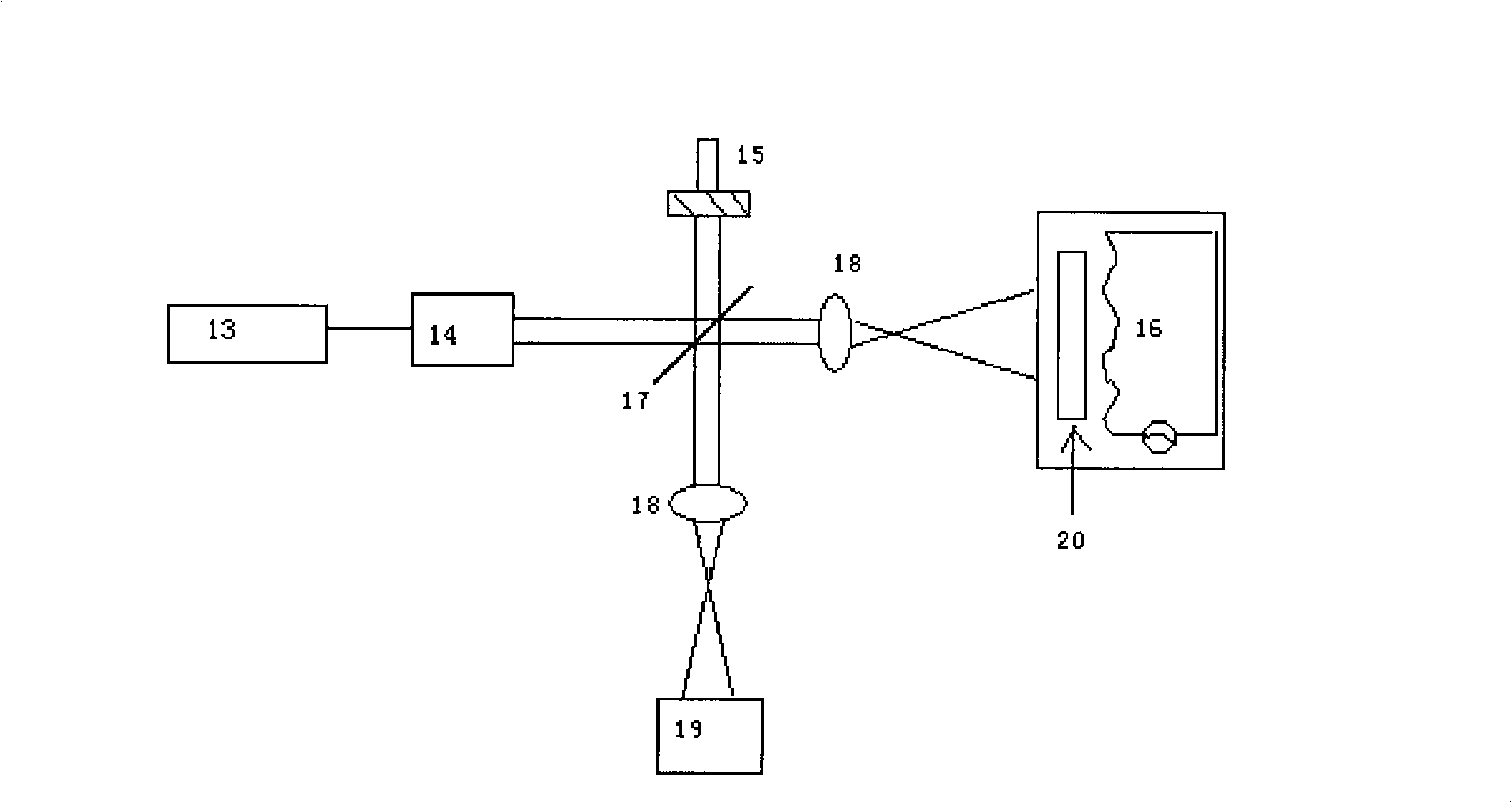

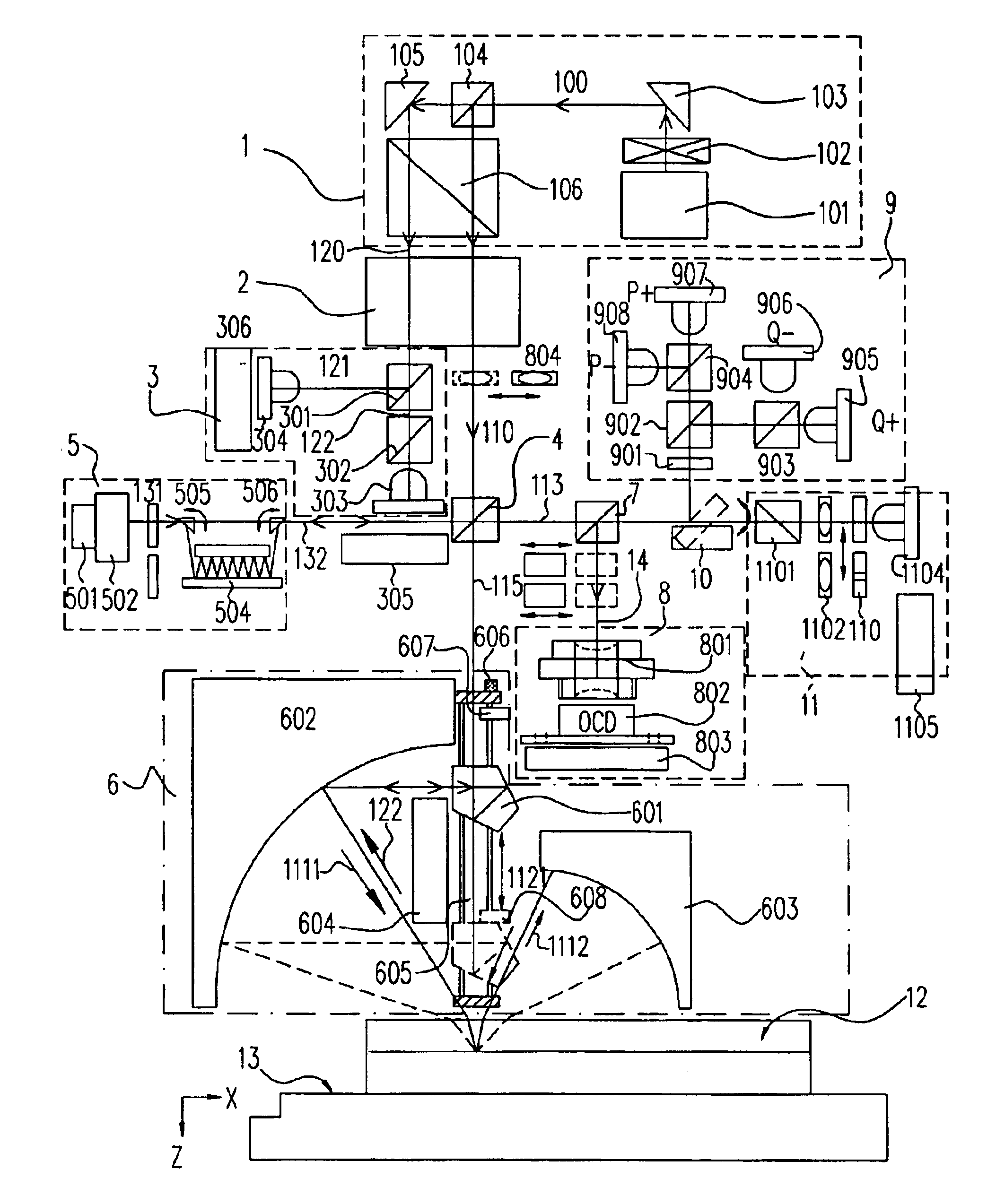

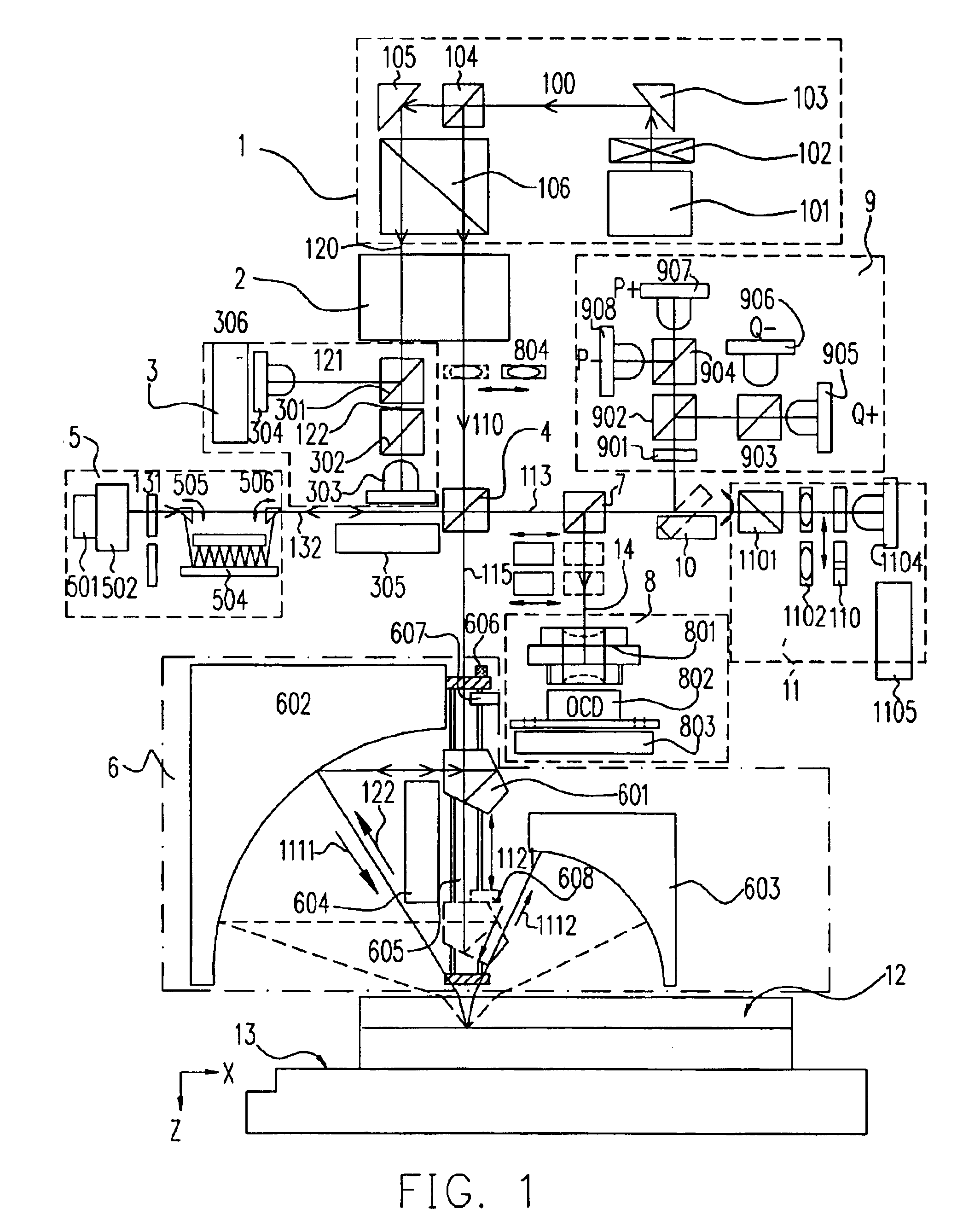

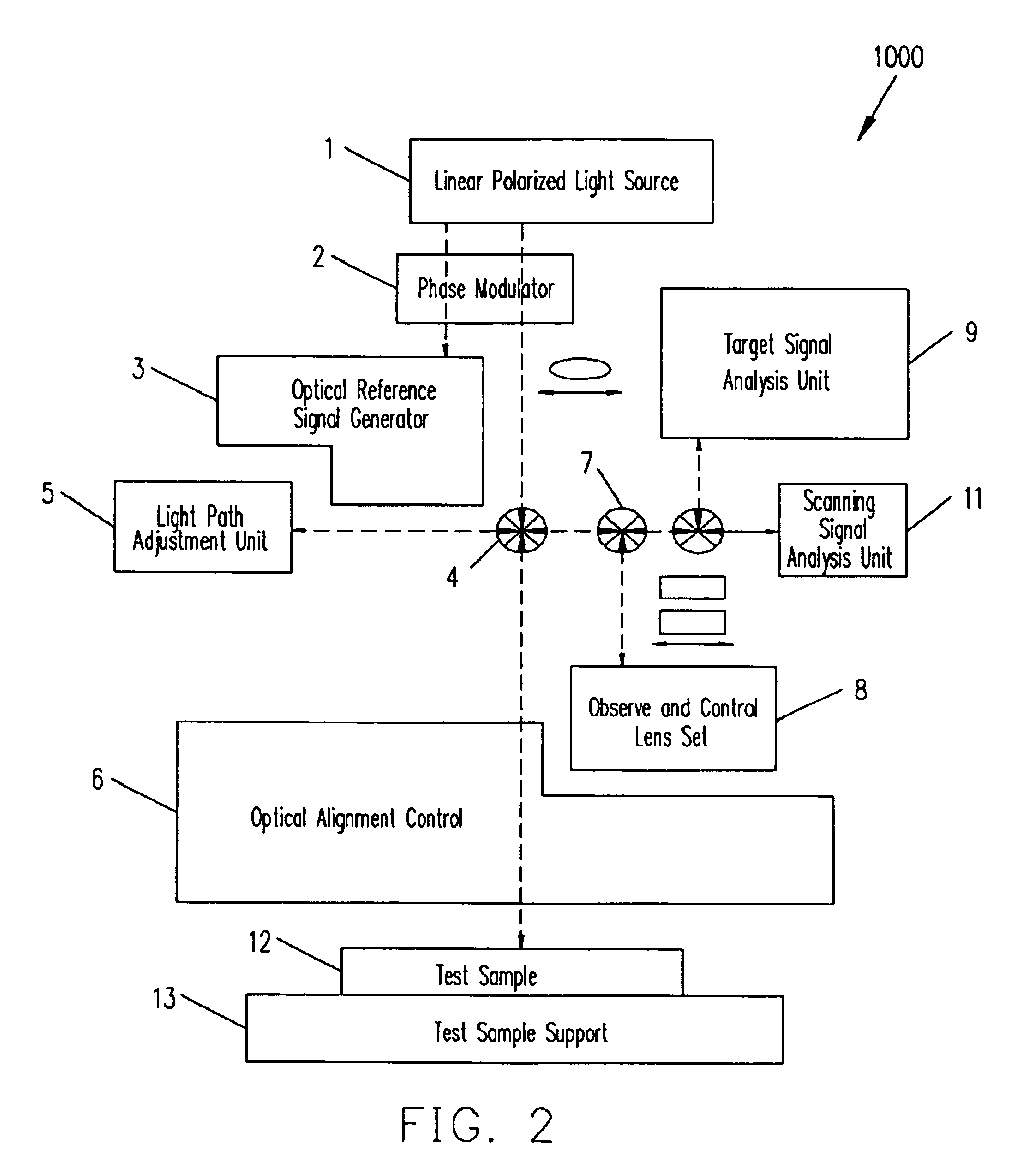

Multi-function opto-electronic detection apparatus

A multi-function opto-electronic detection apparatus for detecting molecular characteristics of a test sample. The appratuses comprises functional mode subsystems including a detecting light source subsystem for generating sampling beams for illuminating the test sample; a manipulation optics subsystem for aligning the sampling beam onto the test sample; a target signal processing subsystem for analyzing target beams emerging from the test sample resulting from the illuminating of the sampling beam; and a sample fixation subsystem for holding the test sample. The detecting light source subsystem, manipulation optics subsystem and target signal processing subsystem are assembled into one of several possible optical sampling setups for the detection characteristics of the test sample. The functional mode setups include at least ellispometer, confocal image scanner, photon tunneling scanning microscope and interferometer.

Owner:NAT TAIWAN UNIV

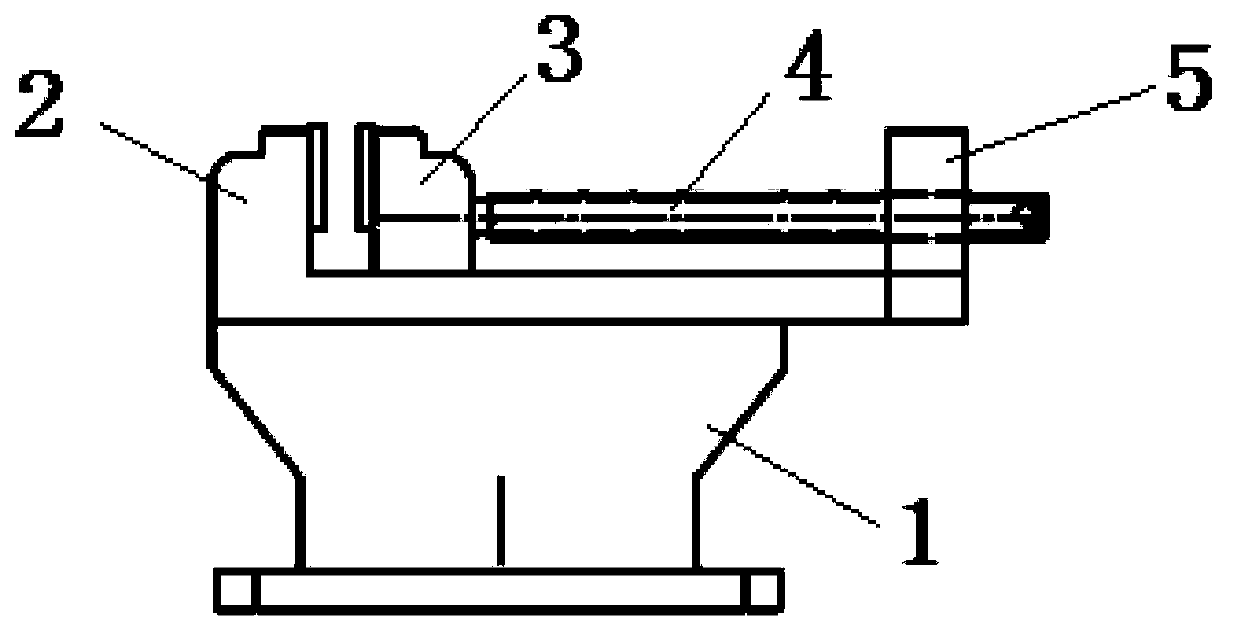

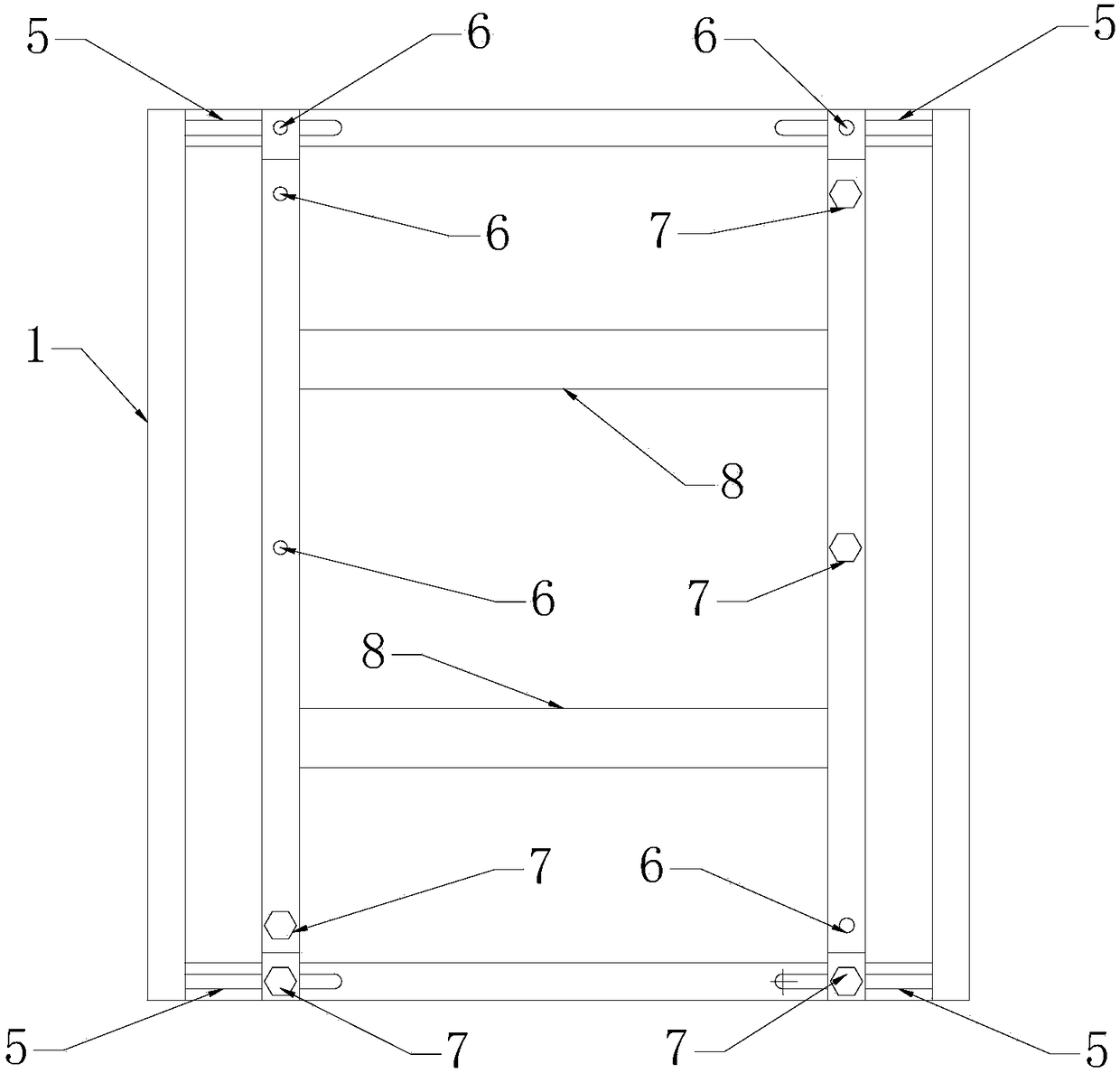

Universal sample fixation device for push-pull test apparatus

The invention relates to a universal sample fixation device for a push-pull test apparatus. The universal sample fixation device comprises a base, and a fixation block, a sliding block and a screw rod disposed on the base. The screw rod is in fixed connection with the sliding block and drives the sliding block to slide on the base. The sample is disposed between the fixation block and the sliding block, and rotation of the screw rod drives the sliding block to slide so as to fix the sample. Compared with the prior art, the universal sample fixation device provided by the invention has the advantages of lowering cost, shortening test schedule, and improving work efficiency, etc.

Owner:DENKEI TECH RANDD SHANGHAI CO LTD

Method for detecting soil and root system structure based on CT scanning of liftable clamp

PendingCN108844979AAvoid affecting test resultsEasy to operateMaterial analysis using wave/particle radiationSample fixationCt scanners

The invention belongs to the technical field of agricultural engineering, and relates to a method for detecting a soil and root system structure based on CT scanning of a liftable clamp. The method comprises the steps of sample cultivation, sample fixation, CT scanning and data processing, wherein in the step of sample fixation, a sample to be detected is fixedly mounted on a support, the supportis clamped in a lifting groove in a base plate in a relatively sliding manner, a magnetic stripe is placed in a magnetic stripe groove in the support, the support is fixed at an appropriate height inside the lifting groove through the magnetic stripe and a magnet placed on the outer wall of the lifting groove, and the sample to be detected is a plant root chip or a test tube with a soil column; inthe step of CT scanning, a lifting device for fixing the sample to be detected is placed on a working table of a CT scanner for scanning detection. The problems that the height of a sample clamped used in the conventional root system CT scanning detection technology cannot be adjusted and the sample clamp is not suitable for overall detection and local detection for the plant root system sample respectively are solved.

Owner:SOUTHWEST UNIV

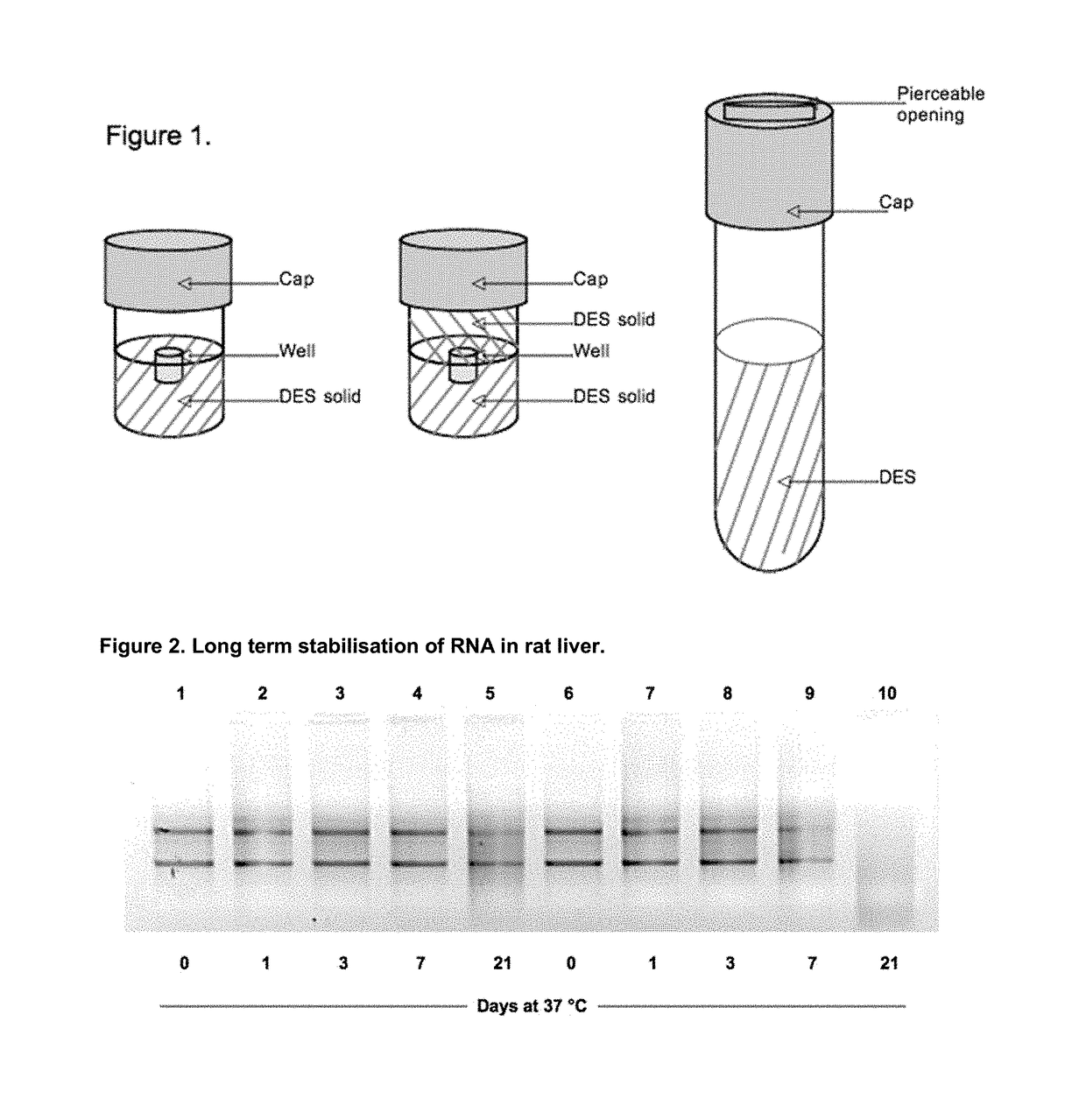

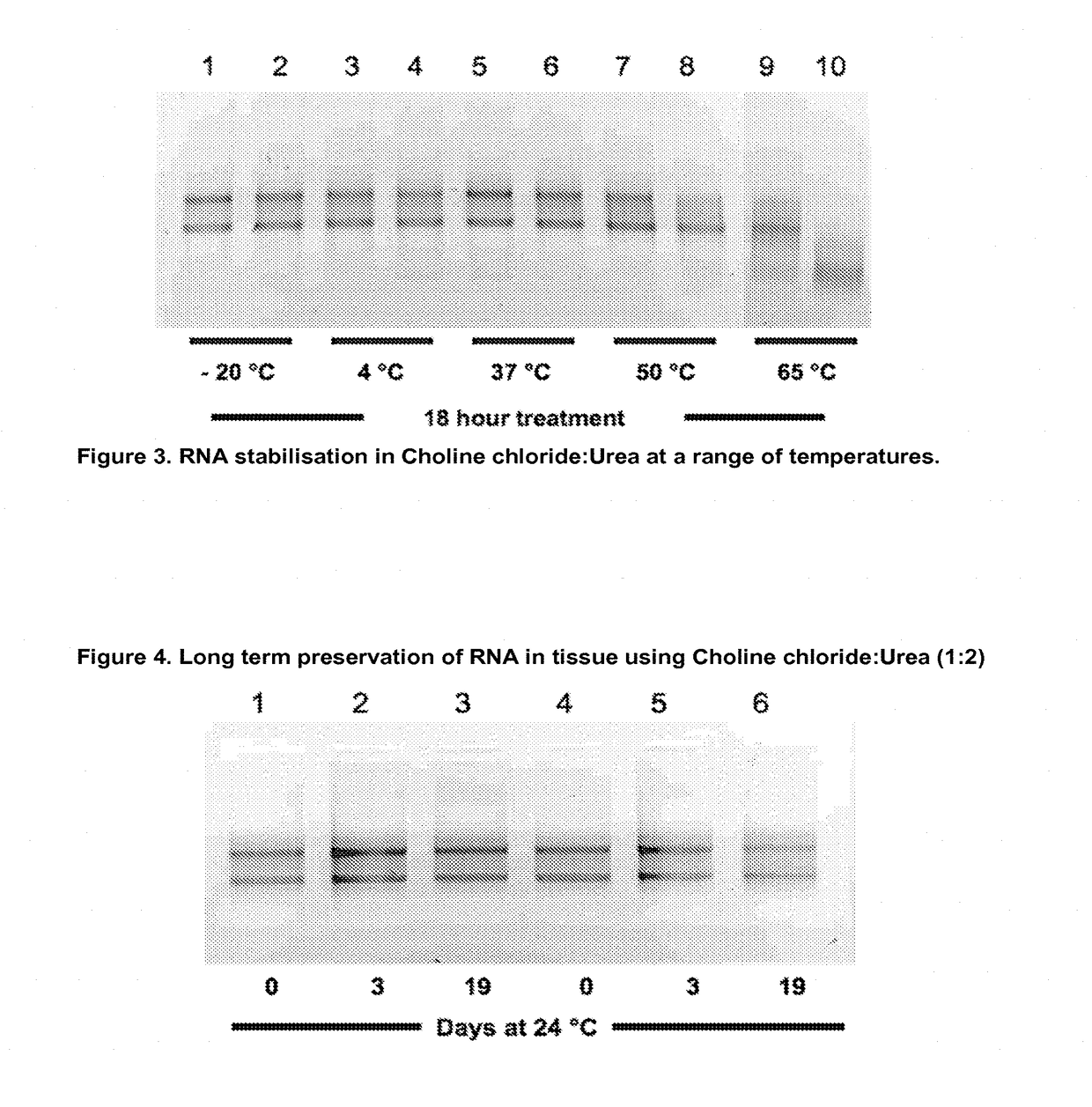

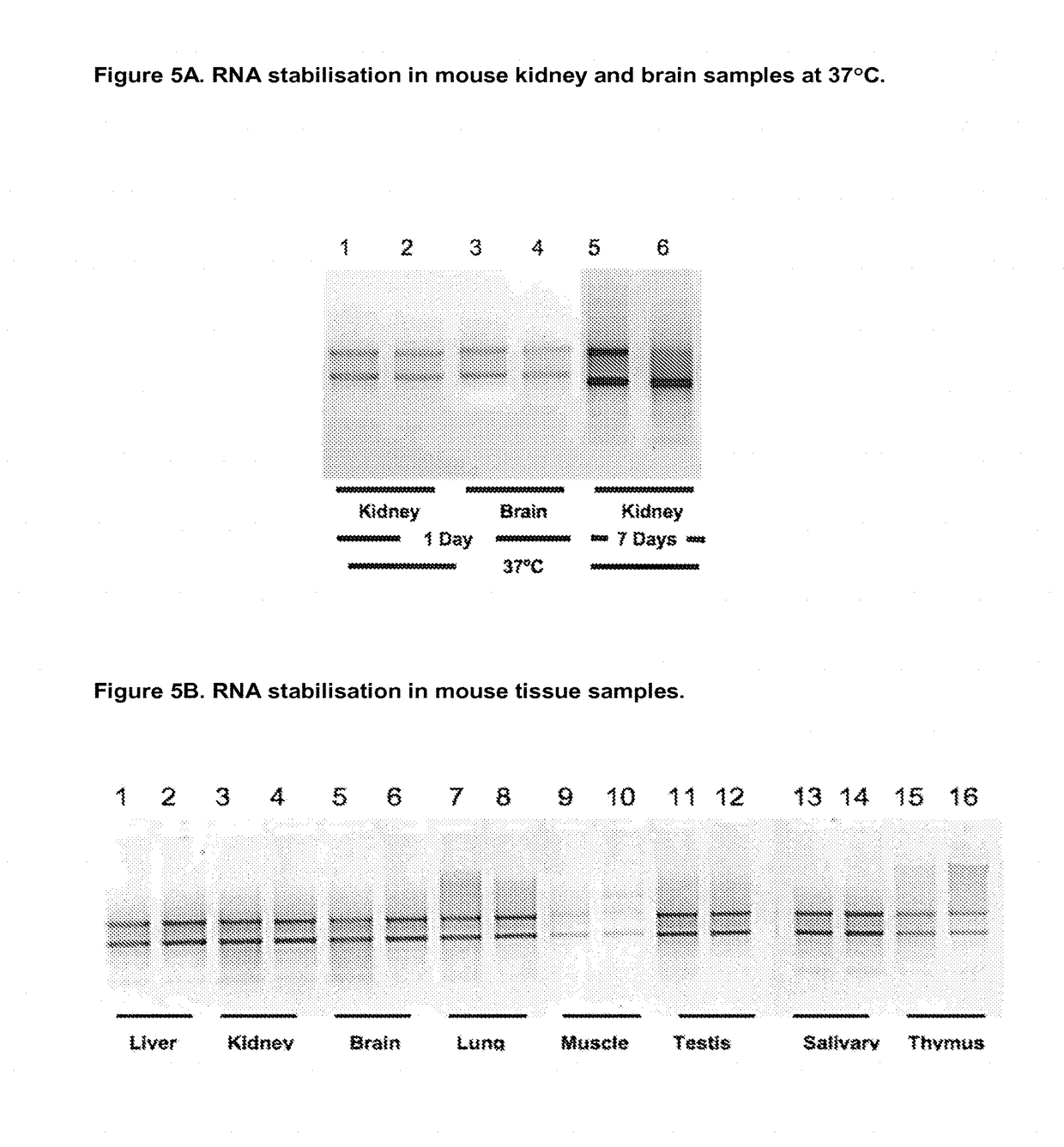

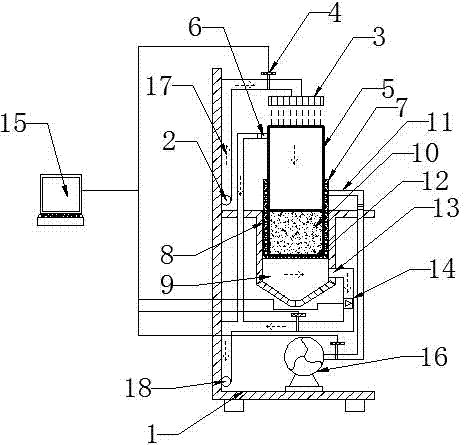

Sample fixation and stabilisation

ActiveUS20170328819A1Easy to prepareLow costPreparing sample for investigationDead animal preservationSample fixationDNA

Owner:RNASSIST LTD

Hollow rubber seal full-automatic permeability coefficient tester and test method thereof

InactiveCN107966394ASolve technical problems with poor sealingImprove test efficiencyPermeability/surface area analysisWater storageRubber ring

The invention discloses a hollow rubber seal full-automatic permeability coefficient tester and a test method thereof. The tester comprises a test stand, a sample fixation device and an electronic control system. The upper part of the test stand is provided with a water inlet pipe, and the ends of the water inlet pipe are provided with nozzles, the middle part of the test stand is equipped with sample placement cavities, and the lower parts of the sample placement cavities are water storage cavities. The sample fixation device includes a circular sleeve and a hollow rubber seal kit, the hollowrubber seal kit is formed by arrangement of several hollow rubber rings, and the rubber rings are internally equipped with air inflation branch pipes, and the air inflation branch pipes are connectedto air inflation main pipes. The electronic control system includes electronic switches disposed on the water inlet pipe pipeline, the air inflation main pipe pipelines and water storage cavity wateroutlet pipelines, flowmeters on the water storage cavity water outlet pipelines and a control center. The tester provided by the invention employs the hollow rubber seal rings to ensure the sample airtightness, improves the permeability coefficient test precision, is convenient to operate, and has high automation degree.

Owner:SICHUAN UNIV

Paraffin sectioning method for Corydalis saxicola Bunting stems

ActiveCN106802253ACross-cut structure is clearLong-term storage and usePreparing sample for investigationAcetic acidParaffin wax

The invention discloses a paraffin sectioning method for Corydalis saxicola Bunting stems. The paraffin sectioning method comprises the following steps: sample fixation, dehydration, transparency treatment, wax dipping, embedding, sectioning and slice expansion, dewaxing, dyeing and slice sealing. The paraffin sectioning method specifically comprises the following steps: before the transparency treatment, putting dehydrated Corydalis saxicola Bunting stems into a 0.8%-1.2% sarranine solution, and carrying out dip dyeing for 8-12 hours; after the dewaxing, carrying out rehydration on a slide carrying the Corydalis saxicola Bunting stems, putting the Corydalis saxicola Bunting stems into an alcohol solution, carrying out color separation, simultaneously adding acetic acid into the alcohol solution for the color separation in a volume ratio of 1 to (800-1000), finally, putting the Corydalis saxicola Bunting stems into a 0.8%-1.2% fast green solution, and carrying out dyeing for 10-20 seconds. By virtue of the paraffin sectioning method disclosed by the invention, a clear Corydalis saxicola Bunting stem structure can be sectioned, a specimen can be stored for a long time for use, is a permanent microscopic slide specimen and can be applied to microscopic identification of Corydalis saxicola Bunting medicinal materials for market normalization.

Owner:GUANGXI BOTANICAL GARDEN OF MEDICINAL PLANTS

Flexibility testing method for flexible panels

InactiveCN104483195AEasy to test softnessAvoid operations such as installation and fixingMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesSample fixationMaterials testing

The invention discloses a flexibility testing method for a flexible panel. The flexibility testing method comprises the following steps: producing a to-be-tested sample, namely cutting the flexible panel, and bonding the two opposite sides of the cut flexible panels, so as to obtain the to-be-tested sample; producing an auxiliary testing device, wherein the auxiliary testing device comprises a first auxiliary testing piece and a second auxiliary testing piece which are oppositely arranged, and a height-variable testing channel is formed between the first auxiliary testing piece and the second auxiliary testing piece and is used for accommodating the to-be-tested sample; assembling the auxiliary testing device with a universal material testing machine, namely mounting the center of the auxiliary testing device in a sensing region of a sensor of the universal material testing machine; and testing, namely pushing the to-be-tested sample into the sensing region along the testing channel, so as to test the flexibility of the flexible panel. According to the flexibility testing method for the flexible panel, the auxiliary testing piece and the universal material testing machine are combined for use by virtue of simple operation, so that the testing efficiency is greatly improved; meanwhile, the operation errors such as sample fixation are avoided, and acquired data are stable and accurate.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +2

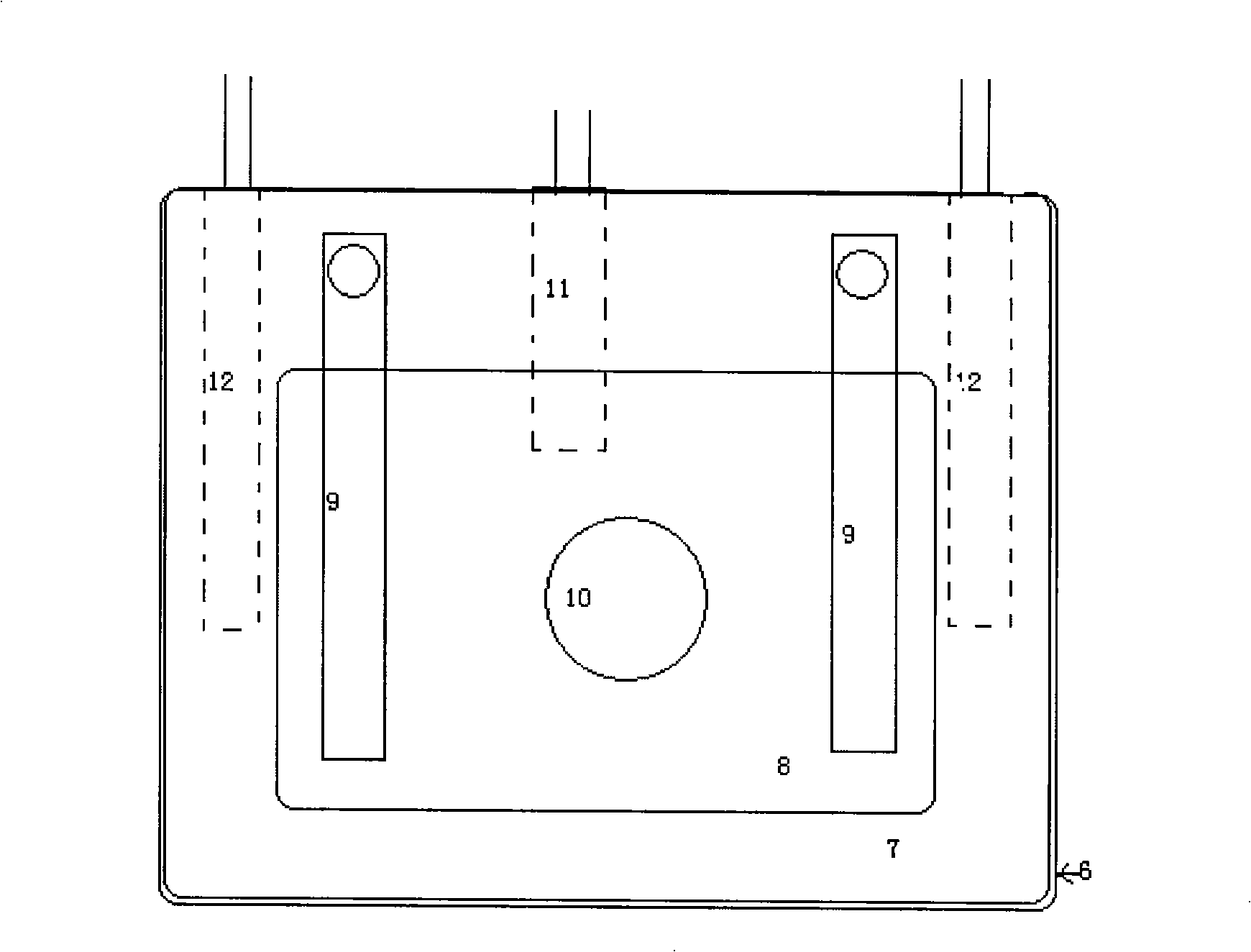

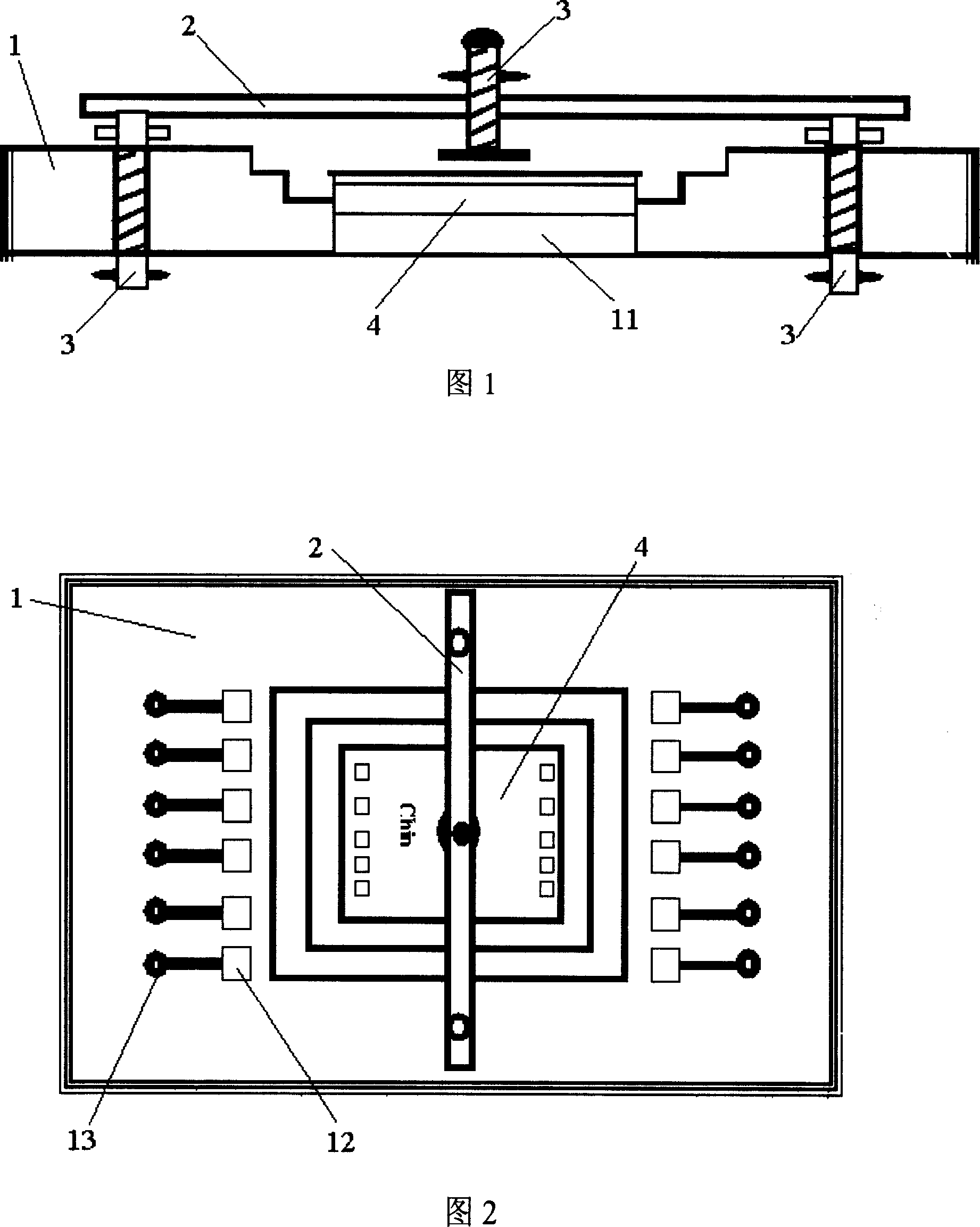

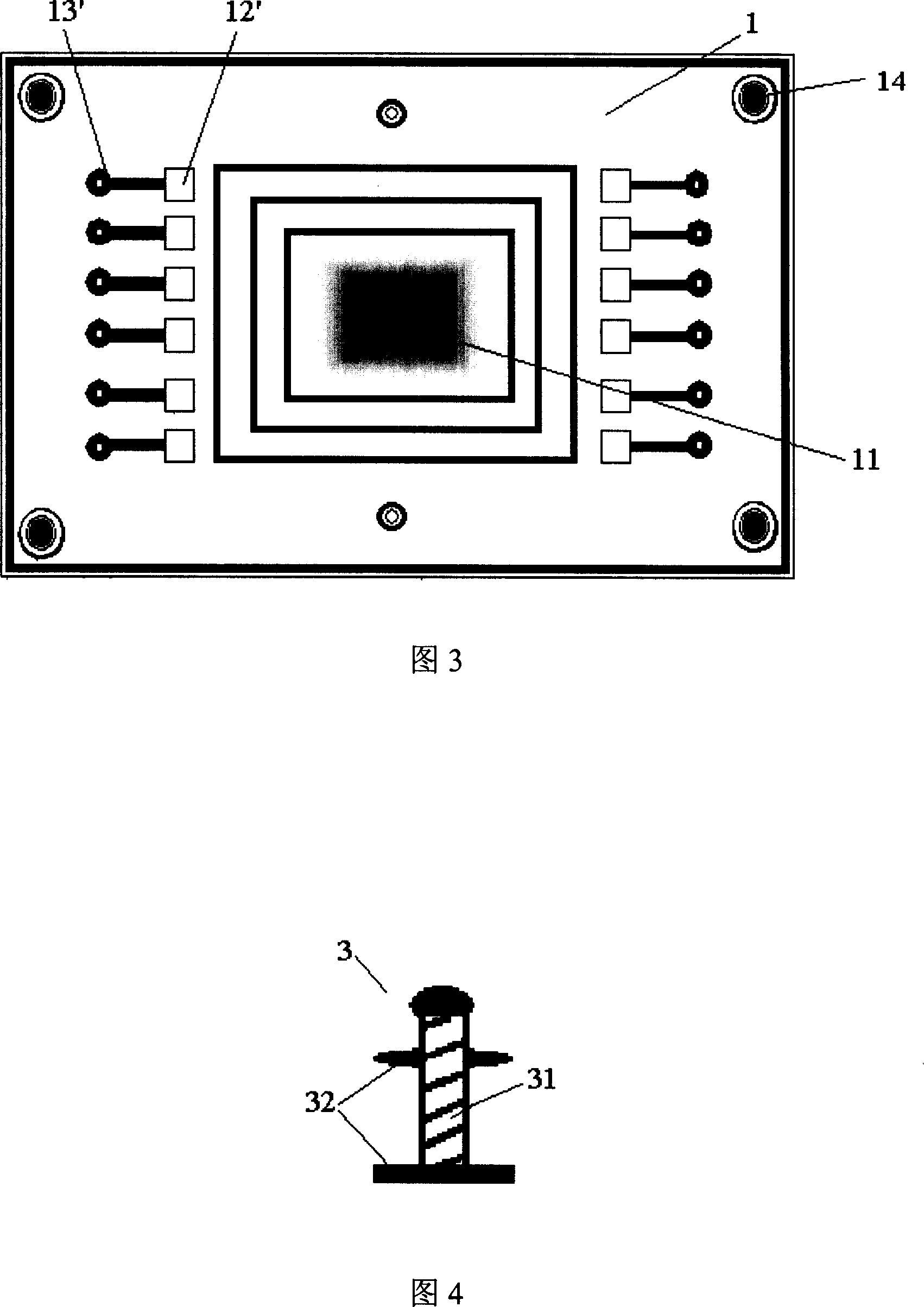

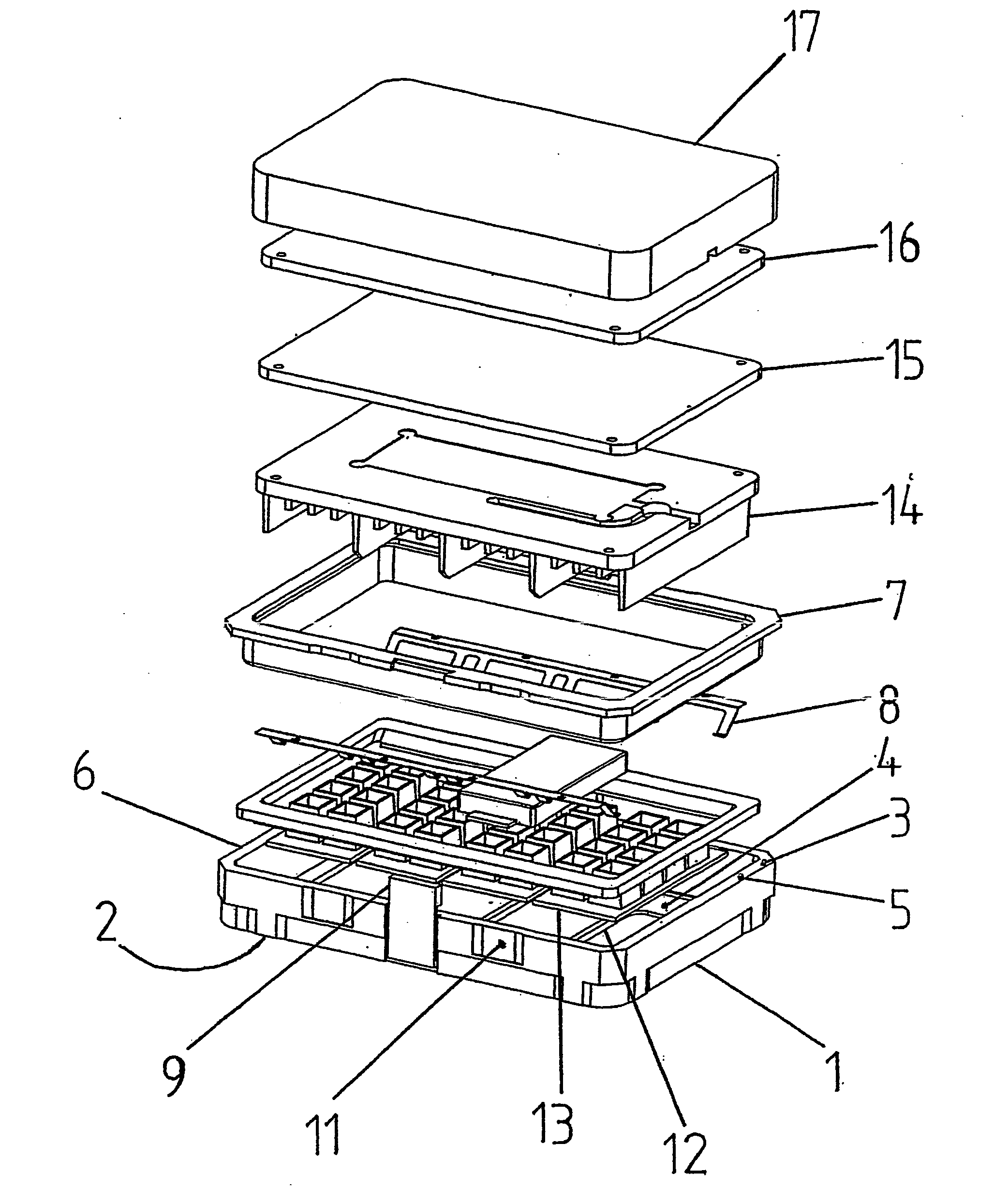

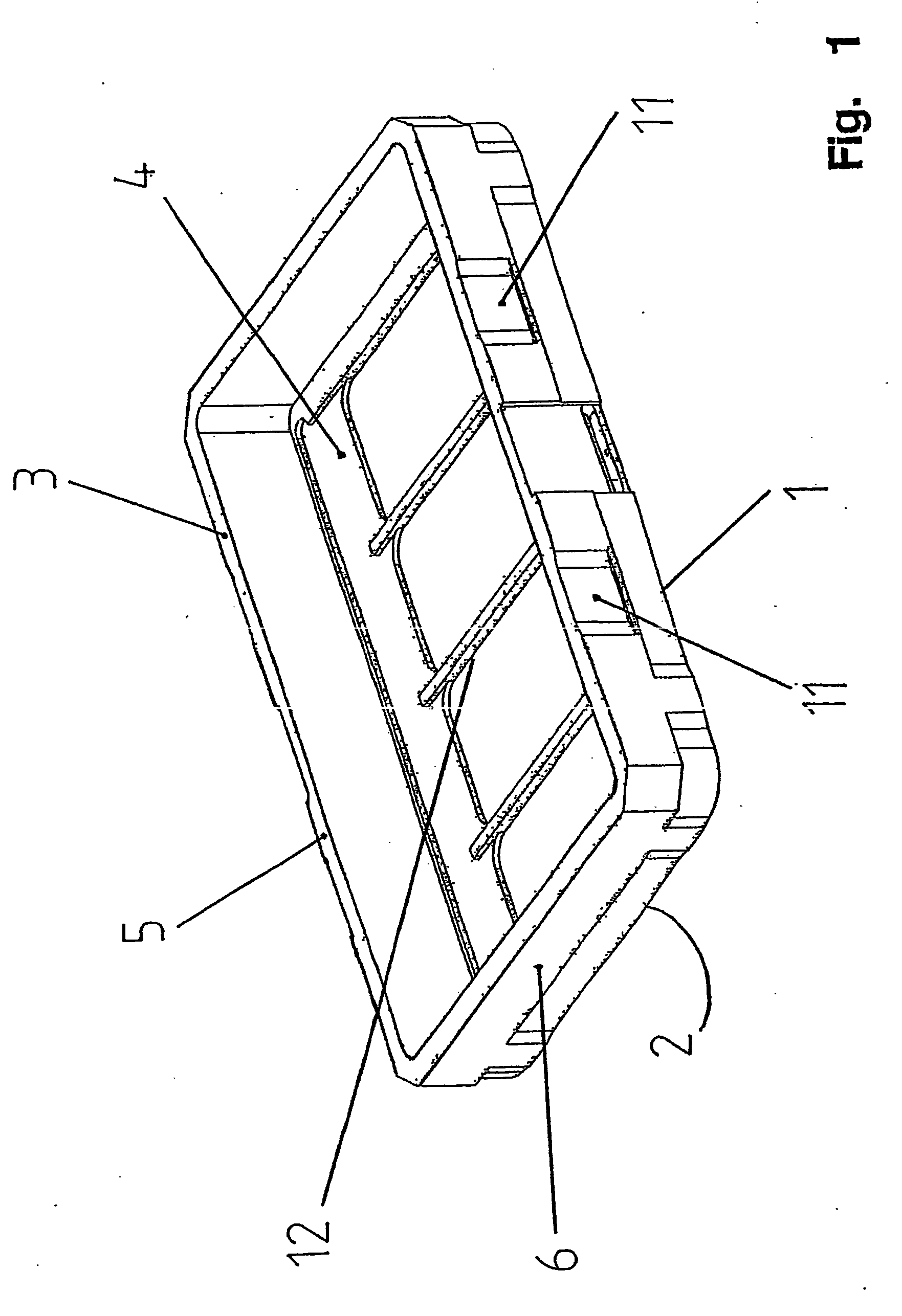

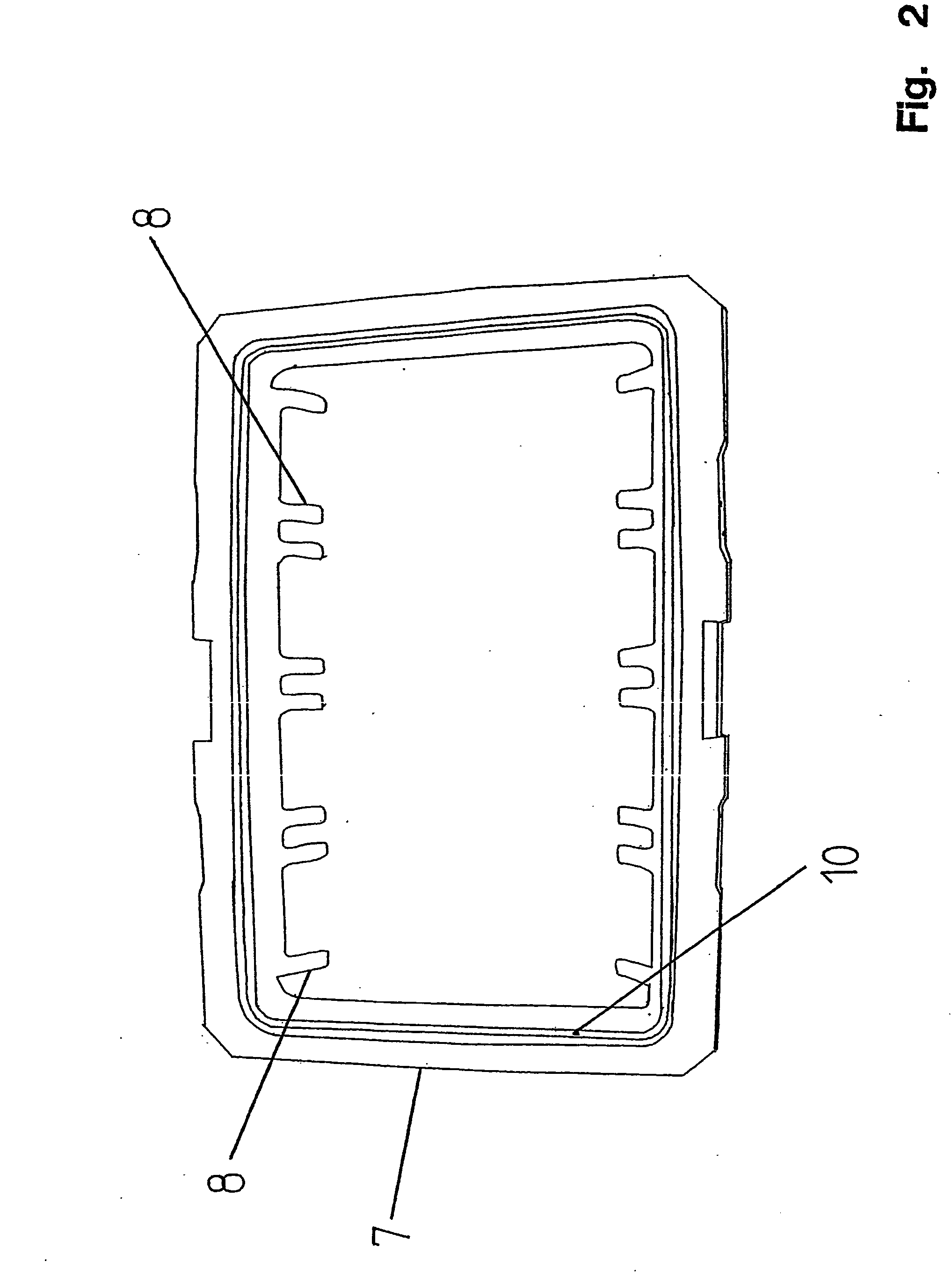

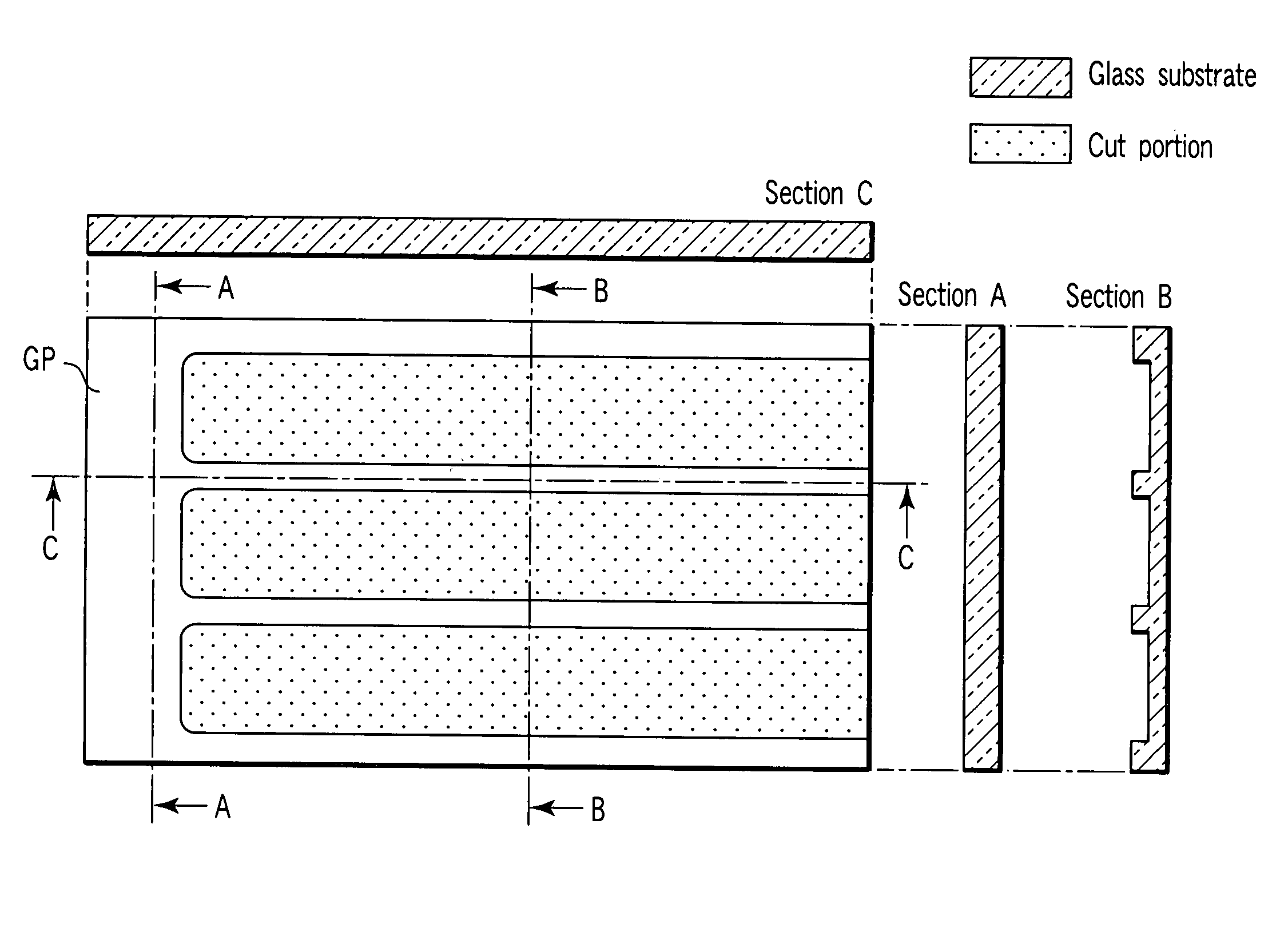

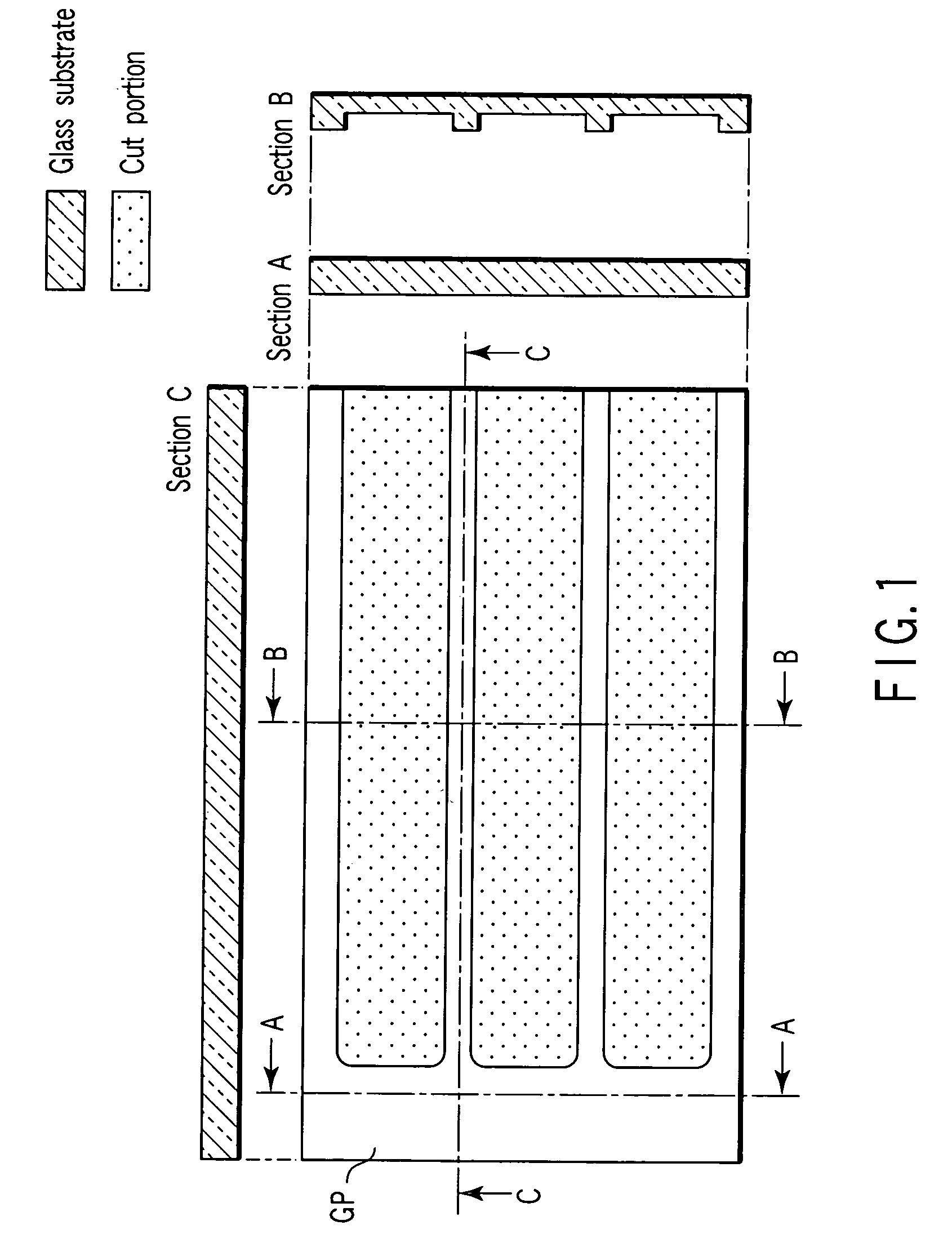

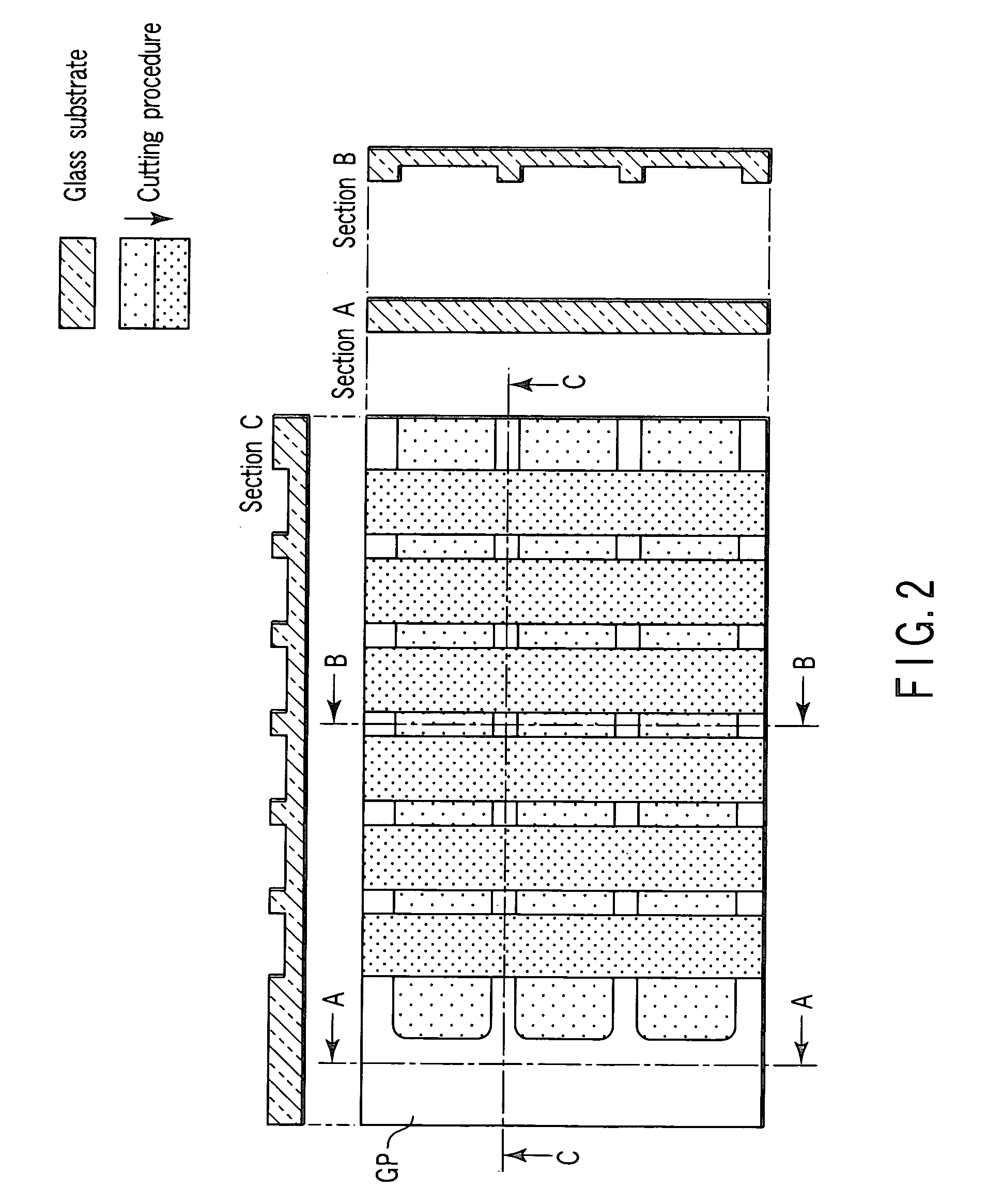

Sample holder and microscope assembly

InactiveUS20060216211A1Reliable warming treatmentHigh sample throughputAnalysis using chemical indicatorsLaboratory glasswaresSample fixationCoupling

A sample holder for handling samples to be viewed under a microscope, and which comprises a base frame 1 provided with a lower surface 2, an upper surface 3, and at least one receiving area 4 for at least one sample. In order to facilitate examination of a large number of samples, the sample holder is provided with a coupling area 5 on its upper surface for receiving at least one other functional element, such as a sample fixing element, a heating or cooling plate, or a cover.

Owner:EURO LAB FUER MOLEKULARBIOLOGIE EMBL

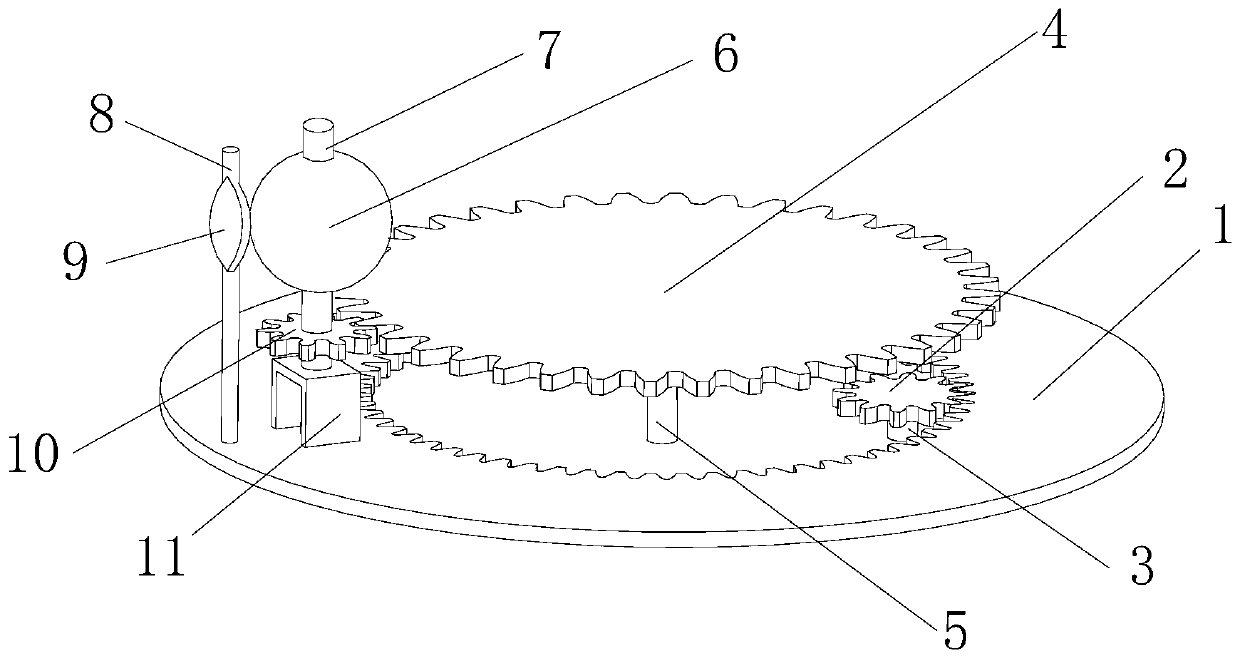

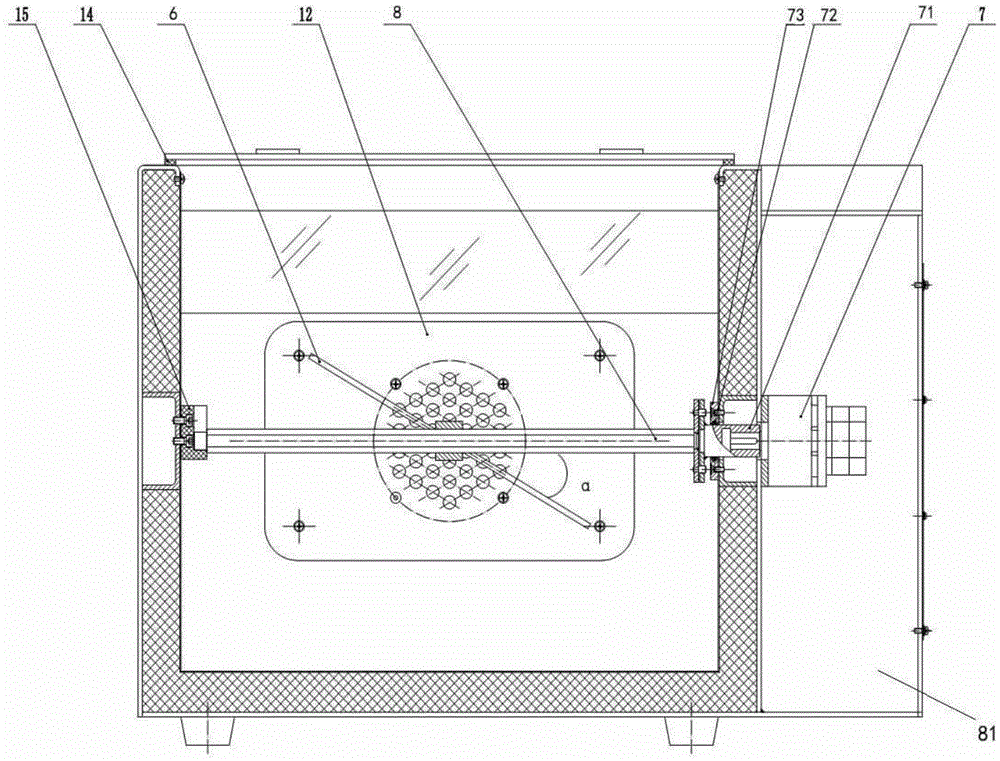

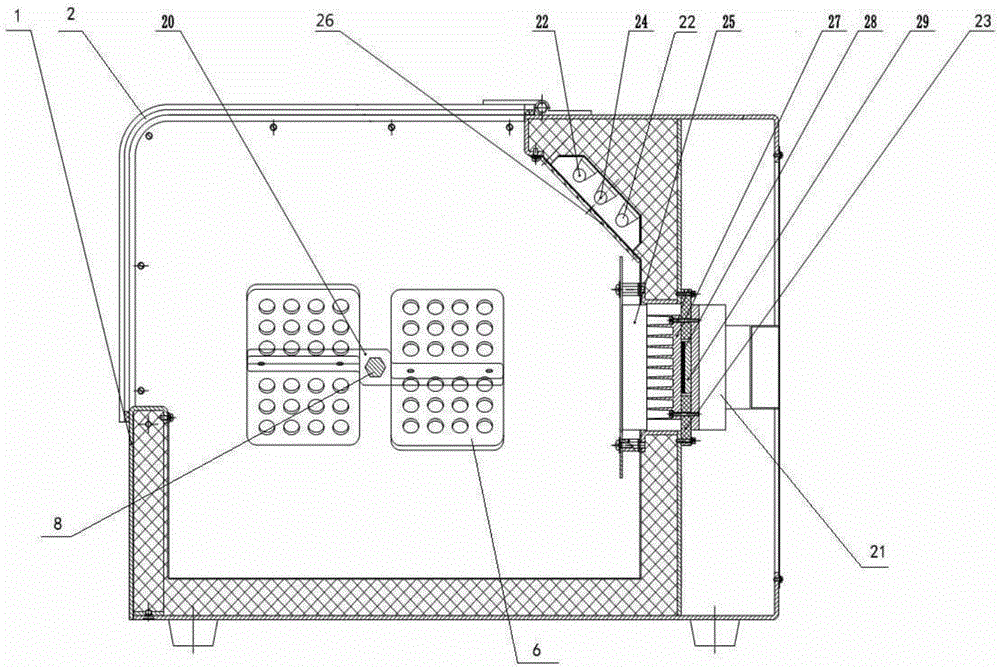

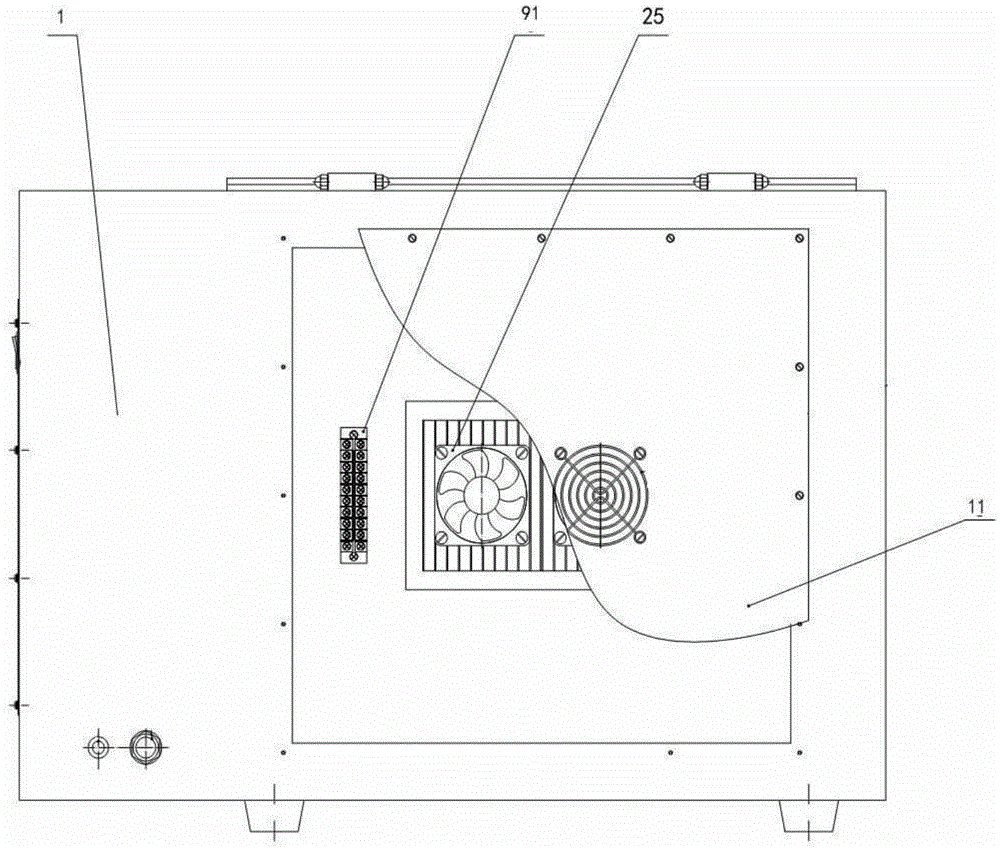

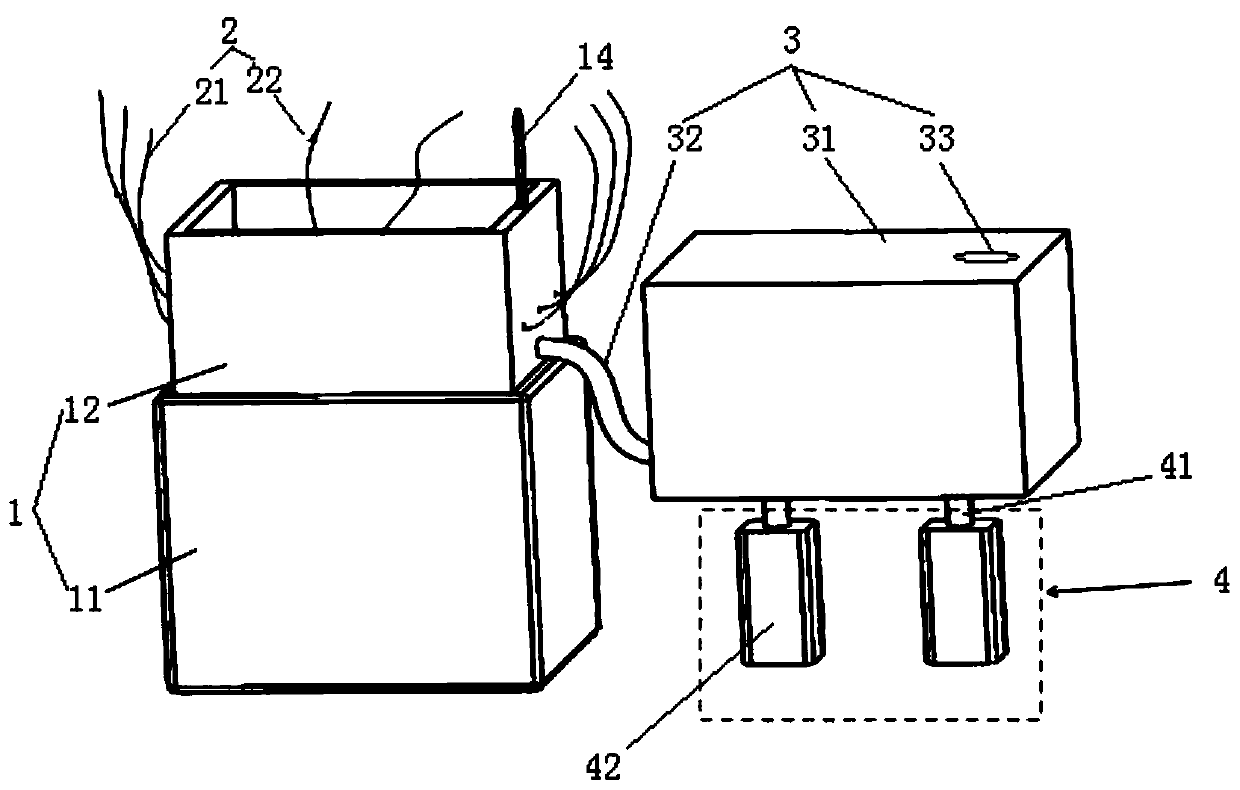

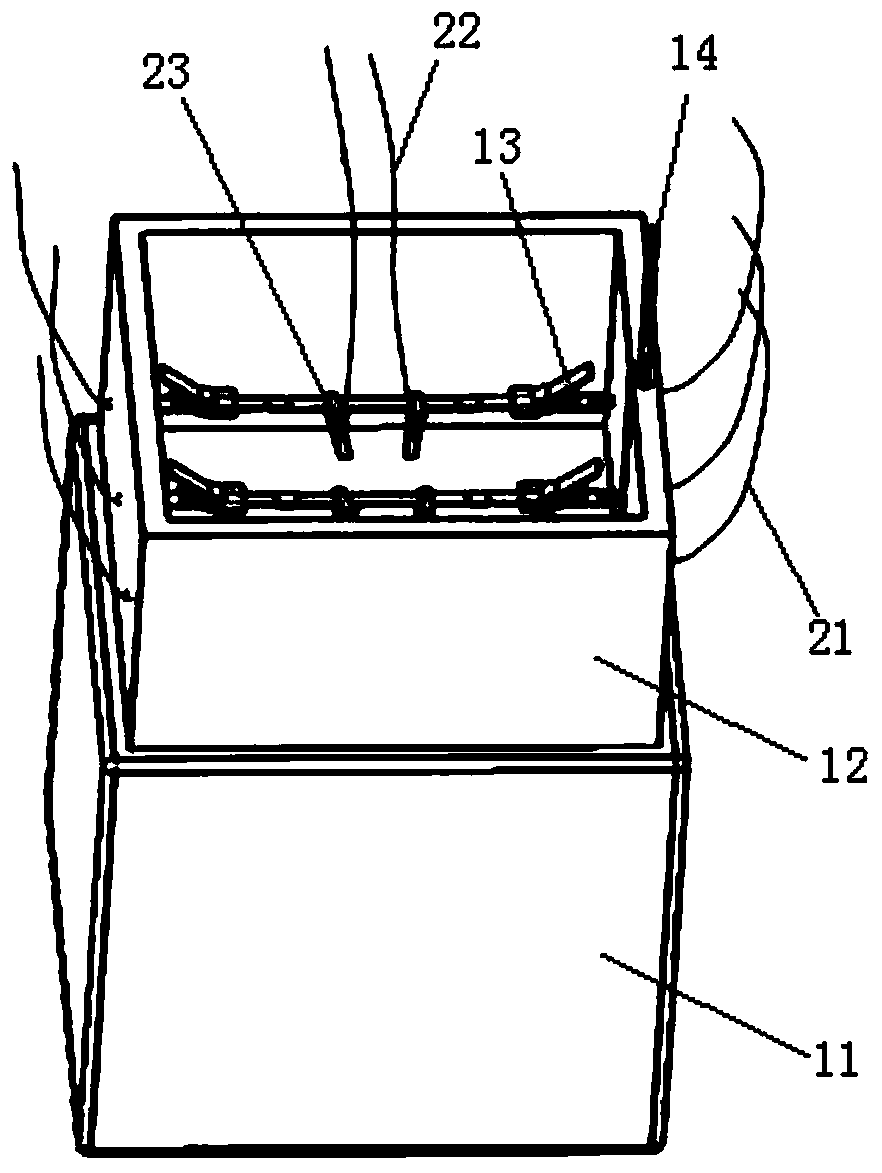

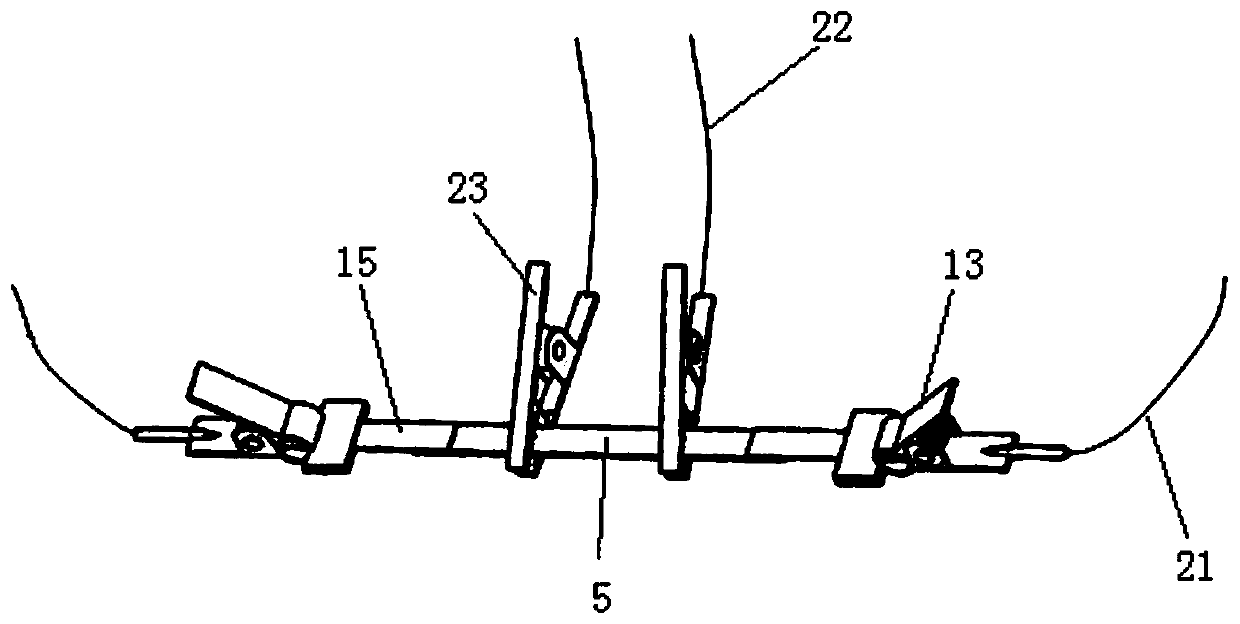

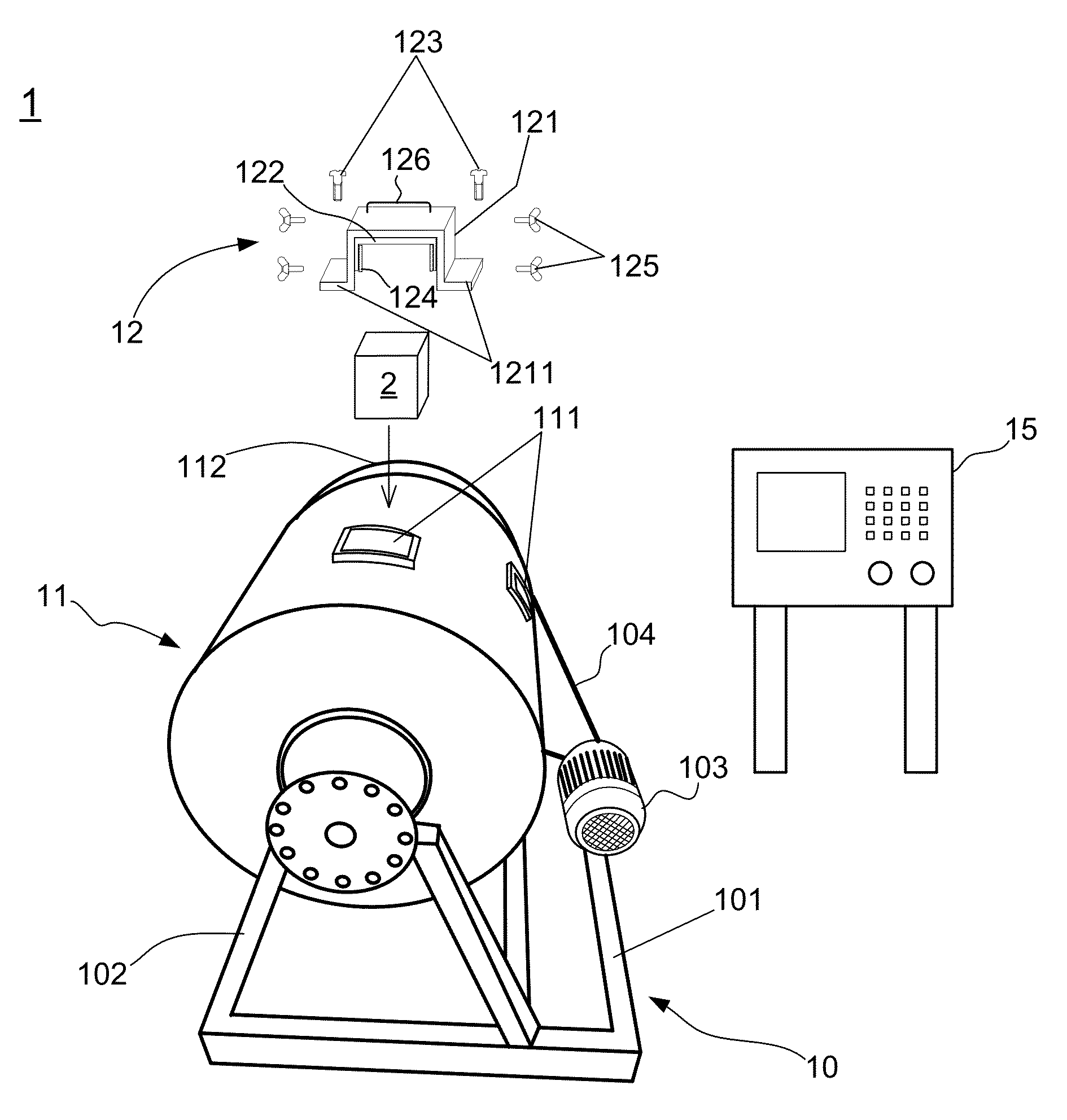

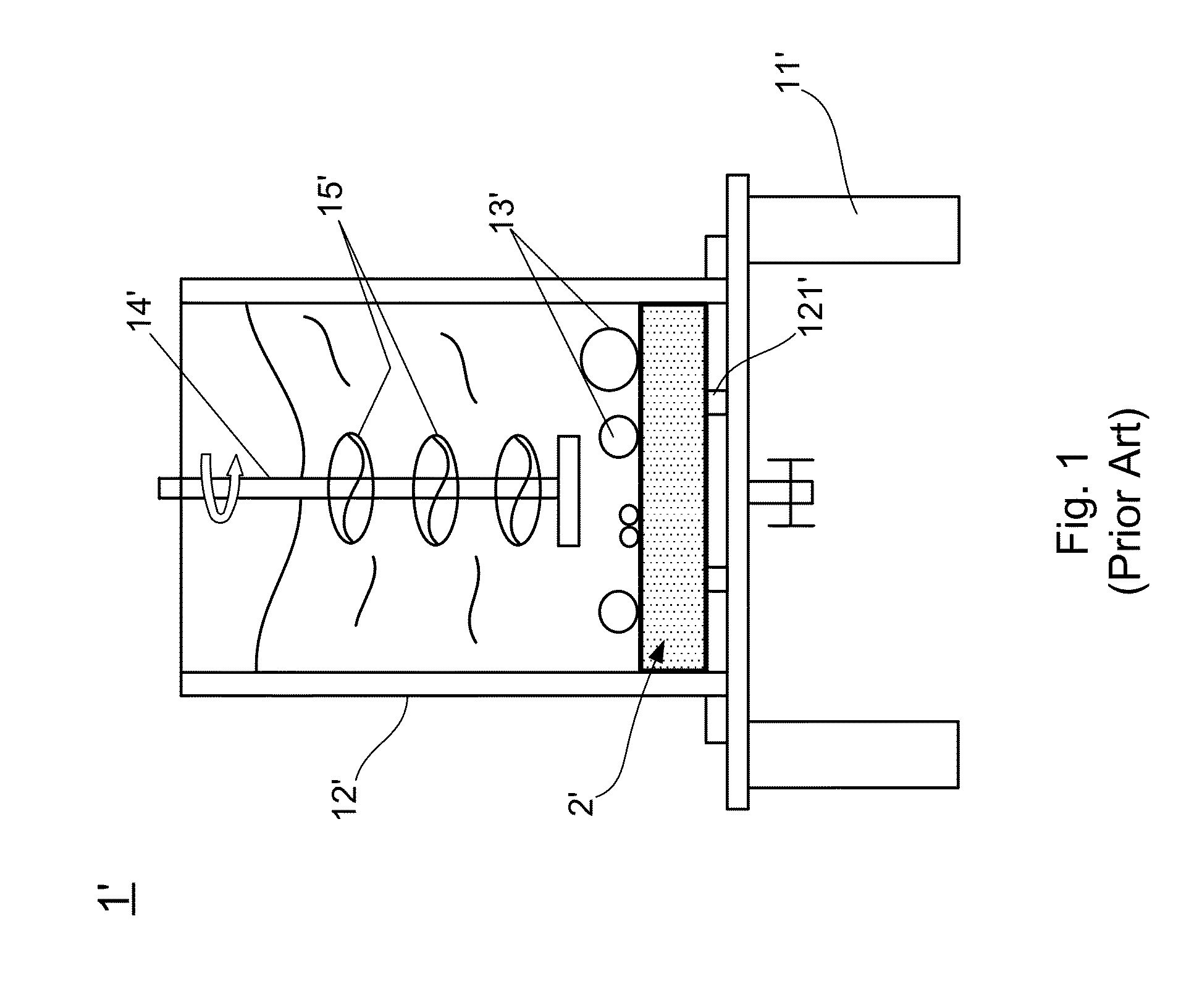

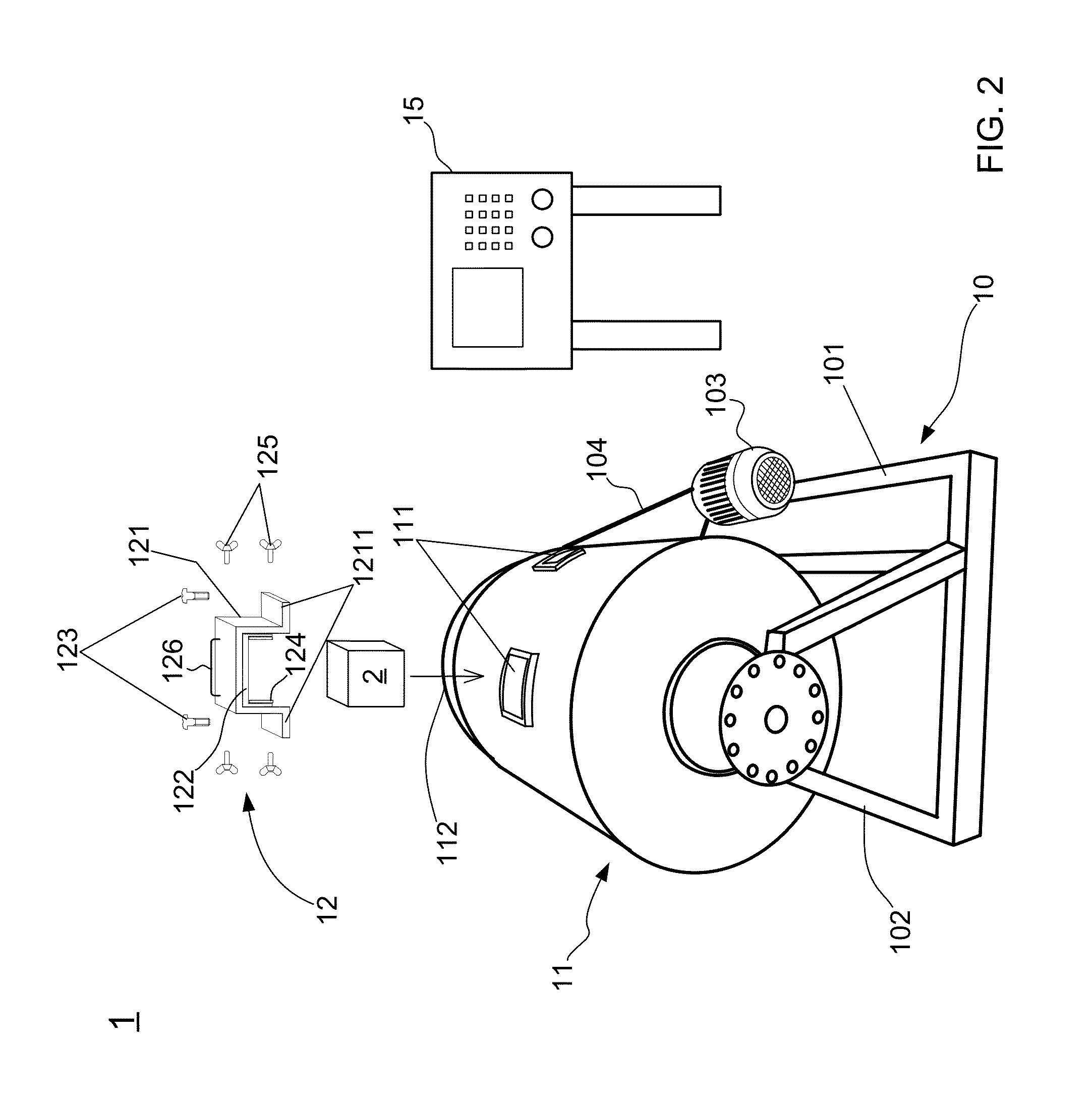

Rotary biochemical reaction box

ActiveCN105056859AAvoid layeringWell mixedEnergy based chemical/physical/physico-chemical processesLight irradiationSurface layer

The present invention relates to a rotary biochemical reaction box, which comprises: a box body, wherein the box body is provided with a box door; a rotating assembly, wherein the rotating assembly comprises a rotating drive device and a rotating shaft, and the rotating shaft is arranged inside the box body and rotates under the driving effect of the rotating drive device; a sample fixation assembly, wherein the sample fixation assembly is arranged on the rotating shaft, can rotate along with the rotating shaft, and is used for fixing a sample; and a light irradiating assembly, wherein the light irradiating assembly is arranged inside the box body and is used for providing light irradiating. According to the present invention, the rotating assembly is arranged to drive the sample to rotate, such that the sample internal substances in the reaction tube are mixed and stirrer so as to prevent the sample from layering, and the reactant positioned inside can move to the reaction tube surface layer during the rotating to completely receive the light irradiation so as to uniformly carry out the biochemical reaction and improve the experiment result; and the equipment has characteristics of simple and convenient operation, concurrent treatment of multiple groups of samples, and high treatment capacity.

Owner:JIANGSU UNIV OF SCI & TECH IND TECH RES INST OF ZHANGJIAGANG

Painting device

InactiveCN105327813AImprove sustainabilityReduce the impact on physical healthLiquid surface applicatorsCoatingsSample fixationLacquer

The invention provides a painting device. The painting device comprises an operation desk, a conveying track and multiple shower nozzle supports, the conveying track is provided with sample mobile clamping positions of which the number is the same as that of the shower nozzle supports, the upper surface of each sample mobile clamping position is the concave surface which fixes a sample to the sample mobile clamping position, two rows of rolling wheels are arranged at the lower end of each sample mobile clamping position, the rolling wheels and the conveying track are embedded, the conveying track drives the sample mobile clamping positions to move through the rolling wheels, the conveying track is connected with a driving mechanism through a circuit, and the driving mechanism is arranged on one side of the operation desk; a shower nozzle fixing seat is arranged on each shower nozzle support, two rows of shower nozzles are arranged on each shower nozzle fixing seat, the upper surface of each shower nozzle is an inclined plane, the inclined plane and the bottom surface of each shower nozzle form a fixed included angle, the included angles of the two rows of the shower nozzles are symmetrical, and each shower nozzle is evenly provided with multiple painting holes. According to the painting device, the conveying track and the sample mobile clamping positions are arranged, the sustainability of sample painting is achieved, and the work efficiency is much higher than that of manual painting.

Owner:TIANJIN HENGYUAN JIEER TECH CO LTD

Wrapping paper indentation detecting device

InactiveCN101837848ARealize instant controlAvoid or reduce the occurrence ofPackagingApparatus for force/torque/work measurementSample fixationBiochemical engineering

The invention relates to a wrapping paper indentation detecting device. The device is arranged on a bracket. A template is arranged at the bottom of the bracket and is provided with a sample model hole. A sample clamping plate is arranged above the template and is fixed by a nut. A paper sample to be detected is fixed between a clamping plate and the template. The indentation of the paper sample exactly faces the model hole. The clamping plate is provided with a through hole, and the through hole exactly faces the model hole. A positioning hole is arranged above the bracket. A pressure rod is inserted in the positioning hole. The lower end of the pressure rod exactly faces the through hole on the fixing plate. The upper end of the pressure rod is provided with a support plate. A weight is arranged on the support plate. By adopting the technical scheme, the paper sample to be detected is fixed between the clamping plate and the template, the pressure rod is pressed on the cutting mark of the paper sample, and then the instant and direct pressure detection can be carried out on the cutting mark by putting the weight on the support plate.

Owner:YUNNAN ENERGY NEW MATERIAL CO LTD

Temperature shock detection method and device for high-temperature superconducting tape

PendingCN110850343AEnables critical current detectionEasy to operateSuperconductive properties measurementsSample fixationHigh temperature superconducting

The invention discloses a temperature shock detection method and a temperature shock detection device for a high-temperature superconducting tape. The temperature shock detection device comprises a sample fixing mechanism, a critical current detection mechanism, a liquid storage mechanism and a driving mechanism, wherein the sample fixing mechanism comprises an operation table, a liquid box and sample fixing frames; the liquid box is arranged on the operation table; at least one sample fixing frame is arranged on the side wall in the liquid box; the critical current detection mechanism comprises current lines and voltage lines; two ends of the sample fixing frames are connected with the current lines respectively; the liquid storage mechanism is communicated with the liquid box; and the driving mechanism drives the liquid storage mechanism to move up and down. According to the temperature shock detection method, a critical current of the superconducting tape is detected through conducting a temperature shock test of the superconducting tape, and a current retention coefficient is calculated. The temperature shock detection method and the temperature shock detection device realize the effect of carrying out temperature shock processing on the high-temperature superconducting tape and directly performing critical current detection, have the advantages of simple operation, simpleequipment, low cost, high repeatability and high applicability, reduce the potential safety hazards of operators, verify the application reliability of the superconducting tape and verify the sealingperformance of the coating.

Owner:EASTERN SUPERCONDUCTOR SCI & TECH SUZHOU CO LTD

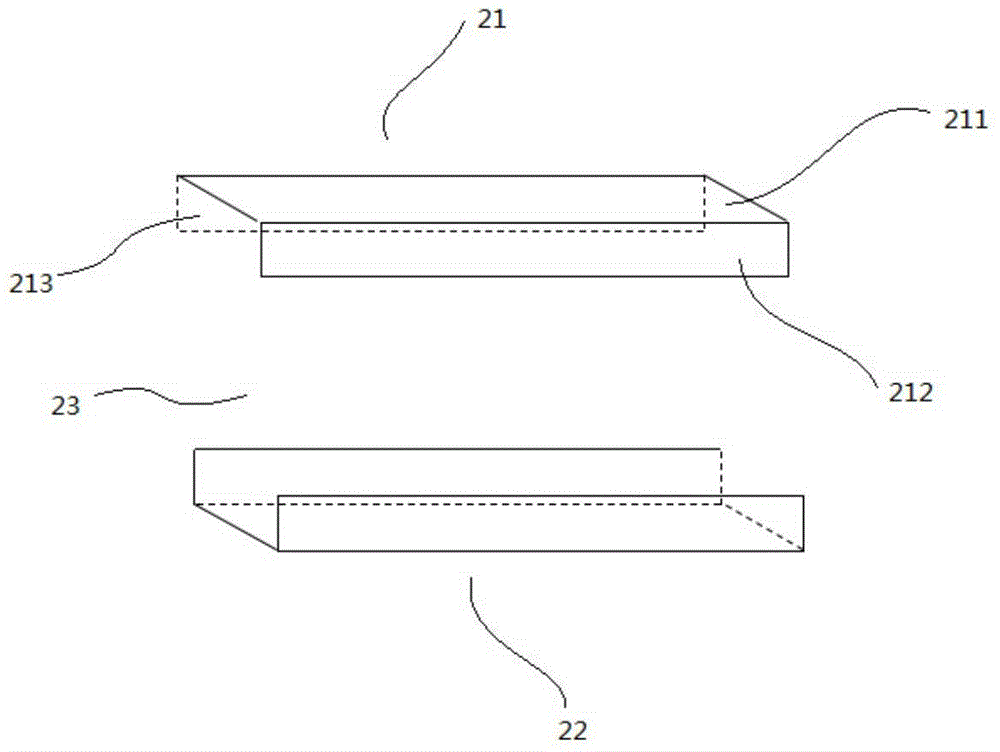

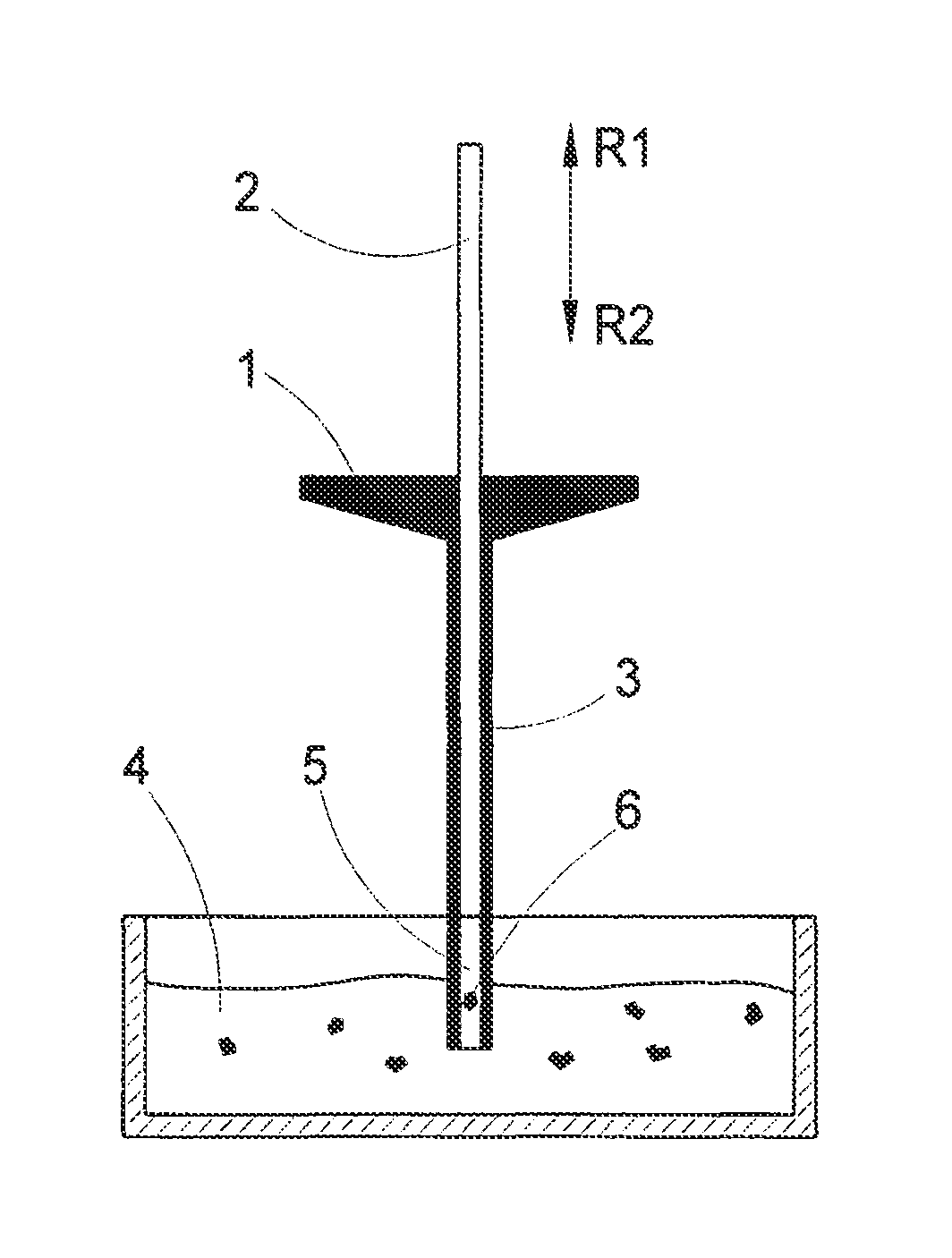

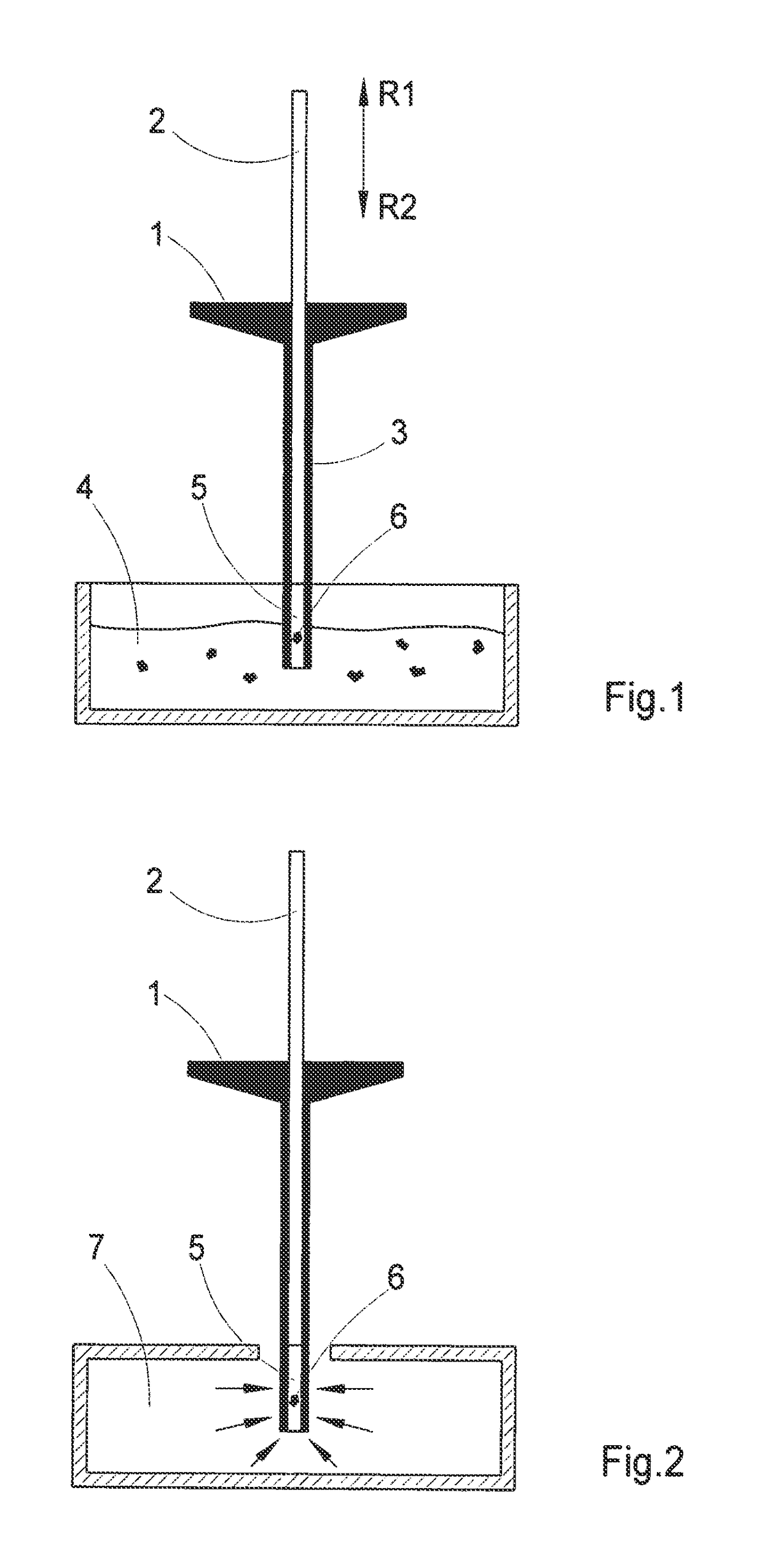

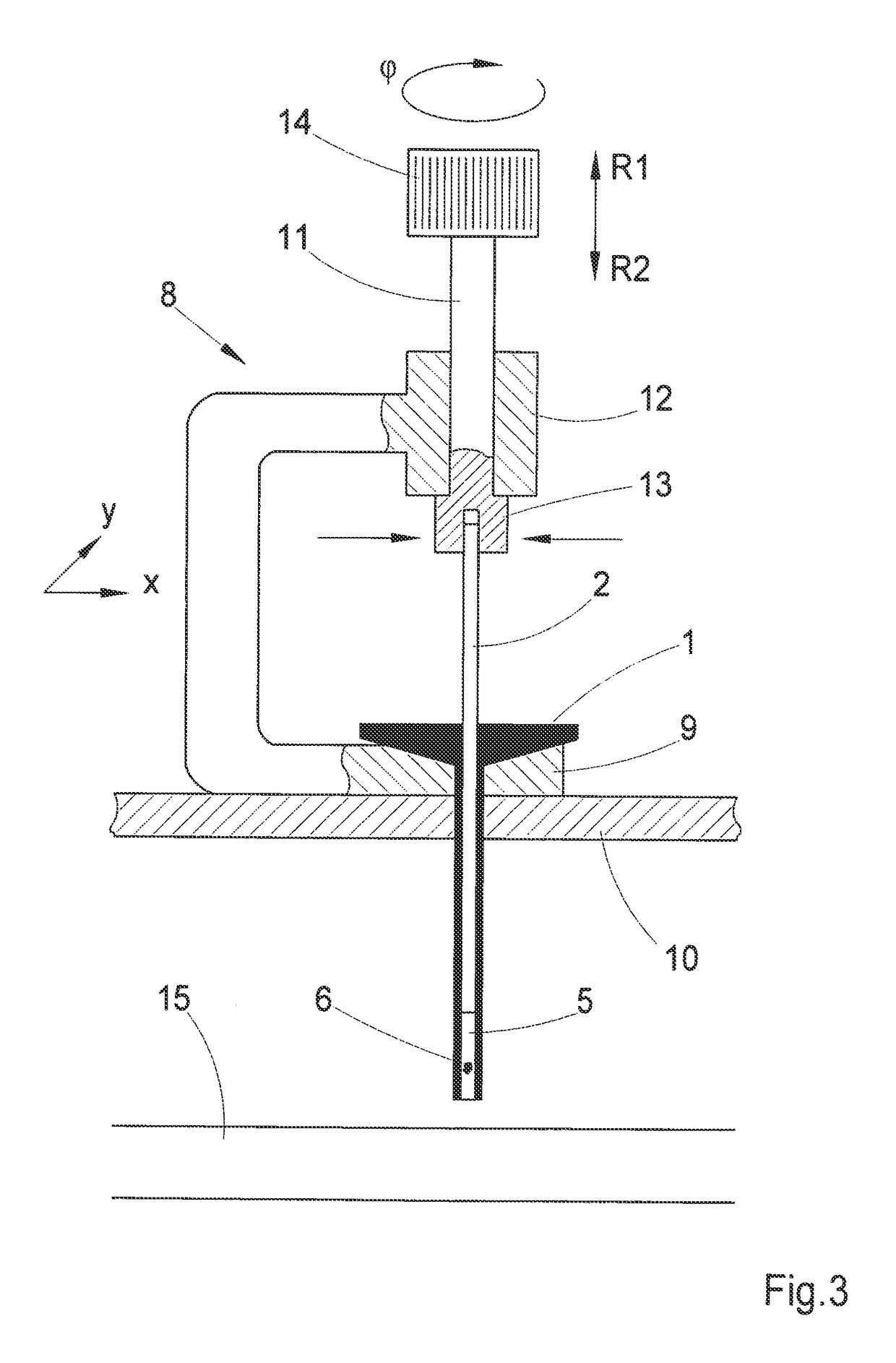

Method for embedding a biological sample in a transparent matrix for analysis using single plane illumination microscopy

ActiveUS9733160B2Valid checkEasy to measurePreparing sample for investigationMicroscopesSample fixationLiquid state

The invention is directed to method for positioning and aligning a preferably biological sample in the detection area of the objective of a microscope arrangement. According to the invention, the method mentioned above has the following method steps: a sample is introduced into a transparent medium, preferably agarose gel, which is initially liquid; the medium is changed from the liquid state to the solid state, wherein the sample is fixated within the medium, but the transparency of the medium is retained; the solidified medium is positioned in the microscope arrangement in such a way that the sample enclosed therein is situated in the detection area of the objective. Further, a device is proposed for positioning and aligning a preferably biological sample in the detection area of the objective of a microscope arrangement.

Owner:CARL ZEISS MICROSCOPY GMBH

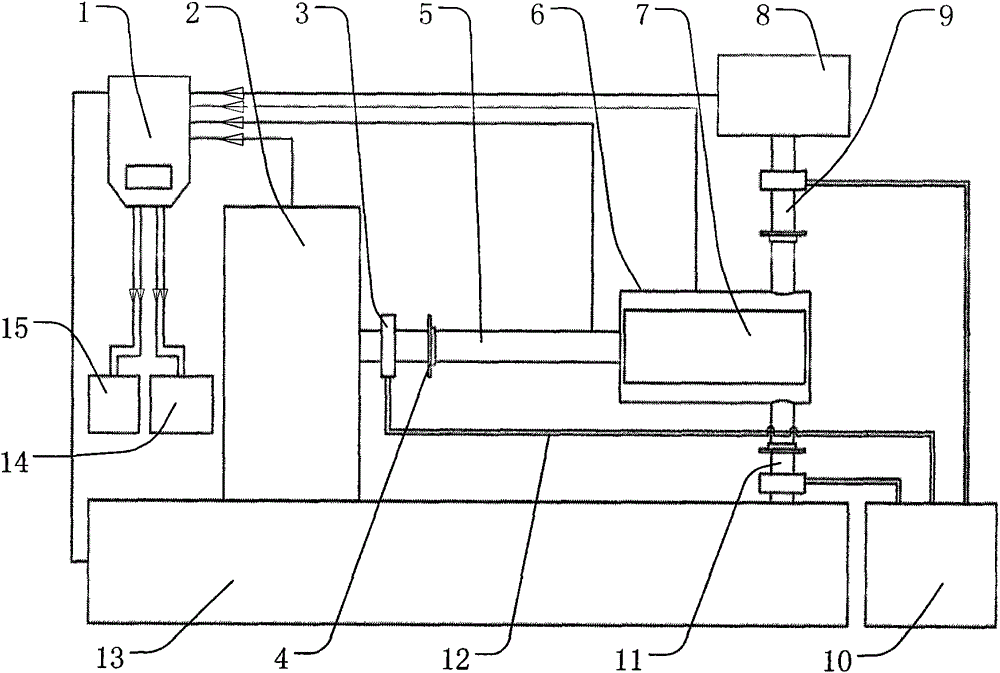

Measuring device for pipe/mold friction coefficient for pipe bending

ActiveCN104132887BAvoid problems such as inability to processAvoid friction coefficient measurement errorsUsing mechanical meansMaterial analysisLubricationAccuracy and precision

The invention relates to a device for measuring a pipe / die friction coefficient during pipe bending forming. The device includes: a horizontal transmission sensor platform, a hydraulic sensor platform, a cooling system, a friction pair instrument, a resistance heating furnace, a temperature sensor, a friction sensor, a charge amplifier, a temperature control instrument and an A / D acquisition computer. A horizontal transmission rod matches with a pipe die fixed station, a pipe sample is fixed on a sample fixation table, an upper die is fixed at the lower end of an upper die fixation rod, which is assembled with the hydraulic sensor platform, the cooling system is assembled with the horizontal transmission rod, the upper die fixation rod and a support seat, and the hydraulic sensor platform, the horizontal transmission sensor platform and all the sensors are respectively connected to the A / D acquisition computer through the charge amplifier. The device provided by the invention can accurately measure the friction coefficient between the pipe inner wall, outer wall and the die under different temperatures, pressures, lubrication states and other conditions, has the advantages of high degree of automation, simple operation and high measurement accuracy, and has a wide range of application for measurement of the pipe forming friction coefficient.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Specimen stage array for scanning probe microscope

InactiveUS20070109636A1Preparing sample for investigationNanotechnologySample fixationScanning electron microscope

Owner:OLYMPUS CORP

Synchronously controllable large dynamic pulse neutron measurement system

PendingCN110988970AMeet the needs of yield measurementPrecise time controlNeutron radiation measurementControl setGamma energy

The invention discloses a synchronously controllable large dynamic pulse neutron measurement system. The system comprises a target bin for placing a target neutron source and a sample carrying assembly, the sample carrying assembly comprises a vacuum isolation straight cylinder and a sample fixing piece positioned in the vacuum isolation straight cylinder, under the driving of a driving mechanism,the vacuum isolation straight cylinder moves linearly to be close to or far away from the target neutron source positioned in the target bin, the sample fixing piece is provided with carrying holes with at least two diameter specifications and / or depth specifications, the carrying holes are used for fixing a to-be-activated sample, and the system also includes a centralized control box, a gamma measurement assembly for measuring the neutron yield of the activated sample, and a trigger synchronous controller for controlling the working time nodes of the centralized control box and the gamma energy spectrum recorder. A synchronous measurement control mechanism is cooperated with the movable vacuum isolation straight cylinder and the sample fixing piece with carrying holes of various specifications, the requirement for large-range neutron yield measurement is met, the time of each step is precisely controlled, and the measurement precision and efficiency are greatly improved.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

Rotary-drum hydraulic-impact abrasion testing machine

InactiveUS8833136B2Using mechanical meansInvestigating abrasion/wear resistanceHydraulic structureEngineering

The present invention relates to a rotary-drum hydraulic-impact abrasion testing machine, which is used to process an abrasion test and a damage simulation for a plurality of hydraulics structures and comprises: a rotary-drum supporting framework, a rotary-drum and a plurality of sample fixing assembly. The sample fixing assembly at least comprises a housing, a first spacer and a plurality of first studs. In which, there are a plurality of sample openings formed on the side wall of the rotary-drum for respectively accommodating the hydraulics structure samples, and each sample opening is disposed with a long blocking plate and a short blocking plate on the two sides thereof. In the present invention, the rotary-drum hydraulic-impact abrasion testing machine is used to simultaneously execute the abrasion test and the damage simulation for multi hydraulics structures precisely.

Owner:NAT TAIWAN UNIV OF SCI & TECH

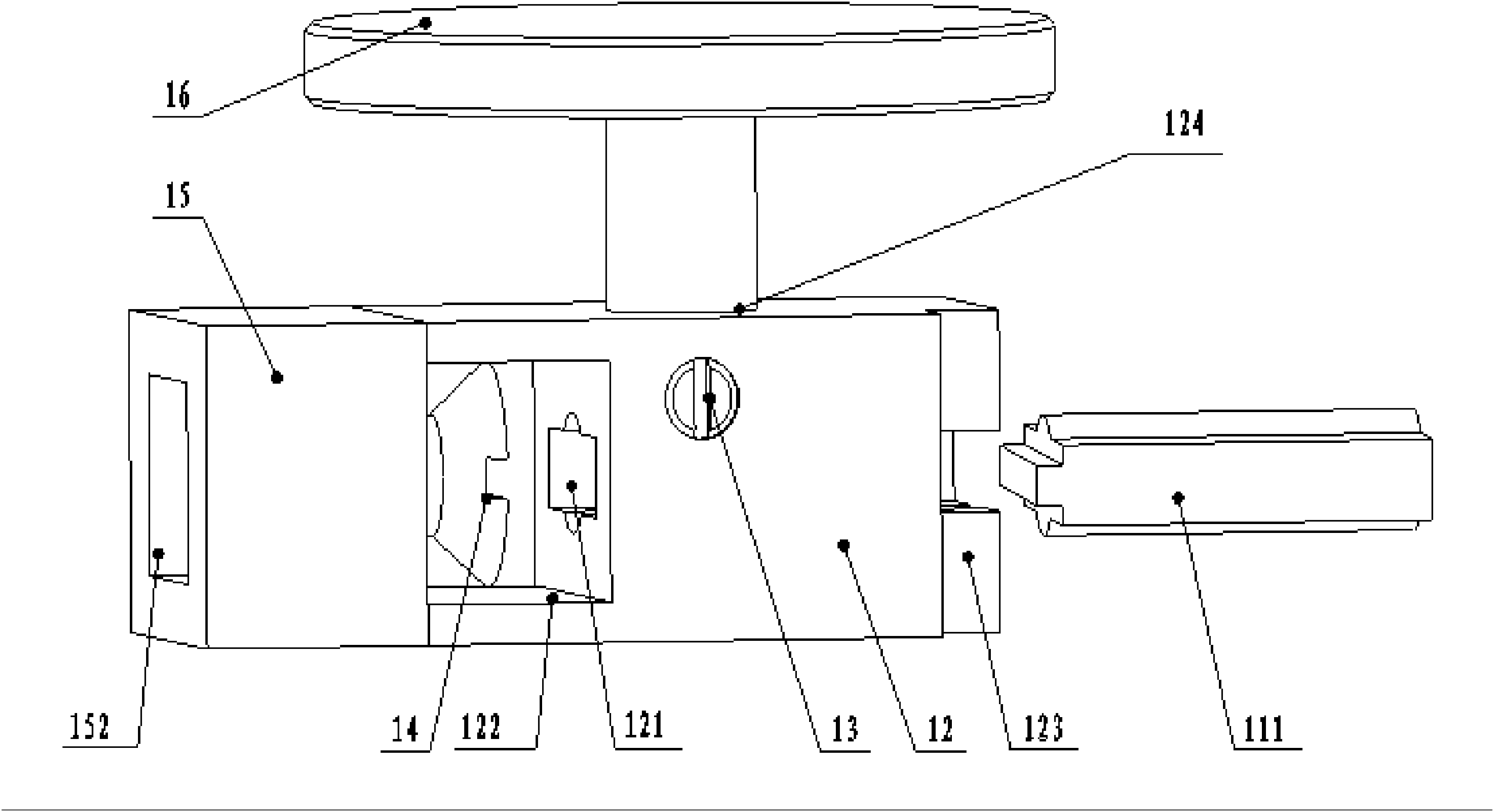

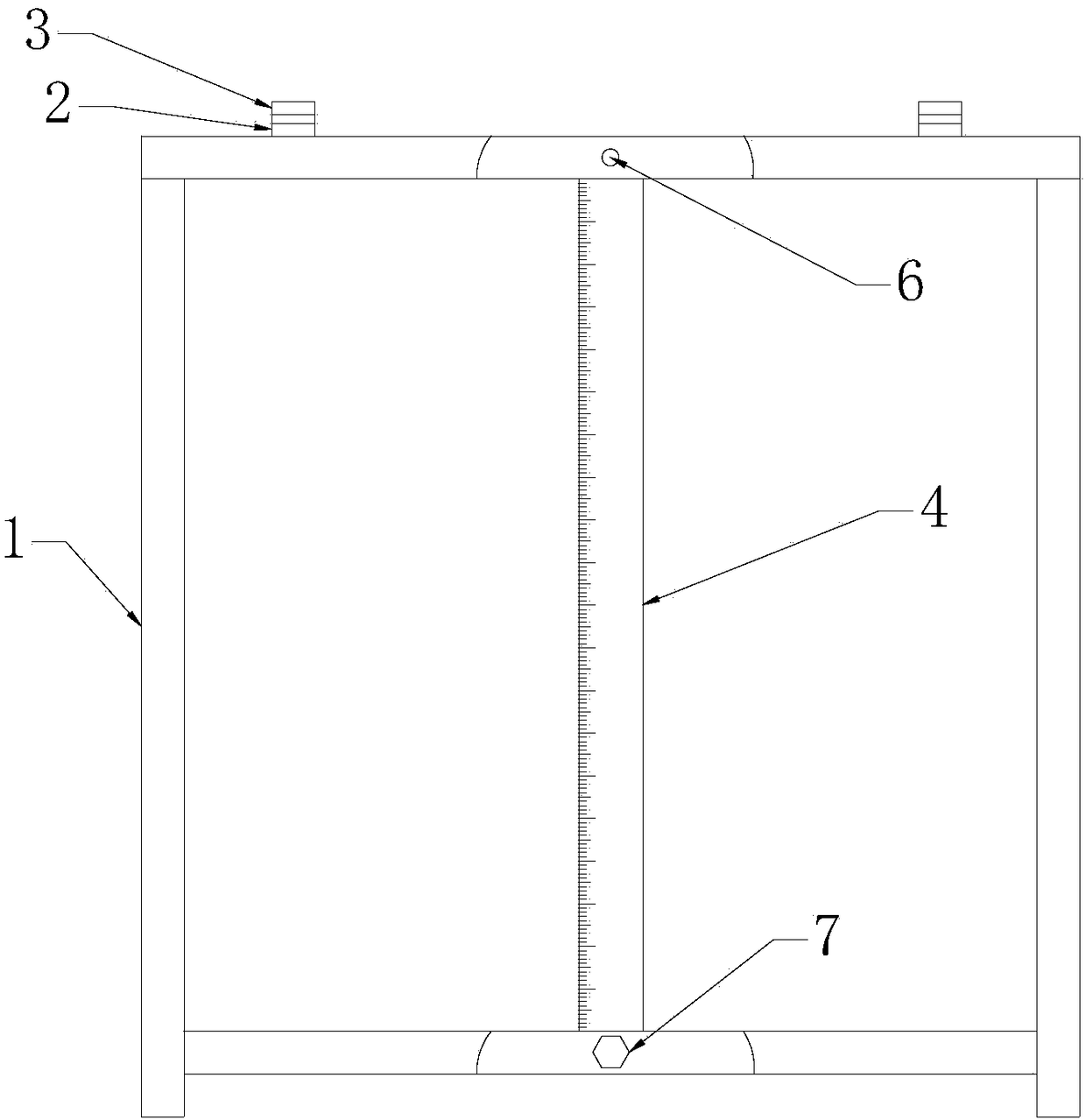

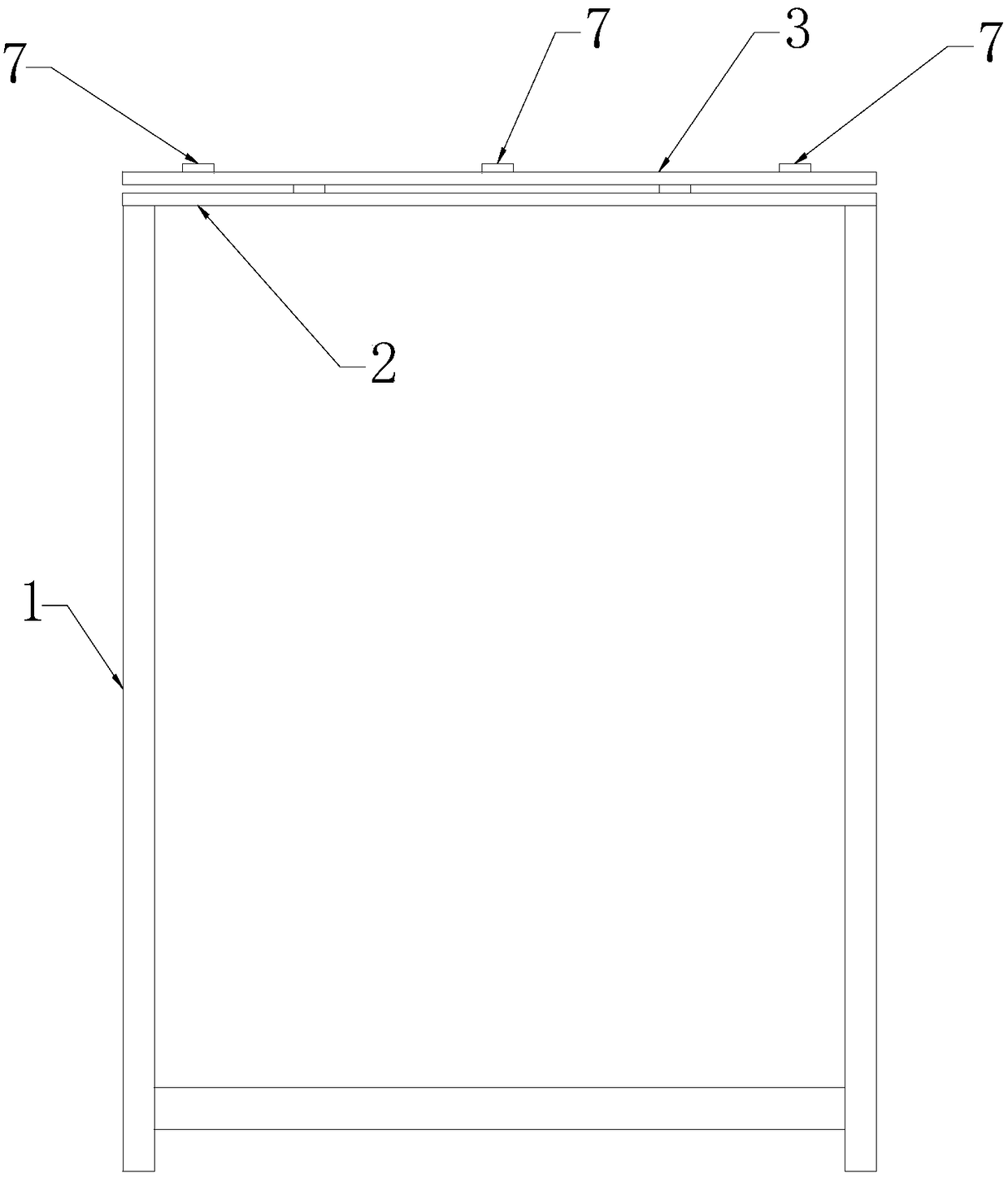

Sample fixation and data collection equipment, and sag resistance performance testing equipment and method

InactiveCN108152320AEasy to manufactureLess investmentPreparing sample for investigationMechanical thickness measurementsSample fixationData acquisition

The invention discloses sample fixation and data collection equipment. The sample fixation and data collection equipment comprises a testing equipment frame, sample fixing strips and a dividing ruler,wherein the testing equipment frame is used for installing the sample fixing strips and the dividing ruler; four bar elongated slots are formed in two ends of two symmetrical sides of the testing equipment frame along the symmetrical sides; the sample fixing strips are fixed inside the bar elongated slots, and can move along the bar elongated slots to change the lengths of testing samples; the white steel dividing ruler is fixed in front of the testing equipment frame from top to bottom. Moreover, the invention provides sag resistance performance testing equipment comprising the sample fixation and data collection equipment. Moreover, the invention further provides a sag resistance performance testing method. The problem that a conventional plastic pipe resin is complex in sag performancetesting, expensive in equipment and not intuitional in property characterization is solved, and the equipment and method for testing plastic pipe sag resistance performance which is simple in operation, cheap in equipment, various in sample specifications, intuitional and accurate in testing data and high in stability are provided.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com