Flexibility testing method for flexible panels

A test method and softness technology, which is applied in the direction of testing material strength by applying stable bending force and testing material strength by applying stable tension/pressure, which can solve the problems of complex operation, large operation error, and unguaranteed accuracy. Achieve the effects of improving detection efficiency, improving test accuracy, and simplifying test steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] A method for testing the softness of a flexible plate in this embodiment comprises the following steps:

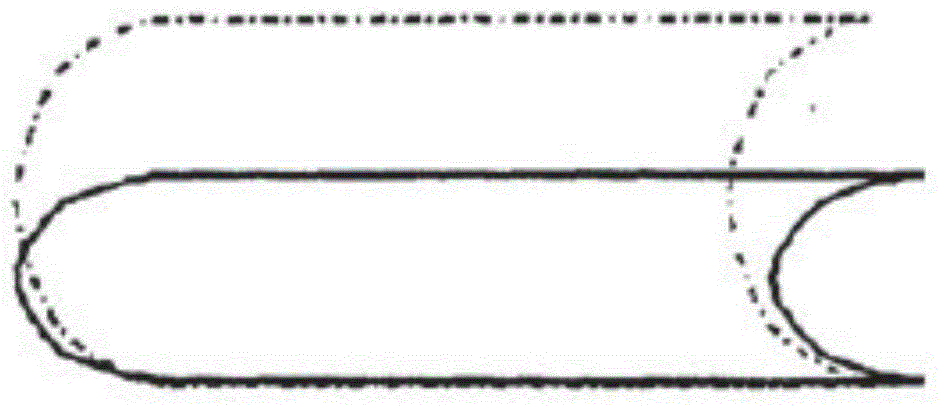

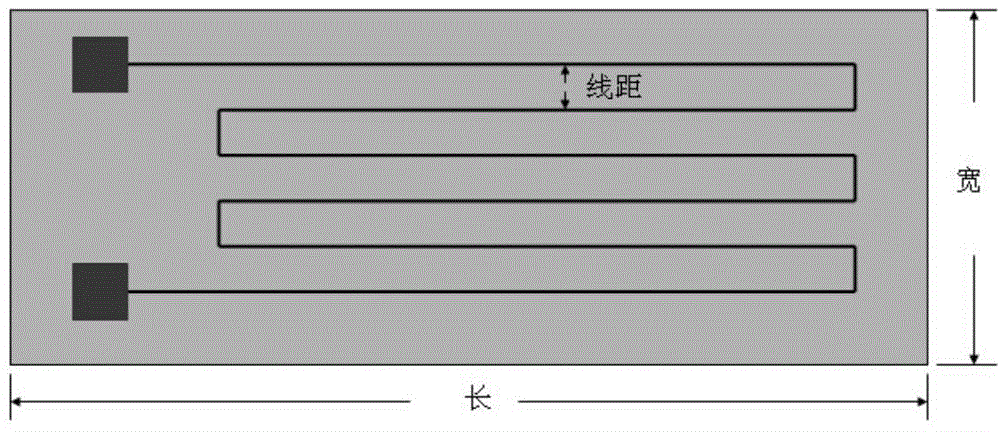

[0032] Preparation of the sample to be tested: cutting the flexible plate to obtain a test board, the length of the test board is 150-200mm, and the width is 8-12mm, bonding the two opposite wide sides of the test board to obtain the sample to be tested;

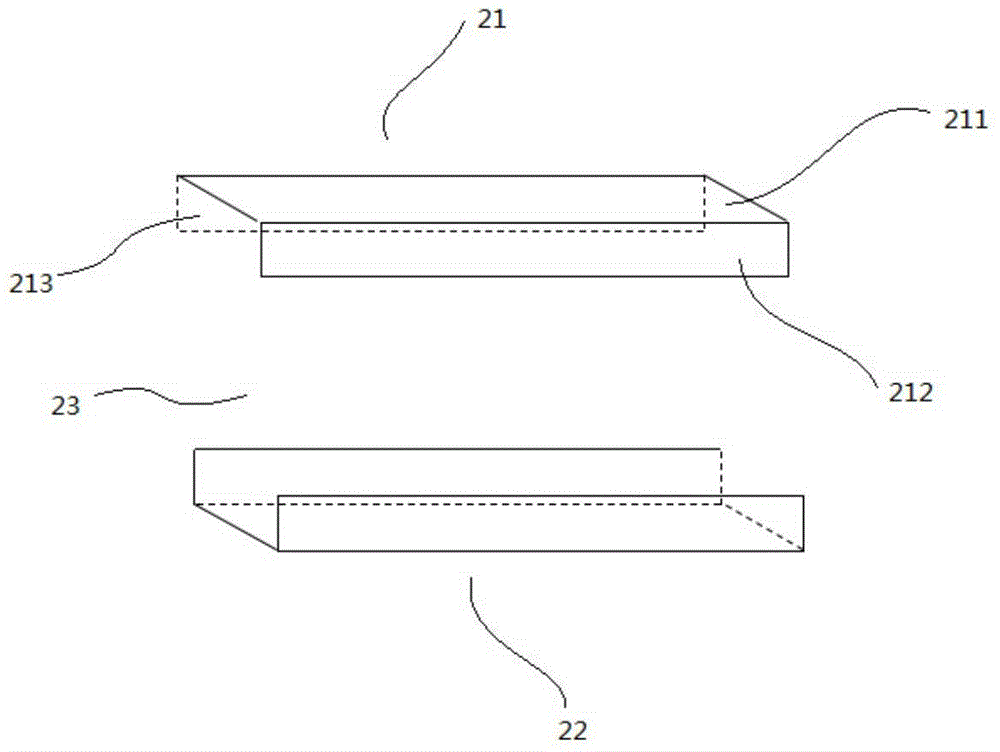

[0033] Auxiliary test device making: described auxiliary test device (such as figure 2 shown) is made of hard paper with a thickness of 2mm, including a first auxiliary test piece 21 and a second auxiliary test piece 22 arranged symmetrically opposite each other. The first limiting portion 212 and the second limiting portion 213 on both sides of the supporting portion; the supporting portion 221 is 70-125mm long and 1-2mm wider than the test plate, and the first limiting portion 212 and The height of the second limiting portion 213 is 1-3 mm.

[0034] A test channel 23 with a height of 20 mm is formed between t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com