Light emission microscope opposite side sample fixer

A light emission microscope, sample fixation technology, applied in microscopes, optics, instruments, etc., can solve the problems of difficulty in analysis, air bubbles on the back of the chip and glass, and pollution on the chip surface, and achieves the effect of easy use, avoidance of waste, and avoidance of pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

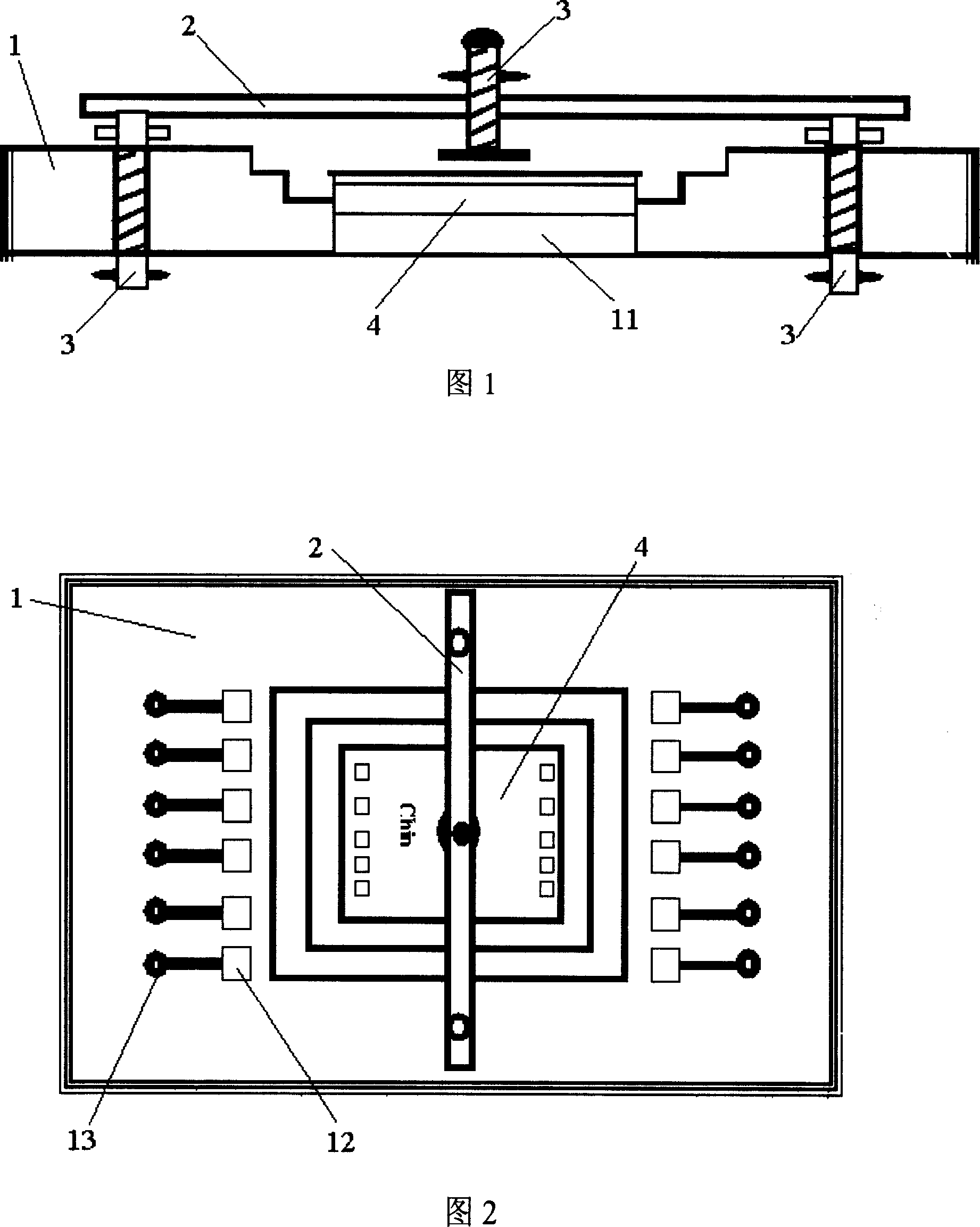

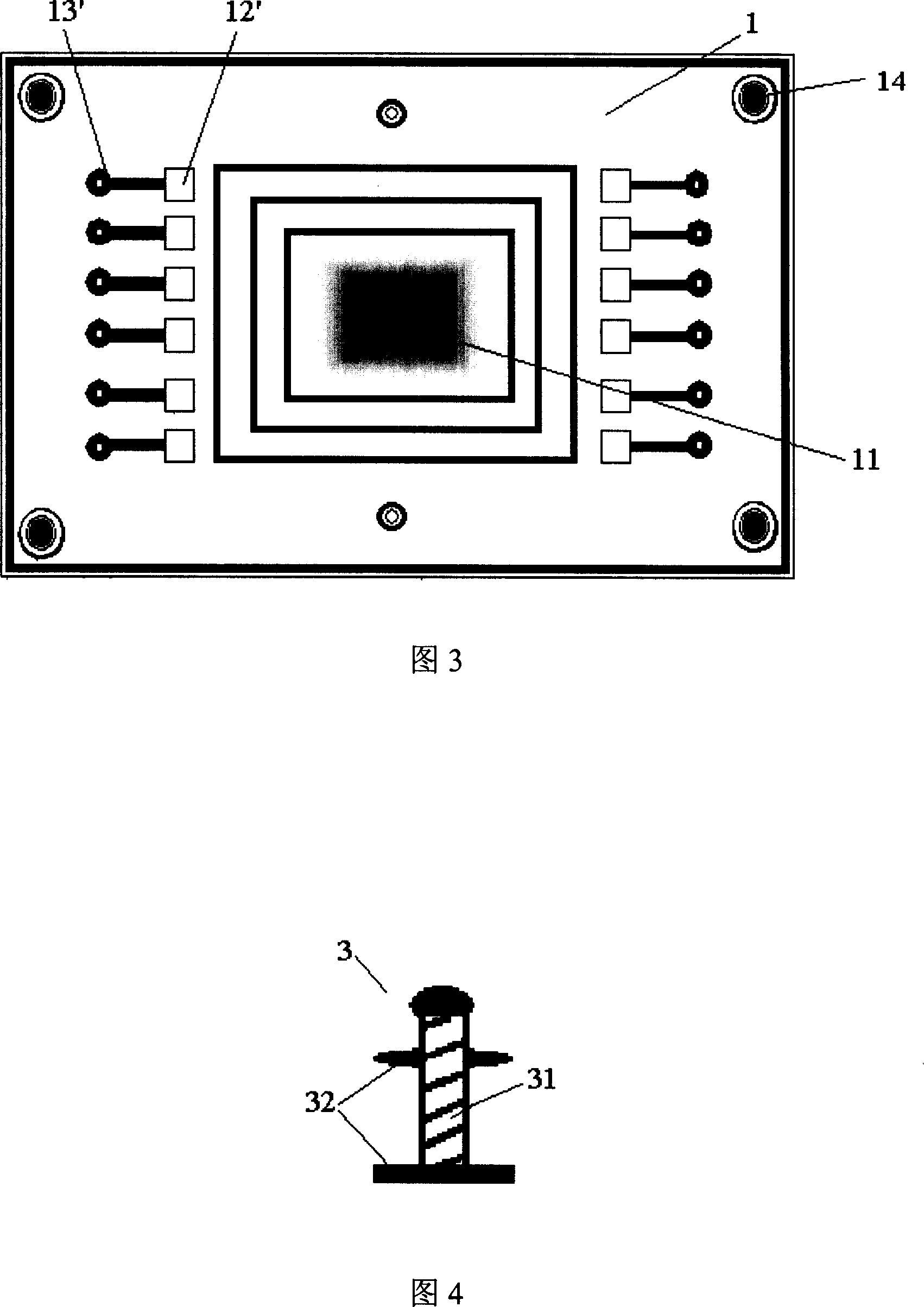

[0036] Fig. 1 shows the sectional view of the sample holder on the back of the light emission microscope of the present invention, which has the following structure: a sample carrying substrate 1, a sample fixing rod 2 and at least three movable threaded gaskets 3;

[0037] A light-transmitting glass sheet 11 is inlaid in the center of the sample carrying substrate as a position for carrying the sample chip 4;

[0038] Both ends of the sample fixing rod 2 are respectively connected to both sides of the sample carrying substrate 1 by movable threaded gaskets 3;

[0039] Among the at least three movable threaded gaskets 3, at least two movable threaded gaskets 3 are penetrated on both sides of the sample carrying substrate 1, and are respectively fixed to the two ends of the sample fixing rod 2, at least one of which can be The moving thread gasket 3 is installed in the middle of the sample fixing rod 2 .

[0040] The specific structure of the above-mentioned sample carrier sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com