Determination apparatus and method for comprehensive properties of heat-shrinkage film

A technology of comprehensive performance and measuring equipment, which is applied in the field of testing, can solve problems such as lack, and achieve the effects of improving testing capabilities, reducing labor intensity, and automating the testing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

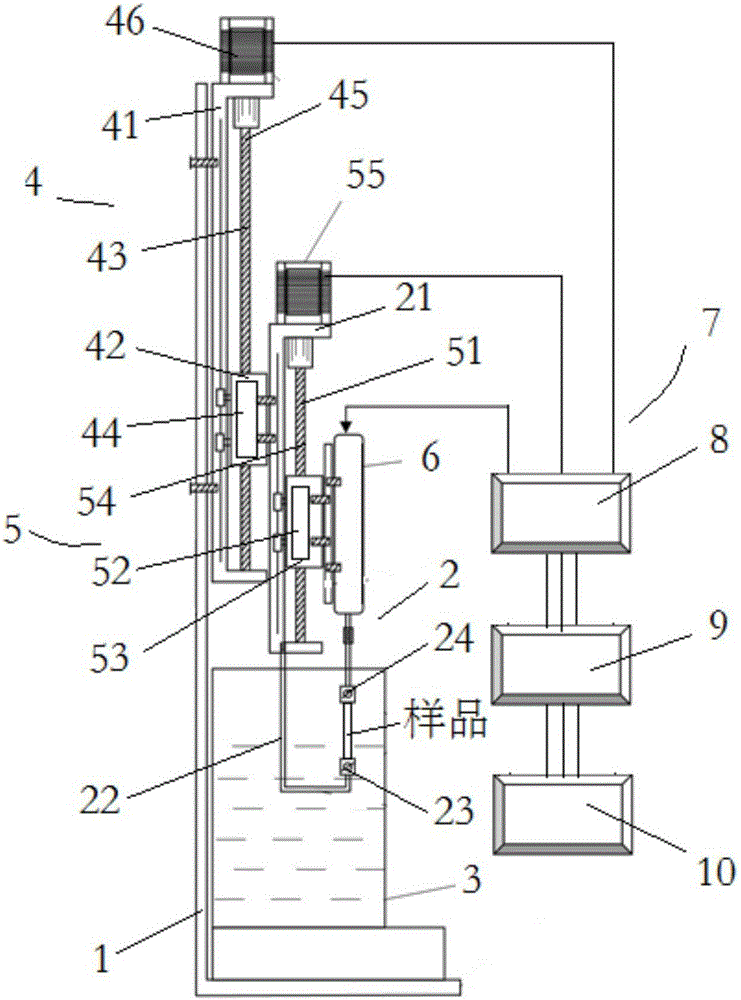

[0048] Invention 1. Heat-shrinkable film comprehensive performance measurement equipment

[0049] figure 1 It is a structural schematic diagram of the present invention, a heat-shrinkable film comprehensive performance measurement equipment, including a base 1, a sample holder 2 and a constant temperature control device 3, the constant temperature temperature control device 3 in this embodiment is a water bath, and the sample holder 2 passes through the lifting device 4 is slidably fixed on the base and is located directly above the constant temperature control device 3,

[0050]The sample holder 2 includes a U-shaped seat 1 21, a fixed chuck 23 fixed by a bracket 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com