Sample fixation and data collection equipment, and sag resistance performance testing equipment and method

A technology of data acquisition equipment and sample fixing, which is applied in the preparation of test samples, measuring devices, and mechanical thickness measurement, etc., which can solve the problems of complex sag performance testing, expensive equipment, and unintuitive performance characterization, and save human resources. Expenses, reduction of test errors, and ease of equipment promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The embodiments of the present invention are described in detail below: the present embodiment is implemented under the premise of the technical solution of the present invention, and detailed implementation methods and processes are provided, but the protection scope of the present invention is not limited to the following embodiments, the following The experimental method that does not indicate specific condition in the embodiment, generally according to routine condition.

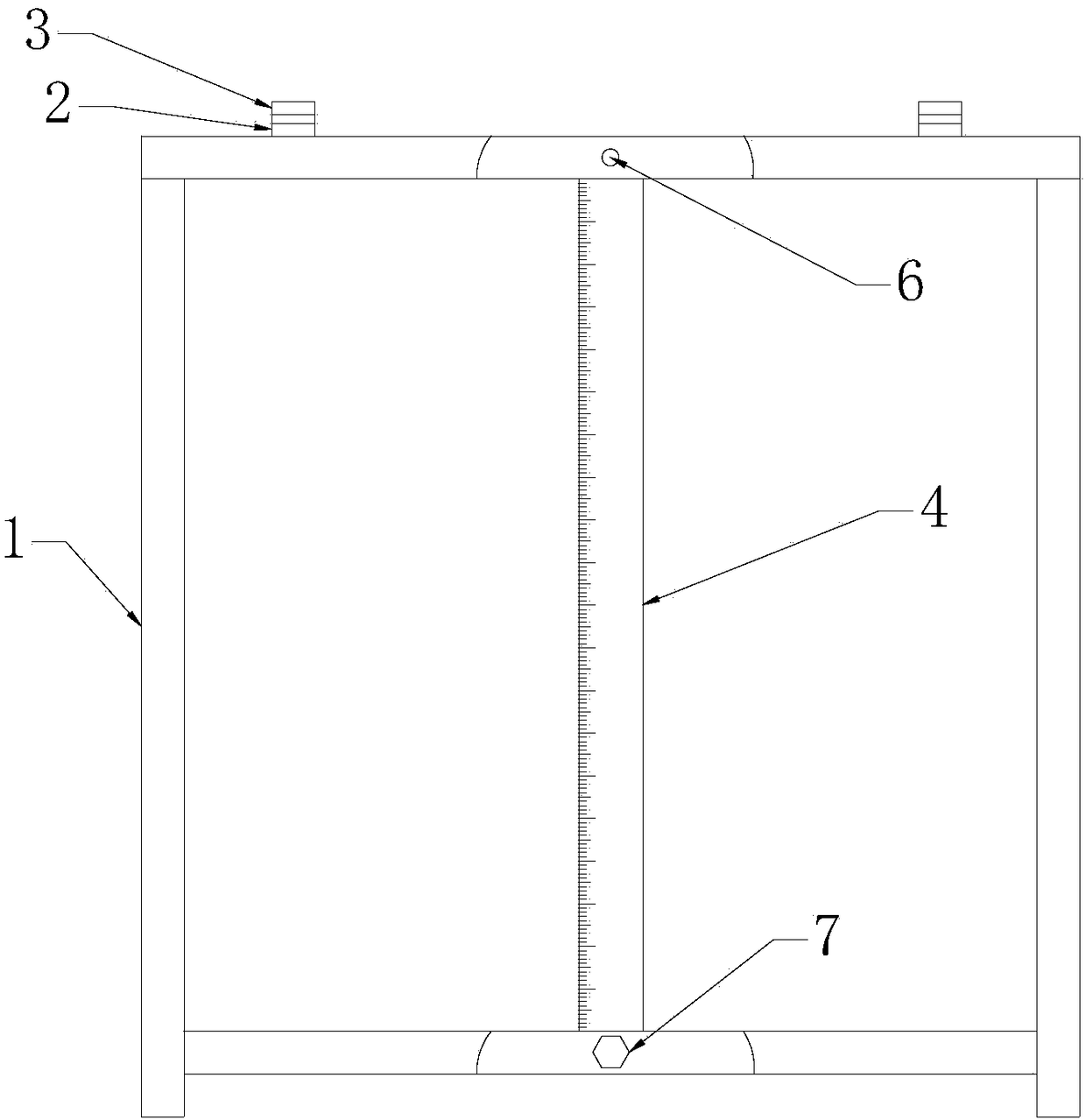

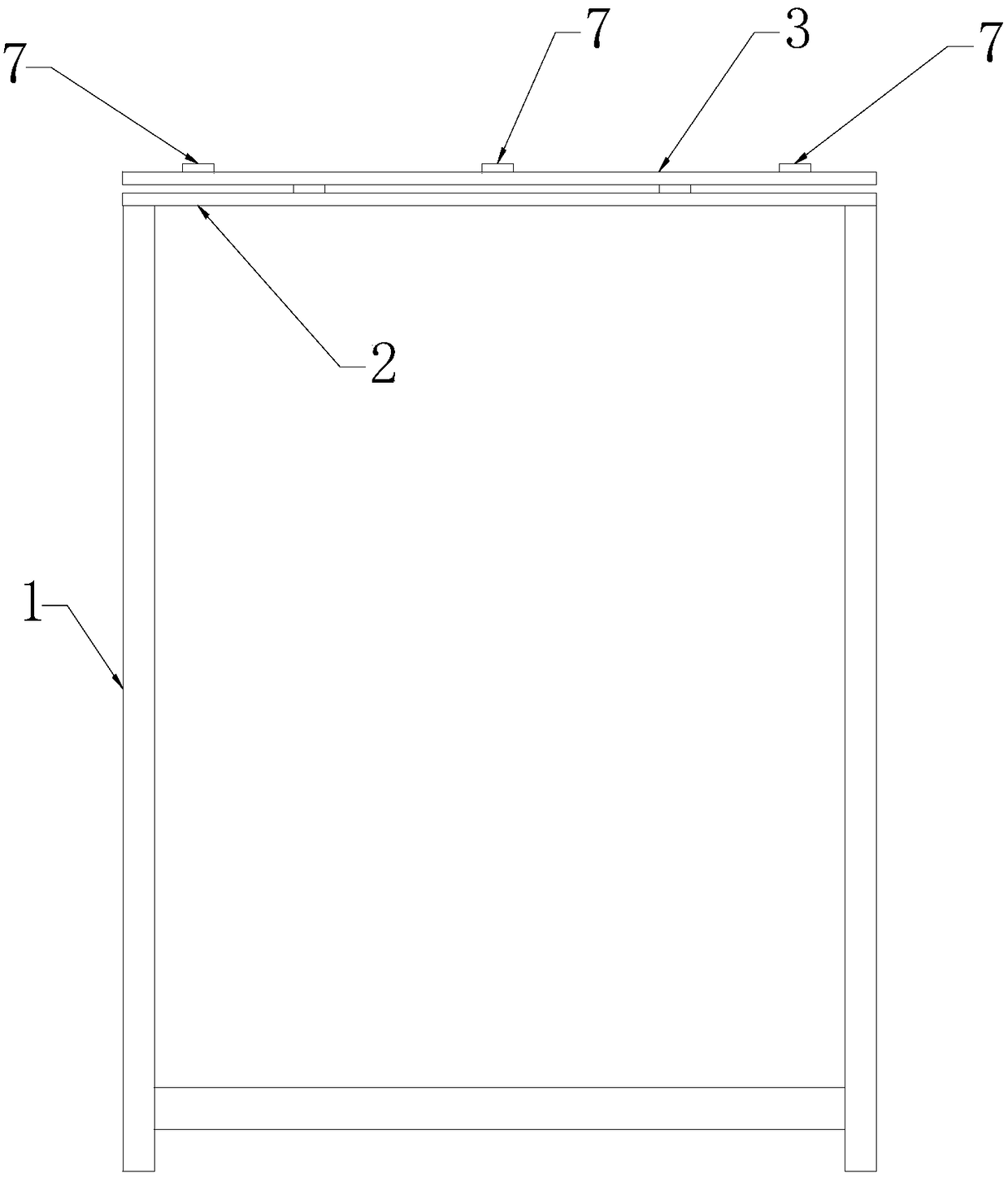

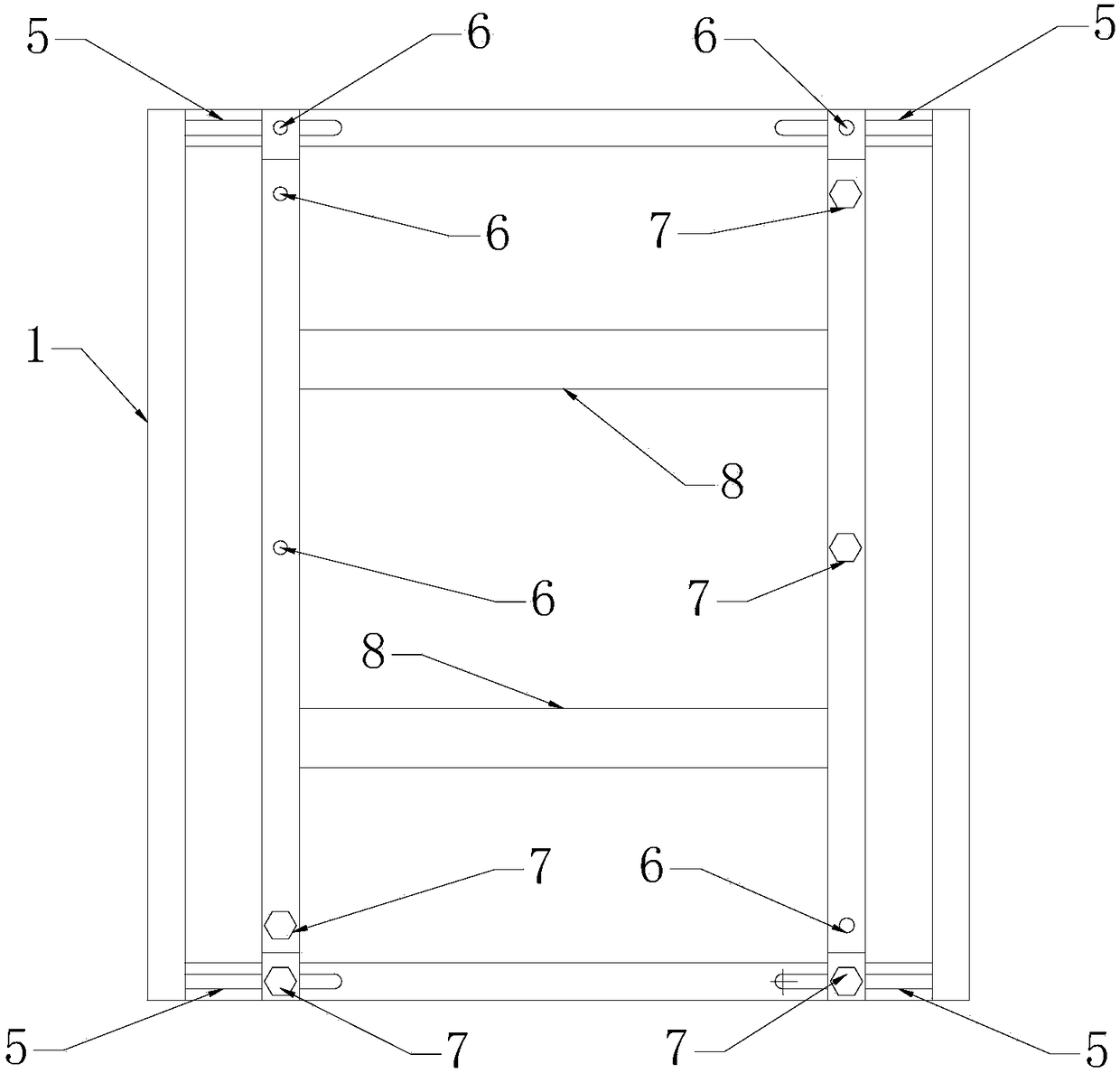

[0053] According to one aspect of the present invention, there is provided a testing device for the anti-sagging performance of plastics for pipes, including: test sample preparation equipment, heating devices, test sample fixing and data collection equipment, and final sample testing devices. The test sample preparation equipment is used to prepare plastic test samples for pipes used in the sag resistance test; the heating device is used to heat the test samples at a preset temperature; the test s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com