Wrapping paper indentation detecting device

A detection device and wrapping paper technology, which is applied to measuring devices, packaging, force/torque/power measuring instruments, etc., can solve the problems of cumbersome detection process, time-consuming and labor-intensive work, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

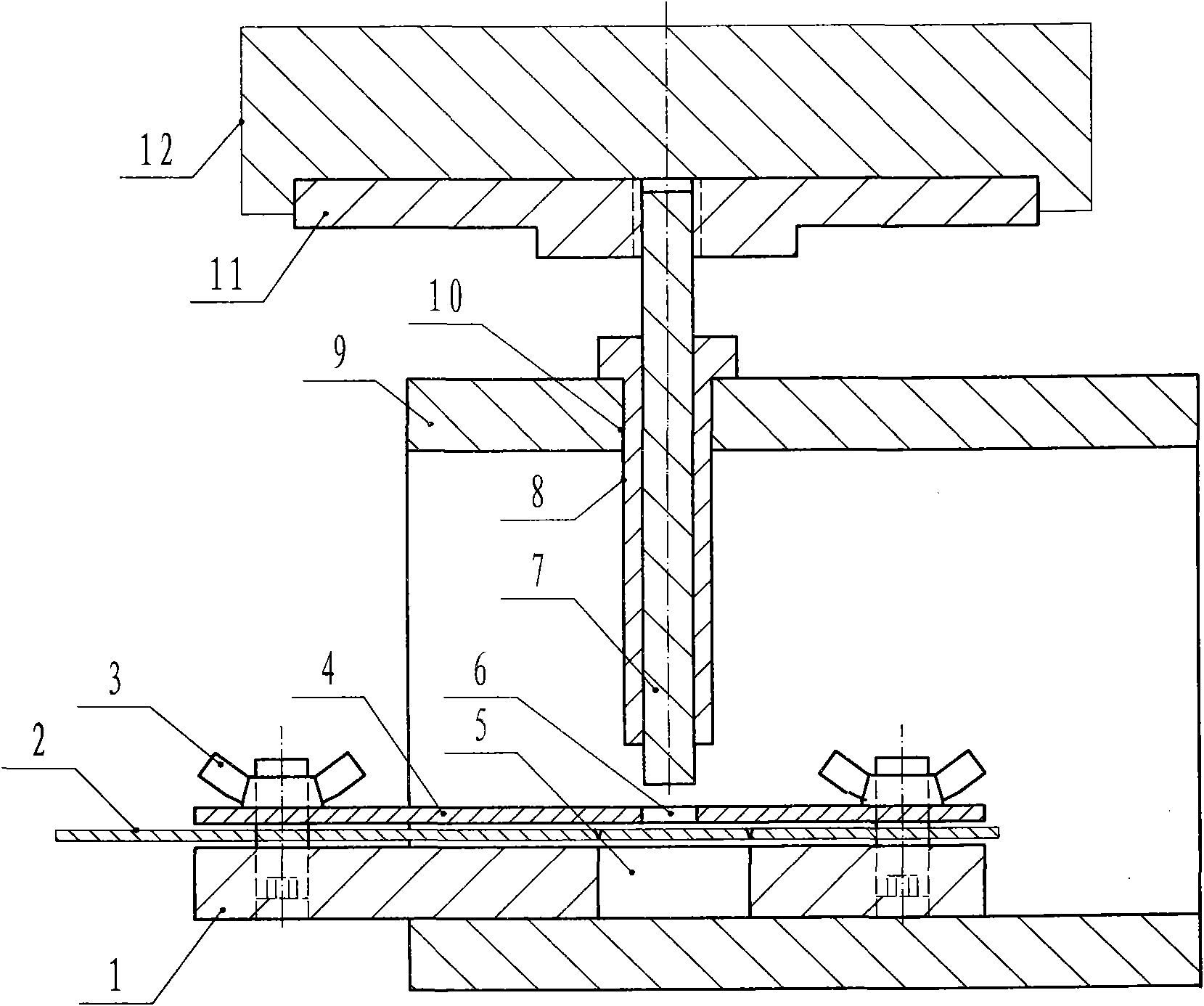

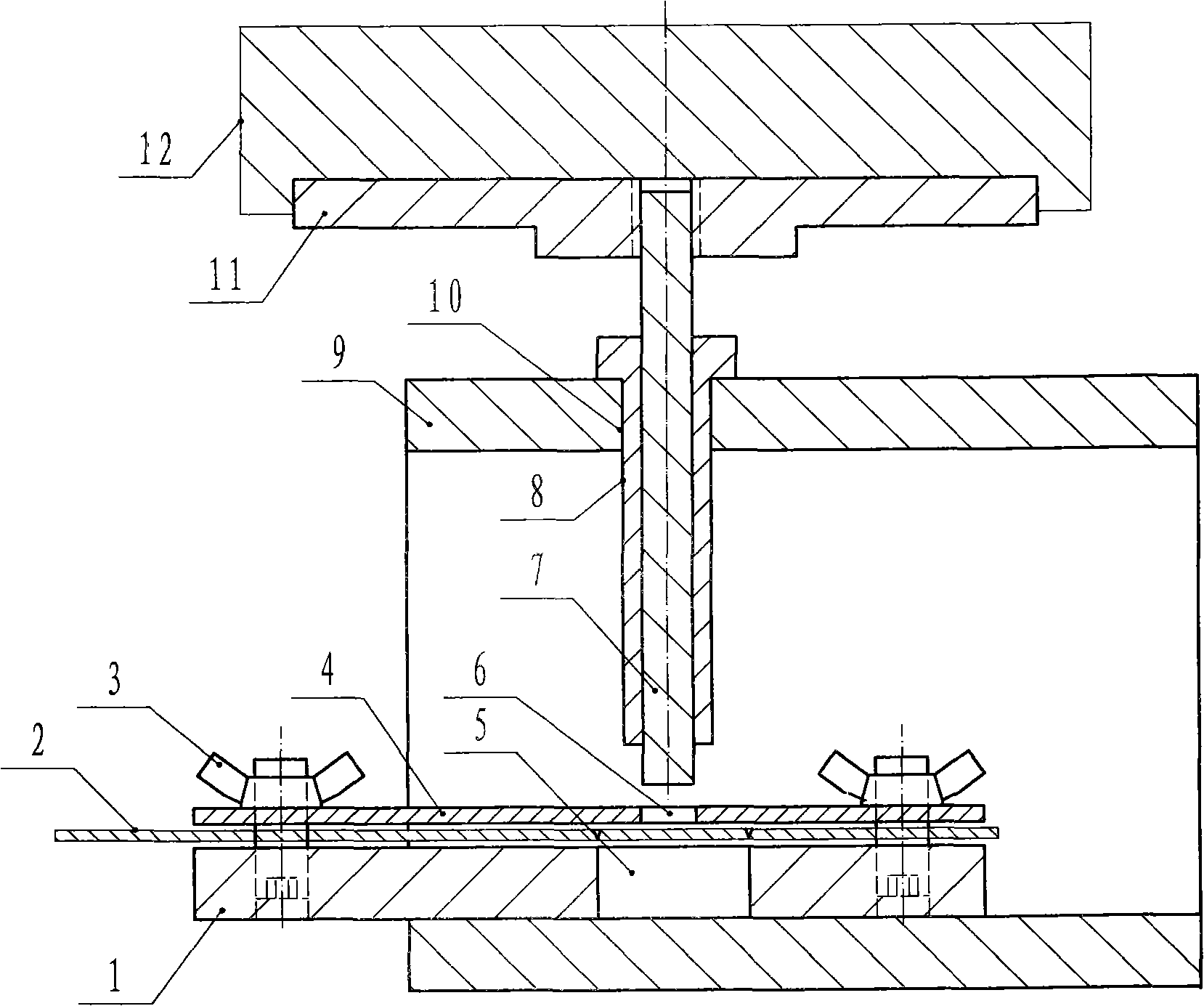

[0007] Example: such as figure 1 As shown, a packaging paper indentation detection device is installed on a support 9, a template 1 is installed on the bottom surface of the support 9, a sample model hole 5 is opened on the template 1, and a clamping plate 4 is installed above the template 1. The clamping plate 4 is fixed with nuts 3, the sample paper 2 to be tested is fixed between the clamping plate 4 and the template 1, the indentation on the paper sample is facing the model hole 5, and the clamping plate 4 has a through hole 6, Through hole 6 is facing model hole 5, has positioning hole 10 on the top of support 9, inserts pressure rod 7 in positioning hole 10, and the lower end of pressure rod 7 is facing the through hole 6 on the fixed plate, and the upper end of pressure rod 7 is processed with Supporting plate 11, gravity weight 12 is placed on supporting plate 11, a guide sleeve 8 is installed in the positioning hole 10 above the support 9, and pressure rod 7 is instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com