A kind of method for preparing low-chlorinated impurity content isocyanate based on salt-forming phosgenation

A technology of isocyanate and impurity content, applied in the field of isocyanate, can solve the problems of low reaction conversion rate, many side reactions, incomplete hydrochloride salt formation, etc., and achieve high yield and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

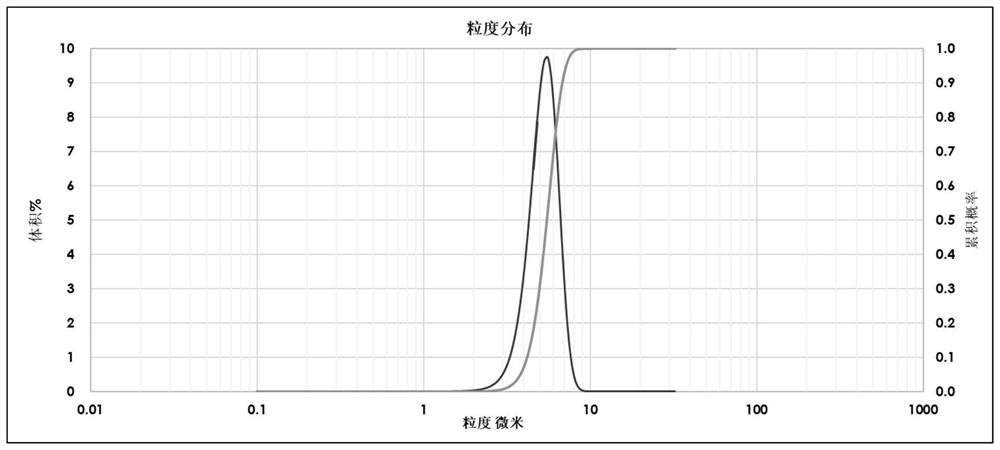

[0064] Drop into 40kg chlorobenzene as the reaction solvent of bottoming in the reaction kettle, open the reaction kettle and stir, the set rotating speed is 200rpm, and 3.2kg (23.5mol) m-xylylenediamine is added in the reactor as a separate stream (The corresponding total amine concentration of the salt-forming reaction solution is 8 wt%). At the beginning of the reaction and during the process, the temperature in the salt-forming reactor was controlled to be 10° C., and the pressure of the reactor was adjusted to 0.1 MPa (absolute pressure). The solutions of the hydrogen chloride gas and the amine stream were divided at 1.1 Nm 3 The flow rate of / h and 2.3kg / h was passed into the salt-forming reaction kettle. After 1.5h, the passing of hydrogen chloride and amine streams was stopped, and the salt-forming reaction was completed. After the salt-forming reaction is completed, sample the particle size of the test sample, keep the stirring state, and use a laser diffraction part...

Embodiment 2

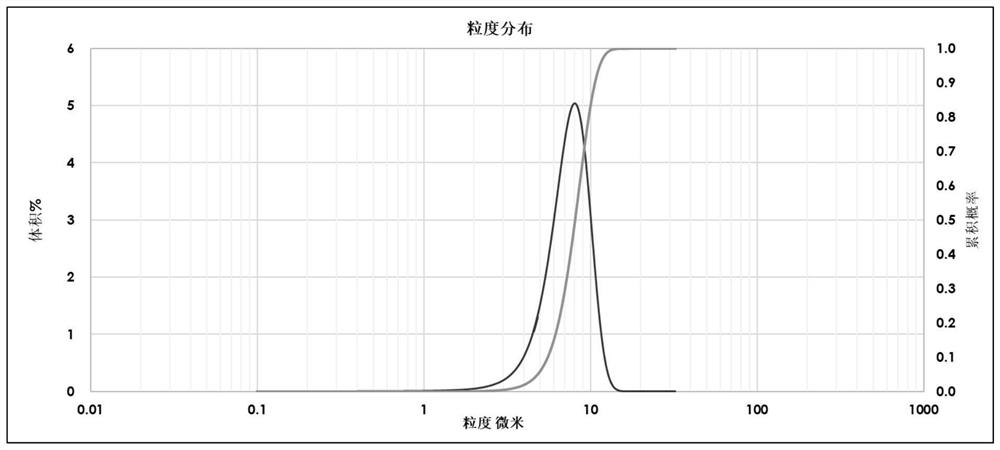

[0067] Drop into 10kg o-dichlorobenzene as the reaction solvent for priming in the reactor, drop into 4.0kg (37mol) p-phenylenediamine and 30kg o-dichlorobenzene in the raw material tank and be configured to be a 13% amine stream suspension ( The corresponding total amine concentration of the salt-forming reaction solution is 10 wt%). The temperature in the reactor was controlled to be 100°C, the pressure of the reactor was adjusted to 0.15MPa (absolute pressure), and the stirring speed of the reactor was adjusted to 200rpm. The suspensions of the hydrogen chloride gas and the amine stream were respectively charged at 4.14 Nm 3 The flow rates of / h and 34kg / h were passed into the salt-forming reactor, and the hydrogen chloride and amine streams were stopped after 1.0h, and the salt-forming reaction was completed. Particles with diameters between 5.60 and 10.40 microns (8.0 microns ± 30%) accounted for 76.99% of all particle size distributions. Transfer the amine hydrochlorid...

Embodiment 3

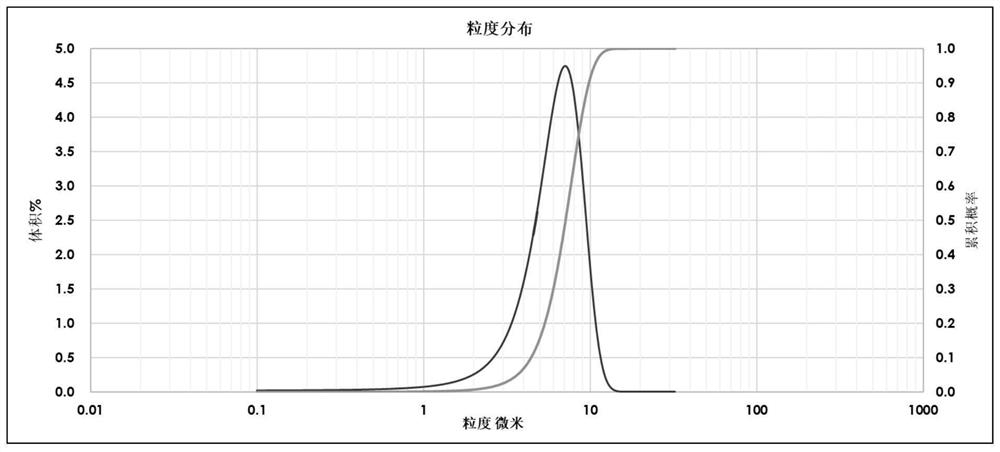

[0070] Drop into 15kg of chlorobenzene as the reaction solvent for bottoming in the reactor, drop into the raw material tank 8.0kg (69mol) of 1,6-hexanediamine and 25kg of chlorobenzene to configure the concentration of 32% amine stream solution (corresponding to The total amine concentration of the salt-forming reaction solution is 20 wt%). The temperature in the salt-forming reactor was controlled to be 40° C., the pressure of the reactor was adjusted to 0.20MPa (absolute pressure), and the stirring speed of the reactor was adjusted to 200rpm. The solutions of the hydrogen chloride gas and the amine stream were divided at 6.18 Nm 3 The flow rates of / h and 16.5kg / h were passed into the salt-forming reaction kettle, the hydrogen chloride and amine streams were stopped after 2.0h, the salt-forming reaction was completed, and the average particle size of the hydrochloride particles obtained by sampling and testing was 12.0 microns, Particles with a particle size between 8.40 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com