Copper ion supplementing device and method for electroplating

A technology of copper ions and electroplating solution, which is applied in the direction of electrolysis process, electrolysis components, cells, etc., can solve the problems of component concentration fluctuation, unfavorable quality control, lack of dissolved copper, etc., so as to keep the component concentration stable, avoid negative effects, Favorable effect of continuous supplementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

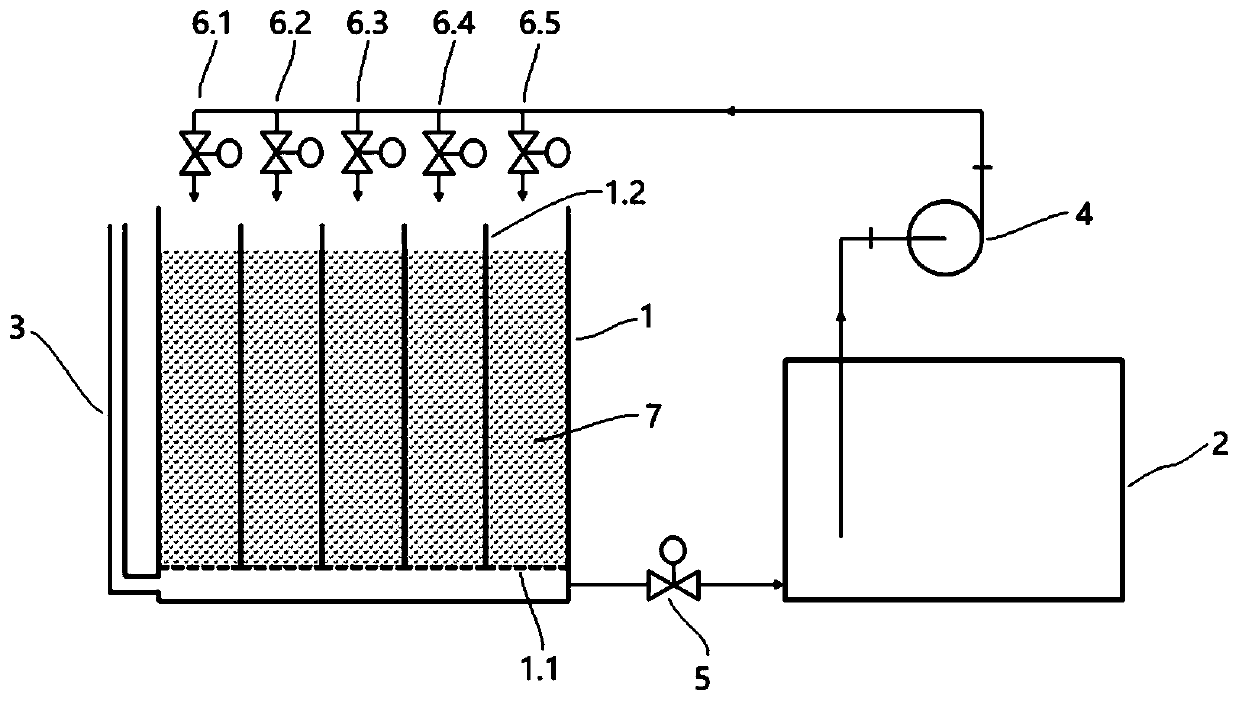

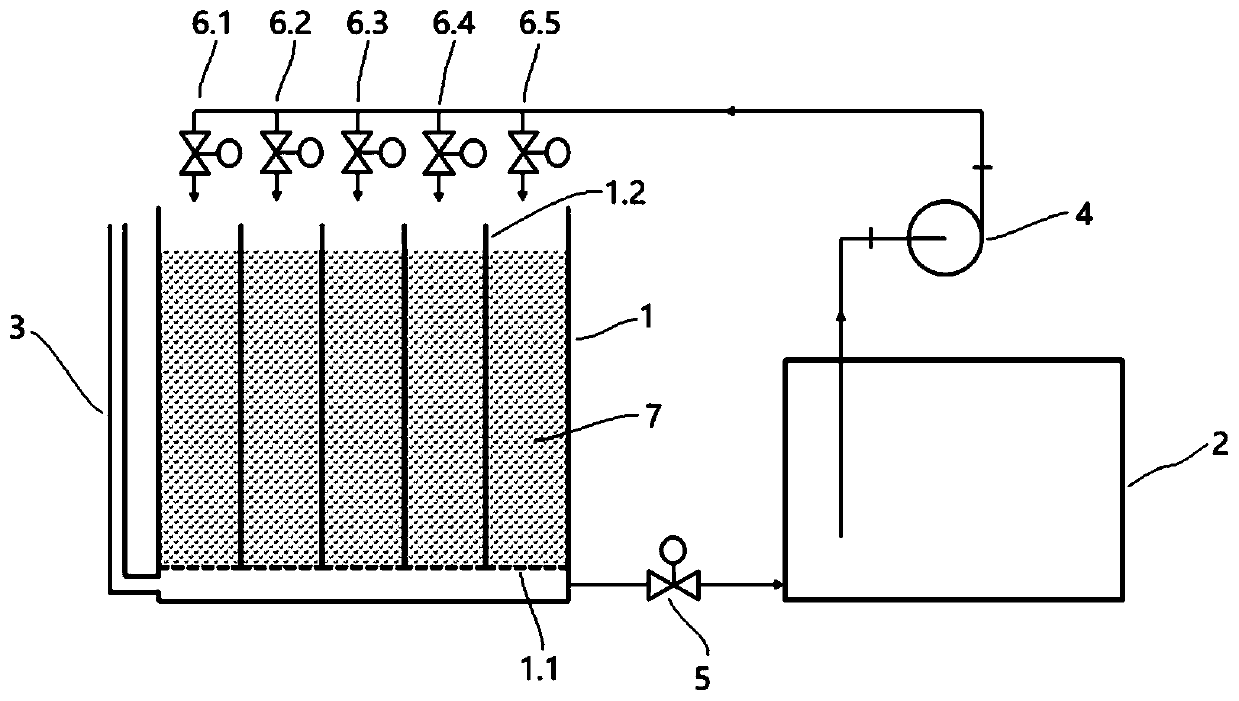

[0044] This embodiment provides a copper ion supplement device for electroplating. The device includes a tank body 1, a centrifugal pump 4, and a liquid storage tank 2. The tank body 1 is divided into 5 independent tank chambers by a partition 1.2. The bottom of the tank is provided with a porous partition 1.1, and each tank is equipped with copper balls (grains) 7. The bottom of the tank is in communication with the liquid storage tank 2 and there is a flow regulating valve 5 between them. The centrifugal pump 4 is located Between the liquid storage tank 2 and the tank body 1, the output end of the centrifugal pump 4 is connected with 5 delivery pipelines, each delivery pipeline corresponds to a tank chamber, which is used to transport the electroplating solution into the tank chamber. The output ends are respectively equipped with electric valves 6.1-6.5.

[0045] The device in this embodiment also includes a liquid level monitoring device 3 connected to the tank chamber, and t...

Embodiment 2

[0048] This embodiment provides a copper ion supplement method for electroplating. The copper ion supplement device provided in Example 1 is used for copper ion supplementation. The specific operations of the method are:

[0049] Select the specific amount of dissolved copper according to the actual working conditions on site, open the valves 6.1 to 6.3 on the delivery pipeline, close 6.4 and 6.5, and transport the electroplating solution in the storage tank 2 through the delivery pipeline to the opened tank chamber through the centrifugal pump 4 , According to the real-time feedback of the liquid level in the tank by the liquid level monitoring device 3, the flow regulating valve 5 is used to adjust the flow of the electroplating solution to keep the liquid level in the tank stable, and the electroplating solution after replenishing copper ions enters the storage tank 2. Used for electroplating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com