Light plastering gypsum taking diatomite waste particles as aggregate and preparation method thereof

A technology for plastering gypsum and waste, applied in the field of light plastering gypsum and its preparation, can solve the problems of waste of resources, unutilized secondary diatomite waste, etc., achieves reduction of labor intensity, excellent leveling effect, The effect of simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

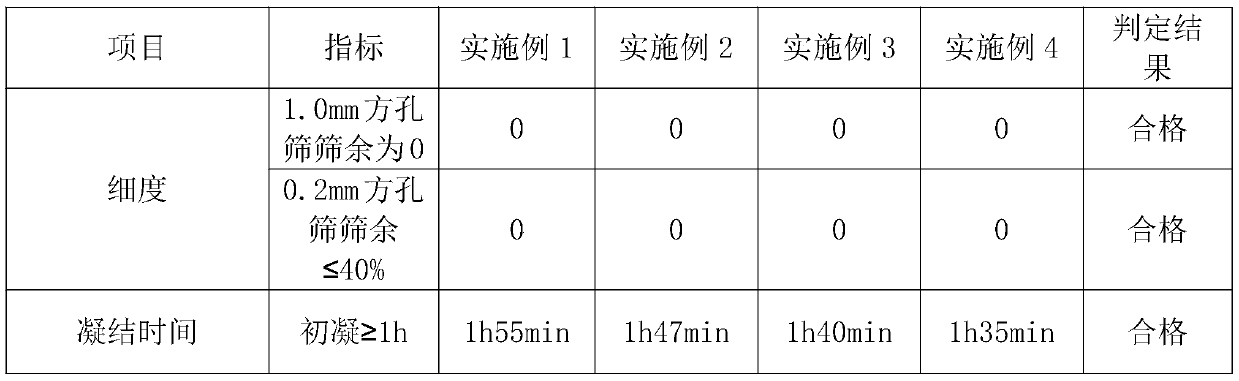

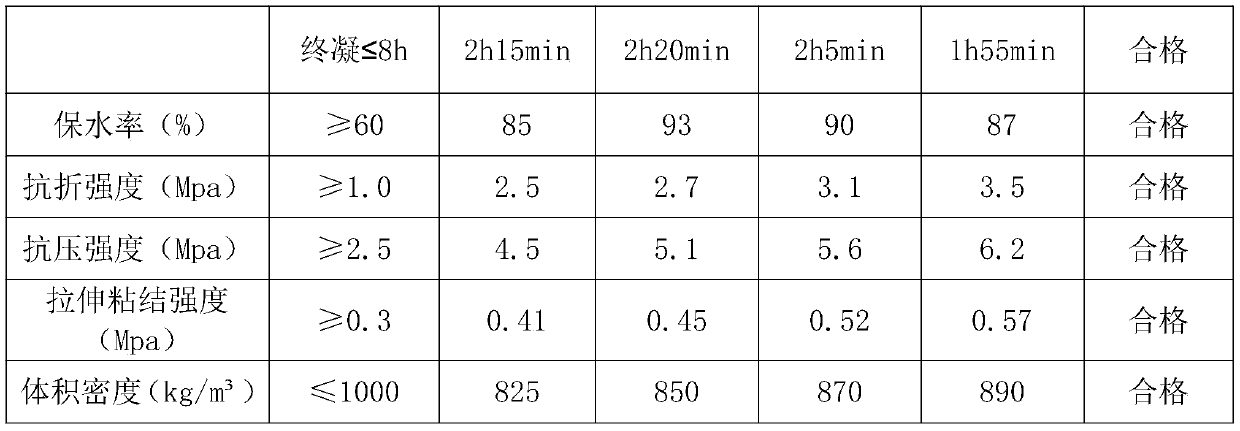

Embodiment 1

[0043]Lightweight plastering gypsum with diatomite waste particles as aggregates is made of the following raw materials in parts by weight: 500 parts of gypsum, 50 parts of cement, 250 parts of diatomite waste particles, 0.5 part of gypsum retarder, 0.5 part of hydroxypropyl methylcellulose ether, 0.5 part of thixotropic agent, and 0.5 part of antifungal agent.

Embodiment 2

[0045] Lightweight plastering gypsum with diatomite waste particles as aggregates is made of the following raw materials in parts by weight: 580 parts of gypsum, 40 parts of cement, 200 parts of diatomite waste particles, 0.75 parts of gypsum retarder, 0.37 parts of hydroxypropyl methylcellulose ether, 0.65 parts of thixotropic agent, and 0.37 parts of antifungal agent.

Embodiment 3

[0047] Lightweight plastering gypsum with diatomite waste particles as aggregate, made of the following raw materials in parts by weight: 660 parts of gypsum, 30 parts of cement, 150 parts of diatomite waste particles, 1 part of gypsum retarder, 0.23 parts of hydroxypropyl methylcellulose ether, 0.8 parts of thixotropic agent, and 0.24 parts of antifungal agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com