Patents

Literature

41results about How to "Good color fastness to washing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

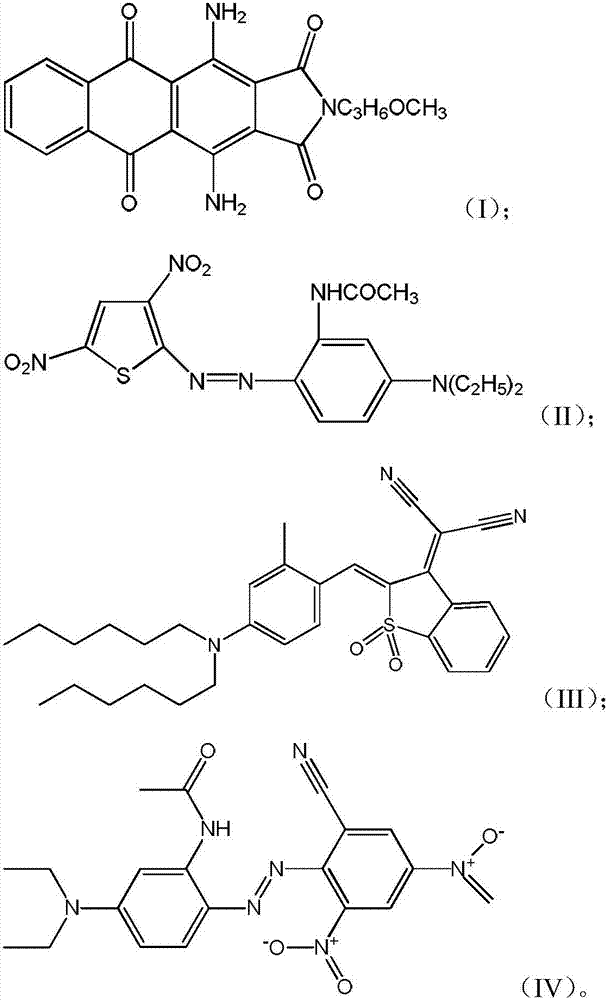

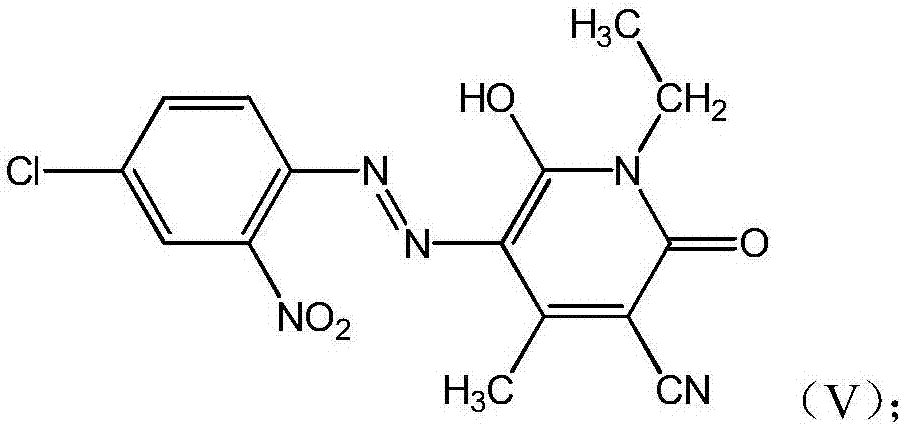

Disperse dye composition and preparing method thereof

ActiveCN105860581AGood color fastness to lightGood color fastness to sublimationOrganic dyesMonomerDisperse dye

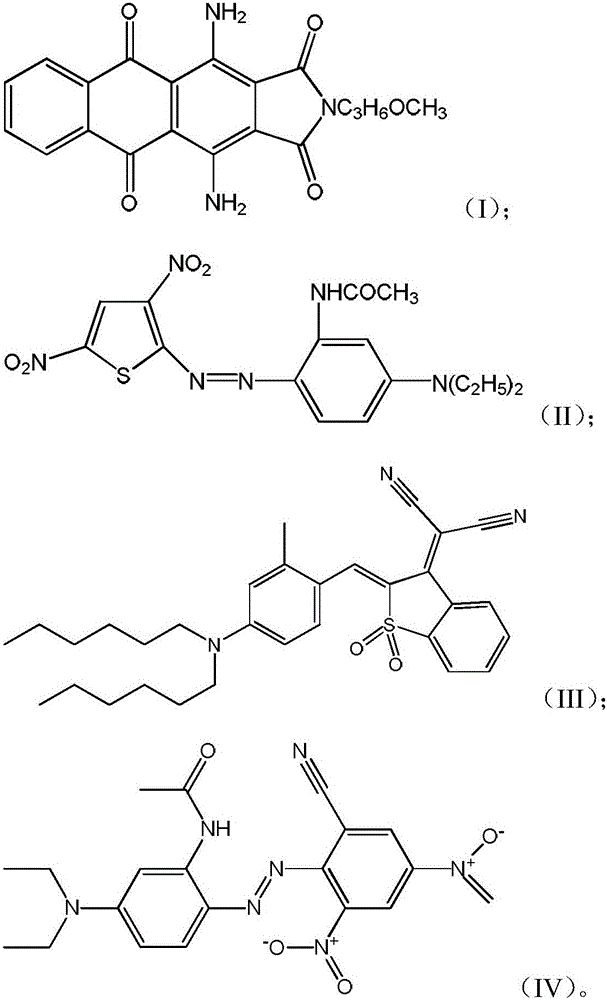

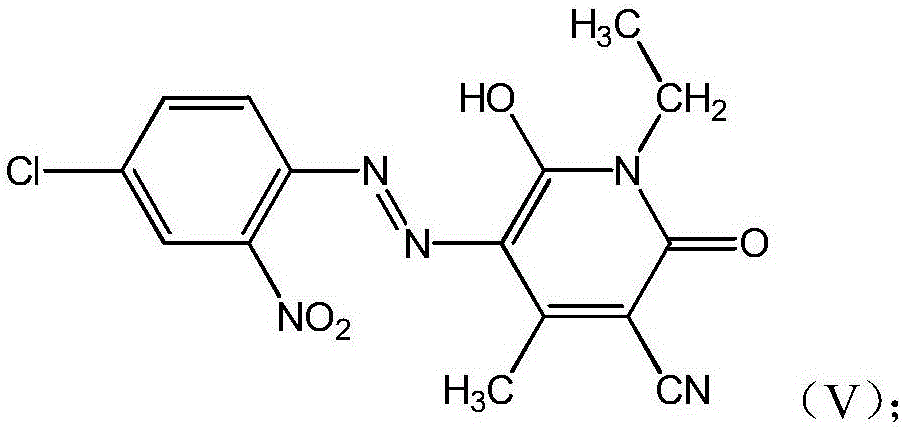

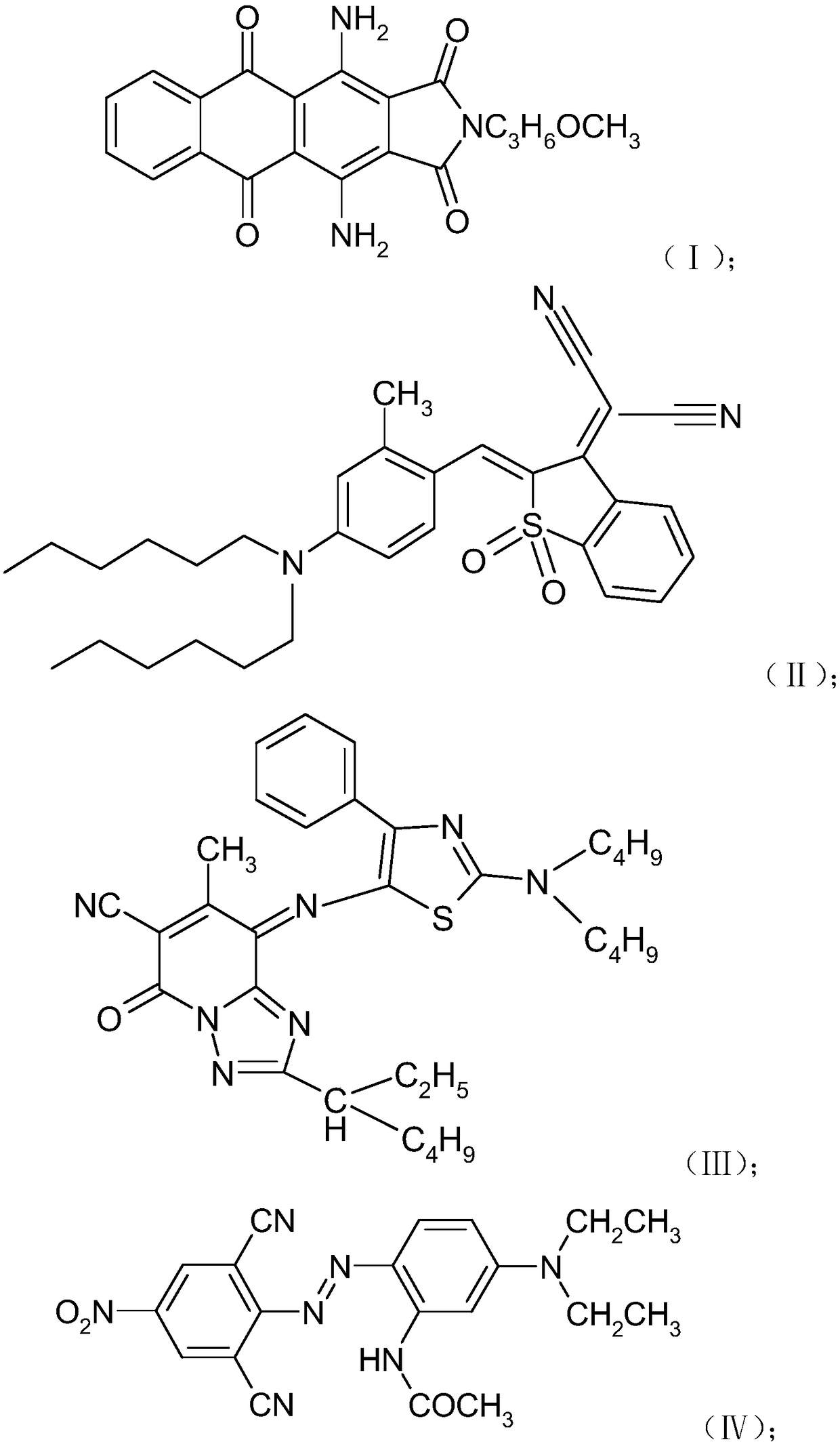

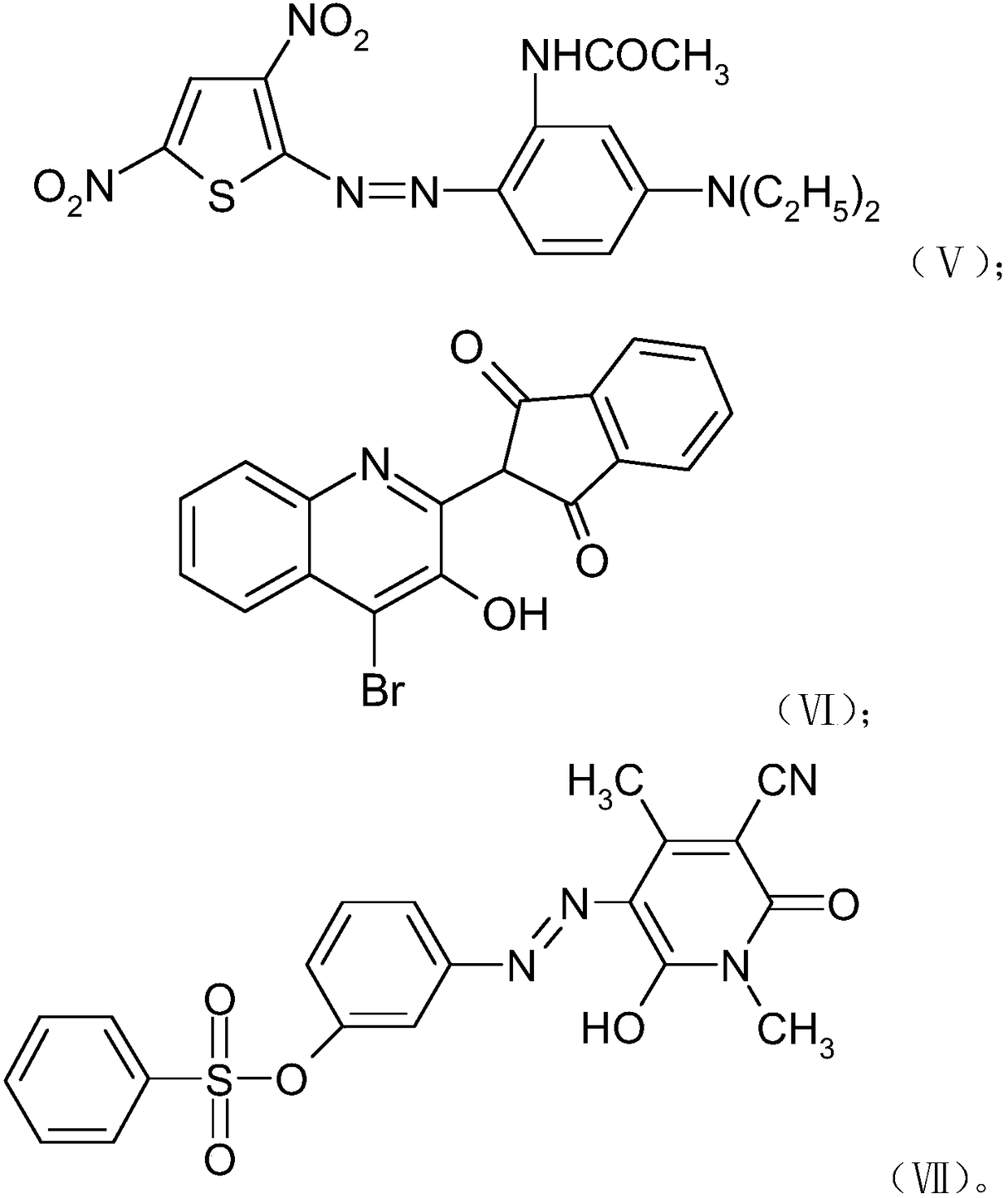

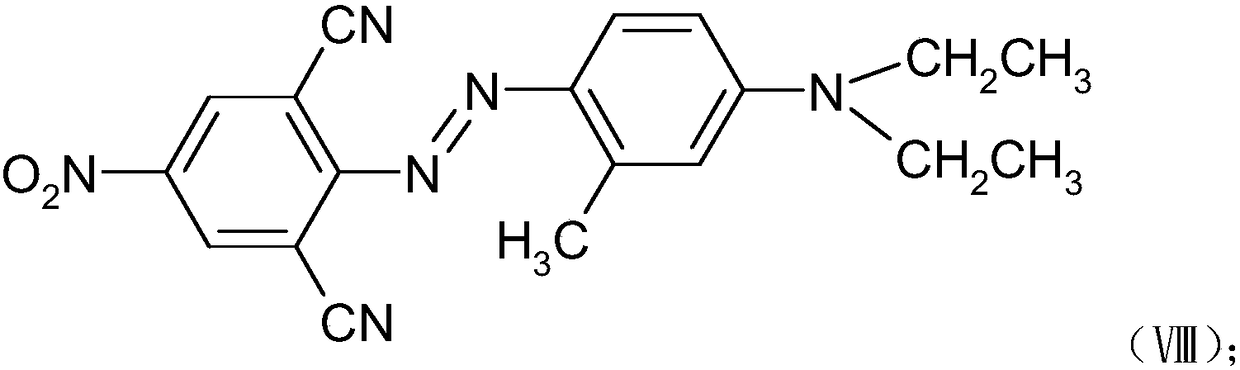

The invention discloses a disperse dye composition capable of improving strength and a preparing method thereof. The disperse dye composition comprises, by weight, 0.1-100 parts of C.I. disperse blue60, 0.1-50 parts of C.I. disperse green9, 0.1-50 parts of C.I. disperse blue354, 0.1-10 parts of C.I. disperse blue165 and 0.1-5 parts of disperse yellow. The preparing method of the disperse dye includes the following steps that 1, C.I. disperse blue60, C.I. disperse green9, C.I. disperse blue354, C.I. disperse blue165 and disperse yellow are taken according to the formula amount and mixed to obtain a mixed dye, wherein the disperse yellow is selected from C.I. disperse yellow211 and / or C.I. disperse yellow114; 2, water is added into the mixed dye obtained in the step 1, the weight dosage ratio of the mixed dye to the water is 1:(2-20), the mixture is mixed, and mixed slurry is obtained; 3, the mixed slurry obtained in the step 2 is sprayed and dried, and the disperse dye composition is obtained.

Owner:ZHEJIANG OUYA CHEM CO LTD

Water-based nano pigment ink for textile printing

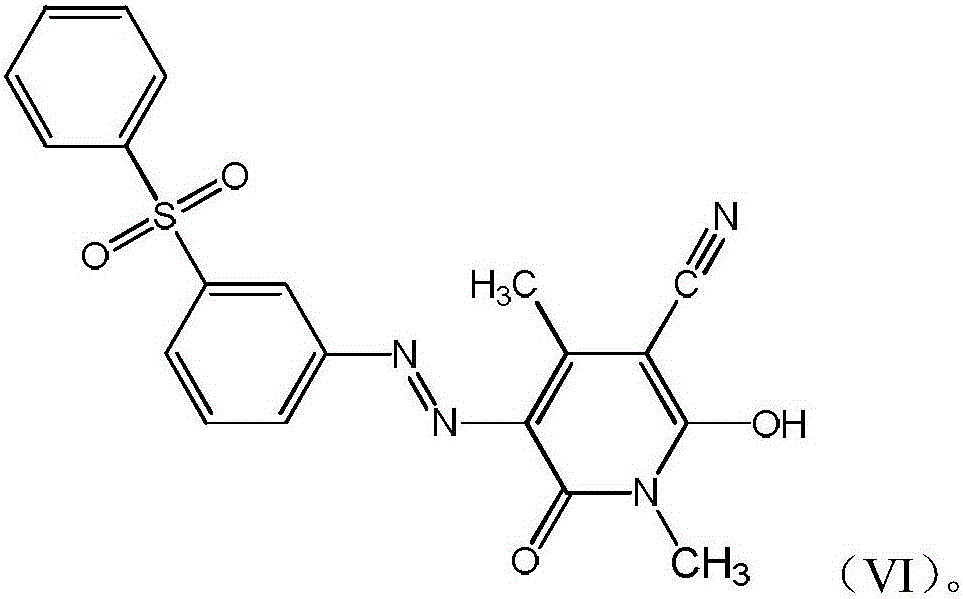

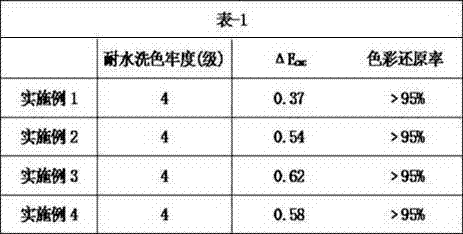

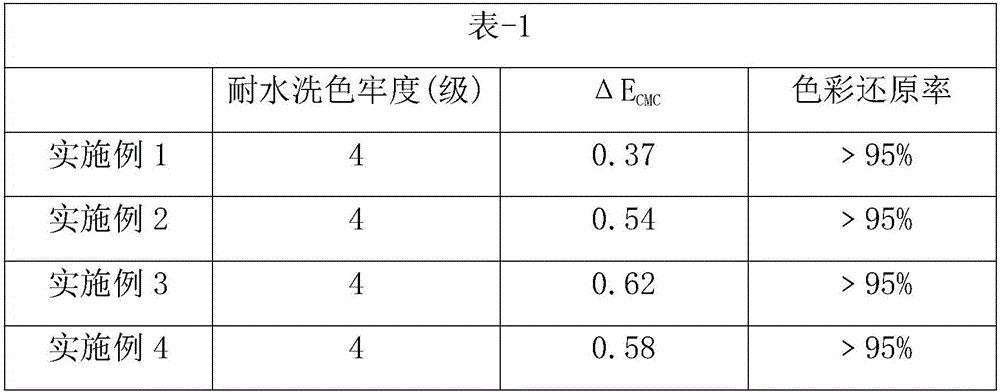

The invention relates to ink and in particular relates to water-based nano pigment ink for textile printing. According to the formula, the ink mainly comprises the following components in parts by weight: 12.4-18.6 parts of water-based pigment slurry, 9.5-14.9 parts of a water-based resin, 5.3-9.6 parts of a quick-dry type solvent, 5.4-9.8 parts of a moisturizing solvent, 0.5-2 parts of a surfactant, 0.05-0.2 part of an antibacterial agent and 50.9-65.55 parts of deionized water. According to the ink disclosed by the invention, textiles do not need to be preheated and heated, and the ink refers to healthy and environment-friendly water-based nano pigment ink which can be directly printed on the textiles. Moreover, a digital ink-jet printing textile prepared by the ink has excellent color fastness to washing, color reduction rate and excellent handfeel.

Owner:南京鼎科纳米技术研究所有限公司

Economical dispersion dye mixture

InactiveCN108727866AGood color fastness to washingGood color fastness to rubbingOrganic dyesDisperse dyeDisperse yellow

The invention discloses an economical dispersion dye mixture. 1000 parts of dispersion dye mixtures are prepared from the following ingredients in parts by weight: 0.1 to 800 parts of C.I. disperse blue 60, 20 to 200 parts of C.I. disperse blue 354 and / or disperse color blue B, 0.1 to 20 parts of C.I. disperse blue 165, 0.1 to 70 parts of C.I. disperse green 9, 0.1 to 5 parts of C.I. disperse yellow 64 and / or C.I. disperse yellow 114, 175 to 800 parts of dispersing agents MF and / or dispersing agents NNO and 0.1 to 5 parts of EDTA-2Na or EDTA-4Na. The economical dispersion dye mixture has thecharacteristics of high washing resistant color fastness, rubbing resistant color fastness, light resistant color fastness and sublimation color fastness, and is applicable to the dyeing effect requirement of various fiber fabrics; the production cost is low; the economical dispersion dye mixture is applicable to large-scale production.

Owner:绍兴金绿洲新材料科技有限公司

Waterproof composite coated fabric and production technology thereof

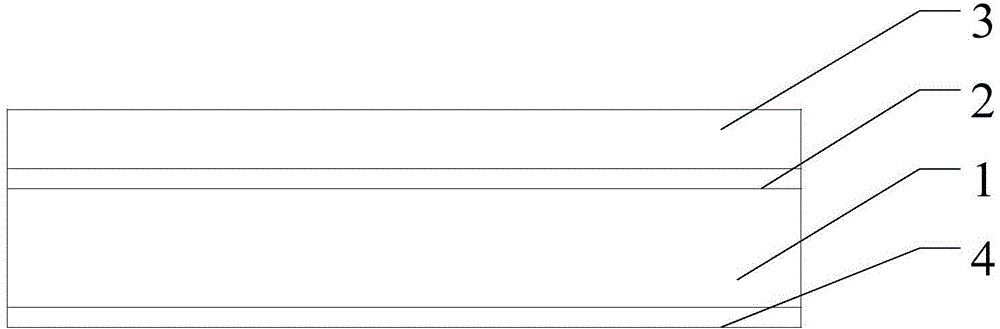

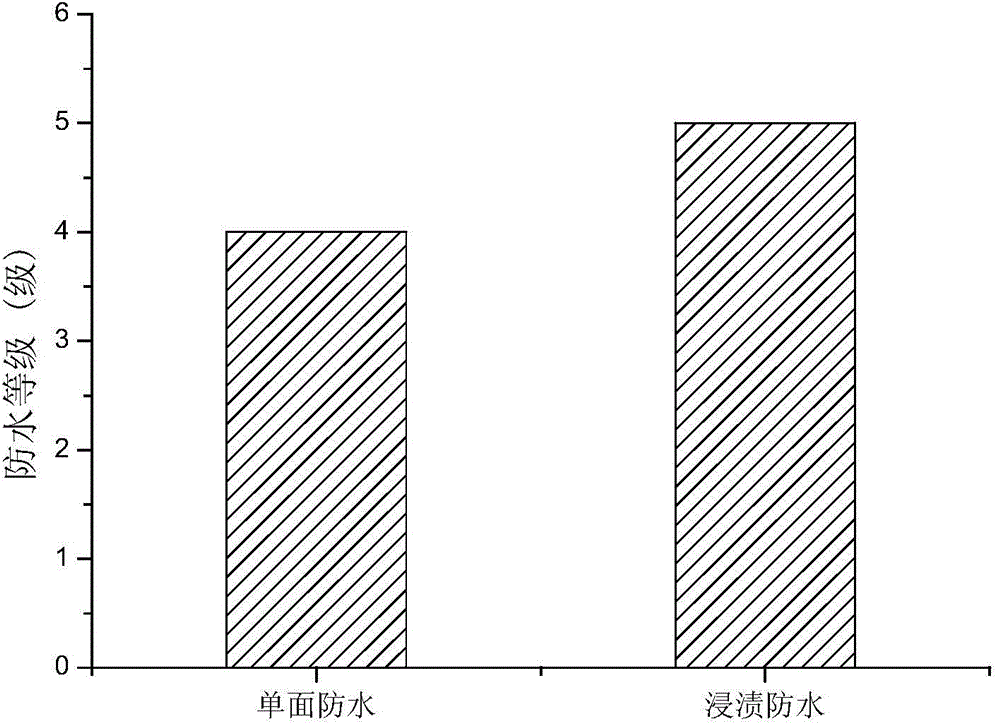

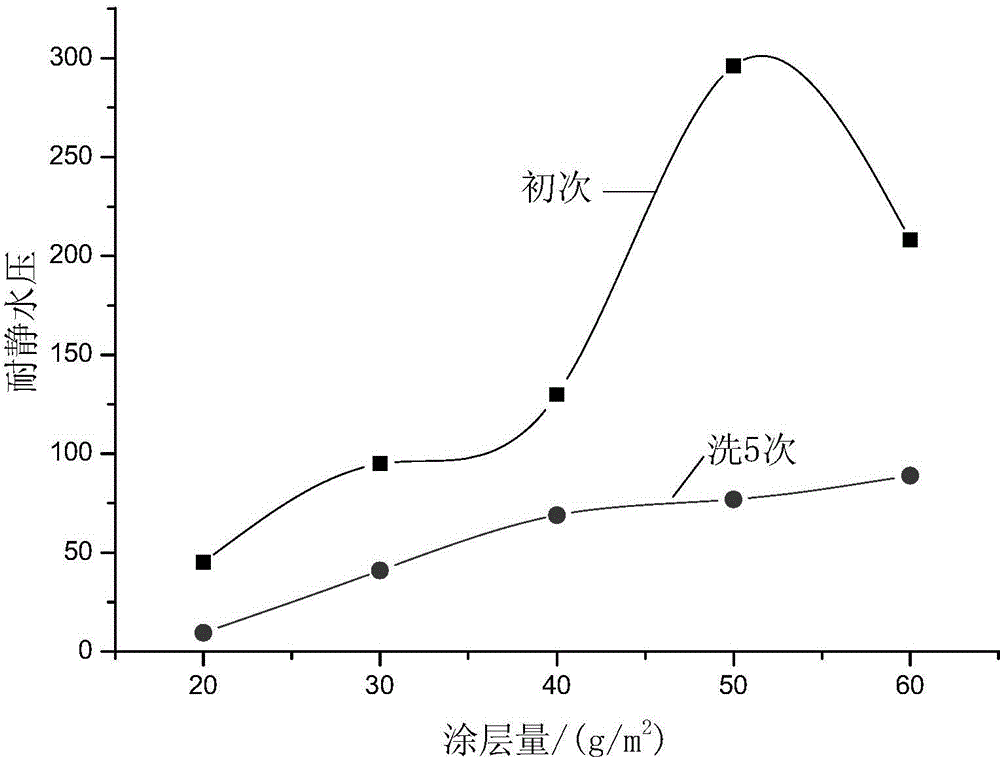

InactiveCN104985889AGood color fastness to rubbingGood color fastness to sea waterSynthetic resin layered productsBagsWear resistantEngineering

The invention provides waterproof composite coated fabric. The waterproof composite coated fabric comprises a nylon fabric layer, a first glue coated layer, a TPU film layer and a second glue coated layer, the first glue coated layer and the second glue coated are arranged at the two sides of the nylon fabric layer respectively, and the TPU film layer is arranged at the other side of the first glue coated layer; glue in the first glue coated layer and in the second glue coated layer comprises, by weight, 50-100 parts of crude glue, 10-30 parts of solvent and 5-10 parts of bridging agents. According to the waterproof composite coated fabric and a production technology thereof, the fabric has the comprehensive performances of being high-performance waterproof, wear resistant, tear resistant and stretch resistant at the same time, the fabric can be effectively applicable to the shell fabric of load carrying equipment of naval crews, the fabric can withstand heavy waves or heavy rainstorm weather as well as frequent stress and tensile deformation on account of drawing and pulling, and the fabric is quite worthy of application and popularization.

Owner:NAVY MEDICINE RES INST OF PLA +1

Heat-transfer printing technology for pure cotton cloth

InactiveCN104947472ABright colorGood color fastness to washingFibre treatmentDuplicating/marking methodsDisperse dyeCotton cloth

The invention discloses a heat-transfer printing technology for pure cotton cloth. The heat-transfer printing technology comprises the following steps: (1) pretreatment of the pure cotton cloth: soaking the pure cotton cloth in an acrylic ester monomer solution for padding pretreatment, carrying out shaping and drying, and then carrying out graft polymerization modification according to a low-temperature plasma technology; (2) preparation of heat-transfer printing paper: printing transfer paper by utilizing a disperse dye, and drying the prepared heat-transfer printing paper and the disperse dye in an electric oven after printing; (3) heat-transfer printing: adhering the heat-transfer printing paper to the front surface of the pure cotton cloth subjected to graft polymerization modification on a heat-transfer printing machine for heat-transfer printing; (4) rolling for packaging and warehousing. The heat-transfer printing technology provided by the invention is novel in design, pollutant-free, environmentally friendly and lower in resource consumption; the pure cotton cloth printed according to the heat-transfer printing technology is bright in color, relatively high in color fastness to washing and softness, comfortable to wear, and broad in market prospect; the heat-transfer printing technology is a novel method for environment-friendly and efficient printing and dyeing of cotton and other fabrics containing natural fibers.

Owner:常熟新锦江印染有限公司

One-bath dyeing method for dyeing cotton-acrylic fabric with direct dye and cationic dye

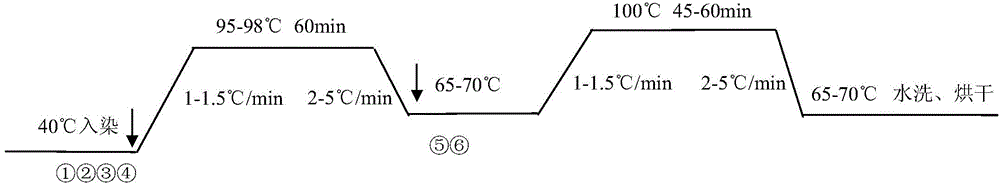

ActiveCN104611954ASolve the shortcomings of low utilizationLow priceDyeing processSubstantive dyePhotochemistry

The invention relates to a one-bath dyeing method for dyeing cotton-acrylic fabric with direct dye and cationic dye. The method comprises steps as follows: first, dye liquor is prepared and then heated to reach 40 DEG C, the cotton-acrylic fabric is added into the dye liquor, the bath ratio is 1:(10-15), stirring and dyeing are performed for 2-10 min, then the temperature is raised to 95-98 DEG C, stirring and dyeing under heat preservation condition are continuously performed for 60 min, the temperature is reduced to 65-70 DEG C, a dispersant and cationic dye are added, the temperature is raised to 100 DEG C at the rate of 1-1.5 DEG C per minute, stirring and dyeing under heat preservation condition are performed for 45-60 min, then the temperature is reduced to 65-70 DEG C at the rate of 2-5 DEG C per minute, and finally, the cotton-acrylic fabric is dried after washing and color fixing treatment. The technical scheme has simple process, is convenient to operate and has no special requirements for equipment, large-scale production can be performed through conventional dyeing equipment, and the one-bath dyeing method has wide application prospect.

Owner:DONGHUA UNIV +1

Method for manufacturing natural plant dyeing cloth or silk fabric

ActiveCN104611947ASoft colorGood colorBiochemical fibre treatmentNatural dyesChange colorEngineering

The invention discloses a method for manufacturing natural plant dyeing cloth or silk fabric. The method comprises the steps of carrying out grinding on the plant raw material, carrying out other steps to obtain dye liquor; and then, carrying out dye material pretreatment, mordanting, washing, dyeing, soaping, and drying in the shade to obtain the plant dyeing cloth, wherein metal salt is fed into mordant dye, so that the functions of color development and color fixation are reached. The plant dyeing cloth or silk fabric is bright in color, uniform in dyeing and good in dye fastness, does not fade and change color, and is multiple in colors, soft, simple, unsophisticated and natural in colors. The method is rich in plant raw material resource, so that planting is easily expanded; the method is non-toxic and harmless; the method solves the problems of the pollution to the environment and the harm to the human body which are caused by synthetic dye, and has a health function. The method provided by the invention can be applied to the clean production of wool textile industry, and the mass production is realized.

Owner:昆明市宜良阳昇工艺品厂

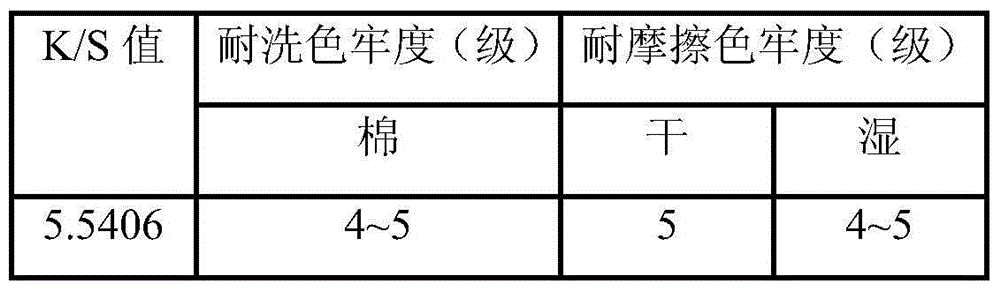

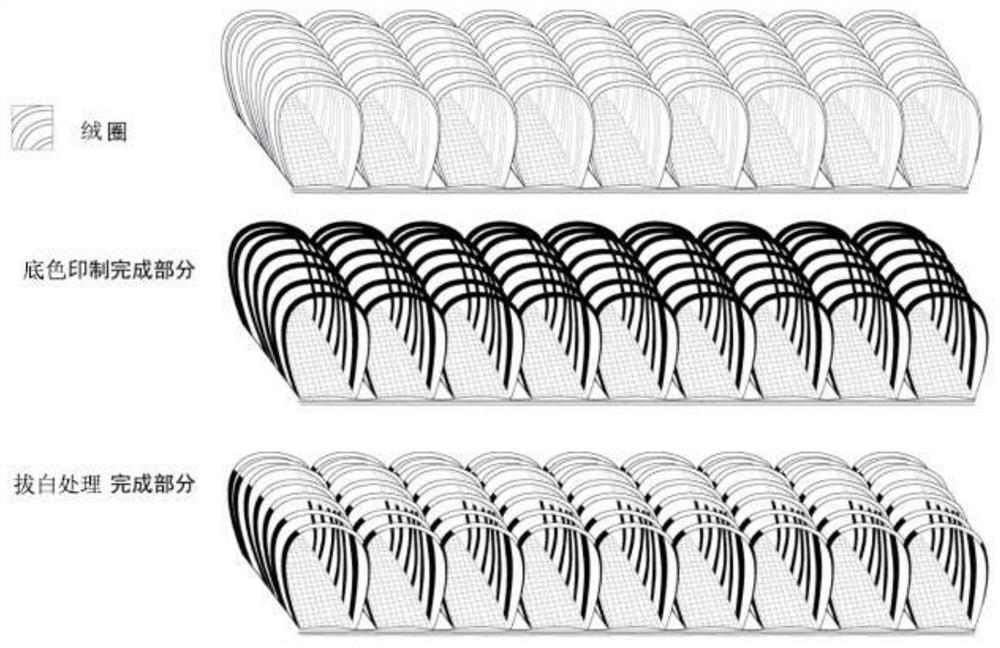

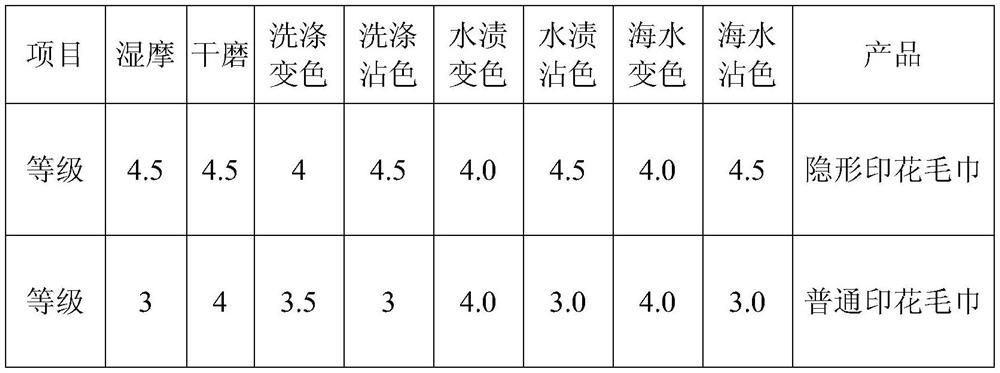

Production method of invisible printed towel

InactiveCN111910447AOpen up the printing formRich in colorDyeing processDomestic applicationsTextile printerProcess engineering

The invention belongs to the technical field of towel production, and particularly relates to a production method of an invisible printed towel. The production method comprises the following steps ofselecting a blank towel, performing blank towel pretreatment, performing pattern design, performing platemaking, performing size mixing, performing white discharging, performing drying, performing ageing, performing washing with water, performing baking, and performing sewing to obtain the invisible printed towel. The prepared invisible printed towel is rich in color, diversified in patterns and more attractive, the printing patterns are developed, the washing and rubbing fastness is improved, and more comfortable experience is brought to a user.

Owner:LOFTEX CHINA LTD

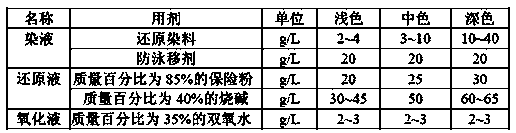

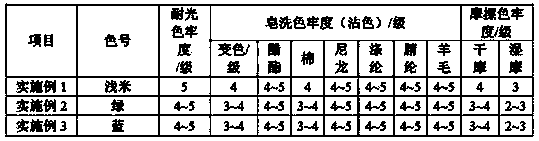

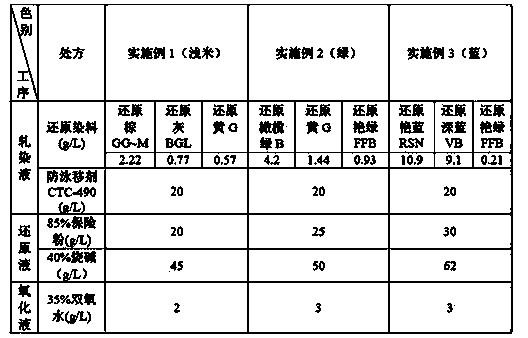

Unstable island type PA6/PU suede superfine fiber synthetic leather pad-dyeing process by using vat dye

InactiveCN103451962AImprove light fastnessGood color fastness to washingSucessive textile treatmentsDyeing processColour fastnessPolymer science

The invention belongs to the technical field of acrylic fiber processing and mainly relates to an unstable island type PA6 / PU (Polyamide / (Poly Urethane) suede superfine fiber synthetic leather pad-dyeing process by using a vat dye. The unstable island type PA6 / PU suede superfine fiber synthetic leather pad-dyeing process by using the vat dye provided by the invention is capable of obtaining the unstable island type PA6 / PU suede superfine fiber synthetic leather through pad dyeing through the following steps: preparing a dyeing liquor by compounding the vat dye with an anionic migration inhibitor, compounding a reducing liquid from sodium hydrosulphite and caustic soda, and taking hydrogen peroxide as an oxidating liquid, and then carrying out the process flow of padding in the dyeing liquid, infrared predrying, drying, baking, padding in the reducing liquid, steaming, water washing, oxidizing for 2-4 times, twice soap-boiling, twice water washing and drying. The unstable island type PA6 / PU suede superfine fiber synthetic leather obtained through the pad-dyeing process provided by the invention has excellent color fastness to light, excellent color fastness to washing, excellent crockfastness and excellent chlorine bleaching resistance.

Owner:SHANDONG VOCATIONAL COLLEGE OF LIGHT IND

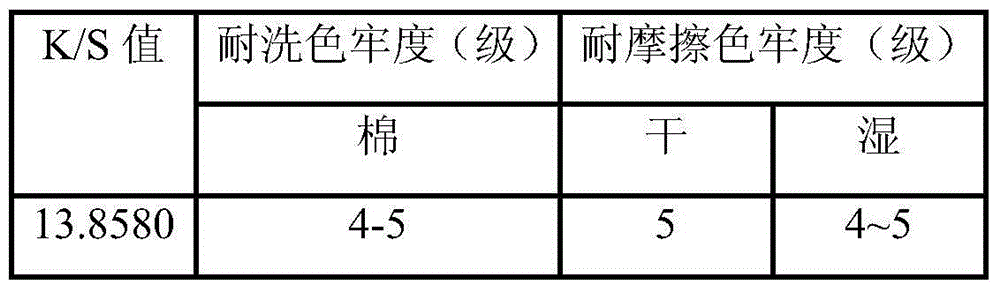

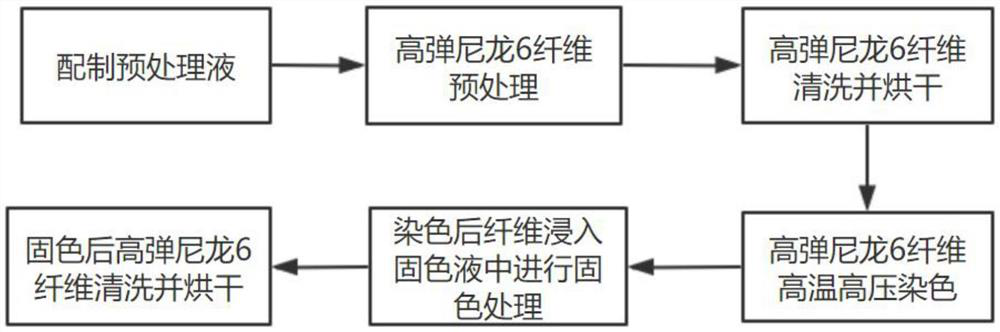

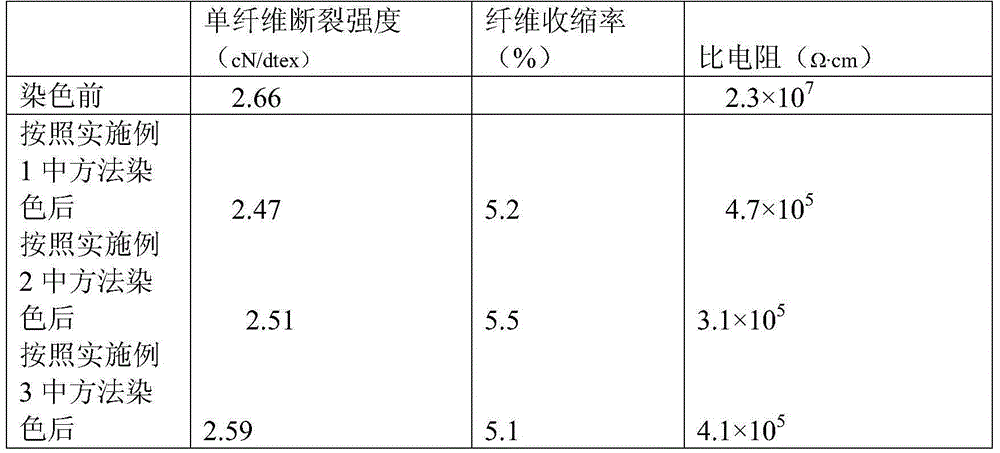

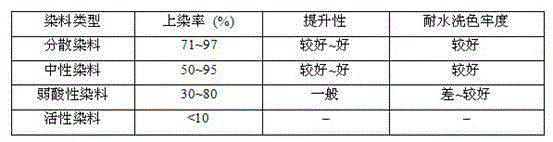

Dyeing method capable of improving dyeing performance of high-elastic nylon 6 fibers

PendingCN113073482AFully dyedImprove color fixationDyeing processColour fastnessEnvironmentally friendly

The invention discloses a dyeing method capable of improving the dyeing performance of high-elastic nylon 6 fibers. The method comprises the steps of dyeing pretreatment, a dyeing process and a color fixing process. According to the dyeing method, the dyeing performance of the high-elastic nylon 6 fibers can be effectively improved, the dyeing rate, the fixation rate, the K / S value and the level dyeing performance of the fibers are remarkably improved, and the washing color fastness, the rubbing color fastness and the light color fastness of fabric are improved. The process is simple and efficient, the usage amount of dye can be remarkably reduced, the method is environmentally friendly, the adopted reagent is efficient in dyeing, bright in color and not prone to fading, and the efficient and lasting dyeing effect can be achieved. On the basis that the dyeing performance of the high-elastic nylon 6 fibers is enhanced, the simplicity, high efficiency and environmental friendliness of the dyeing process are further improved, and wide application of the high-elastic nylon 6 fibers and fabric can be promoted.

Owner:绍兴市柯桥区东纺纺织产业创新研究院

Supersoft cotton-like polyesteramide fiber blended colored yarn and production method thereof

InactiveCN105155069AChromatography is completeColorfulYarnLiquid/gas/vapor yarns/filaments treatmentYarnFiber

The invention discloses a supersoft cotton-like polyesteramide fiber blended colored yarn. The blended colored yarn is prepared by carrying out colored spinning on raw fibers with different colors, wherein the raw fibers contain at least 30wt% of supersoft cotton-like polyesteramide fibers. The supersoft cotton-like polyesteramide fiber blended colored yarn disclosed by the invention not only is good in spinnability, but also has the advantages of soft hand feeling, pilling resistance and high moisture absorption speed.

Owner:ZHEJIANG HUAFU COLOR TEXTILE

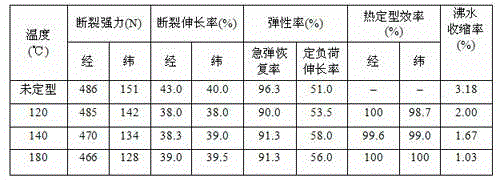

Processing method of mucilage glue elastic shell fabric

InactiveCN104611864AImprove stabilityLow shrinkageHeating/cooling textile fabricsDry-cleaning apparatus for textilesPolymer scienceSodium metasilicate

The invention discloses a processing method of a mucilage glue elastic shell fabric. The method comprises the following steps that firstly, preprocessing is conducted, wherein the mucilage glue elastic shell fabric is immersed in sodium carbonate with the massic volume ratio of 0.5-1.2 g / L; secondly, primary degumming is conducted, wherein the shell fabric subjected to preprocessing is immersed in first mixed liquid composed of sodium carbonate, sodium metasilicate, liquid soap 852, Lamepon A and sodium hydrosulfite; thirdly, secondary degumming is conducted, wherein the shell fabric subjected to primary degumming is immersed in second mixed liquid composed of sodium carbonate, sodium metasilicate, liquid soap 852 and sodium hydrosulfite; fourthly, water washing is conducted, wherein the shell fabric subjected to secondary degumming is washed through hot water and cold water in sequence; fifthly, preforming is conducted; sixthly, thermoforming is conducted and the finished product is obtained. The method is simple, and the obtained shell fabric is good in stability, high in dye uptake and resistant to water washing and has good market prospects.

Owner:HAITAI TEXTILE SUZHOU

A kind of reactive dye exhaust dyeing process of cotton fabric

ActiveCN106245369BHigh color fixing rateIncrease profitBiochemical treatment with enzymes/microorganismsDyeing processThermal insulationRoom temperature

Owner:ANHUI YAYUAN PRINTING & DYEING CO LTD

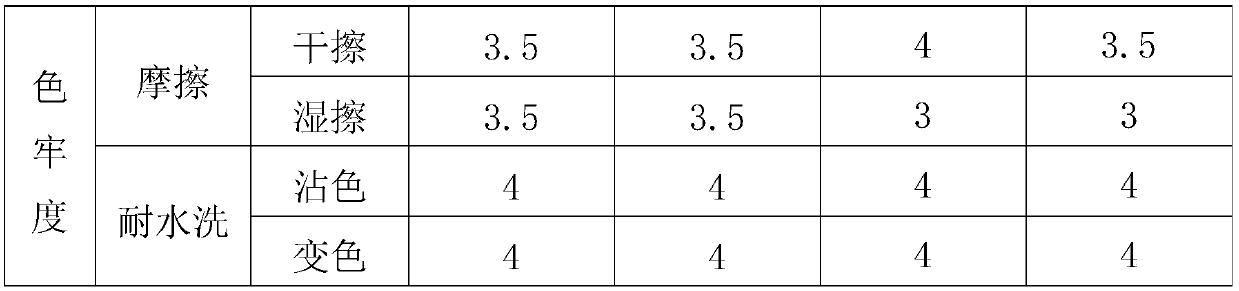

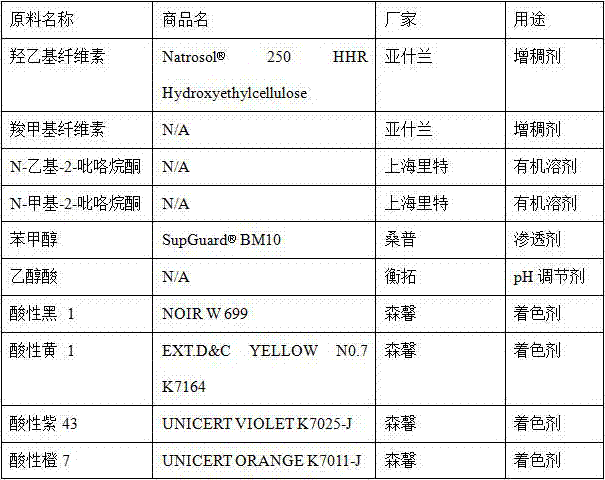

Acidic hair dye and hair dyeing method thereof

InactiveCN107997986AGood coloring effectGood color fastness to washingCosmetic preparationsHair cosmeticsCelluloseHair dyes

The invention discloses an acidic hair dye. The acidic hair dye is prepared from the following components by weight percent: 0.5 to 3 percent of cellulose thickening agent, 5 to 15 percent of cyclic ketone, 5 to 15 percent of aromatic alcohols, 0.01 to 1 percent of acidic dye, 0 to 1.5 percent of pH adjusting agent, 0 to 2 percent of additives, and the balance of water. The acidic hair dye has theadvantages of rapidness in coloring, good in coloring performance, high in washing color fastness, no irritation for skin and the like. The invention also discloses a coloring method of the hair dye.The coloring method has the characteristics of rapidness in coloring, good coloring performance, high washing color fastness, no irritation to the skin and the like.

Owner:HUAANTANG BIOTECH GRP CO LTD

Printing liquid for inkjet printing of cotton fabric

The invention discloses printing liquid for inkjet printing of a cotton fabric. The printing liquid is prepared from the following components in parts by mass: 20 to 40 parts of jujube skin pigment, 15 to 25 parts of maleic anhydride resin, 1 to 3 parts of a surfactant, 0.3 to 0.7 part of malic acid, 10 to 16 parts of a humectant, 1.5 to 3.5 parts of aloe vera gel, 6 to 12 parts of a viscosity modifier, 1 to 5 parts of an antibacterial agent, and 50 to 60 parts of deionized water. The printing liquid provided by the invention has the beneficial effects of being environmentally friendly, and capable of obtaining comfortable fabric handfeel and excellent color fastness to washing without pretreatment on the surface of the cotton fabric, and heating and baking after printing.

Owner:勤力印花工业(太仓)有限公司

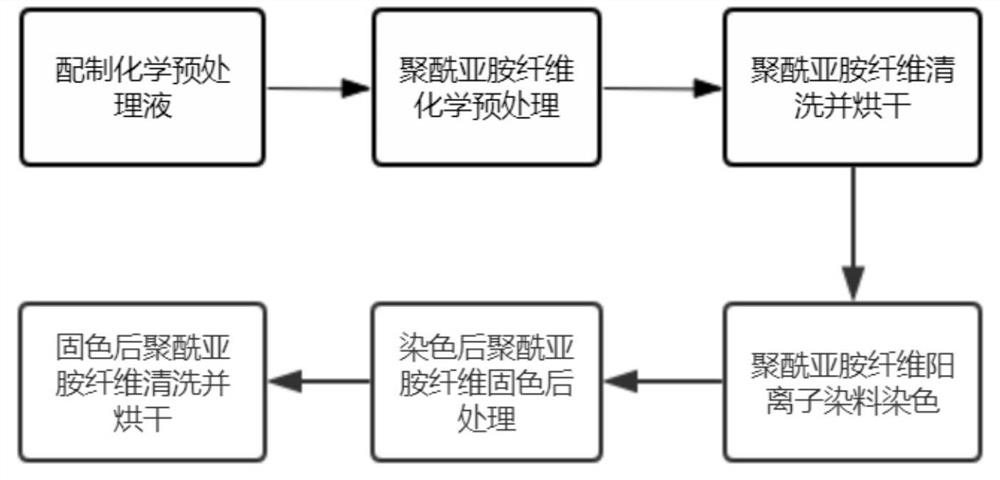

Dyeing method for improving dyeing performance of polyimide fibers

PendingCN113445331AGood leveling effectGood color fastness to washingDyeing processColour fastnessFiber

The invention discloses a dyeing method for improving the dyeing performance of polyimide fibers. The method comprises the steps of pretreatment liquid preparation, fiber pretreatment, fiber dyeing and fiber color fixation. According to the dyeing method provided by the invention, the dyeing performance of the polyimide fibers can be effectively improved, the fiber dye uptake, the fixation rate and the K / S value of the fabric are remarkably improved, and the wet color fastness and the rubbing color fastness of the fabric are improved. The process disclosed by the invention is simple in steps, high in dyeing efficiency, capable of remarkably reducing the use amount of cationic dyes and reducing environmental pollution, green and friendly; the adopted chemical pretreatment process is simple and efficient, and the dyeing performance of the polyimide fibers can be remarkably improved; and the cationic dyes are bright in color and not prone to fading, and the efficient and lasting dyeing effect can be achieved. According to the dyeing method for improving the dyeing performance of the polyimide fibers provided by the invention, on the basis that simple and efficient chemical pretreatment is carried out on the polyimide fibers, the dyeing performance of the polyimide fibers is enhanced, the dyeing efficiency of the dyeing process is further improved, the influence on the mechanical performance of the fibers is small, the environmental friendliness is improved, and wide application of the polyimide fibers and fabrics in the field of clothing can be promoted.

Owner:绍兴市柯桥区东纺纺织产业创新研究院

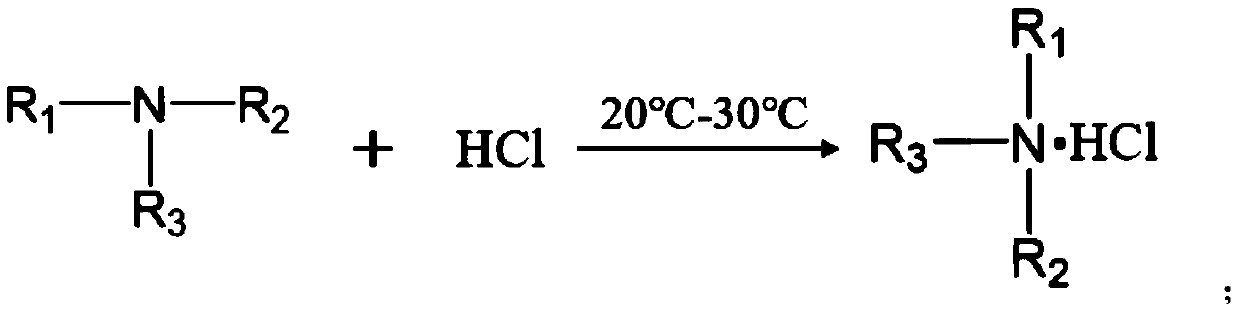

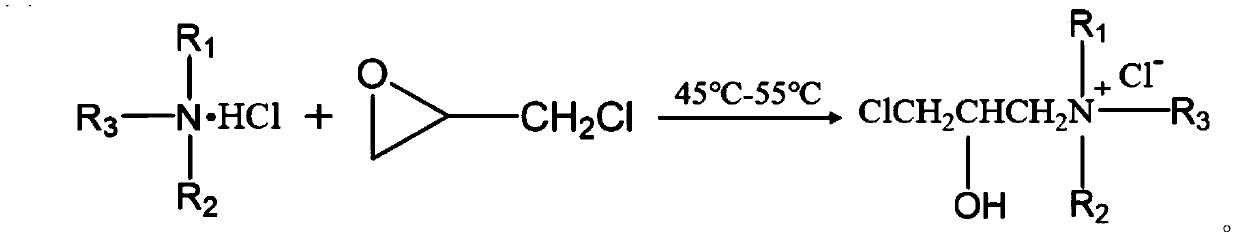

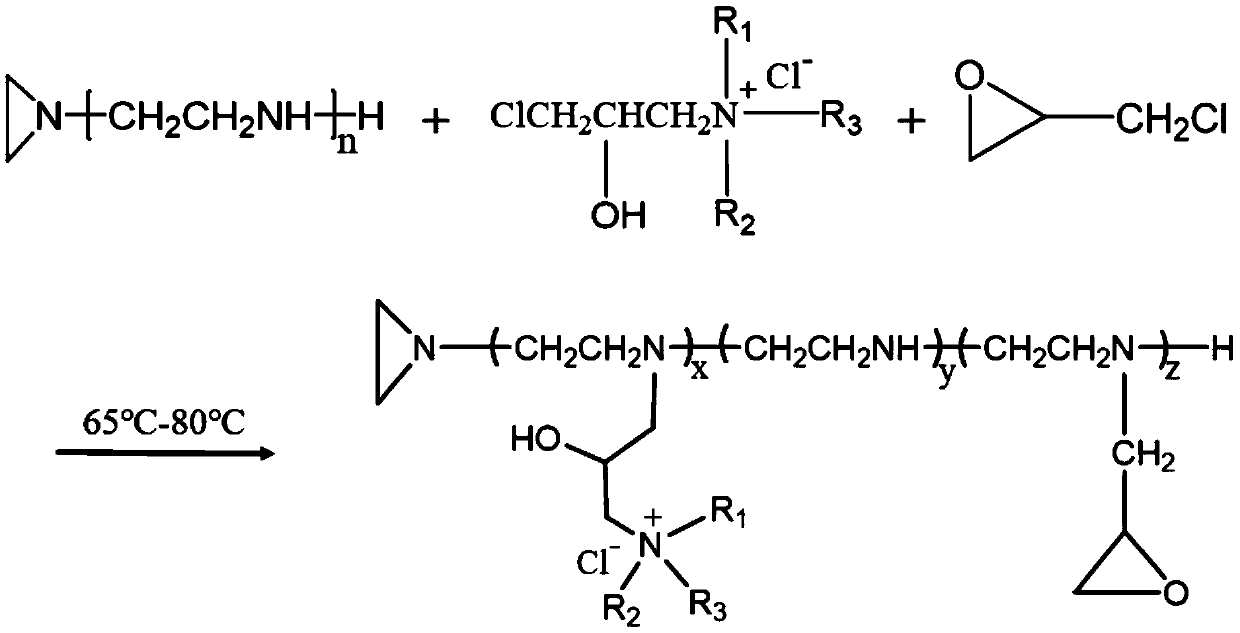

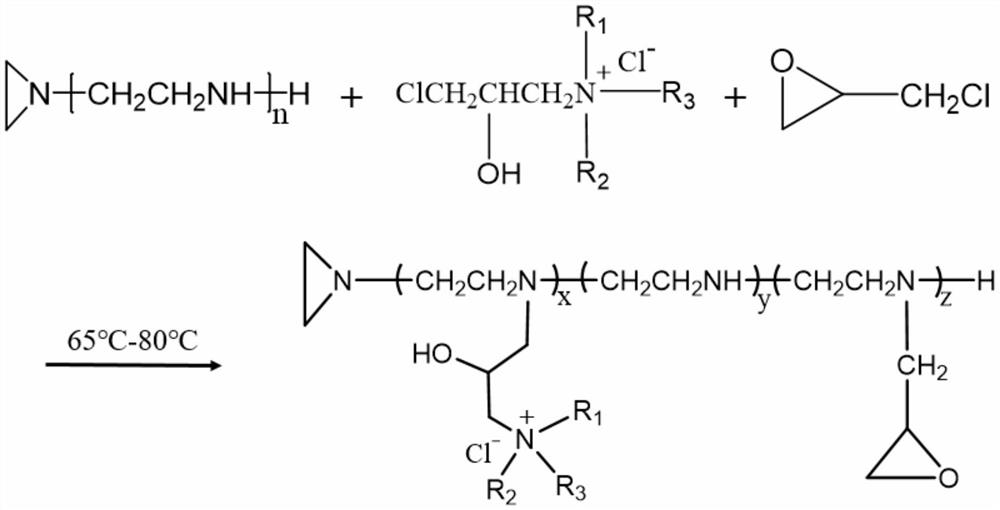

Preparation method and application of active hydrophilic formaldehyde-free color fixing agent

ActiveCN111138662AGood color fixing effectImprove hydrophilicityDyeing processMaterials scienceChemistry

The invention relates to a preparation method of an active hydrophilic formaldehyde-free color fixing agent. The preparation method comprises the following steps: S1) stirring concentrated hydrochloric acid, slowly dropwise adding tertiary amine, carrying out a heat-preserved reaction, and regulating the pH value of the obtained solution to 3-4 by using tertiary amine; S2) carrying out heating to45 DEG C, slowly and dropwise adding epoxy chloropropane, keeping a temperature at 45-55 DEG C, conducting a reaction for 1.0-2.5 hours under a heat preservation condition so as to obtain a homogeneous solution, regulating the pH value, and performing cooling to obtain an intermediate product; and b) adding the intermediate product, polyethyleneimine and deionized water into a reaction bottle, slowly and dropwise adding epoxy chloropropane while stirring, carrying out a heat-preserved reaction at 20-40 DEG C for 5-7 hours, regulating the pH value to 6-7, and performing cooling to obtain the hydrophilic color fixing agent. The hydrophilic formaldehyde-free color fixing agent disclosed by the invention has a relatively high cation degree and reactive epoxy groups, and also has good hydrophilicity and color fixing effect; and after a cotton fabric is subjected to color fixing treatment with the agent, the washing fastness of the fabric reaches level 3-5 and accords with the national regulation that hygroscopicity is within 5 seconds in China, the finishing of a subsequent procedure can be reduced, and the use requirements of printing and dyeing plants are met.

Owner:DYMATIC CHEM

Processing process of high-count and high-density corn fiber fabric

InactiveCN107488924AGood color fastness to washingGood color fastness to rubbingTextile storage in superimposed formBiochemical fibre treatmentFiberColour fastness

The invention discloses a processing process of a high-count and high-density corn fiber fabric and relates to the technical field of textile. The processing process comprises the following steps of 1) corn fiber selection and pretreatment; 2) cotton opening and cleaning procedure; 3) cotton carding procedure; 4) drawing procedure; 5) rough sanding procedure; 6) spinning procedure; 7) warp sizing and desizing procedure; 8) weaving procedure; 9) dyeing procedure; and 10) antibacterial finishing procedure. The processing process provided by the invention is reasonable in design and avoids the electrostatic phenomenon and the cotton sliver breaking phenomenon; and the prepared fabric is high in count and density, good in colour fastness to washing, small in washing size change and excellent in mechanical performance and friction resistance.

Owner:安徽三宝棉纺针织投资有限公司

Waterproof and wear-resistant printed oxford fabric

InactiveCN105128465AGood color fastness to washingImprove waterproof performanceTransfer printing processSynthetic resin layered productsWear resistantEngineering

The invention discloses a waterproof and wear-resistant printed oxford fabric. The oxford fabric comprises a printed oxford fabric basic layer and a transparent waterproof PVC film, which is covered on the external surface of the printed oxford fabric basic layer. The printed oxford fabric is prepared from grey fabric of oxford fabric through a printing technology. The grey fabric of oxford fabric is prepared by weaving warps and wefts, wherein the warp accounts for 60 to 65 wt% of grey fabric and is prepared from terylene FDY64D / 24F, and the weft accounts for 35 to 40wt% of grey fabric and is prepared from terylene FDY150D / 36F. The thickness of the transparent waterproof PVC film is 0.1 to 0.3 mm. The provided oxford fabric overcomes the shortage that the color fastness of dyed oxford fabric is bad, and has the advantages of excellent waterproof performance and wear resistant property.

Owner:苏州京龙皮件服饰有限公司

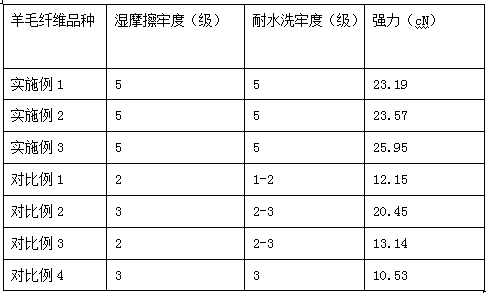

Dyeing method of wool fibers

InactiveCN108360274AReduce lossesGood color fastness to washingDyeing processColour fastnessPolymer science

The invention belongs to the technical field of textile dyeing, and particularly relates to a dyeing method of wool fibers. The method comprises the following steps: (1), preprocessing the wool fibers, specially, firstly mixing propolis, ethanol and water; performing microwave processing; then adding the wool fibers; soaking the wool fibers and then performing ultrasonic treatment for 20 to 40 minutes; then adding a yeast aqueous solution and performing ultrasonic treatment again; then fumigating the wool fibers by using rice water at 75 to 90 DEG C and then soaking the wool fibers in an ethanol solution; finally, washing the wool fibers with water and performing vacuum drying; (2) performing dip dyeing; (3) performing post-processing; (4) washing; (5) fixing color. According to the dyeingmethod of wool fibers disclosed by the invention, the wool fibers are preprocessed, so that loss of strength of the wool fibers due to dyeing is reduced, the colour fastness to washing and fastness to wet rubbing of the dyed wool fibers are good, the wool fibers soft handfeel, and the quality of the wool fibers is improved.

Owner:SHAANXI SCI TECH UNIV

Preparation method of printing liquid containing purple sweet potato pigment

InactiveCN107904985AHigh color fastnessGuaranteed feelNatural dyesDyeing processColour fastnessSURFACTANT BLEND

The invention discloses a preparation method for printing liquid containing a purple sweet potato pigment. The preparation method comprises the following steps: (1) uniformly mixing a surfactant, malic acid, a humectant, aloe gel, a viscosity regulating agent, a sterilizing agent and deionized water to obtain mixed liquid; (2) adding alkyd resin into the mixed liquid obtained in the last step, andstirring and mixing uniformly; (3) adding the purple sweet potato pigment into the mixed liquid in the step (2), and stirring and mixing uniformly; (4) filtering the mixed liquid obtained in the step(3) by using a filter membrane of which the aperture precision is not greater than 0.45 [mu]m, and taking filtrate, wherein the printing liquid comprises the following components in parts by weight:20 to 28 parts of the purple sweet potato pigment, 12 to 25 parts of the alkyd resin, 1 to 5 parts of the surfactant, 0.5 to 0.8 part of the malic acid, 8 to 12 parts of the humectant, 2 to 3 parts ofthe aloe gel, 2 to 10 parts of the viscosity regulating agent, 2 to 5 parts of the sterilizing agent and 60 to 70 parts of the deionized water. The printing liquid prepared by the preparation methodis good in printing fluency and has saturated and bright patterns, colour and lustre; a printed cotton fabric feels soft; both the colour fastness to washing and the colour fastness to rubbing can reach level 4.

Owner:FOSHAN GAOMING HAIDI CERAMIC RAW MATERIAL CO LTD

A kind of disperse dye composition and preparation method thereof

ActiveCN105860581BGood color fastness to washingGood color fastness to rubbingOrganic dyesDisperse dyeSpray dried

The invention discloses a disperse dye composition capable of improving strength and a preparing method thereof. The disperse dye composition comprises, by weight, 0.1-100 parts of C.I. disperse blue60, 0.1-50 parts of C.I. disperse green9, 0.1-50 parts of C.I. disperse blue354, 0.1-10 parts of C.I. disperse blue165 and 0.1-5 parts of disperse yellow. The preparing method of the disperse dye includes the following steps that 1, C.I. disperse blue60, C.I. disperse green9, C.I. disperse blue354, C.I. disperse blue165 and disperse yellow are taken according to the formula amount and mixed to obtain a mixed dye, wherein the disperse yellow is selected from C.I. disperse yellow211 and / or C.I. disperse yellow114; 2, water is added into the mixed dye obtained in the step 1, the weight dosage ratio of the mixed dye to the water is 1:(2-20), the mixture is mixed, and mixed slurry is obtained; 3, the mixed slurry obtained in the step 2 is sprayed and dried, and the disperse dye composition is obtained.

Owner:ZHEJIANG OUYA CHEM CO LTD

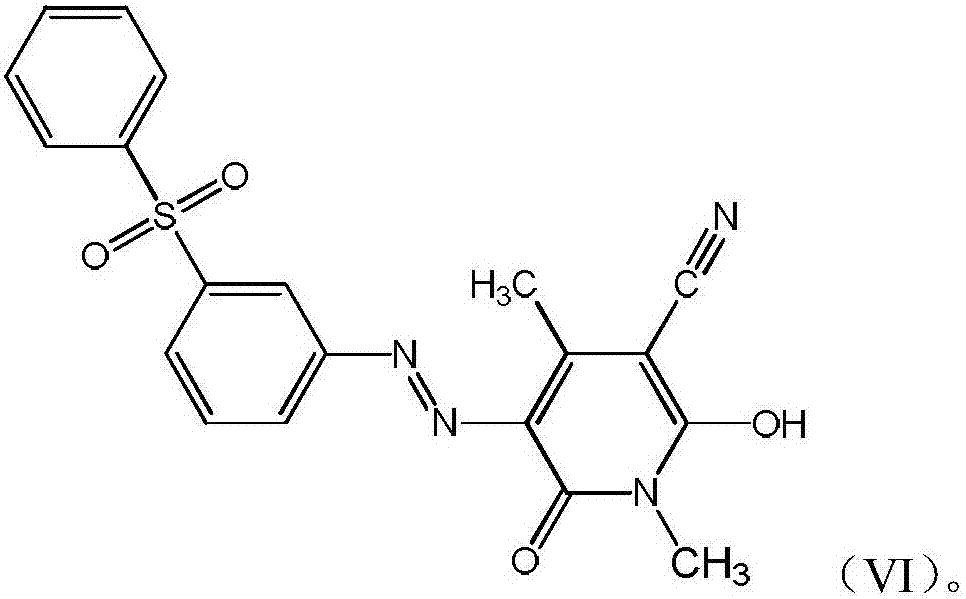

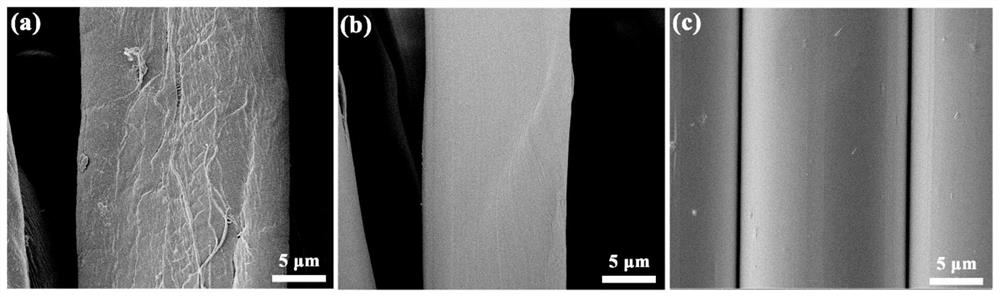

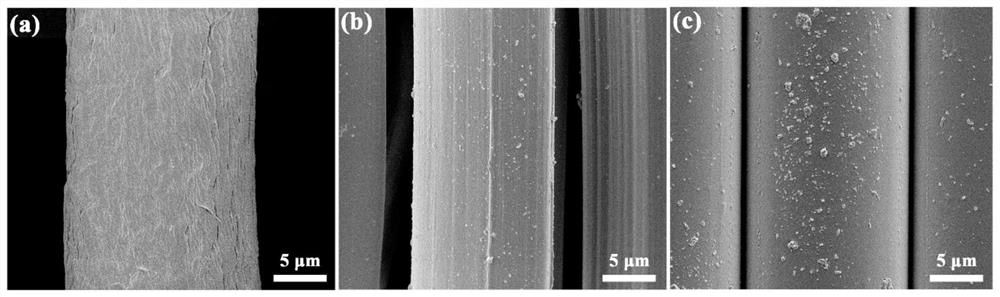

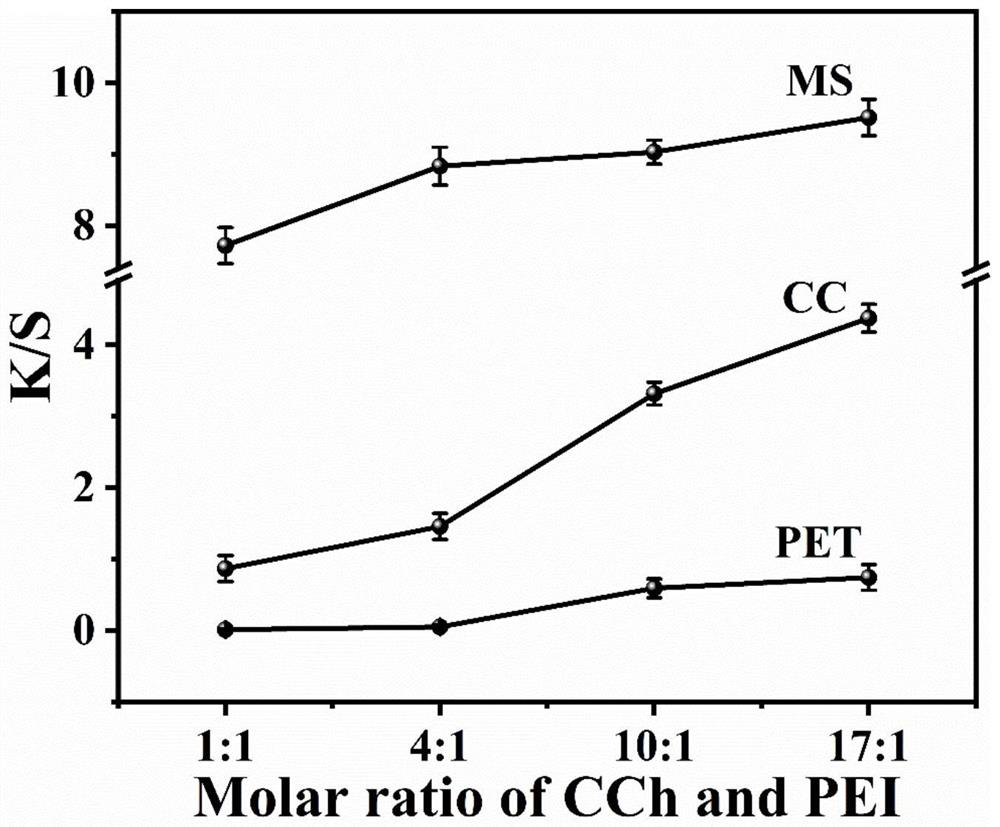

Application of polyphenol amine dye in printing and dyeing of fabric fibers and dyeing method

ActiveCN114645474AQuick stainReduce manufacturing costTextile/flexible product manufactureDyeing processTextile printerFiber

The invention belongs to the technical field of textile printing and dyeing, and relates to application of a polyphenol amine dye in printing and dyeing fabric fibers and a dyeing method. The preparation method comprises the following steps: carrying out oxidative polymerization reaction on polyethyleneimine and catechol in water in the presence of oxygen to obtain the polyphenol amine dye, and adding fabric fibers into the polyphenol amine dye for dyeing. According to the present invention, with the application of the polyphenol amine dye to dyeing, the printing and dyeing auxiliary agent can be omitted, the fresh water consumption can be reduced, the color fastness can be improved, and the printed and dyed material can have the antibacterial property.

Owner:QILU UNIV OF TECH

A kind of water-based nano pigment ink for textile printing

The invention relates to ink and in particular relates to water-based nano pigment ink for textile printing. According to the formula, the ink mainly comprises the following components in parts by weight: 12.4-18.6 parts of water-based pigment slurry, 9.5-14.9 parts of a water-based resin, 5.3-9.6 parts of a quick-dry type solvent, 5.4-9.8 parts of a moisturizing solvent, 0.5-2 parts of a surfactant, 0.05-0.2 part of an antibacterial agent and 50.9-65.55 parts of deionized water. According to the ink disclosed by the invention, textiles do not need to be preheated and heated, and the ink refers to healthy and environment-friendly water-based nano pigment ink which can be directly printed on the textiles. Moreover, a digital ink-jet printing textile prepared by the ink has excellent color fastness to washing, color reduction rate and excellent handfeel.

Owner:南京鼎科纳米技术研究所有限公司

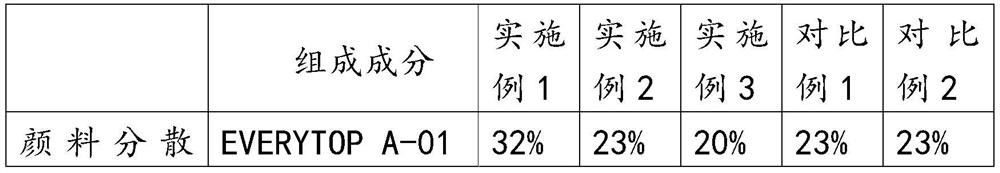

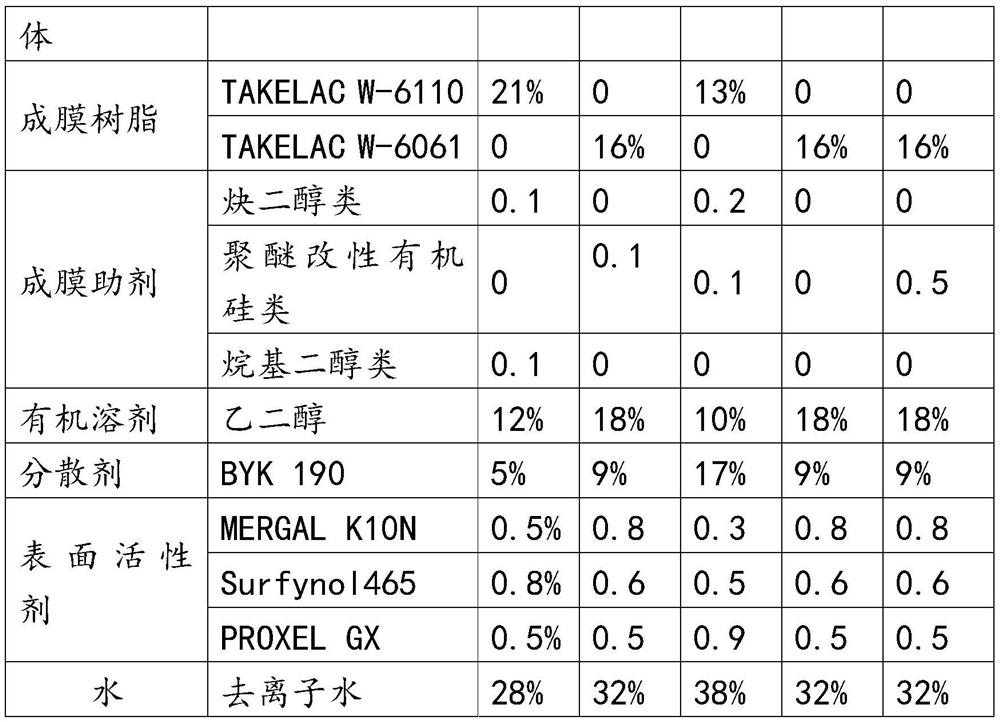

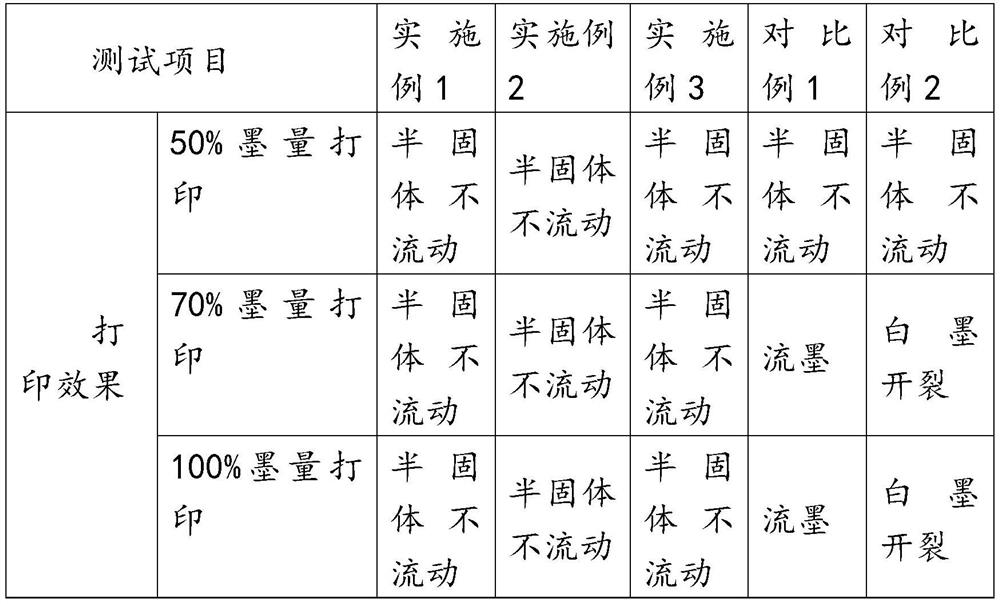

Pyrography ink with high ink bearing capacity and preparation method thereof

The invention provides pyrography ink with high ink bearing capacity and a preparation method of the pyrography ink. The pyrography ink comprises a pigment dispersion, a water-soluble organic solvent, water-soluble film-forming resin, a coalescing agent, a dispersing agent and a surfactant, the water-soluble film-forming resin is modified polyurethane resin with the glass transition temperature lower than-5 DEG C, the film-forming auxiliary agent comprises at least one of alkynediol, polyether modified organic silicon and alkyl diol, and the ratio of the film-forming resin to the film-forming auxiliary agent is 300: 1-150: 1. By controlling the addition amount of the coalescing agent, during film forming, the coalescing agent reduces the glass transition temperature of film-forming resin and accelerates the film forming speed of ink on a pyrograph medium, so that the ink can be rapidly fixed on the pyrograph medium and forms a film, the plasticization effect of the coalescing agent on the film-forming resin is realized, the conditions of halo ink, flowing ink, diffusion and the like are avoided, and the film-forming efficiency is improved. The problems that ink is low in ink bearing capacity and poor in compatibility with a transfer printing film are solved.

Owner:ZHUHAI FREE TRADE ZONE NEOJET APOLLOJET IMAGING MATERIALS

Production method of warp knitting leather imitation cloth possessing high strength wear resistant property

InactiveCN100491633CHigh strengthImprove wear resistanceFibre treatmentHeating/cooling textile fabricsWear resistantProcess engineering

The invention relates to a production method of warp knitted leather base cloth with high-strength wear resistant. Step is as follows: 1) Fore treatment: adding 1.5-2g / L pure caustic soda to loom stare with the bath ratio of 1:15. After heating-up to 50deg.C-60deg.C, wash it twice and then make it clean with room temperature waiting for dye. 2) Dyeing: adding dyestuff and staining solution to loom stare after treated (room temperature). 3) Approved product: After dewatering and open width, the loom stare begin to pro-approved. Adding raising flexible agent, hygroscopic quick-drying dressing agent, then approve it on 190deg.C. Depth rising three times by 851 24 needle roll redouble raising machine, carding once by raising machine. Then finish approved, the temperature is higher then pro-approved, with the temperature of about 195deg.C-200deg.C,at the speed of 35-40m / min. Control the open width of end products at 150cm and thickness at 1-1.2mm. The method is characterized in that the products have high strength, good wear-resisting property, function and ring protection. Various performance indexes of the products are all higher than others.

Owner:浙江锦达新材料股份有限公司

Multicolor real silk or real silk-containing fabric capable of displaying ultraviolet intensity and manufacturing process thereof

PendingCN113005794AHas the ability to change colorGood color fastness to washingDyeing processColour fastnessTextile printer

The invention relates to a multicolor real silk or real silk-containing fabric capable of displaying the ultraviolet intensity and a manufacturing process thereof. The manufacturing process comprises the following steps of 1) mixing a photosensitive coating, a luminescent coating, an adhesive, a thickening agent and water to prepare coating color paste, and scraping and printing the coating color paste on a fabric through a screen; 2) mixing dye, a thickening agent and water to prepare dye color paste, and scraping and printing the dye color paste on the fabric through a screen, wherein the dye is reactive dye or acid dye; 3) baking the printed fabric; 4) carrying out ageing and washing on the baked fabric; and 5) carrying out overfeeding softening and rolling inspection on the washed fabric. The fabric is endowed with the functions of displaying various colors in different environments and realizing ultraviolet indication, and meanwhile, the color fastness to washing of the fabric is improved through research optimization of a printing process.

Owner:ZHEJIANG SILK TECH

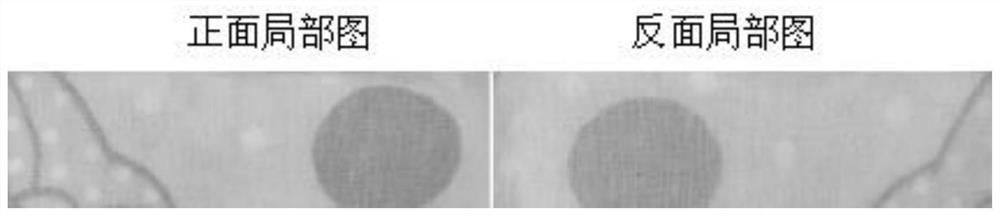

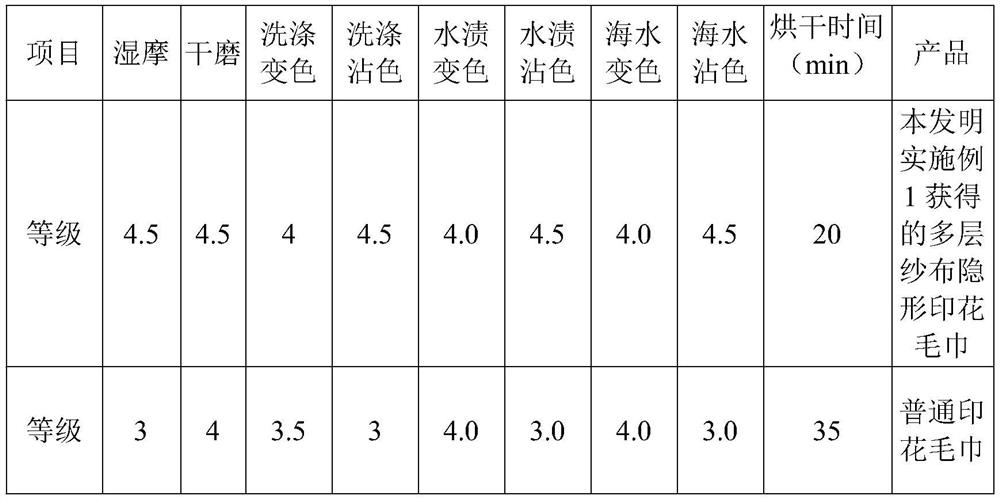

Production method of multilayer gauze invisible printed towel

The invention belongs to the technical field of towel production, and particularly relates to a production method of an invisible printed towel. The invisible printed towel is based on non-pure cotton multilayer gauze fabric, the upper surface layer and the lower surface layer of multilayer gauze are pure cotton layers, the middle layer or multiple layers are non-pure cotton layers containing chemical fiber yarns, and the characteristic that disperse dyes cannot be colored on pure cotton is utilized; the slurry containing the disperse dyes is printed on the non-pure cotton multi-layer fabric through a printing machine, so that the slurry permeates into the non-pure cotton layer in the middle; and after washing, the upper surface layer and the lower surface layer of the towel are white, and the middle layer of the towel is provided with printed patterns, so that the appearance with a hazy effect is achieved. The upper surface layer and the lower surface layer are made of white pure cotton materials, so that the washing and rubbing fastness is improved, the fabric is more suitable for skin-friendly use, meanwhile, the fabric contains chemical fibers, so that the fabric saves more time and has a quick-drying effect compared with a pure cotton fabric in the airing or drying process.

Owner:LOFTEX CHINA LTD

Printing paste for polyvinyl chloride leaf handicraft and preparation method of printing paste

The invention discloses printing paste for a polyvinyl chloride leaf handicraft and a preparation method of the printing paste. The paste is formed by performing emulsification and polymerization on acrylic acid, acrylamide, butyl acrylate, acrylonitrile, hydroxyethyl methylacrylate, methyl methacrylate, 1,6-hexanediol diacrylate, styrene, alcohol polyoxyethylene ether (AEO 9), dodecylbenzene sulfonic acid and deionized water, and compounding with an anti-bleeding thickener, a wetting agent, a rheological agent and an anti-blocking agent. A film formed by the printing paste is strong in transparency, high in gloss and good in elasticity and oxidative resistance; and the printed polyvinyl chloride material is improved in folding resistance, and good in color fastness to rubbing and color fastness to washing.

Owner:LIAONING FIXED STAR FINE CHEM

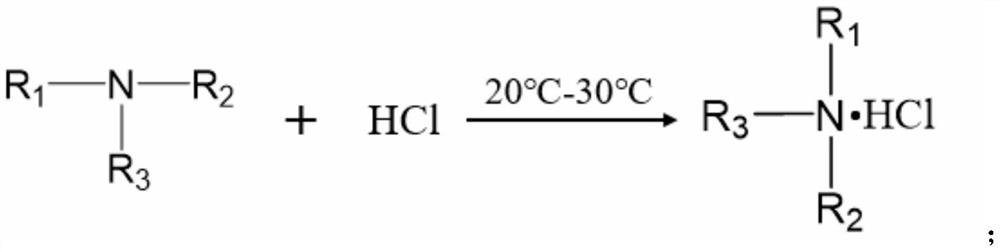

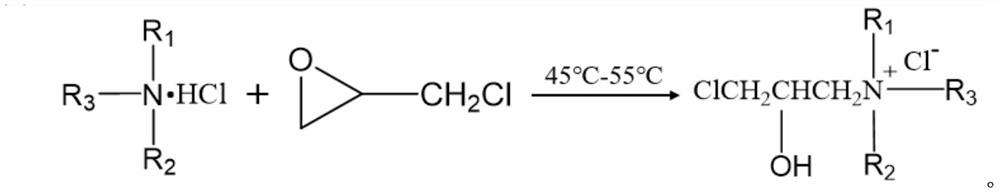

A kind of preparation method and application of active hydrophilic type formaldehyde-free color fixing agent

ActiveCN111138662BGood color fixing effectImprove hydrophilicityDyeing processEpichlorohydrinBis epoxide

The invention relates to a preparation method of an active hydrophilic formaldehyde-free color fixing agent, a) preparation of an intermediate product: S1) stirring concentrated hydrochloric acid and slowly adding a tertiary amine dropwise, keeping warm for reaction, and adjusting the pH of the solution to 3 with the tertiary amine ~4; S2) Heating up to 45°C, slowly adding epichlorohydrin dropwise at a temperature of 45-55°C, keeping the temperature for 1.0-2.5h to reach a homogeneous solution, then adjusting the pH value, and cooling down to obtain an intermediate product; b) Intermediate product , polyethylenimine and deionized water into the reaction bottle, stirring slowly drop epichlorohydrin, 20 ~ 40 ℃, heat preservation reaction 5 ~ 7h, 65 ~ 80 ℃, adjust the pH value to 6 ~ 7, cool down Water color fixing agent. The hydrophilic formaldehyde-free color-fixing agent of the present invention has high cationicity and reactive epoxy groups, and has good hydrophilicity and color-fixing effect. The fastness reaches grades 3-5, and meets the national regulation on hygroscopicity within 5 seconds, which can reduce the finishing of subsequent processes and meet the needs of printing and dyeing factories.

Owner:DYMATIC CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com