Production method of multilayer gauze invisible printed towel

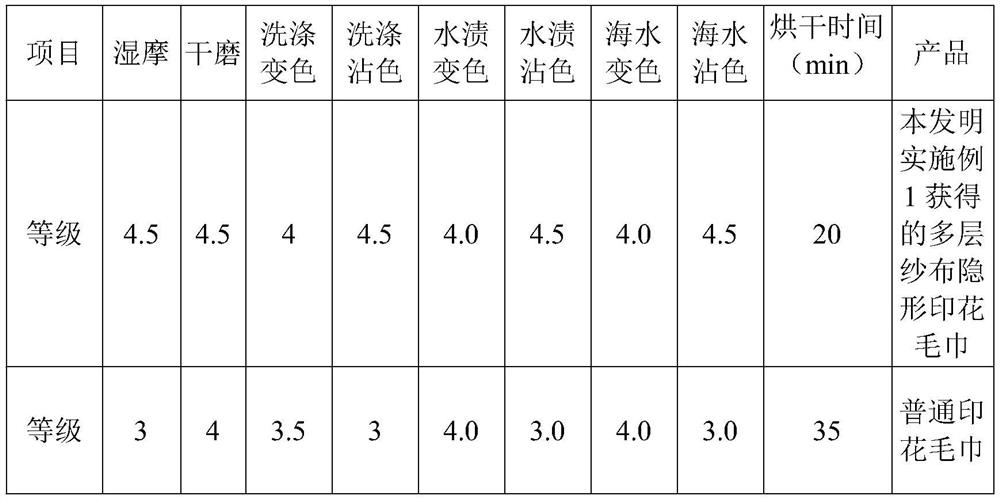

A technology of invisible printing and production method, which is applied to multi-strand fabrics, textiles, fabrics, etc., can solve the problems of substandard color fastness, single color, and direct contact with skin, so as to improve washing and rubbing fastness, save time, rich color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A kind of production method of multi-layer gauze invisible printing towel, concrete technological process is as follows:

[0026] Blank towel specifications: 34*35cm-42g three-layer gauze, the upper and lower surfaces are pure cotton, and the middle layer uses 80% polyester + 20% cotton blended yarn;

[0027] Pre-treatment of blank scarf (scouring and bleaching): the known technology of oxygen bleaching makes the dynamic water absorption of blank scarf reach 10cm;

[0028] Flower pattern design (can be designed according to different market preferences): cartoon pattern pattern;

[0029] Prepare the screen plate required for printing: the pattern plate of the normal printing color, the mesh number is 120 mesh;

[0030] Prepare color paste: prepare the known technology of color material,

[0031] Disperse dye: SE-GL ruby 5.2g / L

[0032] 5G bright yellow 3.5g / L

[0033] Thickener: P-6 40g / L

[0034] Water: make up 1L

[0035] Printing: use a magnetic rod with a di...

Embodiment 2

[0038] A kind of production method of multi-layer gauze invisible printing towel, concrete technological process is as follows:

[0039] Blank scarf specifications: 34*80cm-95g five-layer gauze, the upper and lower surface layers are pure cotton, the middle three-layer weft yarn uses 90% nylon + 10% cotton blended yarn, and the ground diameter uses 90% nylon + 10% cotton blended yarn ;

[0040] Pretreatment (desizing) of blank towels: known technology of oxygen bleaching, with a capillary effect of 10.5cm;

[0041] Pattern design (design according to different market preferences): cartoon type pattern;

[0042] Prepare the screen plate required for printing: the pattern plate of the normal printing color, the mesh number is 80 mesh;

[0043] Preparation of color paste: the known technology of preparation of colorants.

[0044] Disperse dye: CRE blue 6.2g / L

[0045] 5G bright yellow 6.5g / L

[0046] Thickener: P-6 42g / L

[0047] Water: make up 1L

[0048] Printing: Print ...

Embodiment 3

[0051] A kind of production method of multi-layer gauze invisible printing towel, concrete technological process is as follows:

[0052] Blank towel specifications: 85*115cm-254g six-layer yarn blank towel; the upper and lower surface gauzes are pure cotton, the middle four layers of gauze are made of 80% polyester + 20% cotton for the ground diameter, and 50% polyester + 50% cotton for the weft yarn;

[0053] Pretreatment (desizing) of blank towels: known technology of oxygen bleaching, with a capillary effect of 11cm;

[0054] Pattern design (design according to different market preferences): cartoon type pattern;

[0055] Prepare the screen plate required for printing: pattern plate of normal printing color, 80 mesh screen;

[0056] Preparation of base color paste: preparation of known technology for colorants,

[0057] Disperse dye: PG black 1.5g / L

[0058] SE-GL Ruby 6.5g / L

[0059] 5G bright yellow 3.8g / L

[0060] Thickener: P-6 45g / L

[0061] Water: make up 1L

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com