Application of polyphenol amine dye in printing and dyeing of fabric fibers and dyeing method

A technology for fabric fibers and dyeing methods, applied in the field of textile printing and dyeing, can solve the problems of increasing the dyeing process, increasing the cost of printing and dyeing, difficult industrial application, etc. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0031] The third embodiment of the present invention provides a method for utilizing the dyed liquid after dyeing. The dyed liquid after dyeing is used as a recycled dye, and fabric fibers are added to the recycled dye for dyeing; the dyed liquid after dyeing is dyed as described above. The remaining liquid material after method dyeing.

[0032] Specifically, the dyeing method is reciprocating oscillation, and the oscillation speed is 100-200 r / min.

[0033] Specifically, the dyed dye solution produced by the post-dyeing dye solution utilization method can still be further processed by the post-dye dye solution utilization method.

[0034] In order to enable those skilled in the art to understand the technical solutions of the present invention more clearly, the technical solutions of the present invention will be described in detail below with reference to specific embodiments and comparative examples.

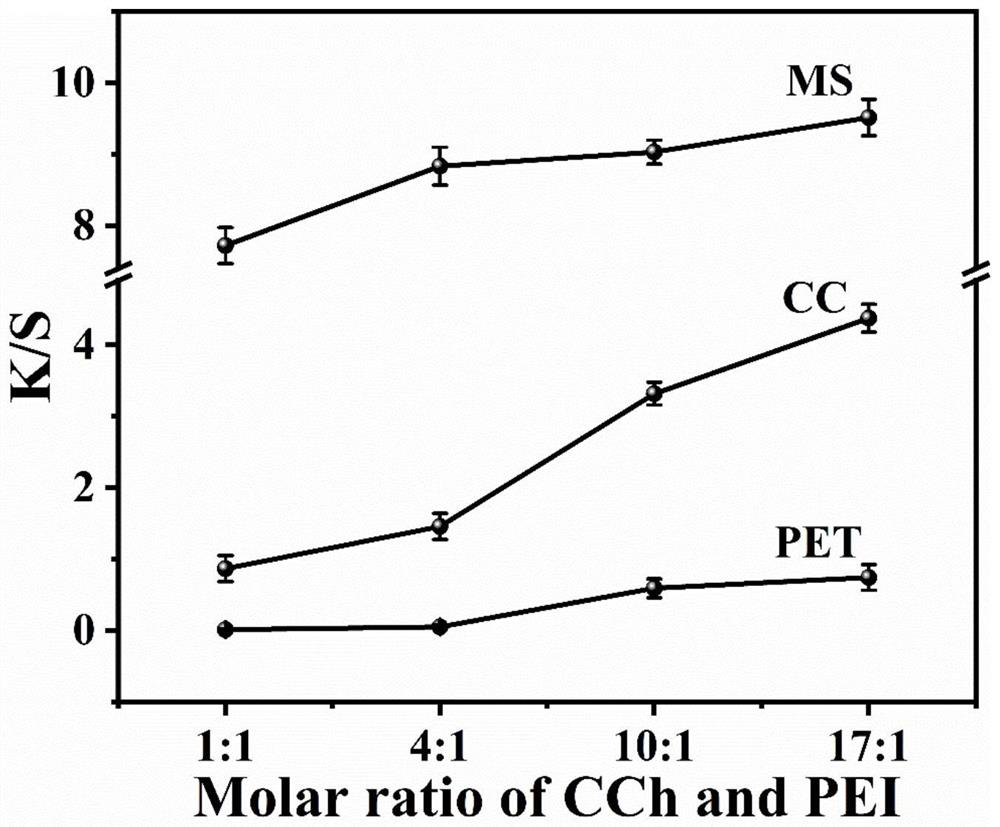

[0035] In the following examples, the cotton fiber is CC (CC cotton, st...

Embodiment 1

[0037] A method for dyeing cotton fibers with novel dyes produced by the polymerization of catechol and polyethyleneimine, comprising the following steps:

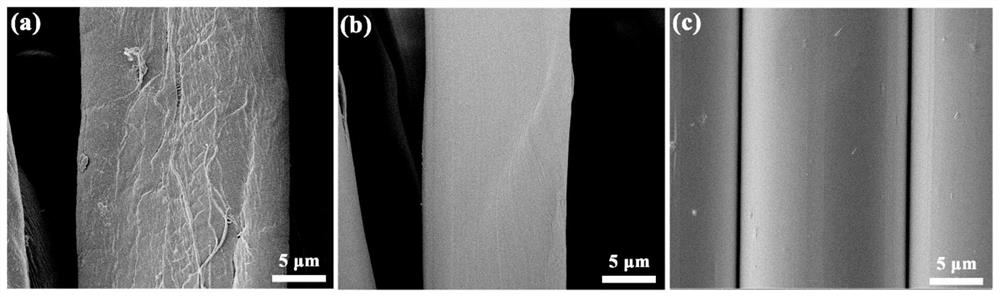

[0038] (1) The cotton fiber was added to deionized water at a liquor ratio of 1:50 (o.w.f.) for washing, and the washing time was 30 min. After washing, after drying at 60 °C for 2 h, the pretreated fabric fibers were obtained, such as figure 1 a shown.

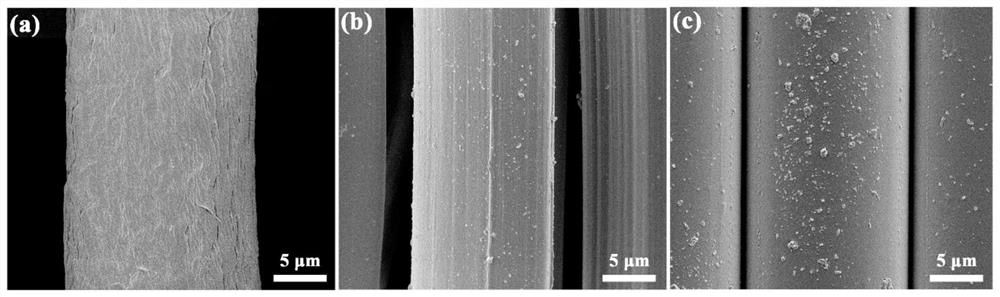

[0039] (2) Take 4 pieces of pretreated fabric fibers with a size of 5 × 10 cm and add them to 200 mL of polyphenolamine dye solution containing 5.05 mL of polyethyleneimine and 1 g of catechol for polymerization at 35 °C for 24 h, and at 35 °C Dyeing for 20min. After being fully washed with deionized water and dried at 60°C for 2 hours, dyed fabric fibers were obtained, such as figure 2 a shown.

Embodiment 2

[0041]A method for dyeing mulberry silk with a novel dye produced by the polymerization of catechol and polyethyleneimine, comprising the following steps:

[0042] (1) Add mulberry silk to 0.3 g / L sodium carbonate solution at a liquor ratio of 1:50 (o.w.f.) for washing, and the washing time is 30 min. After washing and drying at room temperature for 2 hours, the pretreated fabric fibers were obtained, such as figure 1 b shown.

[0043] (2) Take 4 pieces of pretreated fabric fibers with a size of 5 × 10 cm and add them to 200 mL of polyphenolamine dye solution containing 5.05 mL of polyethyleneimine and 1 g of catechol for polymerization at 35 °C for 24 h, and at 35 °C Dyeing for 20min. After being fully washed with deionized water and dried at room temperature for 2 hours, dyed fabric fibers are obtained, such as figure 2 b shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com