Pyrography ink with high ink bearing capacity and preparation method thereof

A technology of ink and ink volume, applied in the field of high ink capacity heat press ink and its preparation, can solve problems such as diffusion, affecting customer experience, penetration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

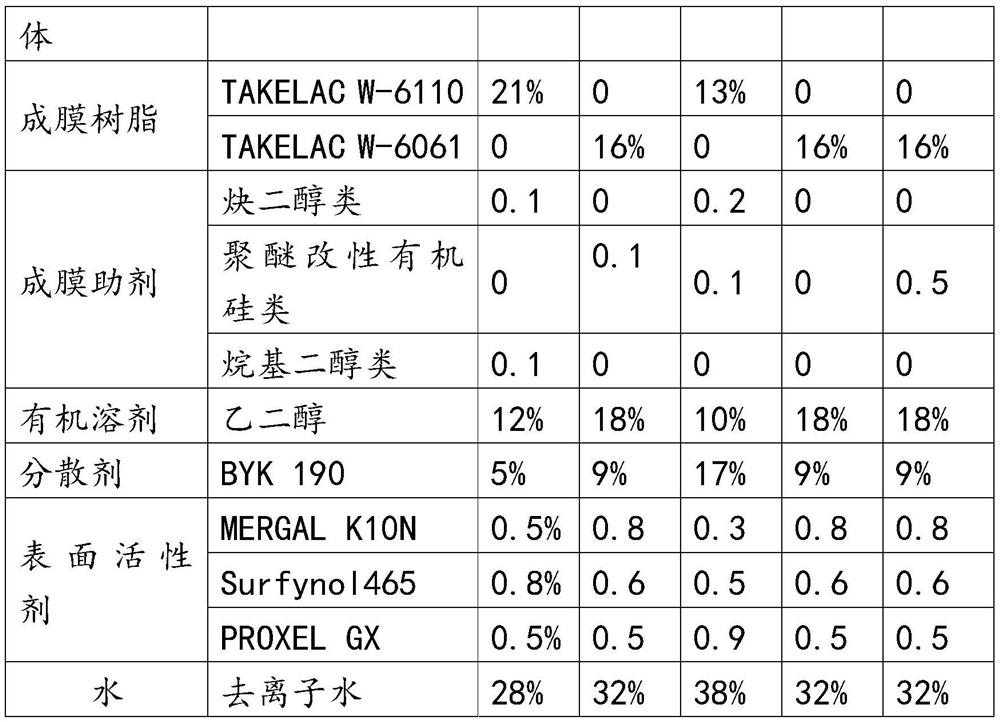

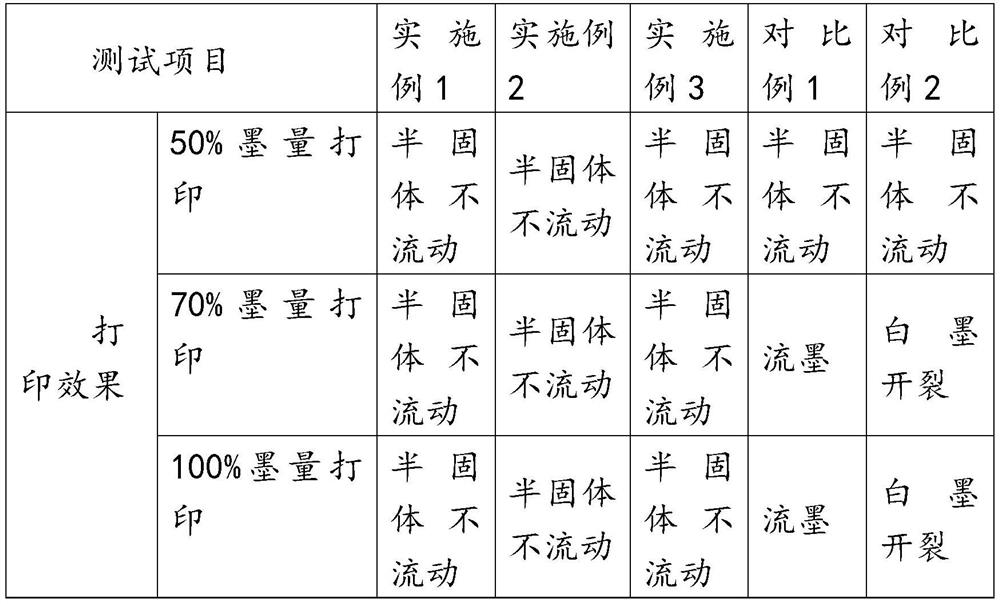

[0022]The high amount of ink perm ink in the present invention is applied to the hot stamping process of the ink, the hot ink is added with a film-forming additive and a film-forming resin, by selecting alkyne glycol, polyether-modified silicone and alkyl glycol in at least one of the film-forming additives to reduce the glass-forming temperature of the film-forming resin, and control the ratio between the film-forming additive and the film-forming resin, can accelerate the film-forming speed of the ink, so that the ink can be quickly fixed on the hot stamping medium and film-forming, to achieve the plasticizing effect of the film-forming additive on the film-forming resin, Thus solving the problem of low ink bearing.

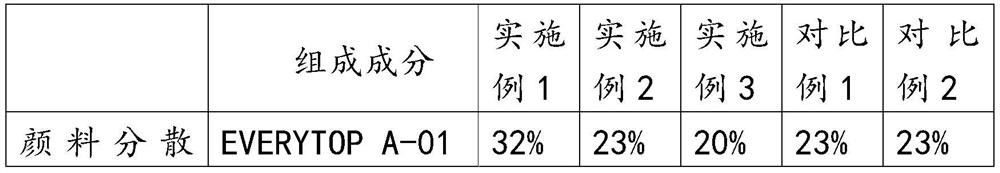

[0023] When the total weight is 1, the hot stamping ink with high ink bearing percentage by weight comprises a hot ink comprising 20% to 40% pigment dispersion, 10% to 20% water-soluble organic solvent, 10% to 25% water-soluble film-forming resin, 0.1% to 0.2% film...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com