Patents

Literature

75 results about "Pyrography" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pyrography or pyrogravure is the free handed art of decorating wood or other materials with burn marks resulting from the controlled application of a heated object such as a poker. It is also known as pokerwork or wood burning.

An image style migration and simulation method for gourd pyrography

PendingCN109712068AThe simulation effect is optimisticImprove viewabilityImage enhancementImage analysisGourdComputer graphics (images)

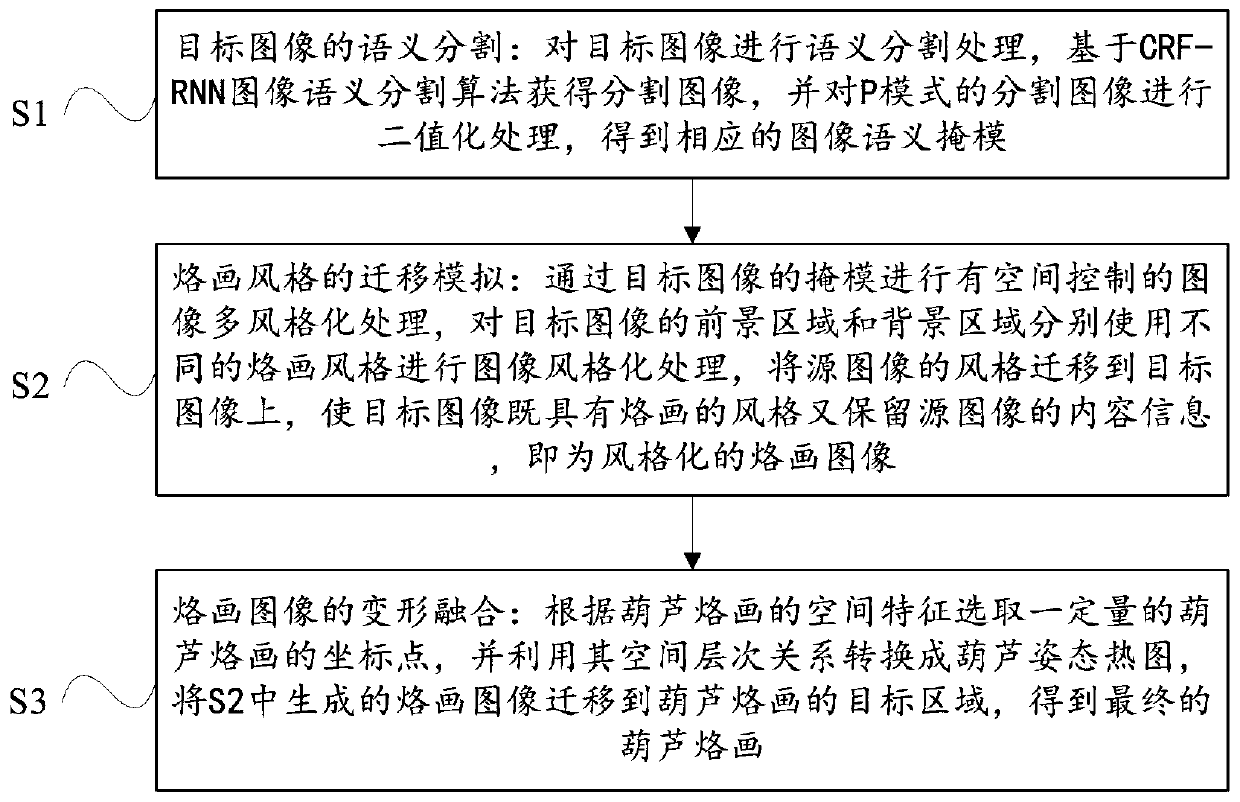

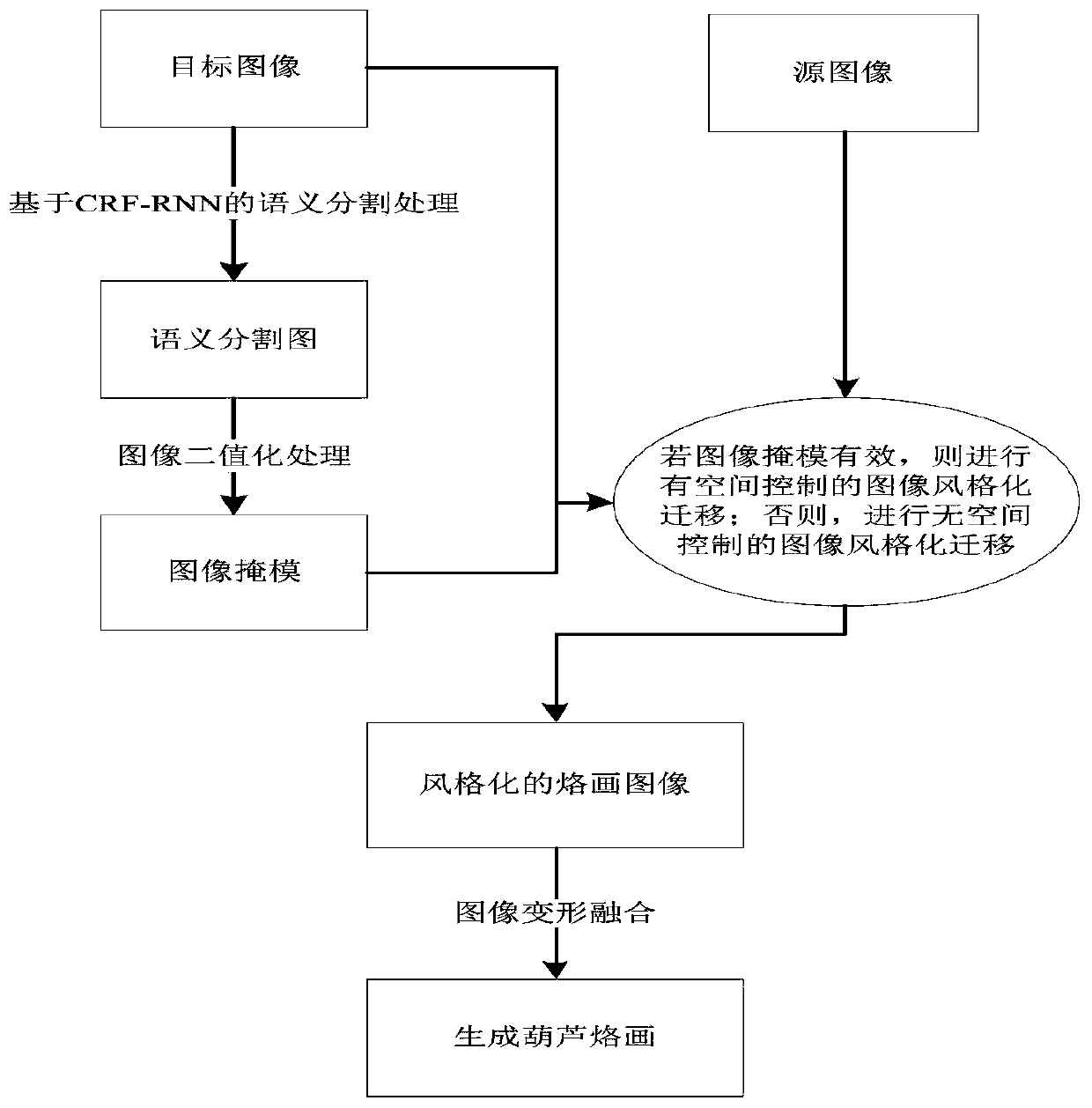

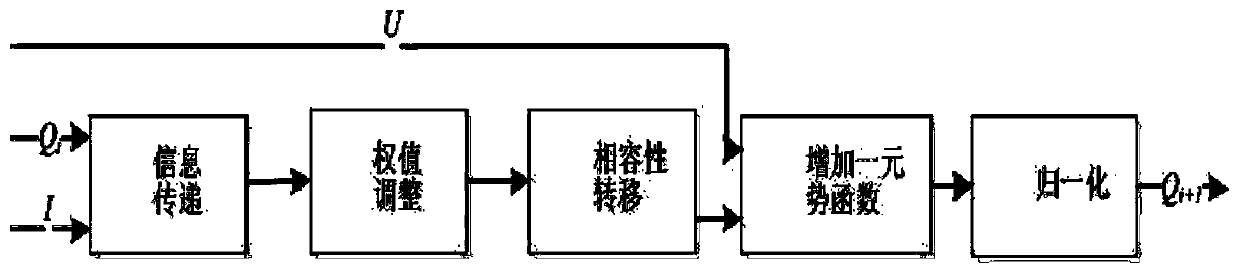

An image style migration and simulation method for the gourd pyrography comprises the steps of conducting semantic segmentation processing on a target image, and based on a CRF-RNN image semantic segmentation algorithm, obtaining a segmented image , and performing binarization processing on the segmented image in the P mode to obtain a corresponding image semantic mask; performing image multi-stylization processing with spatial control through the target image mask; carrying out image stylization processing on the foreground area and the background area of the target image by using different pyrograph styles respectively, and migrating the style of the source image to the target image, so that the target image has the pyrograph style and retains the content information of the source image,namely the stylized pyrograph image; A certain amount of coordinate points of the gourd pyrograph are selected according to spatial characteristics of the gourd pyrograph, the spatial hierarchical relation of the coordinate points is converted into a gourd posture heat map, the pyrograph image is migrated to a target area of the gourd pyrograph, the final gourd pyrograph is obtained, and the operation efficiency, flexibility and migration effect of image style migration are improved.

Owner:YUNNAN UNIV

Process for producing embossment braided picture

InactiveCN101318439AEnhance grade valueImprove naturalnessDecorative surface effectsSpecial ornamental structuresSurface layerTactile sensation

A manufacturing technique of a relief pyrography consisting of the technical processes of selecting materials, pre-treating, shaping, cauterizing and painting, coating, lining and packaging overcomes the defects of single color, no depth change of color, no tactile sensation and no bright-dark effects of a relief artwork as well as the defect that the pyrography has no remarkable 3D sensation on tactile sensation and vision; the manufacturing technique organically combines the techniques of relief and pyrography to lead the new artwork to have remarkable 3D sensation. The surface layer of the finished green body medium of the relief is carbonized in different degrees by the methods of cauterizing and scalding and thermal flame roasting, etc. The color of the relief pyrography has remarkable bright and dark change as well as is stable and permanent; the picture tactile sensation is a remarkably enhanced, which shows to be antique and natural. The durability, the environment-friendly property and the nationality of the relief pyrography are fully ensured and improved; the aesthetic feeling, the appreciation effects and the collection values are improved by a plurality of times.

Owner:李峰

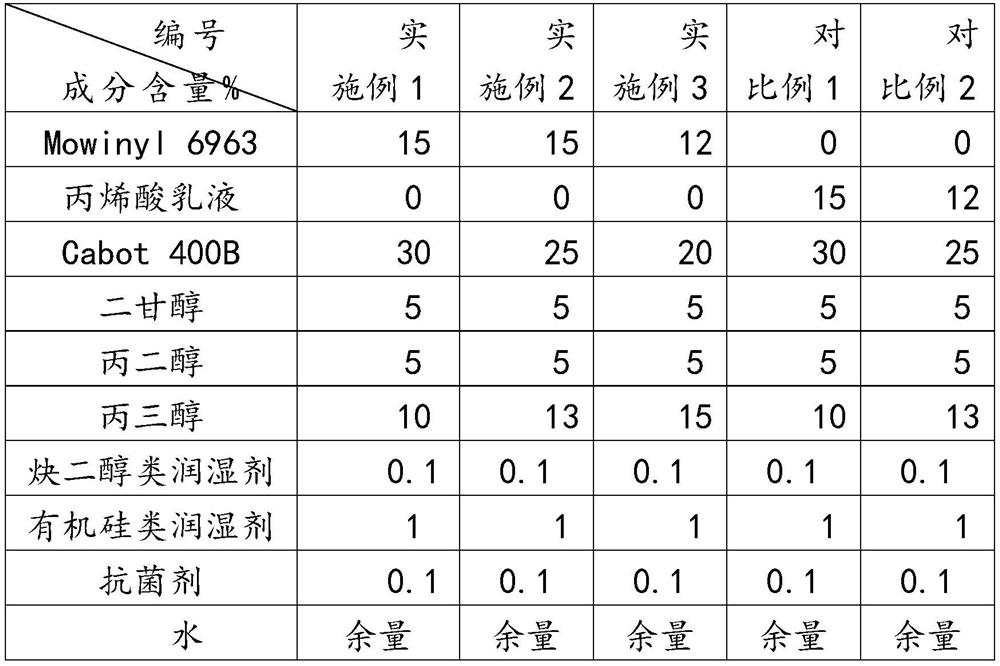

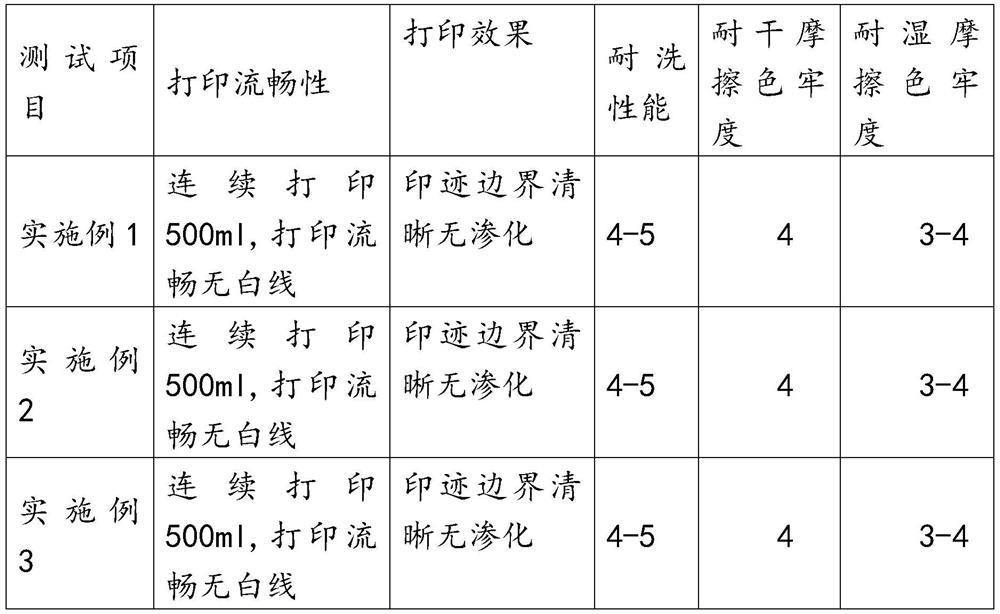

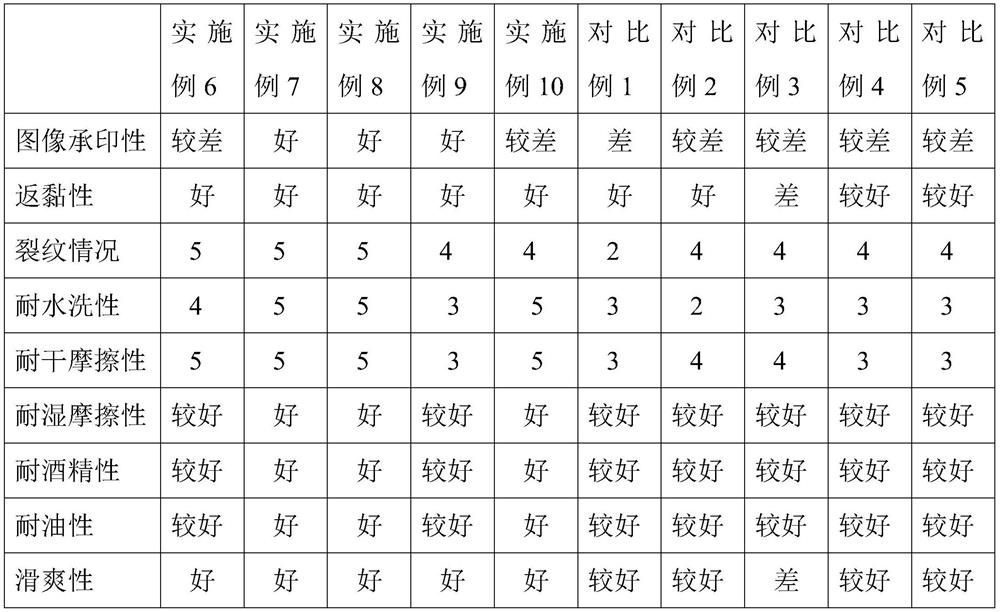

Environment-friendly pyrography ink, PET film heat transfer printing method and application of environment-friendly pyrography ink

ActiveCN111607286AMeet the requirements of environmentally friendly digital printingImprove coloring performanceDuplicating/marking methodsInksTextile printerPolymer science

The invention provides environment-friendly pyrography ink, a PET film heat transfer printing method and application of the environment-friendly pyrography ink and the PET film heat transfer printingmethod. The environment-friendly pyrography ink comprises pigment color paste, a water-soluble organic solvent, a surfactant and a styrene-acrylic polymer emulsion with the glass transition temperature of less than 0 DEG C, the ink is printed on a PET film through an ink-jet printer; the PET film is used for carrying out a heat transfer printing process on pure cotton or cotton blended fabric; thestyrene-acrylic polymer emulsion can form a film layer with good adhesive force and tensile strength on the PET film; the permeation phenomenon of the water-based pigment ink on the PET film is improved; the styrene-acrylic polymer emulsion is low in glass transition temperature, so that the styrene-acrylic polymer emulsion is in a soft state during heat transfer printing, ink is more easily transferred to the fabric from the PET film, the adhesive force of printed patterns is enhanced, and the friction resistance and the color fastness to washing of the printed patterns on the fabric are effectively improved.

Owner:ZHUHAI FREE TRADE ZONE NEOJET APOLLOJET IMAGING MATERIALS

Printing process of UV flash three-dimensional pyrography

InactiveCN107443942AStrong concave-convex feelGood three-dimensional effectOther printing apparatusPrinting after-treatmentCartonPrinting ink

The invention discloses a printing process of UV flash three-dimensional pyrography, which is used for printing on cartons. The printing process comprises the following steps of (1) plating silver: partially plating silver on the cartons; (2) calibrating: determining that the gilding position and the printing position are kept consistent through the registration of a positioning film; (3) printing patterns: partially printing patterns on the cartons with printing ink, wherein the registration error of the printing patterns is less than or equal to 0.05 mm; (4) performing matte printing: performing matte printing on full pages of the cartons; and (5) glazing: registering gilding and printing contents, and glazing with UV varnish. The printing process of the UV flash three-dimensional pyrography has the following advantages that (1) the visual stereoscopic effect of the surfaces of the graphic cartons is good, and the display effect is good; (2) the UV flash three-dimensional pyrography has a strong concave-convex feeling.

Owner:昆山科望快速印务有限公司

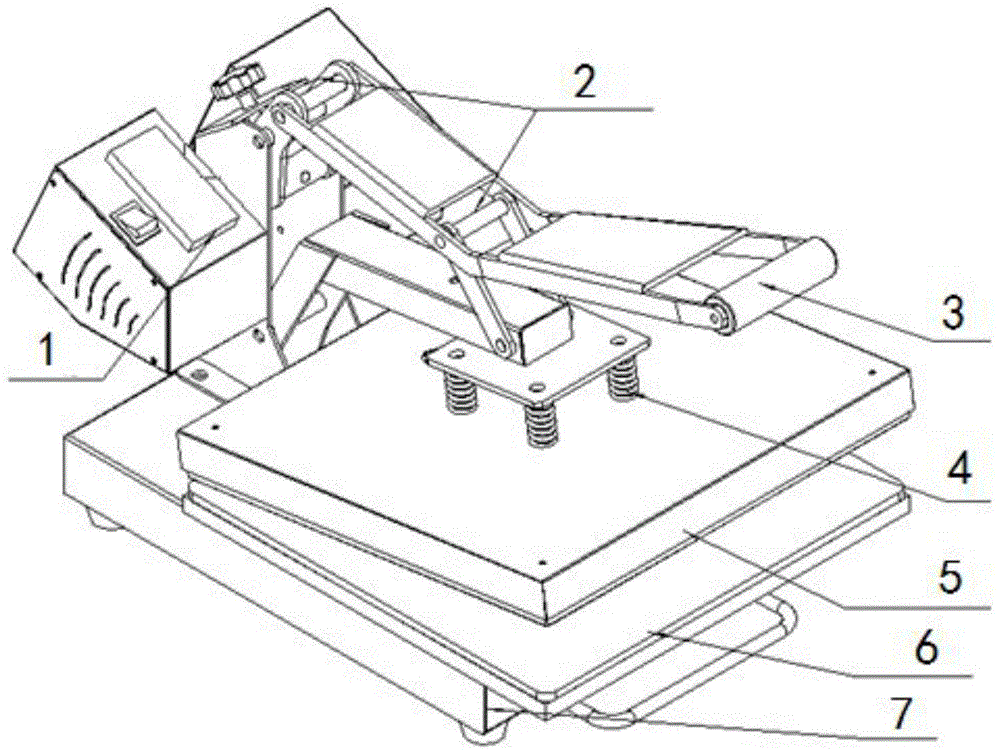

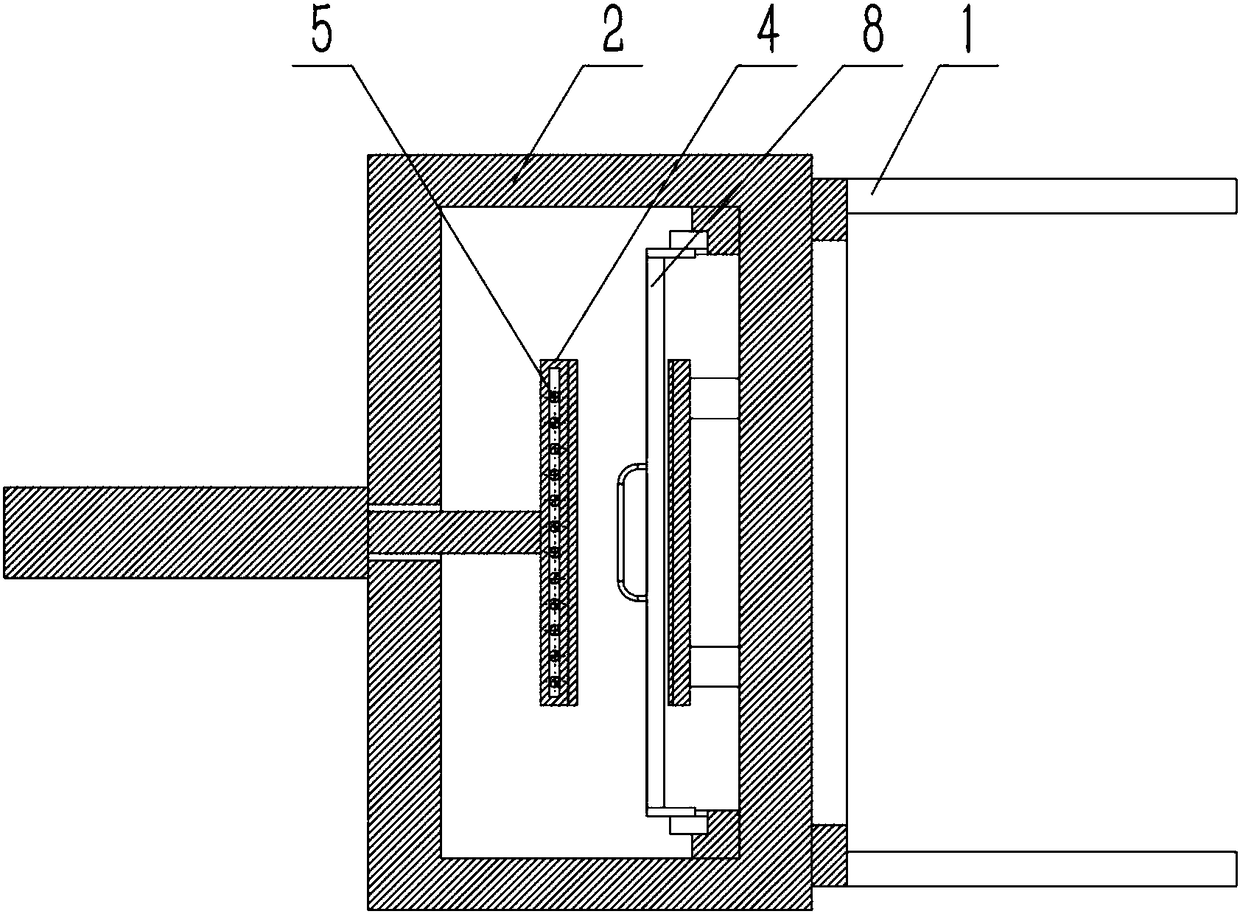

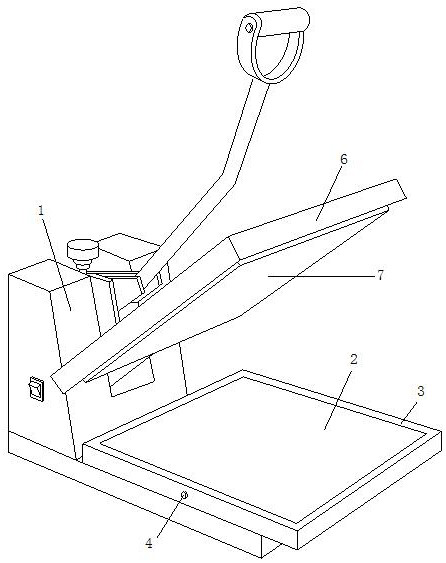

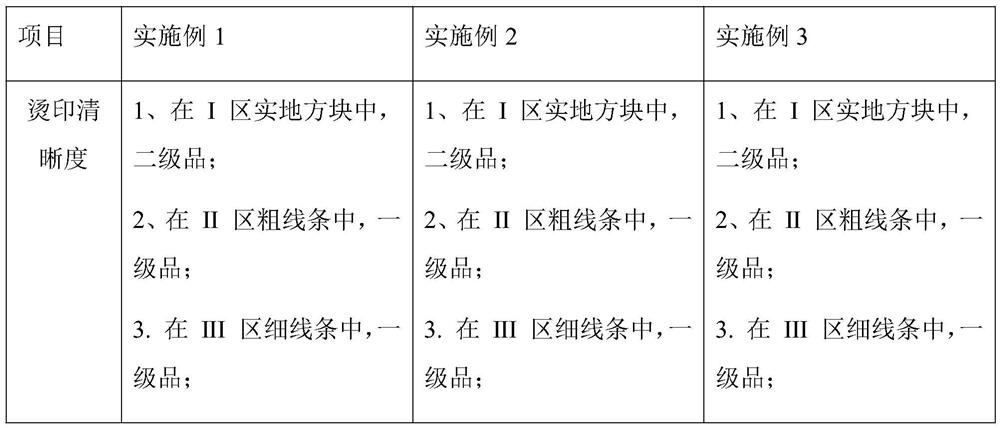

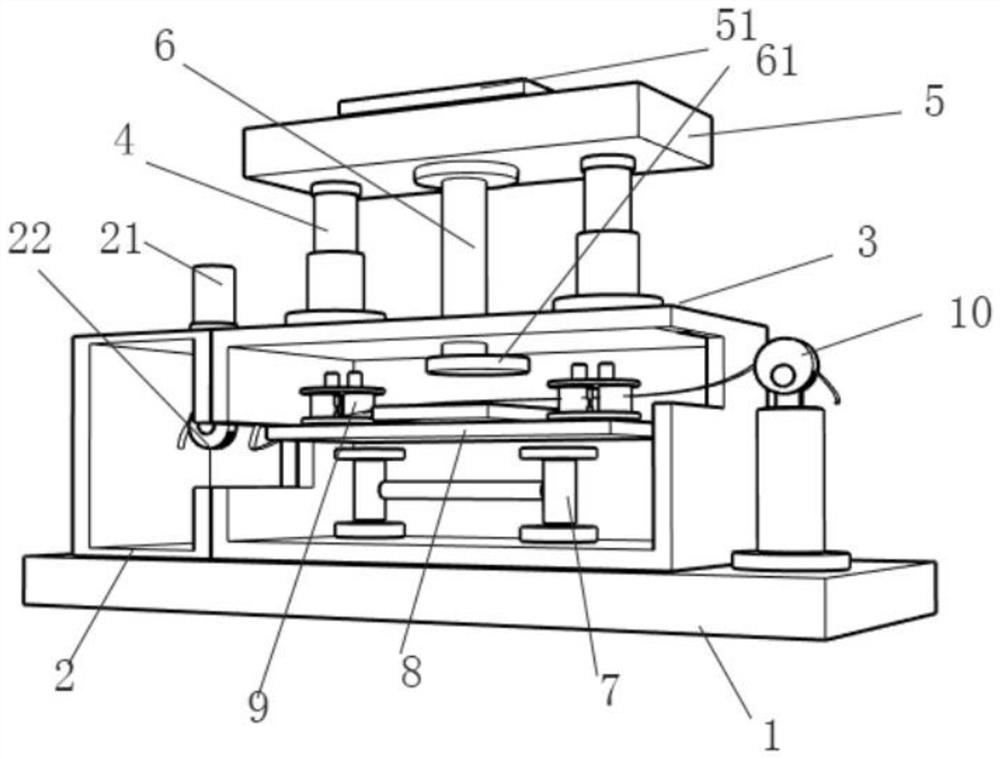

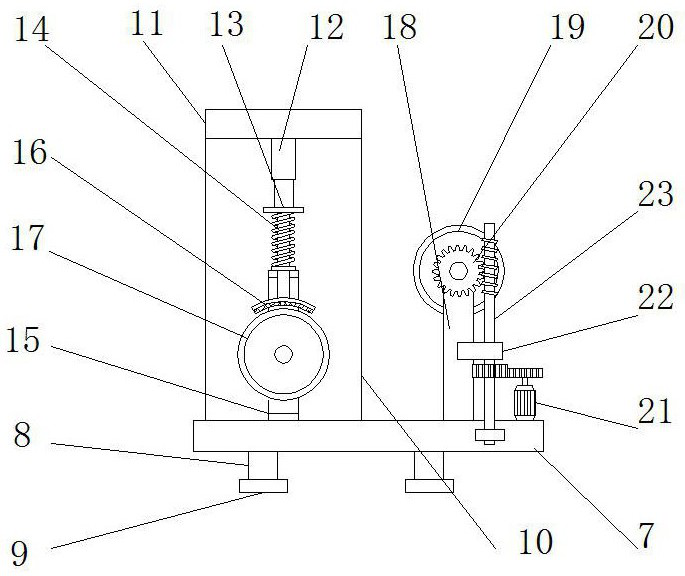

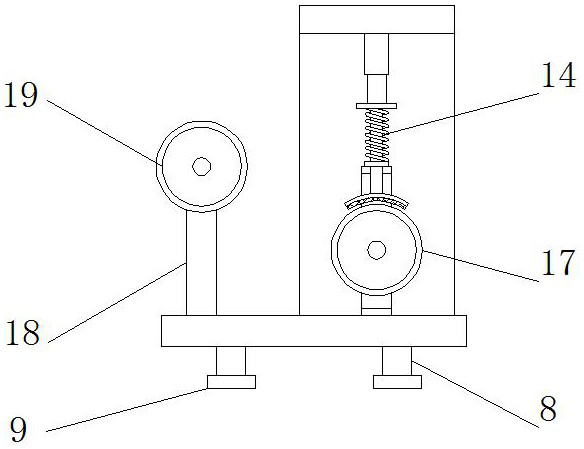

Manual high-pressure pyrography machine

InactiveCN105082741AEasy to useReasonable structural designTransfer printingEngineeringPressure balance

The invention provides a manual high-pressure pyrography machine, and relates to the field of pyrography machine equipment. The machine mainly comprises a basal body, a lower aluminum casting plate, a heating plate, a pressure balance device, a connecting rod structure and a handle, wherein the lower aluminum casting plate is fixed on the basal body; the pressure balance device is arranged on the upper end surface of the heating plate, and is connected with the handle through the connecting rod mechanism; and the lower end surface of the heating plate is oppositely combined with the upper end surface of the lower aluminum casting plate. The machine is reasonable in structural design and light in use, can efficiently and clearly finish the heat transfer printing process, is little in strength in the use process, is more convenient for women and children to use, and can solve the problems of nonuniform four-corner pressure and insufficient whole pressure in the pyrography process.

Owner:HEFEI KAXING DIGITAL CONTROL EQUIP

Method for manufacturing bamboo rind pyrograph

InactiveCN101734089AImprove toughnessHigh temperature resistantDecorative surface effectsWood treatment detailsWhiteboardEngineering

The invention discloses a method for manufacturing a bamboo rind pyrograph. According to the method, bamboo rind is used to replace a white board to manufacture a bottom board of the pyrograph; the complete bamboo rind pyrograph is manufactured through multiple processes such as bleaching, airing, ironing, rolling, re-ironing, polishing, splicing, sticking, pyrography, mounting and the like. The bamboo rind pyrograph manufactured by the method is quite convenient to curl, carry and transport, and makes up the defects that the pyrograph using the white board as the bottom board is inconvenientto carry and transport due to large volume and heaviness. Meanwhile, the bamboo rind pyrograph has the characteristic of high temperature resistance; and patterns and flowers with different depths can be branded on a bamboo rind sheet, so the whole pyrograph produces a mottled, simple and deep artistic effect. The expression content and the expression form of the surface of the pyrograph manufactured by the method are colorful, the artistic expression and the artistic impact of the pyrograph surface are strong, and the appreciation is obviously improved.

Owner:朱林寿

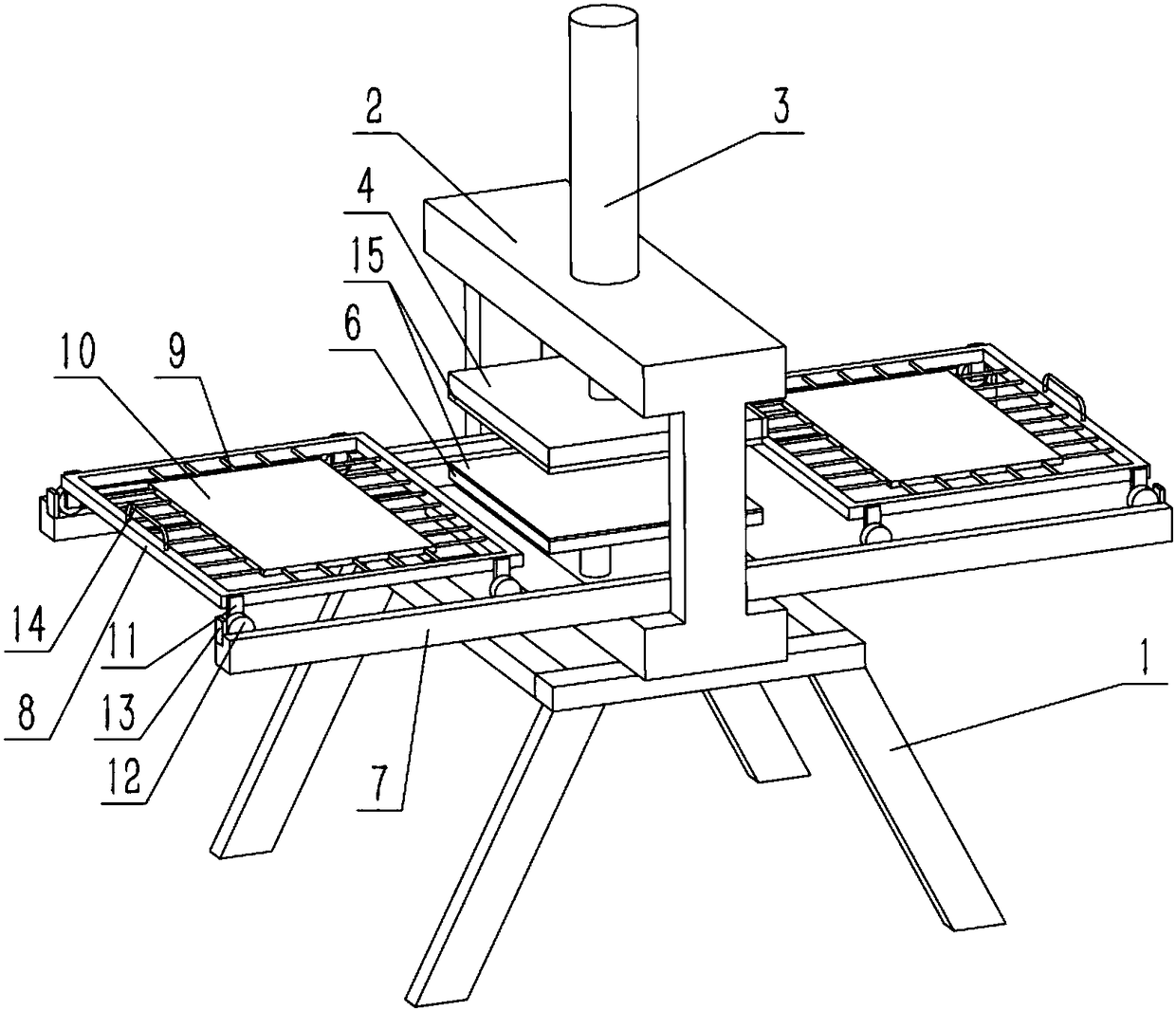

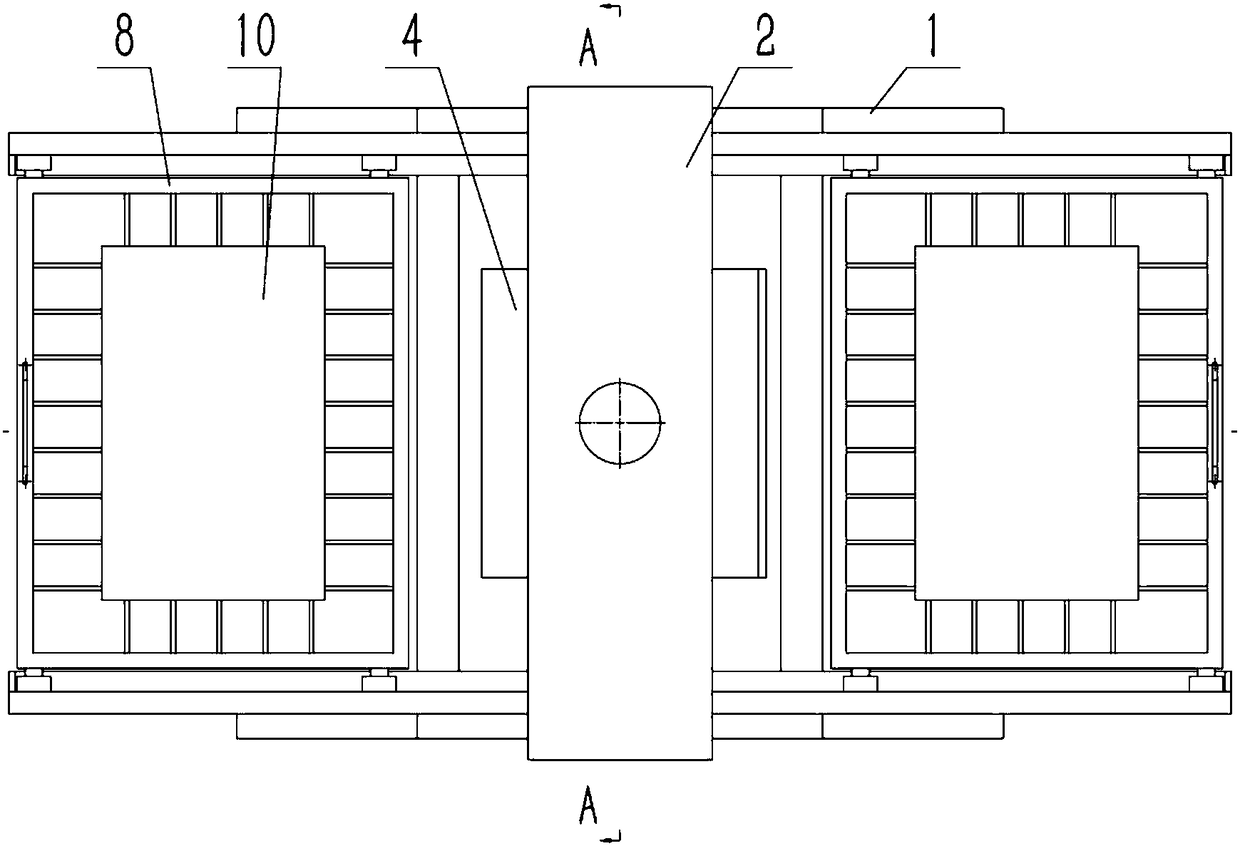

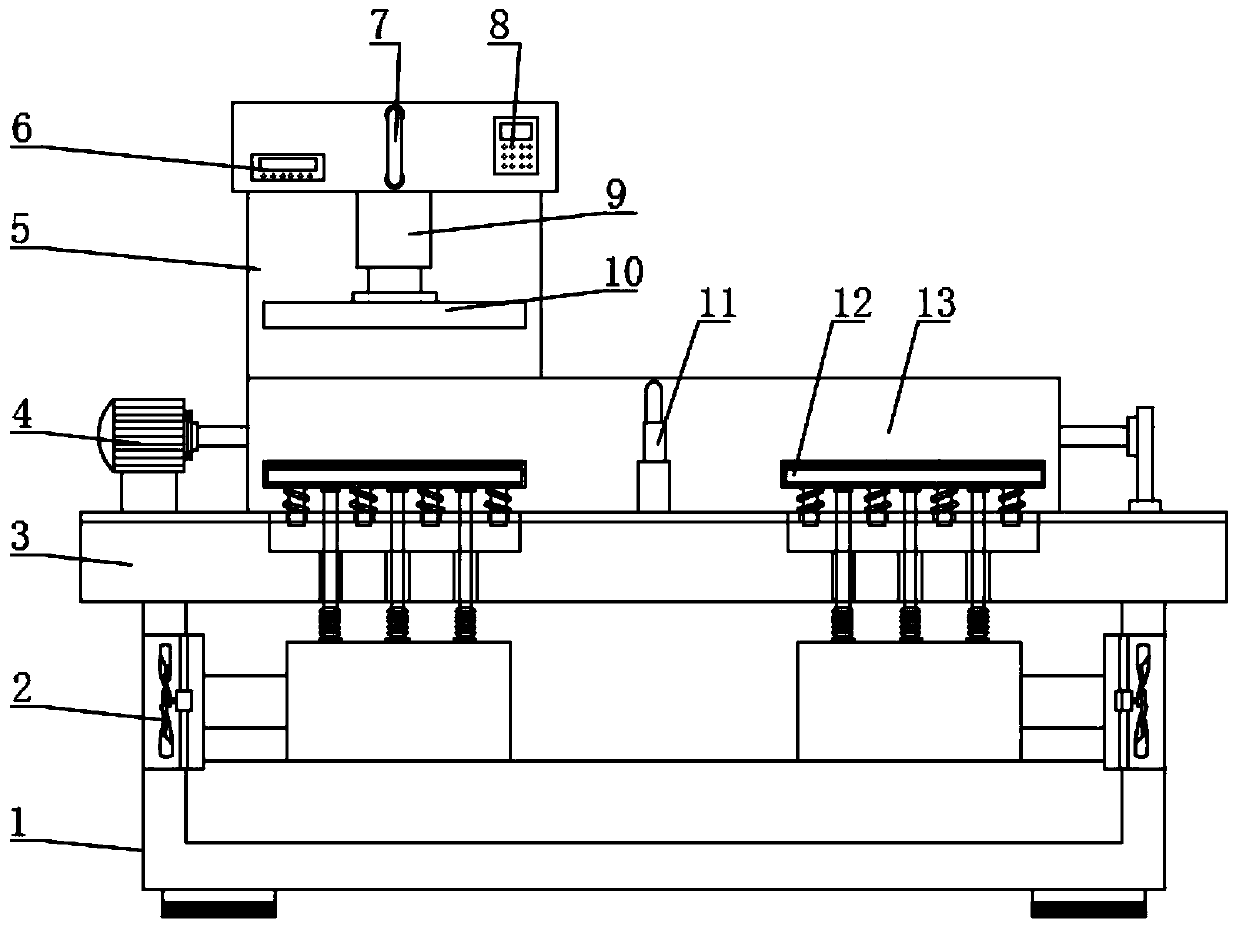

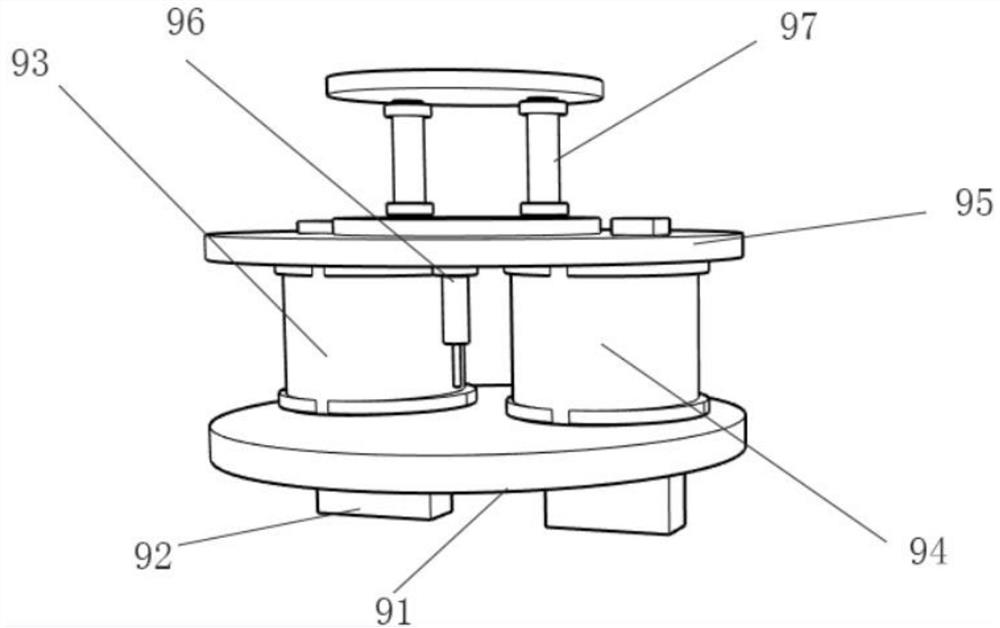

Double-station pressing ironing machine

InactiveCN108407440AImprove heat transfer efficiencyTransfer printingPulp and paper industryPiston rod

The invention discloses a double-station pressing ironing machine. The double-station pressing ironing machine comprises a support; a framework is fixed to the top face of the support; a cylinder witha piston rod downwards arranged is fixed to the top face of the framework; a hollow heating plate is horizontally fixed to the end portion of the piston rod of the cylinder; a plurality of heating pipes electrically connected with the exterior are fixed in the heating plate; a bearing and supporting plate is fixed corresponding to the position under the heating plate; guide rails are fixed in theportions, on the two sides of the bearing and supporting plate, of the framework; and the guide rails extend to the two sides of the framework. The double-station pressing ironing machine has the beneficial effects that due to the fact that the two sides of a frame body are each provided with a movable frame and the movable frames serve as double stations for operation of double persons, pressingironing can be performed ceaselessly, and the pyrography efficiency is improved.

Owner:金福生

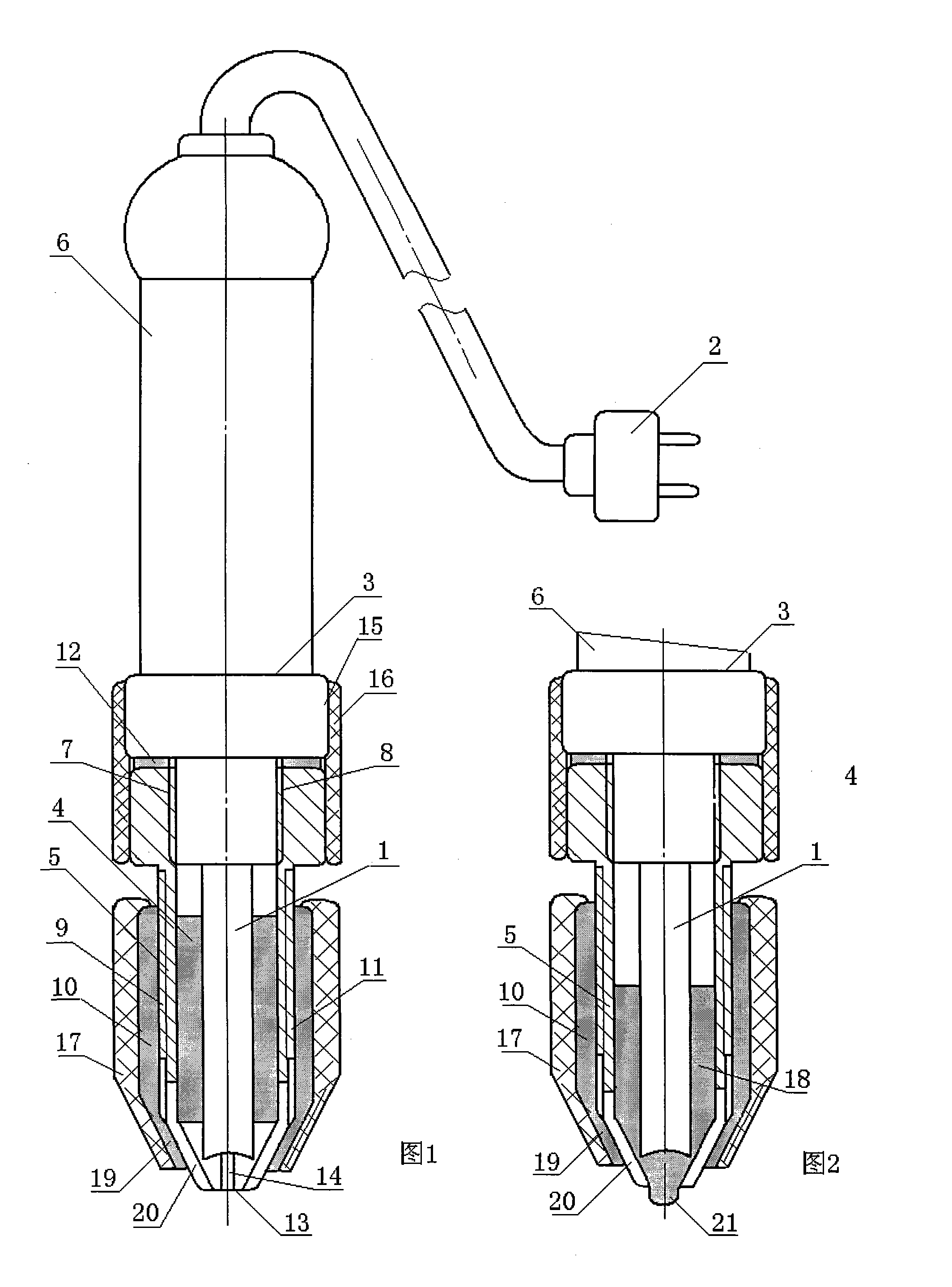

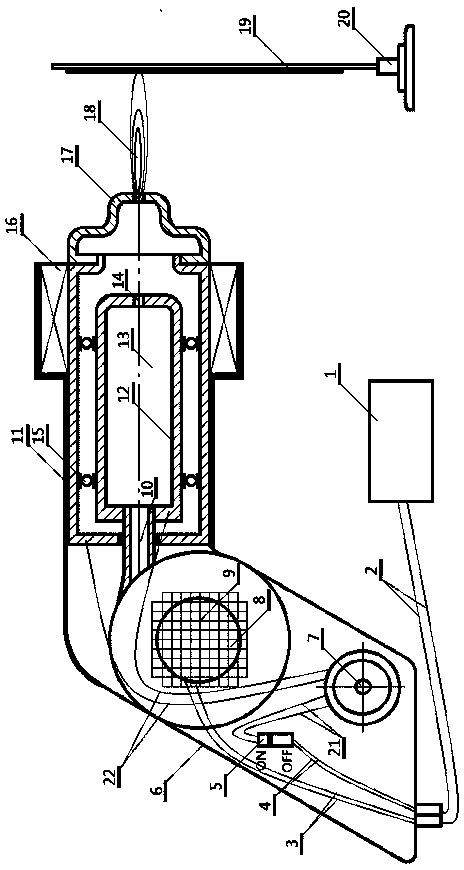

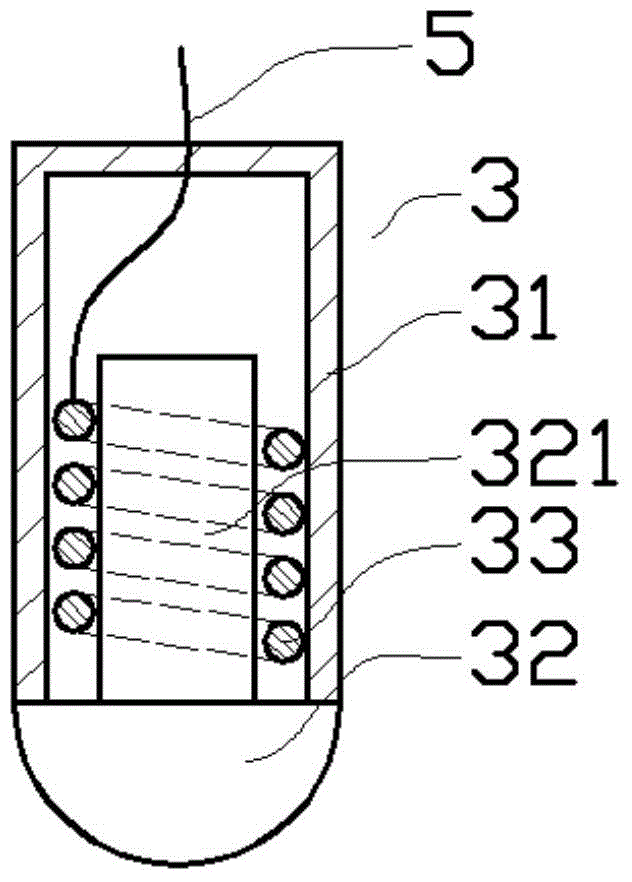

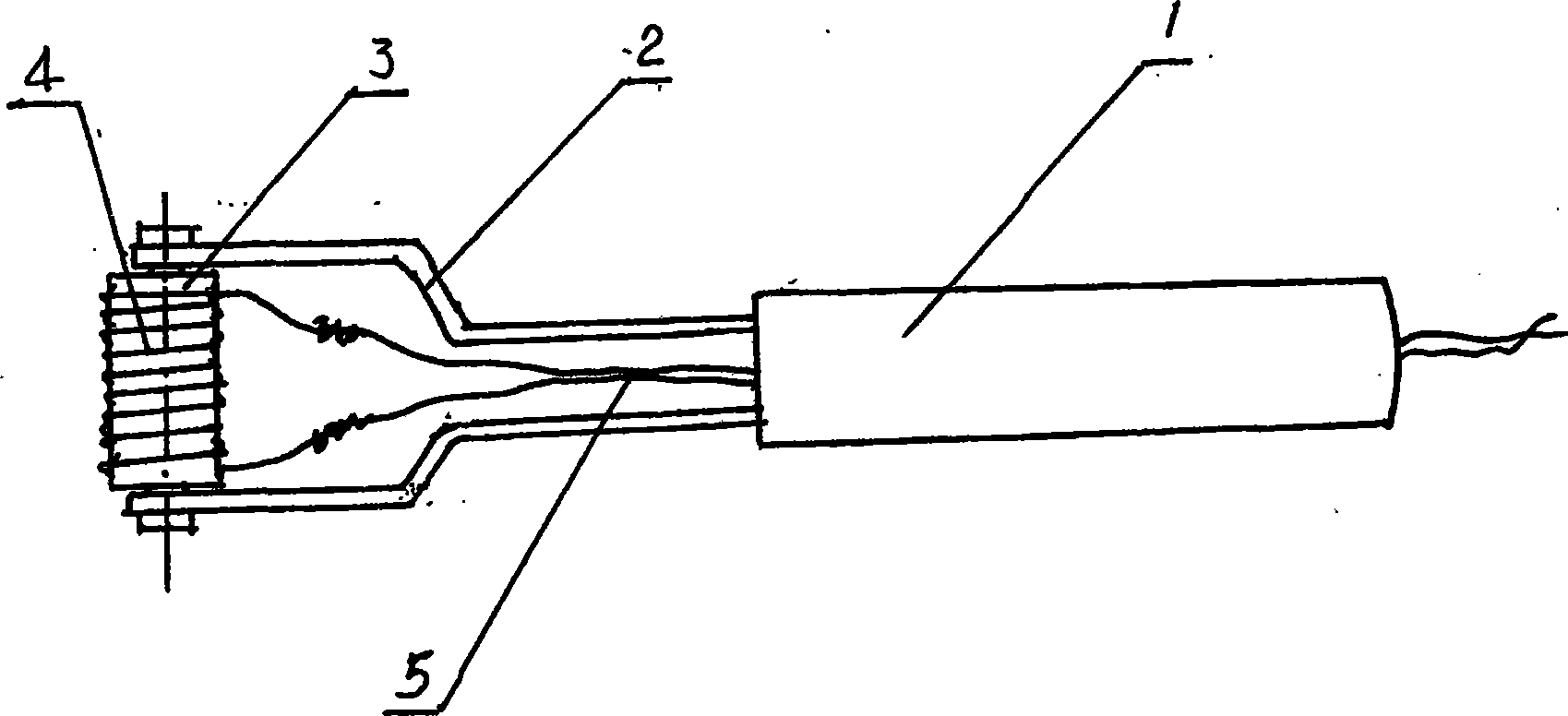

Electrical purography pen

The invention relates to an electrical purography pen which comprises an electrical heating element and an attaching plug. The electrical purography pen is provided with a metal liquid penpoint which consists of the electrical heating element, a metal stannum core and a pen tip. The electrical heating element of the metal liquid penpoint is fixedly connected in the pen tip,the metal satnnum core is arranged in the pen tip and is sheathed outside the electrical heating element. The working theory of the electrical purography pen is as follows: the electrical purography pen is connected with a power supply; the electrical heating element in the electrical purography pen is used for melting the metal stannum core into metal liquid; and the metal liquid is used for pyrographing. The electrical purography pen has the beneficial effects that the metal liquid is used for pyrographing, due to the compact contact of metal liquid pyrography with a drawing board, the speed of the metal liquid pyrographing is faster than the pyrographing speed of an ordinary electrical cautery pen; the electrical purography pen saves electrical energy; the penpoint is liquid, so the electrical purography pen does not damage the drawing board easily.

Owner:NANTONG YAOLONG METAL MFG

Pyrography film and production process thereof

ActiveCN111619257AImprove adhesionGood weather resistanceLiquid surface applicatorsCoatingsPolymer scienceWeather resistance

The invention relates to a pyrography film and a production process thereof. The pyrography film comprises an anti-sticking layer, a substrate layer, a release layer, a polyurethane layer, an ink layer and a glue layer, wherein all the layers are sequentially connected. The pyrography film has a novel six-layer structure, and the release layer is used for better separating a carrier from the ink layer in the processing process; the anti-sticking layer is used for preventing the pyrography film to be stuck to the glue layer when the pyrography film is reeled; and the polyurethane layer is a main functional layer and is used for enabling the adhesive force and the weather-proof performance of the pyrography film to be better.

Owner:DONGGUAN XIONGLIN NEW MATERIAL TECH

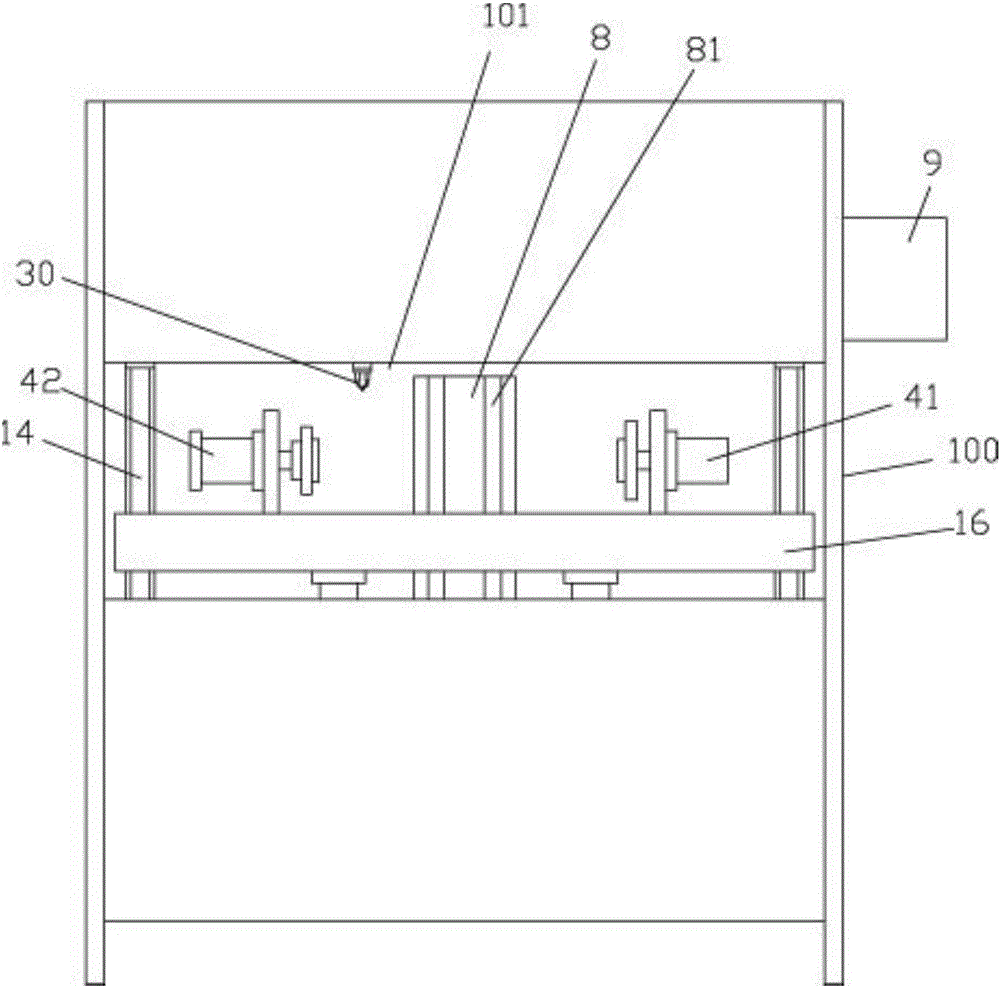

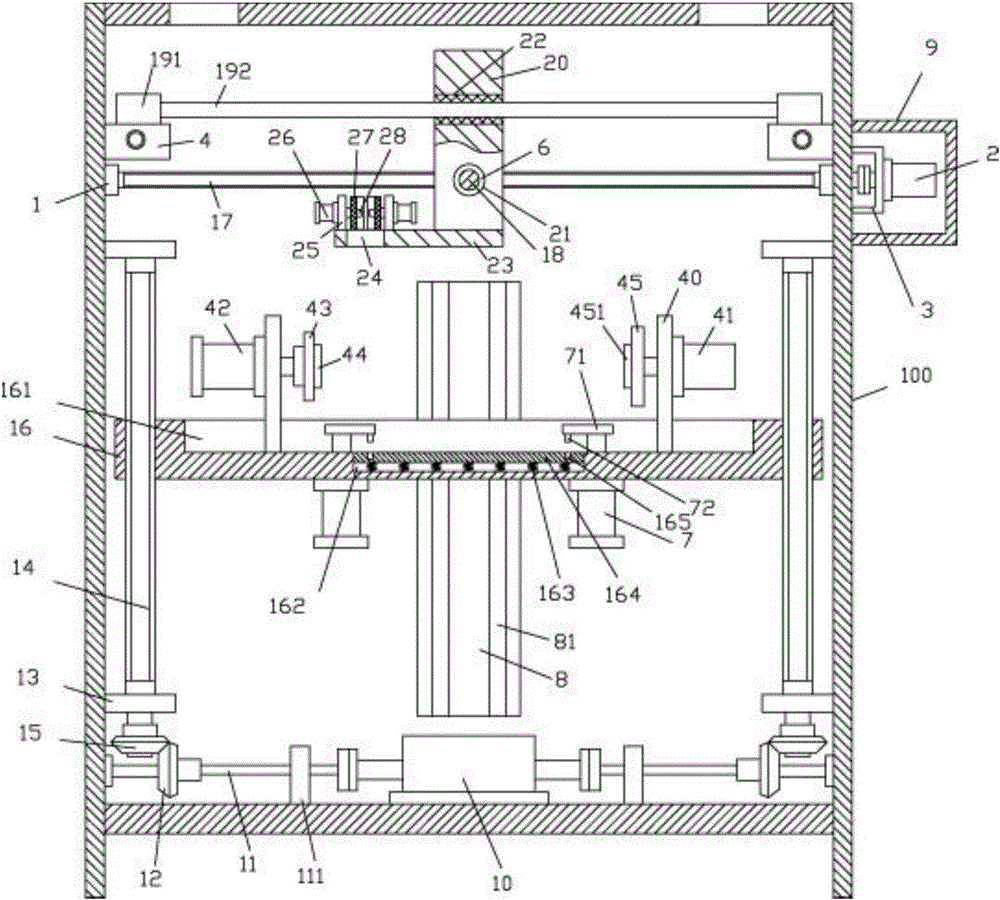

Full-automatic pyrography machine

InactiveCN105711321AHigh degree of automationGood effectBranding equipmentDecorative surface effectsCouplingOn board

The invention discloses a full-automatic pyrographer, which comprises a case. The middle part of the front plate body of the case has a feeding and discharging channel. The middle part of the top surface of the bottom plate of the case is fixed with a double output shaft servo motor. The shaft is located on both sides of the double-shaft servo motor, one end of the connecting shaft is connected to the output shaft of the double-shaft servo motor through a coupling, and the other end of the connecting shaft is hinged on the left or right side of the corresponding chassis , the driving bevel gear is fixed on the connecting shaft, two support plates arranged up and down are fixed on the inner wall of the left side plate and the right side plate of the chassis, the two ends of the transmission screw are hinged on the two support plates, the lower end of the transmission screw The lower supporting plate is protruded and the transmission bevel gear is fixed, and the transmission bevel gear meshes with the corresponding drive bevel gear; it can automatically clamp boards such as wooden boards or bamboo boards or cylinders, and automatically pyrograph, with a high degree of automation , the effect is good.

Owner:SHAOXING UNIVERSITY

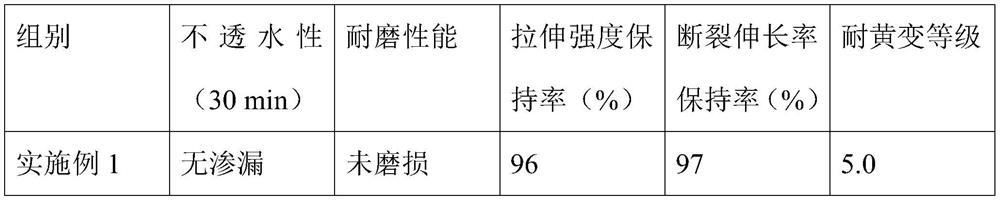

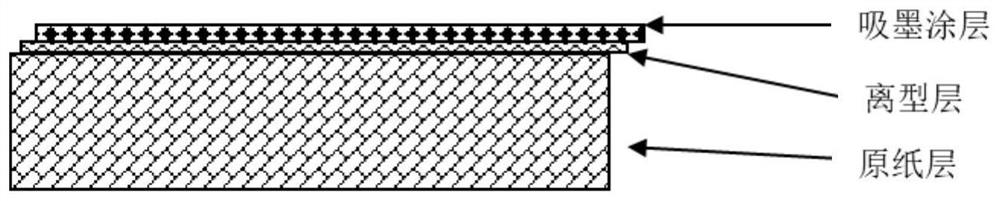

Coating composition for pyrography transfer paper, pyrography transfer paper and preparation methods of coating composition and pyrography transfer paper

PendingCN113512906AImprove transfer rateHigh image resolutionCoatings with pigmentsSpecial paperPolymer scienceStearic acid

The invention relates to the technical field of ink-jet printing, in particular to a coating composition for pyrography transfer paper, the pyrography transfer paper and preparation methods of the coating composition and the pyrography transfer paper. The coating composition for the pyrography transfer paper is prepared from the following components in parts by weight: 30 to 40 parts of cation exchange resin, 0.5 to 1 part of a fixing agent, 10 to 30 parts of butadiene and styrene copolymer emulsion, 5 to 10 parts of waterborne polyurethane, 1 to 5 parts of calcium stearate emulsion, 10 to 30 parts of silicon dioxide and 0.5 to 2 parts of polysiloxane. The cation exchange resin, the fixing agent and the waterborne polyurethane in the composition have a synergistic effect, so that the permeation of ink is prevented, and the transfer rate and the image resolution of the pyrograph transfer paper are improved. According to the pyrograph transfer paper, body paper serves as the base material, the ink absorption coating is formed on the surface of the body paper in a coating mode, and compared with a PET film prepared with PET as the base material in the prior art, more cost is saved, and better water resistance and printing performance are achieved.

Owner:赵慧哲

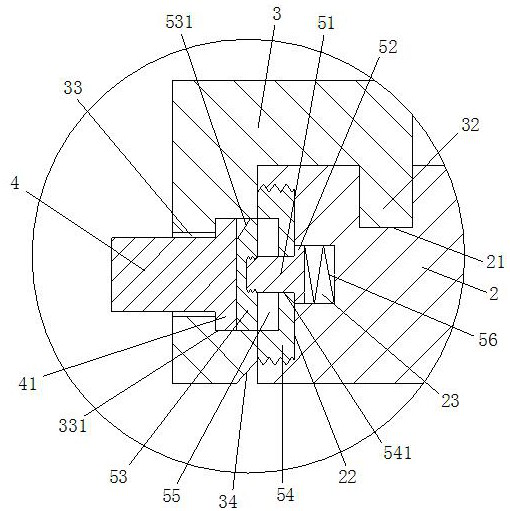

Air source plasma pyrography apparatus and painting method thereof

InactiveCN103465711AWorking temperature can be controlledReduce use costDecorative surface effectsPlasma generatorEngineering

The invention provides an air source plasma pyrography apparatus and a painting method thereof. The apparatus comprises a plasma generator and a plasma power supply. The plasma generator comprises a working handle, an external electrode and an internal electrode, wherein an internal electrode moving trail is arranged between the internal electrode and the external electrode, an air chamber is formed in the internal electrode, one end of the internal electrode and one end of the external electrode are respectively provided with a corresponding forced air outlet, a nozzle is arranged at one side of the external electrode provided with the forced air outlet, the handle is provided with a plasma intensity controller, a plasma connection switch and a fan, the plasma intensity controller is connected with the plasma connection switch through a lead, the plasma intensity controller is connected with the internal electrode and the external electrode through leads, the plasma connection switch and the fan are respectively connected with the plasma power supply through connecting lines, the fan is provided with an air inlet and an air inlet duct, and a forced air introducing channel is arranged between the air inlet duct and the air chamber. The apparatus provided by the invention is convenient to use, safe, reliable and portable.

Owner:YANGZHOU UNIV

Method for pyrographing on rice paper

InactiveCN101579989AGuaranteed StrengthShorten the timeDecorative surface effectsColor effectSurface layer

The invention discloses a method for pyrographing on rice paper, which comprises the following steps: spreading out the rice paper on a flat plate made from metals or inorganic matters; pyrographing with electric soldering iron; when line drawings are pyrographed, spraying hot air by a hot air gun to apply colors to the drawings; performing carbonizing treatment on the surface layer of the rice layer at different degrees; and dipping a pigment by using a sponge to knead colors on the drawings. Because the flat plate made from the metals or the inorganic matters has certain hardness and good heat radiating performance at the same time, the rice paper can be ensured not to be burnt out or singed so as to keep the original strength of the bottom surface of the rice paper. By using the method, the drawings not only have the style of pyrographies, but also have uncontemplated three-dimensional effect by using the hot air gun to apply colors to the drawings, and then through coloration, the color effect of the drawings is more enriched.

Owner:汤征

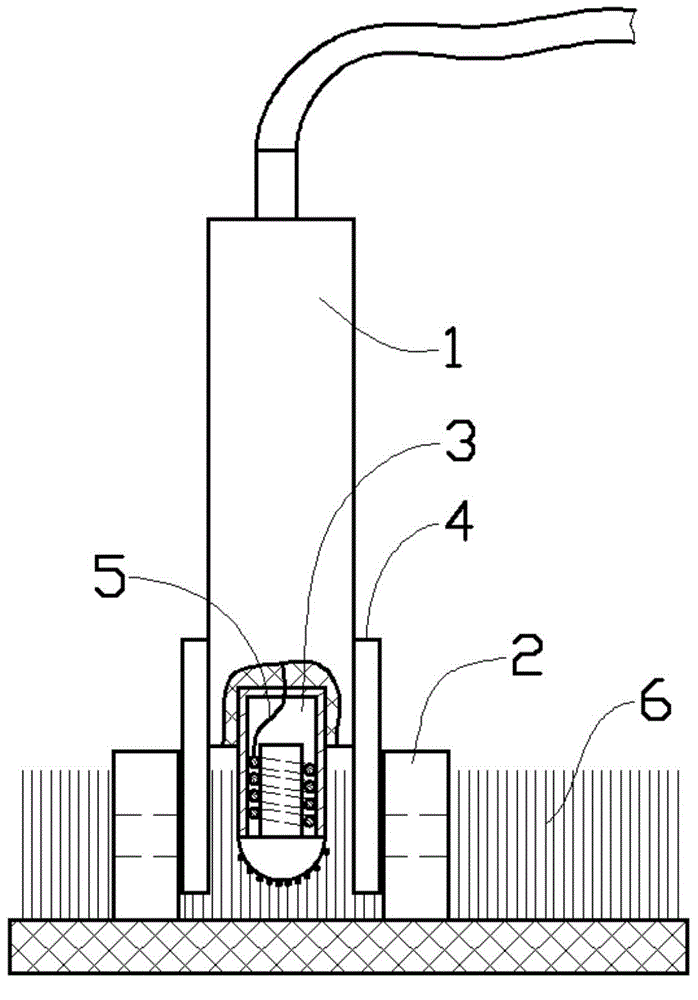

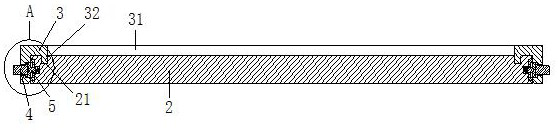

Flannelette handicraft pyrography bar

The invention provides a flannelette handicraft pyrography bar which comprises a holding rod, rollers and a heating rod, wherein the holding rod is cylindrical, and is vertically placed when in operation; connecting arms are symmetrically assembled on two sides of the lower part of the holding rod; the rollers, which can rotate around a shaft, are symmetrically assembled on two sides of each of the two connecting arms; the heating rod extending out downwards is assembled at the lower part of the holding rod; the lower part of the holding rod is spherical; the bottom end of the heating rod is 5-15 m higher than the bottom ends of the rollers. The operating principle of the flannelette handicraft pyrography bar is that in the power-up state, the heating rod is heated, the holding rod is held vertically by hand after heating, flannelette villus is tiled upwards, then the heating rod is inserted into flannelette, the rollers are attached to the flannelette, and in movement, required patterns are heat-pressed on the flannelette villus by the heating rod.

Owner:吴江双俊织造有限公司

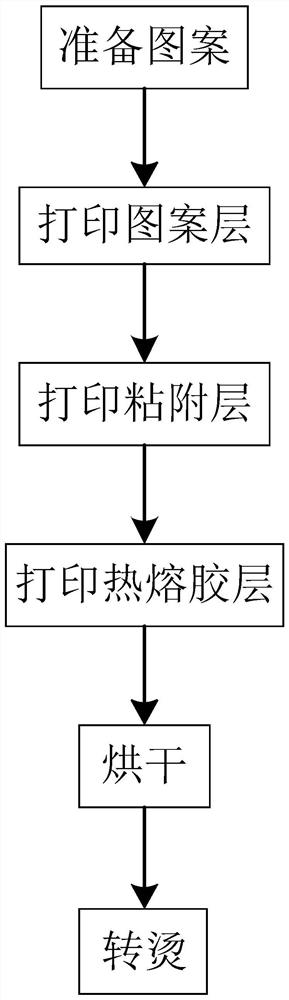

Digital pyrography method

InactiveCN111942050AEasy to produceEasy to operatePrinting after-treatmentInk transfer from master sheetProcess engineeringHot melt

The invention discloses a digital pyrography method. The method comprises the following steps of pattern preparation, pattern layer printing, adhesion layer printing, hot melt adhesive layer printing,drying and transfer hot printing. Ink dissolved with hydrosol is directly printed on a heat transfer printing base material through a printing device to form a hot melt adhesive layer, then the hot melt adhesive layer is dried to obtain a needed pattern, and the tedious steps of hot melt powder scattering, excessive hot melt powder removing, hot melt curing to form the hot melt adhesive layer andthe like are not needed. The digital pyrography method is simple in step, simple in production process, easy to operate, low in production cost, high in yield, high in practicability and suitable formarket popularization and application, and a large number of devices and equipment for production do not need to be used and maintained.

Owner:TAOTECH DIGITAL TECH

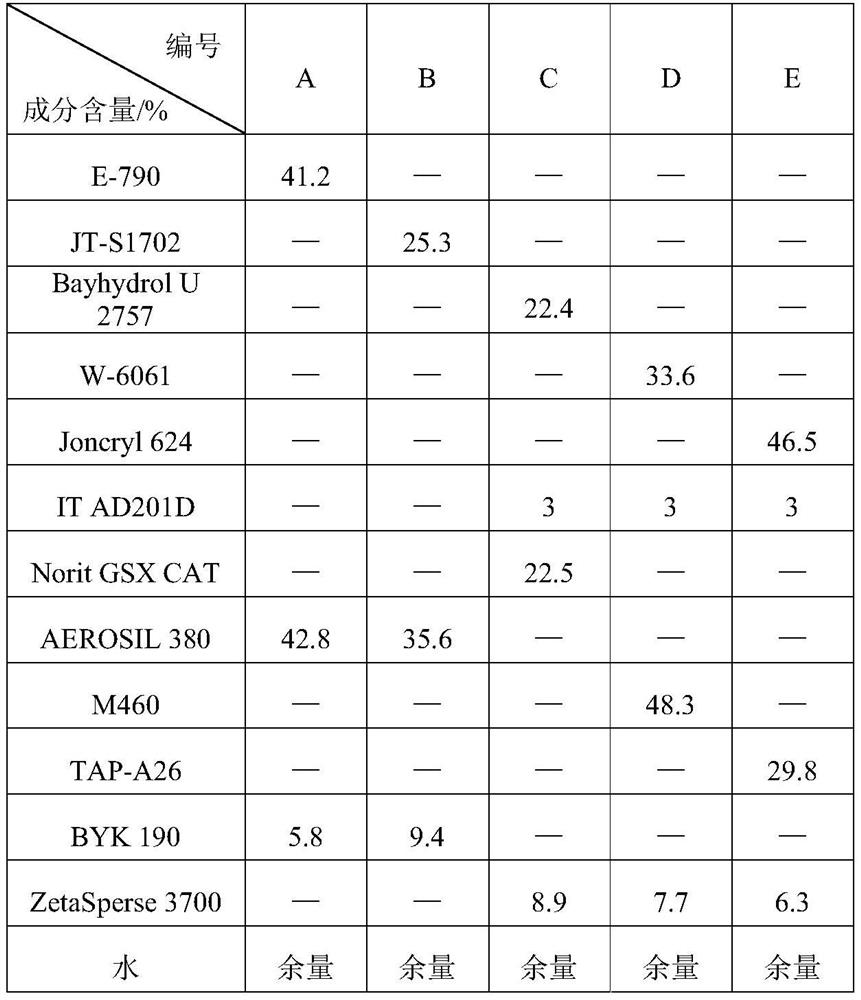

Anti-sublimation pyrography ink and preparation method thereof

ActiveCN112267315AHomogeneous dispersionEasy to integrateTransfer printing processDyeing processTextile printerPolymer science

The invention relates to the technical field of printing ink, in particular to anti-sublimation pyrography ink and a preparation method thereof. The anti-sublimation pyrography ink comprises anti-sublimation resin dispersoid, and the anti-sublimation resin dispersoid comprises water-based polymer resin, an adsorbent, an internal dispersing agent and water. The water-based polymer resin is modifiedacrylic resin or modified polyurethane resin or styrene acrylic resin with the molecular weight ranging from 10,000 to 500,000 and Tg smaller than or equal to 0 DEG C; the adsorbent is nano activatedcarbon or fumed silica or carbon black or activated aluminum oxide; and the anti-sublimation resin dispersoid accounts for 10%-30% of the total weight of the anti-sublimation pyrography ink. According to the pyrography ink, an ideal printing effect can be obtained on a dark-color fabric by directly carrying out heat transfer printing through a conventional pyrography process, the pyrography process can be simplified, the printing efficiency is improved, and the printing cost is reduced.

Owner:ZHUHAI FREE TRADE ZONE NEOJET APOLLOJET IMAGING MATERIALS

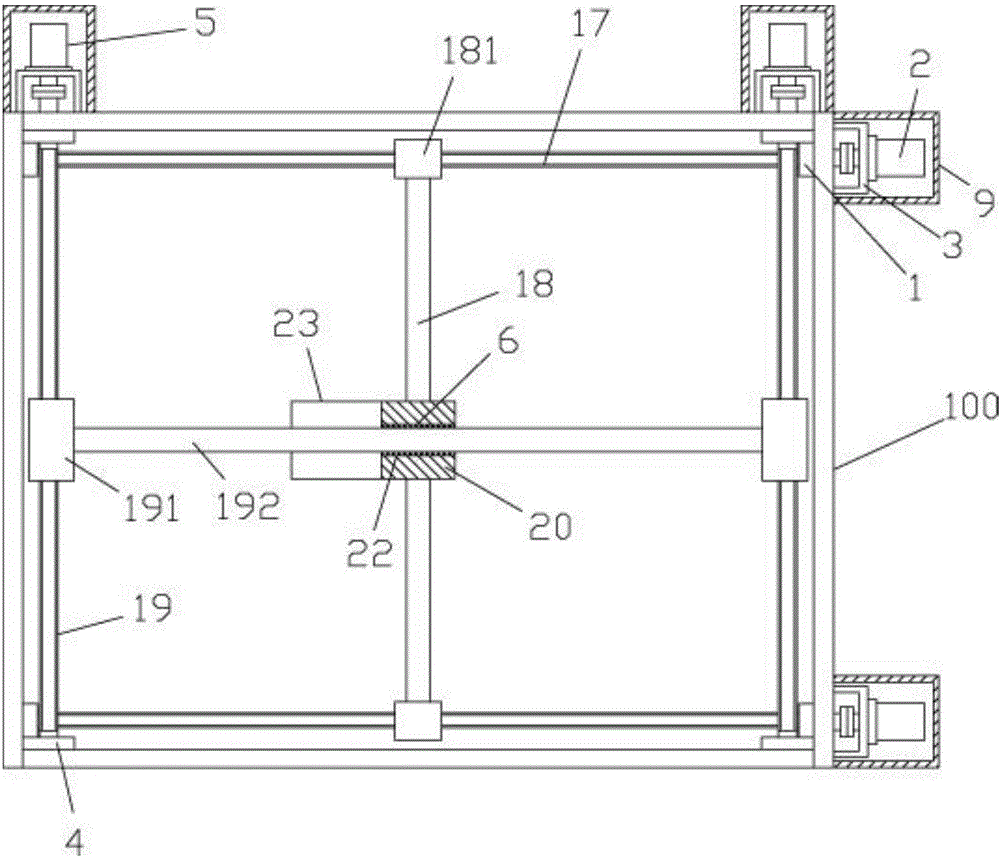

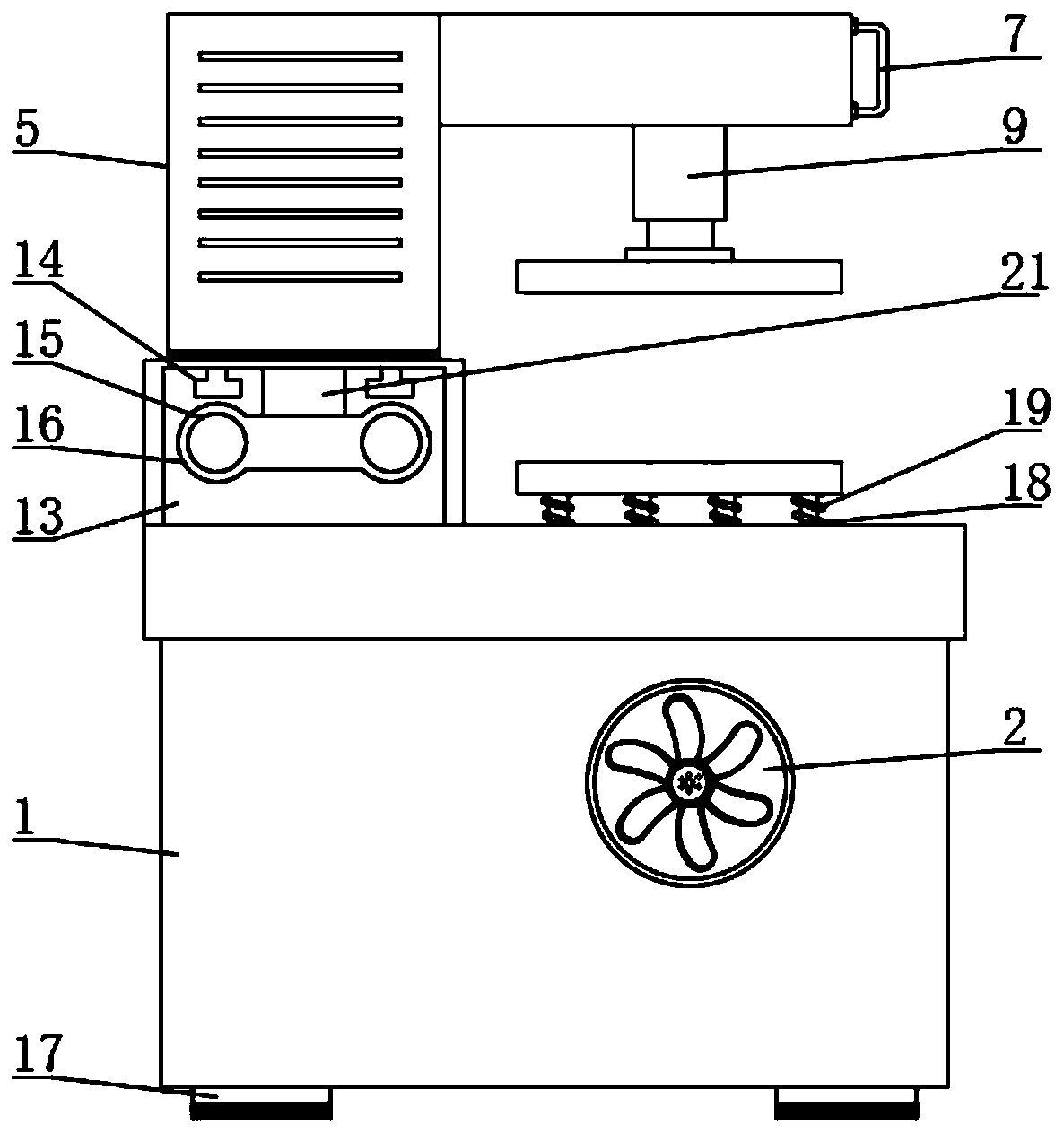

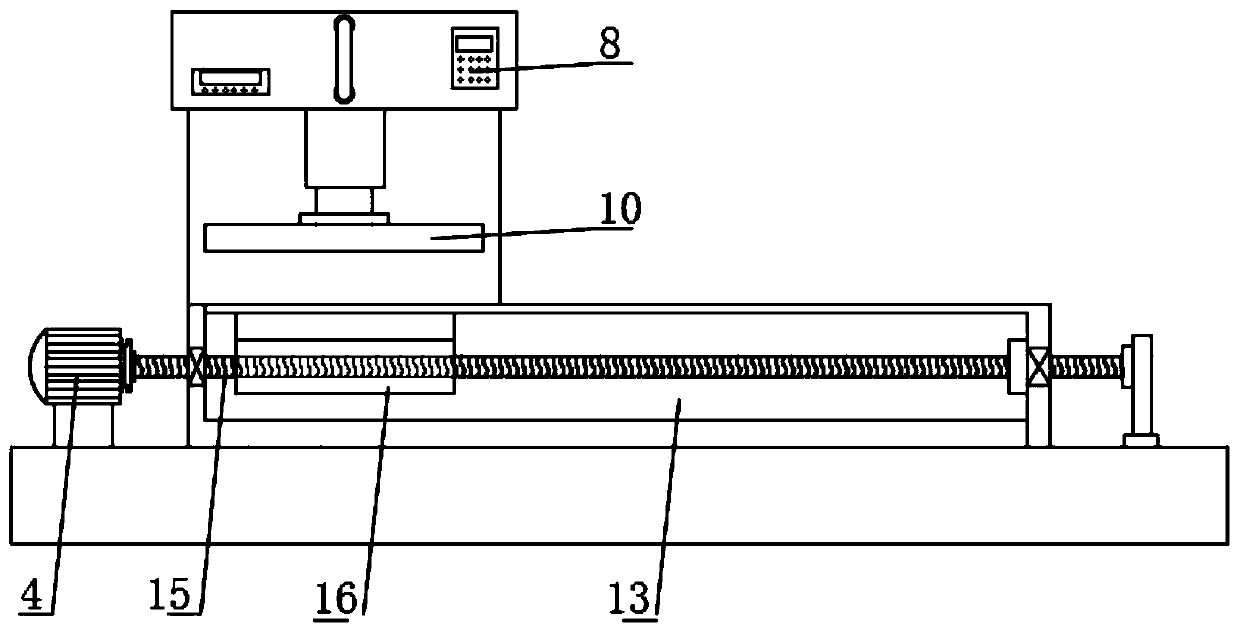

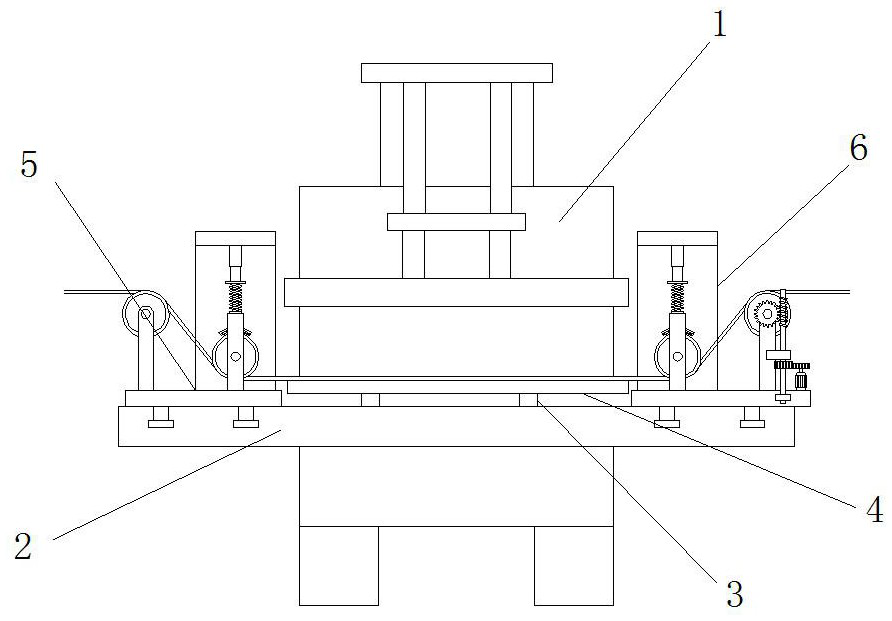

Double-station pyrography machine

InactiveCN110893714AImprove stabilityImprove work efficiencyTransfer printingElectric machineryEngineering

The invention discloses a double-station pyrography machine. The machine comprises a pyrography machine body, and a workbench is installed at a top of the pyrography machine body. In the invention, the pyrography machine body is provided with a double-station mode so that working efficiency is greatly improved. In this way, when an upper pressing plate and a lower pressing plate in the pyrographymachine are pressed, a worker can lay materials above the other lower pressing plate. After press fit is completed, the worker starts a stepping motor with a rotating speed adjusted in advance througha controller, then the stepping motor drives a screw rod at one end to rotate, and then the screw rod drives a threaded sleeve on a surface to rotate so that a pyrography mechanism moves to the position above the next lower pressing plate under rotation of the threaded sleeve, and press fit work is performed. And repeated working is performed. Through the above mode, the working efficiency is improved, a sliding block is installed at a bottom end of the pyrography mechanism and is connected with a first sliding rail arranged on the surface of the top of a movable table in a sliding mode, andstability of the pyrography mechanism in a moving process is improved through cooperation of the sliding block and the first sliding rail.

Owner:义乌市帝峰烫画有限公司

China paper pyrography root art character method

InactiveCN101117069AReliable workmanshipFor long-term storageDecorative surface effectsOxalateOXALIC ACID DIHYDRATE

A method of pyrographing root art character on rice paper is provided, wherein the contour line of a letterform is portrayed on rice paper, and then a writing brush is used for dipping in a preparation compounded with chemical materials on the edge of a double-hook word document; after the preparation compounded with chemical materials is smeared, the paper is dried a little and then ironed. The present invention is characterized in that the formulation of the preparation compounded with chemical materials contains 100 g of water added with 2-10 g of salt, 5-10 g of oxalic acid, 5-10 g of alum and 6-12 g of ammonium sulfate or zinc sulfate, wherein the salt makes the rice paper wet, thereby ironing pen is difficult to slip during pyrograph process; the alum plays a role in making the rice paper difficult to penetrating water; the ammonium sulfate and zinc sulfate play a role in flame retardancy; the oxalic acid playes a role in increasing colors. The present invention is reliable in process, greatly reduces the difficulty of pyrographing on the rice paper, does not hurt the rice paper, can be conserved for a long time, is natural and unsophisticated in the color of pyrograph root art character, has very good ornamental and decorative value, and has collection value, which can be used for other various pyrograph and various pyrograph in various paper characteristics.

Owner:陈 国梁

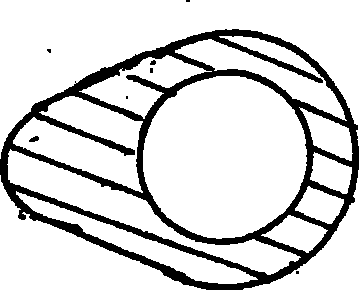

Electric pyrography tool

The present invention discloses a tool for an electrocautery picture, which consists of a handgrip and a cauterizing head, wherein the cauterizing head is provided with heating wires intertvined with a magnetic tube, and the heating wires are connected with conducting wires. The shape of the circumferential section of the magnetic tube is in the shape of a pebble-shaped closed curve, and the small head of the pebble-shaped closed curve faces to a picture board. The instrument for an electrocautery picture can cauterize various vivid pictures which are like the skill of traditional Chinese paintings according to different operating skills.

Owner:徐灿清

Novel clothing crease-resistant printing plane pyrography machine and mounting method thereof

InactiveCN112519397AEasy to removeCause wrinklesTransfer printingTextile printerStructural engineering

The invention relates to the field of plane pyrography machines, in particular to a novel clothing crease-resistant printing plane pyrography machine which comprises a main body, a bottom plate is arranged on the main body, a frame fixer is arranged on the bottom plate, and under the action that a pressing block of the frame fixer is matched with a corresponding pressing groove in the bottom plate, clothes flatly laid on the bottom plate can be pressed into the pressing groove through the pressing block, so that a clothes frame is fixed, the clothes cannot be wrinkled only when the clothes arepressed downwards through a pressing plate to be subjected to pyrography, flatness of the surface of the clothes during pyrography is guaranteed, and meanwhile under the action of fixators on the twosides of the bottom plate, the frame fixer can be conveniently fixed on the bottom plate so as to prevent the frame fixer from being easily separated from the bottom plate to cause wrinkles of clothes, and the frame fixer can be conveniently detached from the bottom plate under the action of a button.

Owner:晋江市激化贸易有限公司

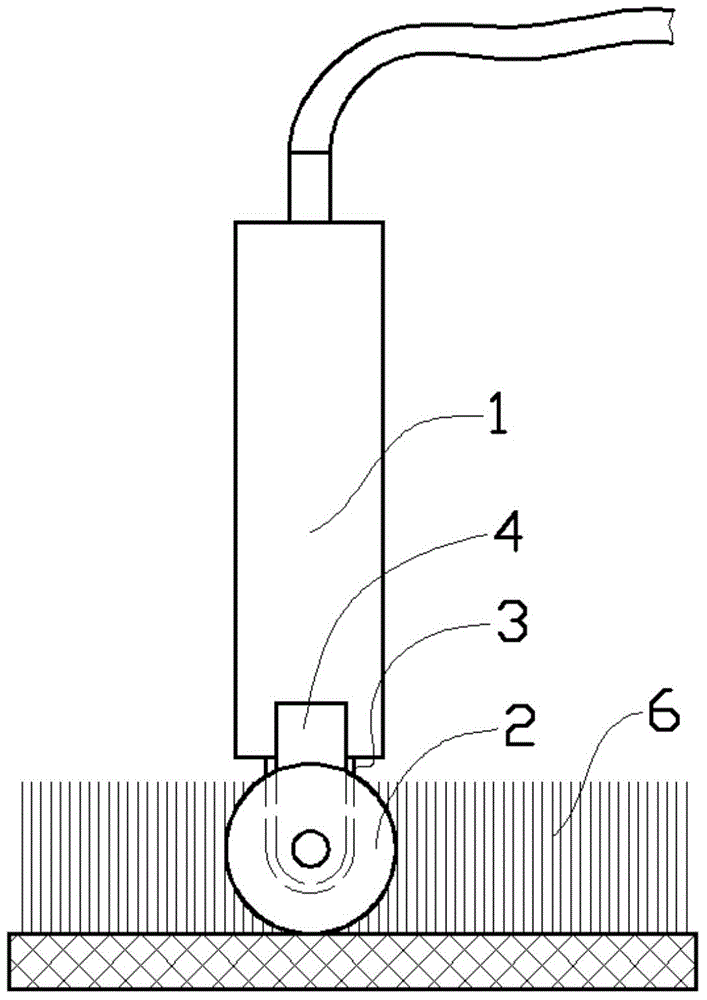

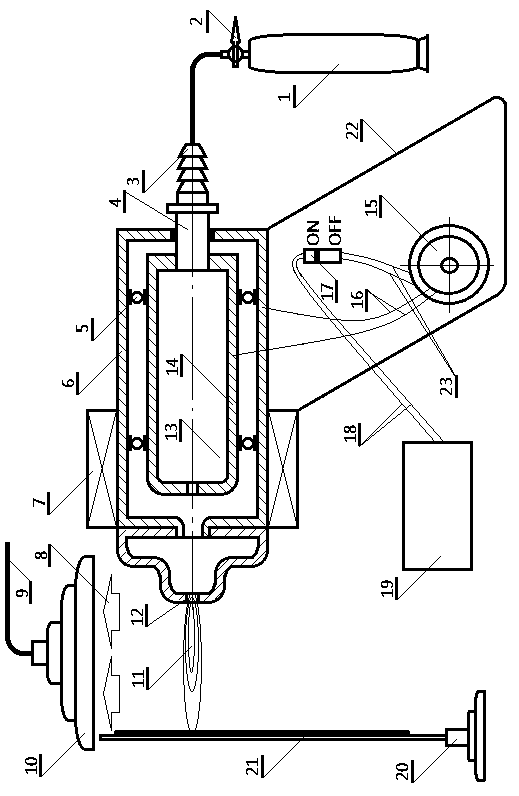

Plasma torch pyrographic device and drawing method thereof

InactiveCN103465709AImprove adaptabilityReal-time control of heating powerBranding equipmentDecorative surface effectsPlasma generatorSpray nozzle

The invention relates to a plasma torch pyrographic device and a drawing method thereof. The plasma torch pyrographic device comprises a gas supply device, a plasma generator, a plasma power supply and a plasma torch spray nozzle. The plasma generator comprises a handle, an outer electrode and an inner electrode. An inner electrode moving track is arranged between the inner electrode and the outer electrode. A gas chamber is formed in the inner electrode. A pressure gas intake passage and a pressure gas outlet are respectively and correspondingly formed in the middle parts of the two sides of the inner electrode and the outer electrode. The spray nozzle is arranged on one side of the outer electrode. A plasma intensity adjuster and a power switch are arranged on the handle and are connected through conducting wires. The plastic intensity adjuster is connected with the inner electrode and the outer electrode. The gas supply device is connected with the gas chamber through the pressure gas intake passage. By applying a plasma torch technique to pyrography, the plasma torch pyrographic device and the drawing method thereof have the advantages that the heating power is controlled in real time, the response speed is fast, the operation is convenient to perform, the adaptability to drawing materials is good, the safety and the reliability are high, and the like.

Owner:YANGZHOU UNIV

Wrinkled jacquard-like fabric and manufacturing technology thereof

ActiveCN108642647ALittle resistanceReduce frictionPattern makingHeating/cooling textile fabricsPolyesterManufacturing technology

The invention relates to a wrinkled jacquard-like fabric and a manufacturing technology thereof, and belongs to the technical field of textile fabric production and processing. The wrinkled jacquard-like fabric is formed from, by mass, 24-34% of warp and 65-75% of weft through plain weave; longitudinal and transverse three-dimensional stripes are formed through wrinkling, the warp is 20-30 D polyamide yarn or polyester yarn, and the weft is 30-60 S cotton yarn or T / C yarn. The manufacturing technology of the wrinkled jacquard-like fabric includes the steps of grey fabric weaving, dyeing, washing with water or reduction clearing, shaping, hot roll wrinkling, inspection, packaging and warehousing. The longitudinal and transverse three-dimensional stripes similar to jacquard and different indensity are formed through wrinkling, a natural texture is formed, and the jacquard-like effect is vivid; the surface of the fabric is endowed with the dotted flash effect through gold powder or silver powder pyrography. The jacquard pattern is flexible and natural, and the fabric is good in texture and hand feeling, light, thin and transparent, free of deformation after being washed many times, high in benefit, high in yield, low in cost, wide in application range and the like.

Owner:绍兴水乡纺织科技有限公司

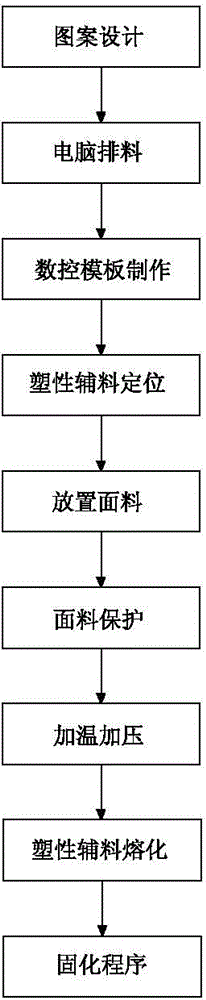

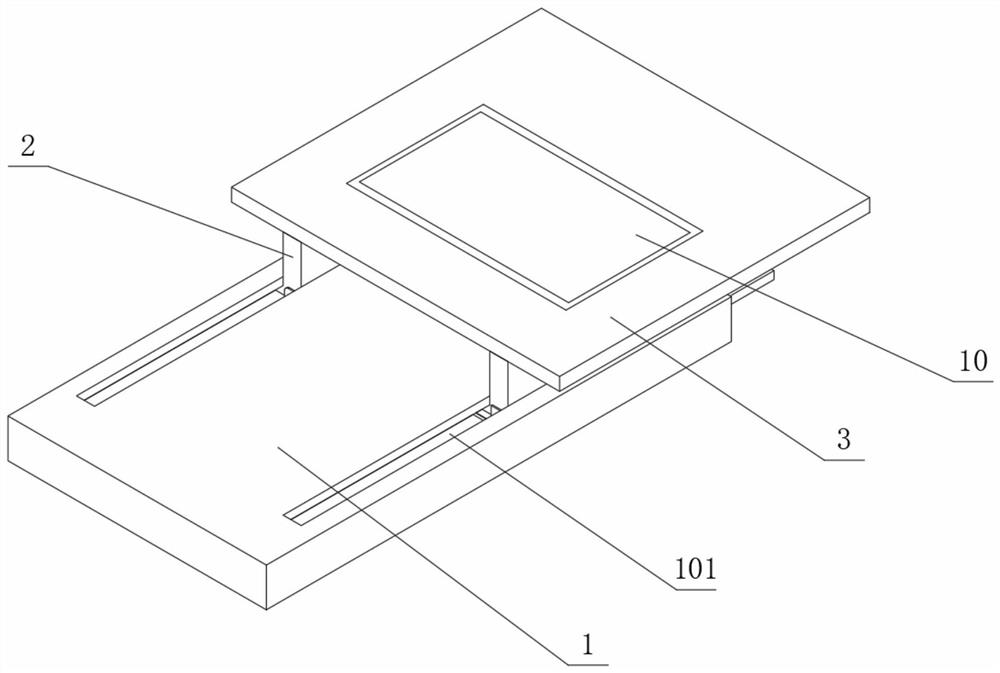

Process method for plastic stamping

The invention discloses a process method for plastic stamping. The process method for plastic stamping comprises the following steps: (1) pattern design; (2) computer material arrangement; (3) numerical control template production; (4) plastic accessory location; (5) fabric placement; (6) fabric protection; (7) heating and pressing; (8) plastic accessory melting; and (9) curing procedure. According to the invention, plastic accessories are located by virtue of a template, the stamped fabric is placed in a proper range of the template, and stamped through a hot stamping machine, and the plastic accessories are melted and bonded onto the fabric under proper temperature, time and pressure, thus the plastic accessories are fixed and form a pattern. The plastic stamping method disclosed by the invention is capable of replacing a part of the traditional manual beading, and further capable of achieving efficient production; the plastic accessories can be much directly melted, fixed and bonded onto the fabric compared with stamping stones and stamping sheets, and one less hot-melt adhesive layer is processed, thus the cost is reduced and the environmental protection concept is met; and moreover, higher standardization and normalization are achieved, and other processes such as embroidery and pyrography can further be mixed to create more different appearances, and then the market competitiveness of products is improved.

Owner:东莞市腾锐智创知识产权有限公司

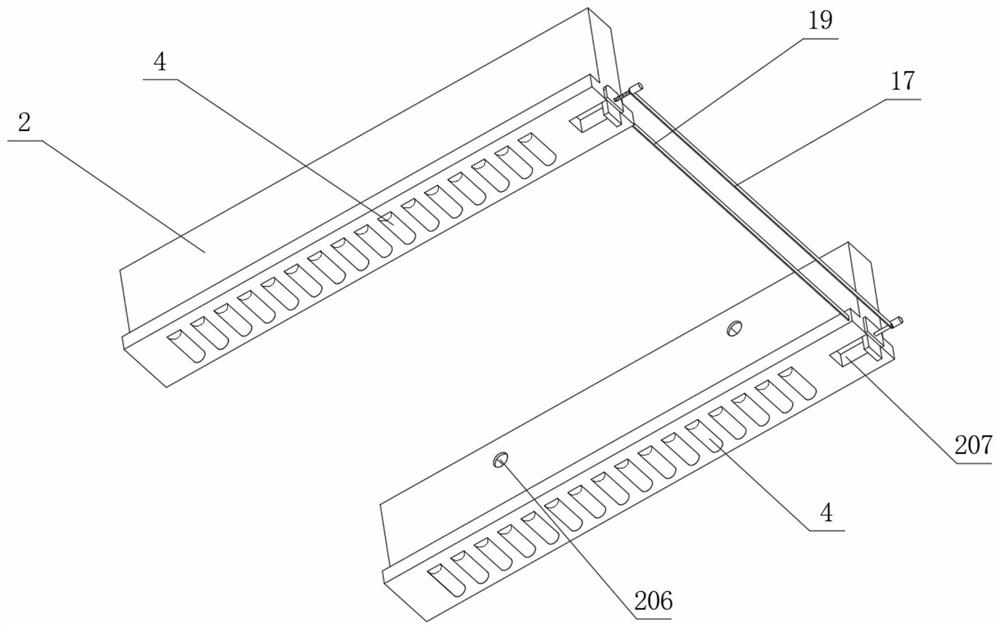

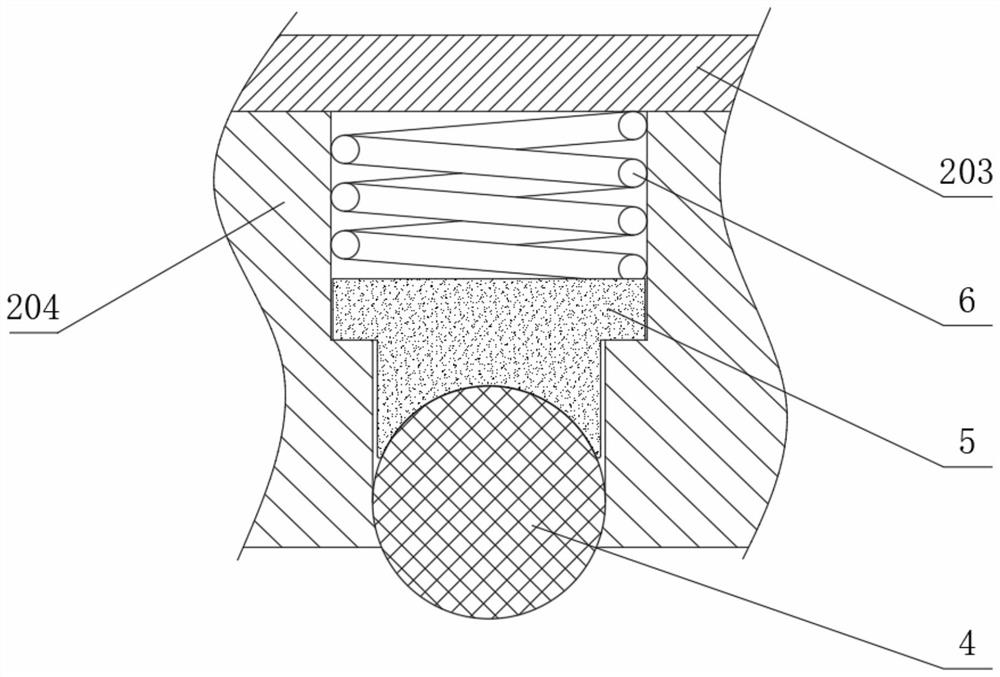

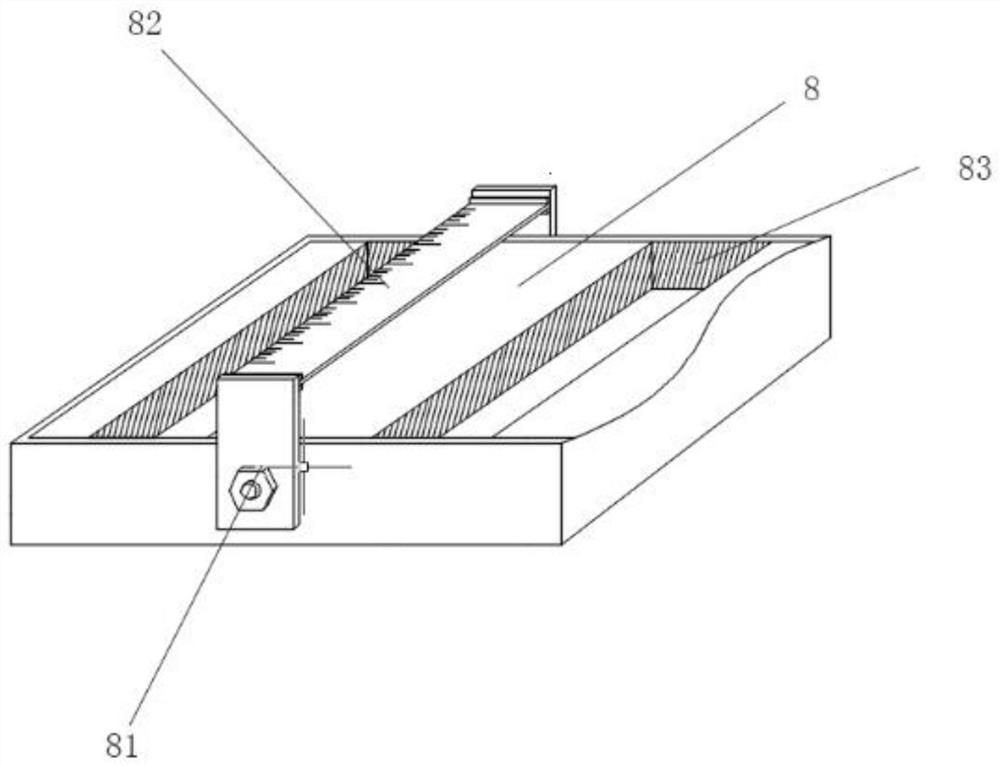

Pyrography machine lower plate seat capable of automatically adjusting levelness

The invention relates to a pyrography machine lower plate seat capable of automatically adjusting levelness, which comprises a horizontal bottom plate, two parallel sliding chutes are formed in the top end of the bottom plate, a supporting seat in sliding connection with the sliding chutes is arranged in the sliding chutes, and a drawing board in clamping connection with the supporting seat is arranged at the top end of the supporting seat; a plurality of roller grooves are formed in the bottom end of the supporting seat in the length direction of the sliding grooves, rollers are arranged in the roller grooves, and shaft sleeves connected with the roller grooves in an up-down sliding mode are arranged between the roller grooves and the rollers. According to the pyrography machine lower plate seat capable of automatically adjusting the levelness, the rollers moving up and down in the roller grooves are used for keeping parallel to an upper plate, the situation that the lower plate seat cannot be tightly attached to the upper plate after being heated and deformed is effectively prevented, and the pyrography effect is guaranteed; the base plate is supported by a base capable of automatically adjusting the horizontal position, the base corrects the height difference of the four corners of the base by recognizing the inclined direction, the adjusting mode is accurate and reliable, and the levelness of the base and the drawing board on the base is effectively guaranteed.

Owner:福建欣弘机电设备有限公司

Process for the manufacture of plant gourd braided handicraft picture

InactiveCN1206118CBright colorOvercome the disadvantages of monotonous appearanceDecorative surface effectsSpecial ornamental structuresGourdEngineering

The invention relates to a method for preparing plant gourd pyrography crafts. It is characterized in that it is prepared according to the following steps: scrape off the outer skin of the natural plant gourd, clean it, soak it in the treatment agent for coloring, hang it on a rope to dry it, burn it and carve it to obtain the handicraft. The method of the invention can make the color of the natural plant gourd bright and golden, and various patterns can be drawn on the surface of the gourd, which overcomes the shortcoming of the monotonous appearance of the traditional gourd. The handicraft has a long shelf life and does not need any coloring. It is natural, simple, elegant and unique. It is in line with people's concept of the times of returning to basics and returning to nature and the requirements of developing green handicrafts.

Owner:临沧地区农业学校工艺葫芦开发中心

Pyrography water-based white ink suitable for Epson nozzle, and preparation method thereof

InactiveCN113214705ASolve technical problems such as mutual halo and insufficient fastnessGood continuous printing performanceInksTextile printerActive agent

The invention discloses pyrography water-based white ink suitable for an Epson nozzle, and a preparation method thereof, and belongs to the technical field of printing ink. The pyrography water-based white ink suitable for the Epson nozzle is prepared from, by mass,20 to 40 percent of a pigment dispersion liquid, 20 to 40 percent of resin, 0.2 to 3 percent of a curing agent, 0.1 to 0.5 percent of an acid-base regulator, 10 to 30 percent of a wetting agent, 0.2 to 2.0 percent of a surfactant, 0.1 to 0.2 percent of a bactericide, and the balance of water. The printing fluency on all Epson sprayers is good, the standby performance is good, the fastness is high, moisture regaining is not prone to occurring, covering is good, ink flowing of any film is avoided, and mutual halo of color ink is avoided.

Owner:珠海君奥新材料科技有限公司

UV flashing three-dimensional pyrography packaging box printing process

ActiveCN112829489ALower surface free energyReduce the binding forcePattern printingInksMethacrylatePolymer science

The invention discloses a UV flashing three-dimensional pyrography packaging box printing process. During printing, the surface of a packaging box is printed through a process of conducting printing after conducting pyrography. During actual operation, firstly, component selection of an electrochemical aluminum film is adjusted, components such as hydrogen-containing silicone oil, vinyl silicone oil, perfluoroalkyl ethylene and 2- (diethylamino) ethyl methacrylate are selected during preparation, the hydrosilylation effect is generated under the effect of a platinum catalyst (chloroplatinic acid-isopropanol mixed solution), and accordingly, a formed mutually-crosslinked organic silicon release layer has an excellent release demolding effect during use. The process is reasonable in design and appropriate in component ratio, the surface pattern of the prepared packaging box is clear, the printing effect is excellent, the cost is low, the process is simple and easy to operate, the process is suitable for large-scale production and application, the ink printing adhesive force is good, and high practicability is achieved.

Owner:CHANGZHOU YADE PRINTING

Anti-deviation mechanism of textile clothing heat transfer printing pyrography device and using method of anti-deviation mechanism

InactiveCN113478953AEasy to useRealize automatic adjustmentTransfer printingPrinting press partsEngineeringPyrography

The invention discloses an anti-deviation mechanism of a textile clothing heat transfer printing pyrography device and a using method of the anti-deviation mechanism, and particularly relates to the field of textile. The anti-deviation mechanism comprises a device base, a feeding box and a pyrography box are fixedly arranged on the top surface of the device base, a first lifting rod is fixedly arranged on the top surface of the pyrography box, a pressing top seat is fixedly arranged on the top surface of the first lifting rod, a pressing rod is fixedly arranged on the bottom face of the pressing top seat, a pressing head is fixedly arranged on the bottom face of the pressing rod, a supporting column is fixedly arranged on the bottom face of an inner cavity of the pyrography box, a pressing table is fixedly arranged on the top face of the supporting column, and anti-deviation mechanism bodies are slidably arranged on the top face of the pressing table. According to the scheme, the anti-deviation mechanism of the textile clothing heat transfer printing pyrography device has the effects that the anti-deviation mechanism bodies are arranged, an infrared emitter and an infrared receiver are used for judging whether a textile material is subjected to wrinkling deviation or not in the conveying process, and if deviation occurs, a controller can control an alarm to give an alarm to remind a worker, so that the usability of the device is improved.

Owner:桐乡市顶帅服饰科技有限公司

Anti-deviation mechanism of pyrography device for textile processing

ActiveCN112391783AEasy to replace and maintainPrevent rotationPattern makingWebs handlingPyrographyIndustrial engineering

The invention discloses an anti-deviation mechanism of a pyrography device for textile processing. The anti-deviation mechanism comprises a pyrography device body, wherein a workbench is fixedly installed on the outer wall of one side of the pyrography device body, a pressed plate is arranged at the top of the workbench, a first limiting mechanism is inserted into one end of the top of the workbench, a second limiting mechanism is inserted into the other end of the top of the workbench, each of the first limiting mechanism and the second limiting mechanism comprises a supporting plate, fixingrods are welded to the four corners of the bottom of each supporting plate, sliding blocks are fixedly connected to the bottoms of the four fixing rods, and a connecting plate is fixedly connected toone end of the top of each supporting plate. Textile passes through the first limiting mechanism and the second limiting mechanism, the textile makes contact with the pressed plate, the pyrography device conducts pyrography operation on the textile on the pressed plate, and the problem that when an existing pyrography device conducts pyrography on textile, due to the fact that the textile cannot be positioned, the position of the textile deviates can be solved.

Owner:吴江市万旺纺织有限公司

China paper pyrography root art character method

InactiveCN100560382CReduce difficultyGood colorDecorative surface effectsOXALIC ACID DIHYDRATEColor effect

A method of pyrographing root art characters on rice paper. Firstly, double-hook the characters on the back of the rice paper, and then use a brush to dip a preparation prepared from a chemical raw material on the edge of the double-hook character draft, and then fill in the chemical raw material. After preparing the prepared preparation, dry it slightly, and then roast it. It is characterized in that: the preparation of the preparation prepared from chemical raw materials is as follows: 100 grams of water plus 2-10 grams of salt, 5-10 grams of oxalic acid, 5-10 grams of alum , 6-12 grams of ammonium sulfate or zinc sulfate. Salt makes the rice paper moist, and the ironing pen is not easy to slip during pyrography; alum makes the rice paper not permeable; ammonium sulfate and zinc sulfate play the role of flame retardancy; oxalic acid plays the role of adding color. It can be used for other kinds of pyrography and various pyrography of various papers.

Owner:陈 国梁

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com