Full-automatic pyrography machine

A fully automatic, painting machine technology, applied in the direction of the machine for branding, painting tools, special decorative structures, etc., can solve the problems of labor-consuming, physical strength, manual can not work continuously, etc., to achieve good effect and high degree of automation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

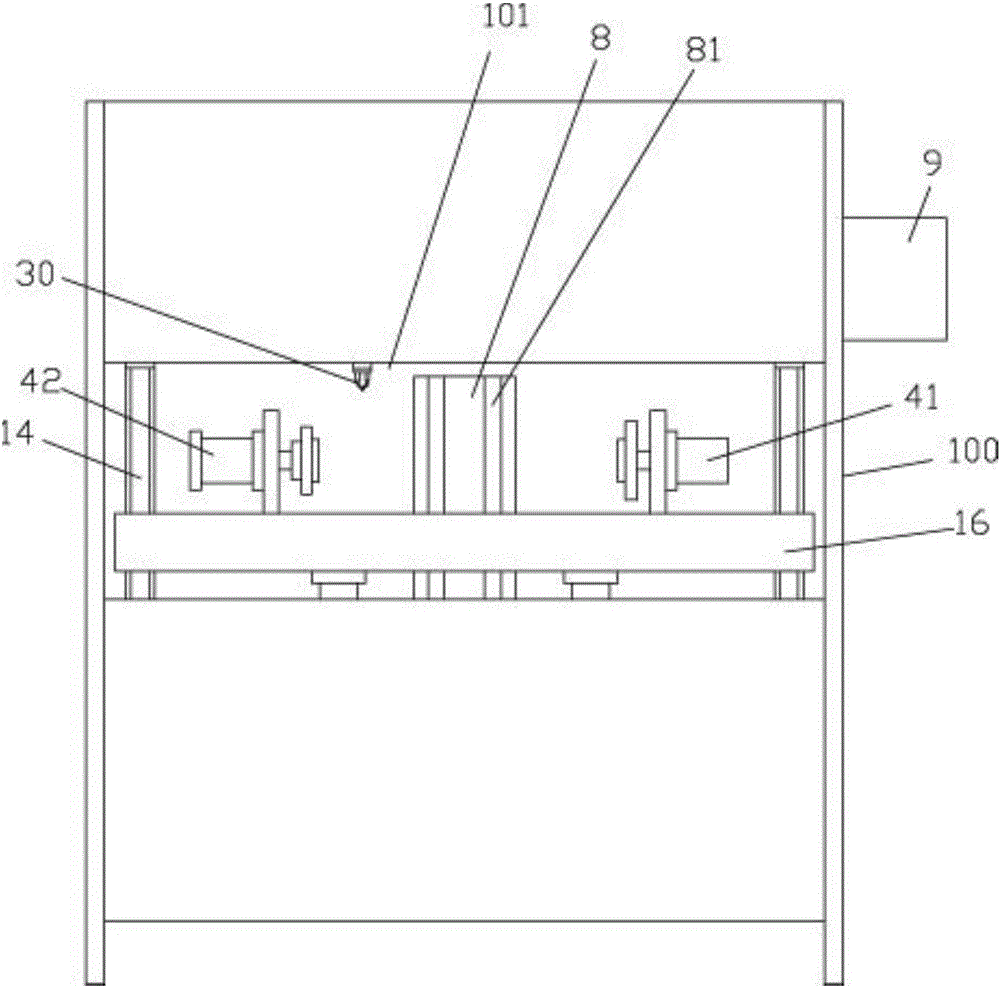

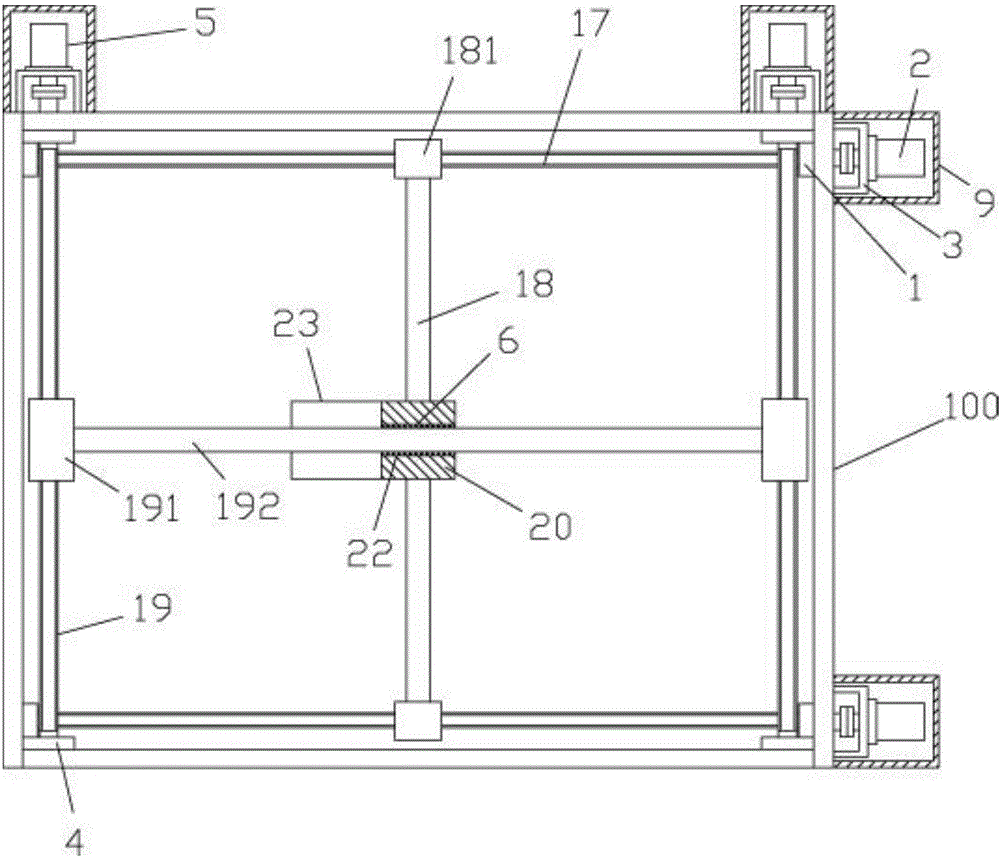

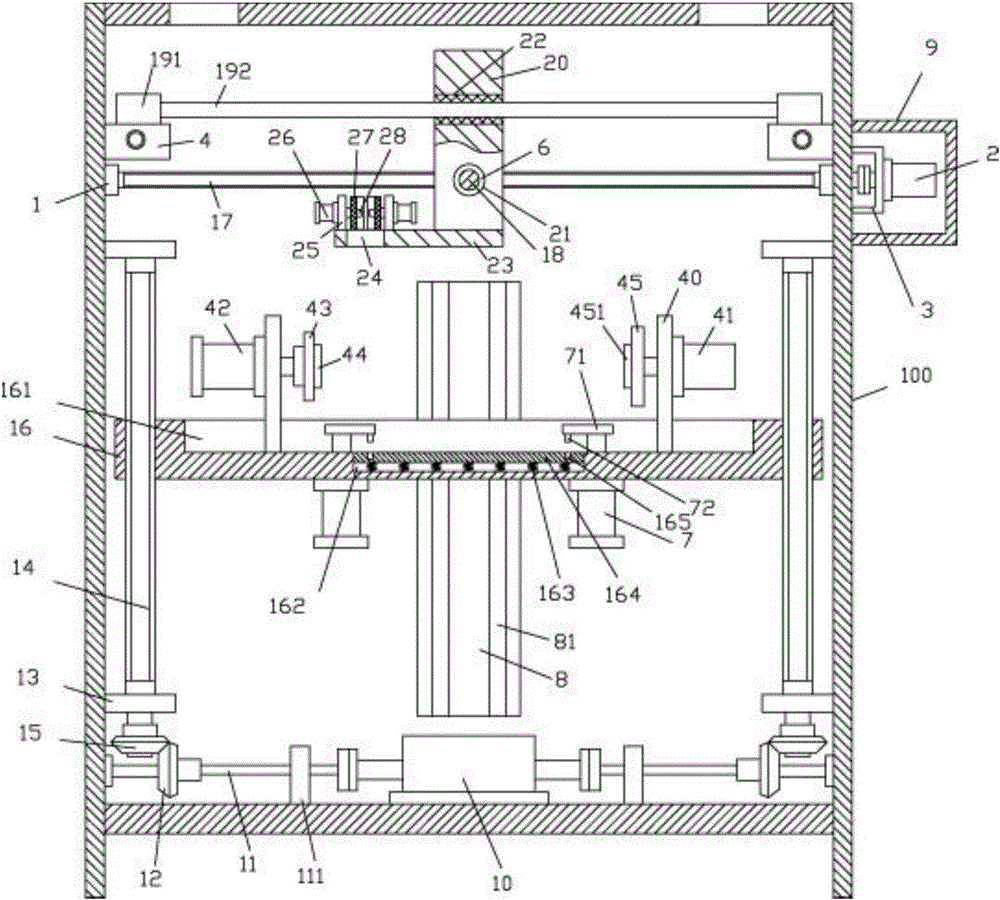

[0025] Example, see as Figure 1 to Figure 6 As shown, a fully automatic pyrography machine includes a chassis 100. The middle of the front plate of the chassis 100 has a feeding and discharging through slot 101, and the middle of the top surface of the bottom plate of the chassis 100 is fixed with a double output shaft servo motor 10 , The two connecting shafts 11 are located on both sides of the double-out shaft servo motor 10, one end of the connecting shaft 11 is connected with the output shaft of the double-out shaft servo motor 10 through a coupling, and the other end of the connecting shaft 11 is hinged to the corresponding chassis On the left or right side plate of 100, the drive bevel gear 12 is fixed on the connecting shaft 11, and the inner side walls of the left side plate and the right side plate of the chassis 100 are fixed with two support plates 13 arranged up and down, and a drive screw 14 The two ends of the drive screw 14 are hinged on the two support plates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com