Plasma torch pyrographic device and drawing method thereof

A technology of plasma torch and plasma, which is applied in decorative arts, machines for branding, and techniques for producing decorative surface effects, etc., can solve the problems of long waiting time, complicated operation process, and low work efficiency, and achieve Strong coloring adhesion, clean working environment and fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further explained below in conjunction with the specific implementation of examples.

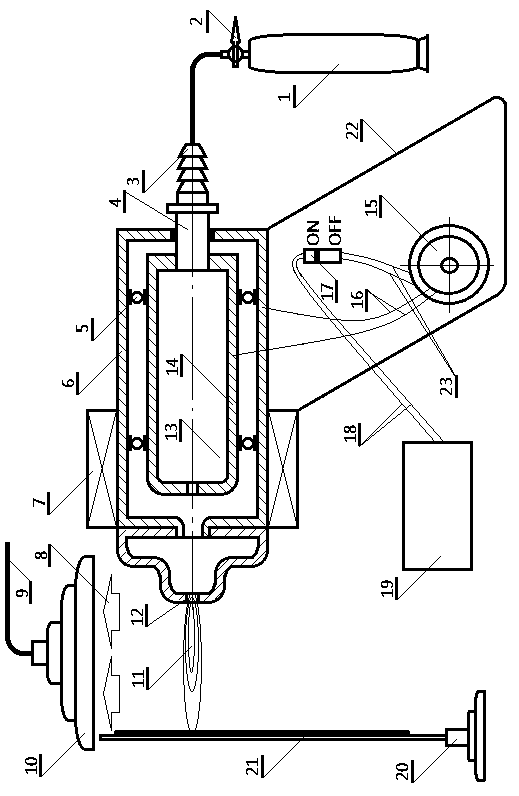

[0024] A plasma torch pyrography device includes a gas source supply device, a plasma generator, a plasma power supply 19 and a nozzle 12.

[0025] The plasma generator includes a handle 22 and an outer electrode 3 and an inner electrode 14 arranged above the handle 22 .

[0026] An inner electrode moving track 5 is installed between the inner electrode 14 and the outer electrode 6 , and the inner electrode 14 is arranged in the outer electrode 6 through the inner electrode moving track 5 . Gas cells 13 are formed within the internal electrodes. The middle parts of both sides of the inner electrode 14 and the outer electrode 6 correspond to the process pressure gas introduction channel 4 and the pressure gas outlet respectively. The nozzle 12 is installed on the side of the external electrode 6 where the pressure gas outlet is provided.

[0027] A plas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com