Process method for plastic stamping

A process method and plastic technology, which is applied in the fields of paper products, fabrics, apparel, clothing, and gifts, can solve problems such as rising labor costs, low production efficiency, and increased costs, and achieve high-efficiency production, good standards and norms, and reduced production costs. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

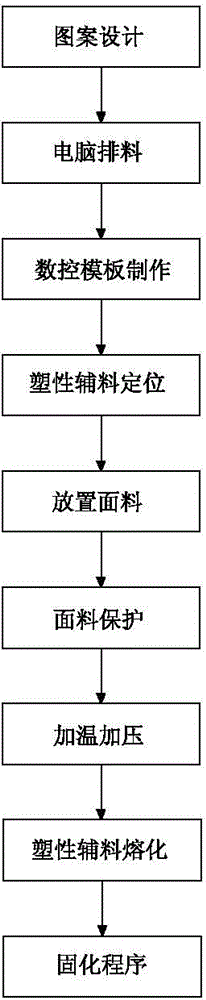

[0028] Please refer to figure 1 As shown, the present invention discloses a kind of hot molding process, comprising the following steps:

[0029] (1) Pattern design: set the appearance and size of the pattern.

[0030] (2) Computer layout: Use computer drawing software to discharge patterns according to the size and shape of plastic accessories.

[0031] (3) Numerical control template production: convert the computer graphic file into data and input it into the numerical control cutting tool. The heat-resistant template made by cutting equipment, the concave position on the template is slightly larger than the plastic auxiliary material placed, so as to be easy to put in and out of the mold, the height of the template is lower than the height of the plastic auxiliary material, and its height must be appropriate , before it can be properly contacted with the heating equipment for the heating and pressing process, otherwise the plastic accessories will not be directly heated a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com