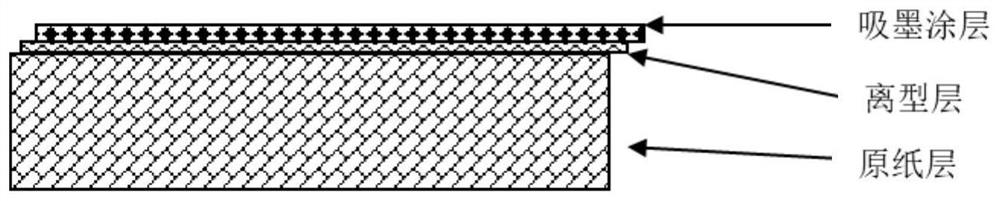

Coating composition for pyrography transfer paper, pyrography transfer paper and preparation methods of coating composition and pyrography transfer paper

A technology of coating composition and transfer printing paper, applied in the direction of transfer printing, coating, paper coating, etc., can solve the problems of high price and cost of PET substrate, long time for screen printing plate making, and non-environmental protection of ink materials, etc. Achieve the effects of preventing ink penetration, good flexibility and adhesion properties, and simple and convenient preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

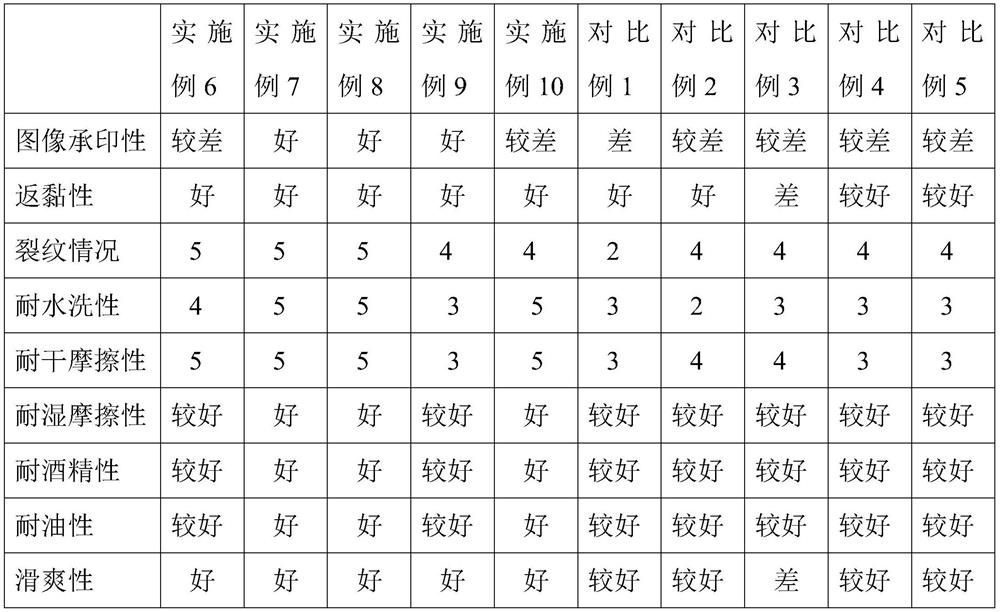

Examples

Embodiment 1

[0042] A coating composition for heat transfer transfer paper, 36 parts by weight, including 36 parts of cation exchange resin, 20 parts of a fixture, butadiene, butadiene copolymerized emulsion, 10 aqueous polyurethane, hard 2 parts of lipohydrate, 30 parts of silica, and 1 polyorganoxane. The cation exchange resin is a copolymer of unmodified styrene and disylene blene; the fixing agent is a censorylpyridine chloride; the aqueous polyurethane is an unmodified aqueous aliphatic polyether polyurethane.

[0043] The preparation method of coating composition of hot transfer transfer paper is as follows:

[0044] 1), in accordance with the ratio, add a certain amount of water into the high speed dispersion tank, then put the calcium stearate emulsion, form dispersion with dispersion, 5MIN at a rotational speed of 500R / min;

[0045] (2), then insertion of silica, dispersion of 30 min under the rotational speed of 2000R / min to obtain a dispersion of silica;

[0046] (3) Raw materia...

Embodiment 2

[0049] A coating composition for hot transfer transfer paper, 20.5 parts of a cation exchange resin, 40 parts of a cation exchange resin, 0.7 parts of a fixture, butadiene and a pyrene, 10 parts of aqueous polyurethane, hard 1.8 servivate emulsions, 26 silicon dioxide, and 0.5 copolymer silicone. The cation exchange resin is a copolymer of a sulfonic acid-based modified acrylate and a diomide; the fixing agent is a cetylpyridine of bromide; the aqueous polyurethane is aldehyde modified nuclear shell type aqueous acrylic modification Polyurethane. Preparation method

[0050] Example 1

Embodiment 3

[0052] A coating composition for heat transfer transfer paper, 32.6 parts of a cation exchange resin, 26.8 parts of a fixed agent, butadiene, and a waterborne polyurethane, hard polyurethane. 1.8 parts of lipohydrate emulsion, 28 parts of silica, and 0.8 copolymer silicone. The cation exchange resin is a copolymer of carboxylic acid-based modified styrene and disylene blene; the fixing agent is a dialkyl methacrylate; the aqueous polyurethane is acetyl acetyl-modified nuclear shell type aqueous acrylic acid Modified polyurethane. The preparation method is in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Tightness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com