Pyrography film and production process thereof

A production process and a technology on the other side, applied in the field of heat transfer film and its production process, can solve the problems of limited water resistance, insufficient adhesion, and unfavorable long-term preservation of patterns, and achieve good adhesion, weather resistance, and coloring properties. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

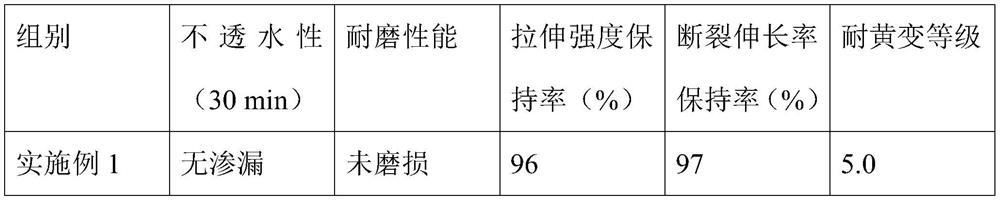

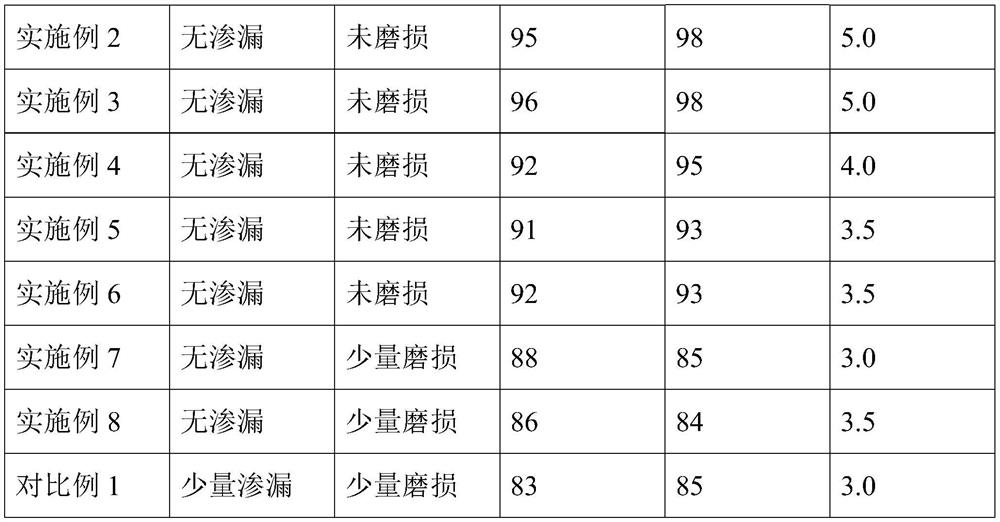

Examples

Embodiment 1

[0053] This embodiment provides a heat transfer film, which includes a release layer of 8 μm, a base layer of 20 μm, a release layer of 15 μm, a polyurethane layer of 10 μm, an ink layer of 12 μm and an adhesive layer of 30 μm connected in sequence.

[0054] The raw materials for the preparation of polyurethane in the polyurethane layer include 30 parts of diisocyanate (isophorone diisocyanate), 60 parts of polyethylene glycol (MW=6000), 10 parts of chain extender (ethylene glycol), catalyst (octanoic acid ethylene glycol) Tin) 5 parts, antioxidant (CHEMNOX 1076) 5 parts, mesoporous silica nanoparticles (average particle diameter 400nm) 30 parts.

[0055] Its preparation method is:

[0056] (1) Coat the release layer on one side of the base layer and dry at 80°C for 7 hours;

[0057] (2) Coat the polyurethane layer on the side of the release layer away from the base layer, and dry at 40°C for 3 hours;

[0058] (3) Coat the ink layer on the side of the polyurethane layer away...

Embodiment 2

[0062] This embodiment provides a heat transfer film, which includes a release layer of 5 μm, a base layer of 15 μm, a release layer of 15 μm, a polyurethane layer of 10 μm, an ink layer of 10 μm and an adhesive layer of 30 μm connected in sequence.

[0063] The raw materials for the preparation of polyurethane in the polyurethane layer include 20 parts of diisocyanate (hexamethylene isocyanate), 40 parts of polyethylene glycol (MW=4000), 5 parts of chain extender (ethylenediamine), catalyst (dicaprylic acid Dibutyltin) 10 parts, antioxidant (CHEMNOX 1010) 10 parts, mesoporous silica nanoparticles (average particle size 500nm) 20 parts.

[0064] Its preparation method is:

[0065] (1) Coating a release layer on one side of the base layer and drying at 90°C for 6 hours;

[0066] (2) Coat the polyurethane layer on the side of the release layer away from the base layer, and dry at 60°C for 2 hours;

[0067] (3) Coat the ink layer on the side of the polyurethane layer away from ...

Embodiment 3

[0071] This embodiment provides a heat transfer film, which includes a release layer of 10 μm, a base layer of 25 μm, a release layer of 25 μm, a polyurethane layer of 20 μm, an ink layer of 15 μm and an adhesive layer of 50 μm connected in sequence.

[0072] The raw materials for preparing polyurethane in the polyurethane layer include 40 parts of diisocyanate (toluene diisocyanate), 80 parts of polyethylene glycol (MW=8000), 20 parts of chain extender (hexanediol), catalyst (dibutyltin dioctoate) ) 10 parts, antioxidant (CHEMNOX 1010) 10 parts, mesoporous silica nanoparticles (average particle diameter 200nm) 40 parts.

[0073] Its preparation method is:

[0074] (1) Coating a release layer on one side of the base layer and drying at 90°C for 6 hours;

[0075] (2) Coat the polyurethane layer on the side of the release layer away from the base layer, and dry at 60°C for 2 hours;

[0076] (3) Coat the ink layer on the side of the polyurethane layer away from the release laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com