Pyrography machine lower plate seat capable of automatically adjusting levelness

A technology of automatic adjustment and heat transfer machine, applied in printing presses, rotary printing machines, printing and other directions, can solve problems such as affecting heat transfer effect, uneven pattern, and production efficiency, so as to ensure heat transfer effect and avoid stuck. Unusual, stable and smooth sliding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

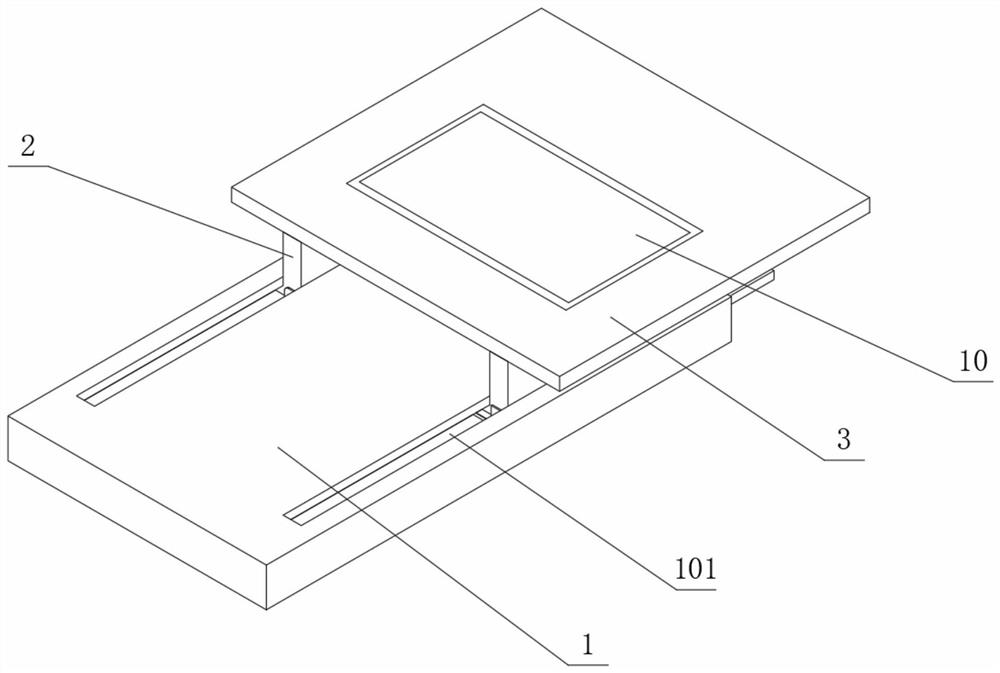

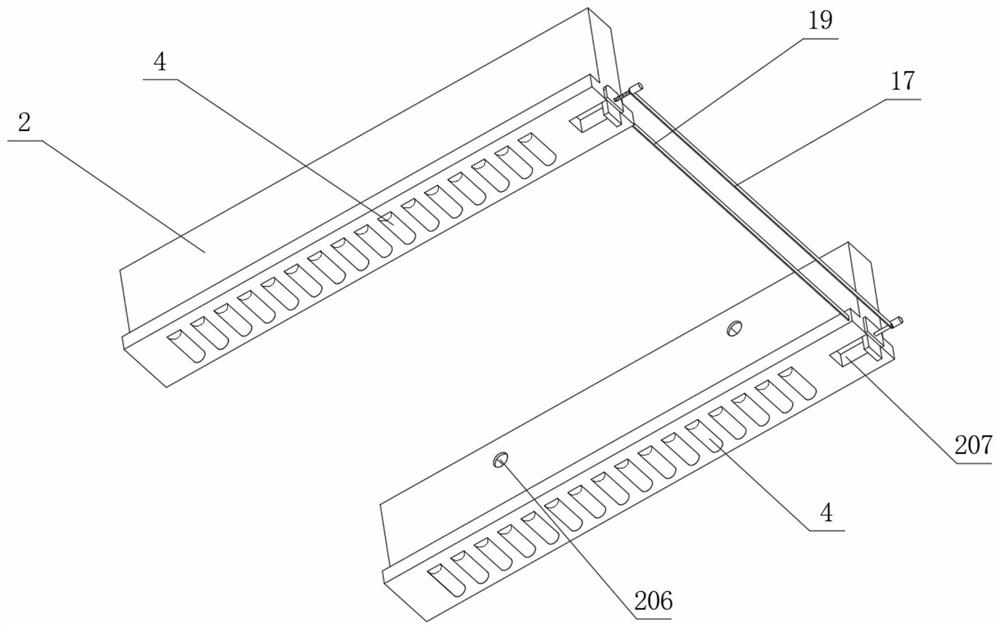

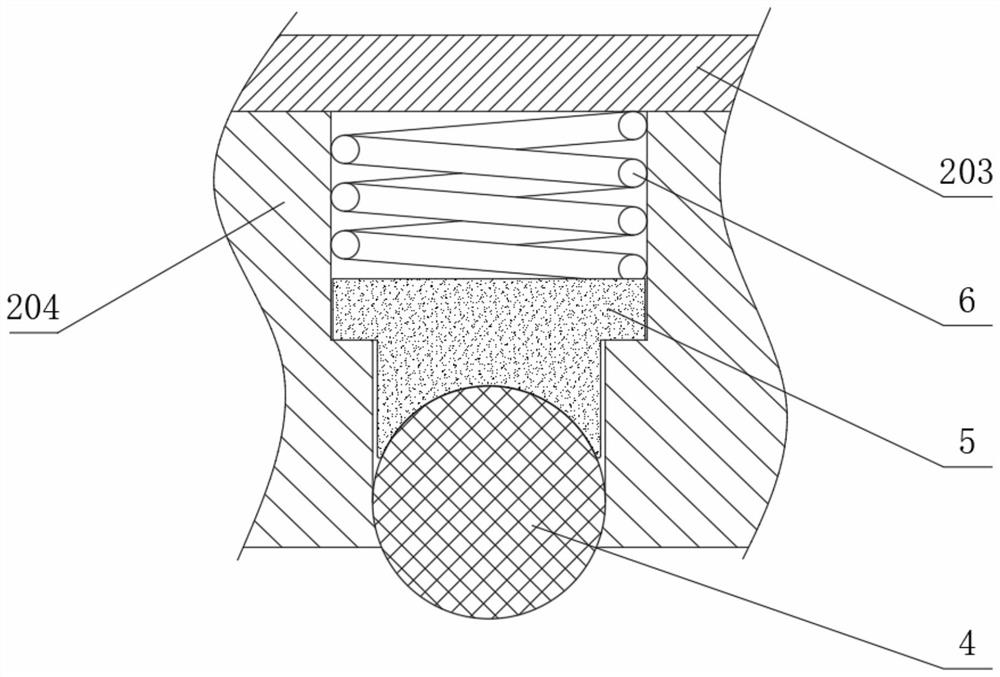

[0045] see Figures 1 to 12 , a heat press machine lower plate seat with automatic level adjustment, including a horizontal base plate 1, two parallel chute 101 is provided on the top of the base plate 1, and a support seat 2 slidably connected with it is provided inside the chute 101 The top of the support seat 2 is provided with a drawing board 3 snapped thereto; the bottom end of the support seat 2 is provided with a plurality of roller grooves 201 along the length direction of the chute 101, and a roller 4 is arranged in the roller groove 201, Between the roller groove 201 and the roller 4, there is an axle sleeve 5 that slides up and down with the roller groove 201, and the roller 4 that moves up and down makes the drawing board 3 and the upper board fit better, ensuring the connection between the drawing board 3 and the upper board. Parallel to effectively prevent the 3 drawing boards from being unable to stick to the upper board after being heated and deformed, and avoi...

Embodiment 2

[0056] The difference between embodiment two and embodiment one is:

[0057] see Figure 4 , a cylinder 7 is arranged between the cover plate 203 and the shaft sleeve 5, the shaft extension end of the cylinder 7 is fixedly connected with the shaft sleeve 5, and the cylinder 7 has no air inlet and outlet ports. After the drawing board 3 is deformed, heat transfer The amount of compression of each cylinder 7 is proportional to the force of the drawing board 3 at the corresponding position, thereby compensating the deformation of the drawing board 3 so that the drawing board 3 can be in parallel contact with the upper board; the connection of the cylinders 7 is stable and reliable, and the compression of the gas has great A good cushioning effect ensures that the drawing board 3 will not be damaged by impact.

Embodiment 3

[0059] The difference between embodiment three and embodiment one is: see Figure 5, the bushing 5 is in sealing and sliding connection with the drum groove 201, and a separator 208 is fixed on the upper part of the roller groove 201; the separator 208 separates the roller groove 201 into an upper chamber 209 and a lower chamber 210; the partition A number of small holes 212 are also provided on the part 208 to communicate with the upper cavity 209 and the lower cavity 210; a second spring 211 is arranged in the lower cavity 210; ; The upper cavity 209 is filled with compressed inert gas, and the lower cavity 210 is filled with electrorheological fluid; the liquid level of the electrorheological fluid is at least higher than that of the small hole 212 under the static state when the heat press machine is stopped; An external circuit applies an electric field to the electrorheological fluid.

[0060] When the heat press machine is working, in the process of heat transfer, if t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com