UV flashing three-dimensional pyrography packaging box printing process

A packaging box, three-dimensional technology, applied in the field of UV flash three-dimensional hot embossing packaging box printing technology, can solve the problems of poor adhesion, ink easy to fall off, inconvenient practical application, etc., achieve low cost, excellent printing effect, component distribution ratio Appropriate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

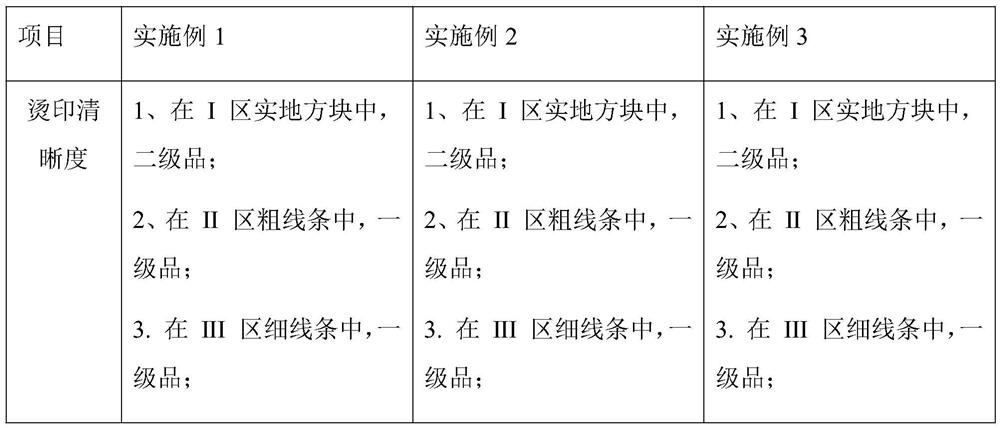

Embodiment 1

[0050] A packaging box printing process of UV flash three-dimensional hot embossing, comprising the following steps:

[0051] (1) Prepare materials;

[0052] (2) Preparation of electrochemical aluminum film:

[0053] Take hydrogen-containing silicone oil, vinyl silicone oil and toluene, mix and stir for 10 minutes, add phenothiazine and platinum catalyst, raise the temperature to 75°C under nitrogen atmosphere, add perfluoroalkylethylene, diethylaminoethyl methacrylate, and heat up To 120 ° C, constant temperature reaction for 18 hours, after the reaction, add alumina powder, mix and stir for 15 minutes, and let stand for 5 minutes to obtain the release material;

[0054] Take starch and deionized water, mix and stir at 80°C for 40 minutes, cool down to 60°C, add styrene acrylate and silane-modified chitosan, and continue stirring for 45 minutes to obtain a protective layer coating solution;

[0055] Take the PET base film, apply a release material on one side of the PET bas...

Embodiment 2

[0063] A packaging box printing process of UV flash three-dimensional hot embossing, comprising the following steps:

[0064] (1) Prepare materials;

[0065] (2) Preparation of electrochemical aluminum film:

[0066] Take hydrogen-containing silicone oil, vinyl silicone oil and toluene, mix and stir for 15 minutes, add phenothiazine and platinum catalyst, raise the temperature to 80 under nitrogen environment, add perfluoroalkylethylene, diethylaminoethyl methacrylate, and heat to 125 ℃, constant temperature reaction 17, add alumina powder after the reaction, mix and stir for 18in, let stand for 7in, and get the release material;

[0067] Take starch and deionized water, mix and stir at 85°C for 35 minutes, cool down to 62°C, add styrene acrylate and silane-modified chitosan, and continue stirring for 38 minutes to obtain a protective layer coating solution;

[0068] Take the PET base film, apply a release material on one side of the PET base film, dry it to form a release l...

Embodiment 3

[0076] A packaging box printing process of UV flash three-dimensional hot embossing, comprising the following steps:

[0077] (1) Prepare materials;

[0078] (2) Preparation of electrochemical aluminum film:

[0079] Take hydrogen-containing silicone oil, vinyl silicone oil and toluene, mix and stir for 20 minutes, add phenothiazine and platinum catalyst, raise the temperature to 85°C under nitrogen atmosphere, add perfluoroalkylethylene, diethylaminoethyl methacrylate, and heat up To 130 ° C, constant temperature reaction for 16 hours, after the reaction, add alumina powder, mix and stir for 20 minutes, and let it stand for 5 minutes to obtain a release material;

[0080] Take starch and deionized water, mix and stir at 90°C for 30 minutes, cool down to 60°C, add styrene acrylate and silane-modified chitosan, and continue stirring for 45 minutes to obtain a protective layer coating solution;

[0081] Take the PET base film, apply a release material on one side of the PET ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com