Electrical purography pen

A paintbrush and electric perm technology, which is applied in the fields of branding machines and decorative arts, can solve the problems of burnt boards, waste of electric energy, and long pyrographing time, and achieve power saving, fast pyrographing speed, and close contact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

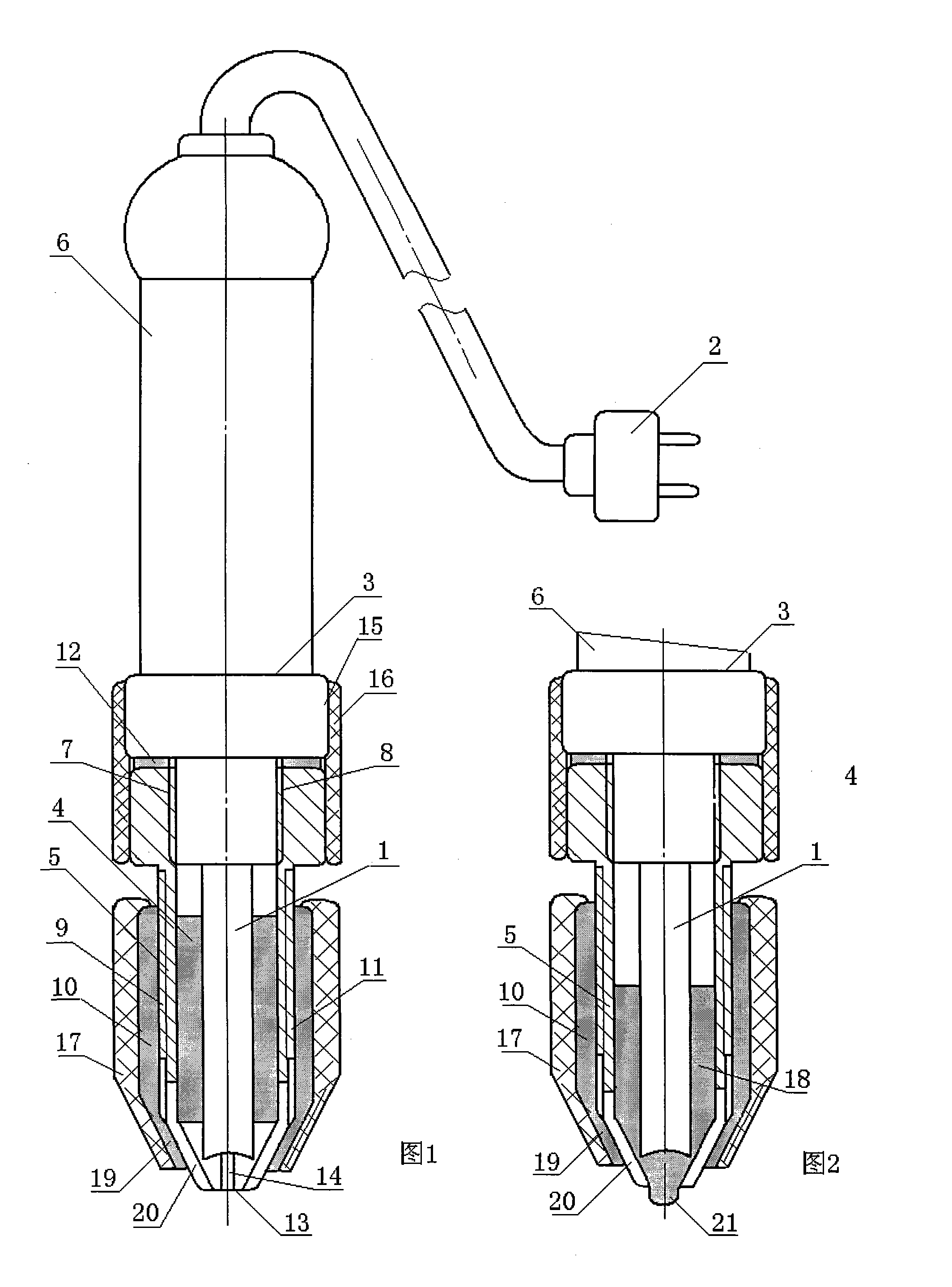

[0009] Below according to accompanying drawing and specific embodiment the present invention is further described:

[0010] figure 1 The schematic diagram of the structure of the ironing brush is shown. The electric ironing brush includes an electric heating element (1) and a power plug (2). The electric ironing brush is provided with a metal liquid nib (3). Tin core (4), nib (5) constitute. The electric heating element (1) of the metal liquid nib (3) is fixedly connected in the nib (5), the metal tin core (4) is located in the nib (5), and the metal tin core (4) is set outside the electric heating element (1) .

[0011] In order to adjust the size of the nib (13) of the nib (5) and change the size of the heat transfer contact surface, the nib (5) is provided with an adjustment sleeve (10), and the external thread (9) of the nib (5) is connected with the adjustment The inner thread (11) of the cover (10) is dynamically fitted and connected, and the nib mouth (13) of the nib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com