Environment-friendly pyrography ink, PET film heat transfer printing method and application of environment-friendly pyrography ink

An environmentally friendly, thermal transfer printing technology, applied in the field of textile printing, can solve the problems of restricting the wide application of inkjet inks, low fastness to rubbing, and insufficient fastness to washing, and achieve excellent color performance, comfortable feel, and satisfactory The effect of color fastness test requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

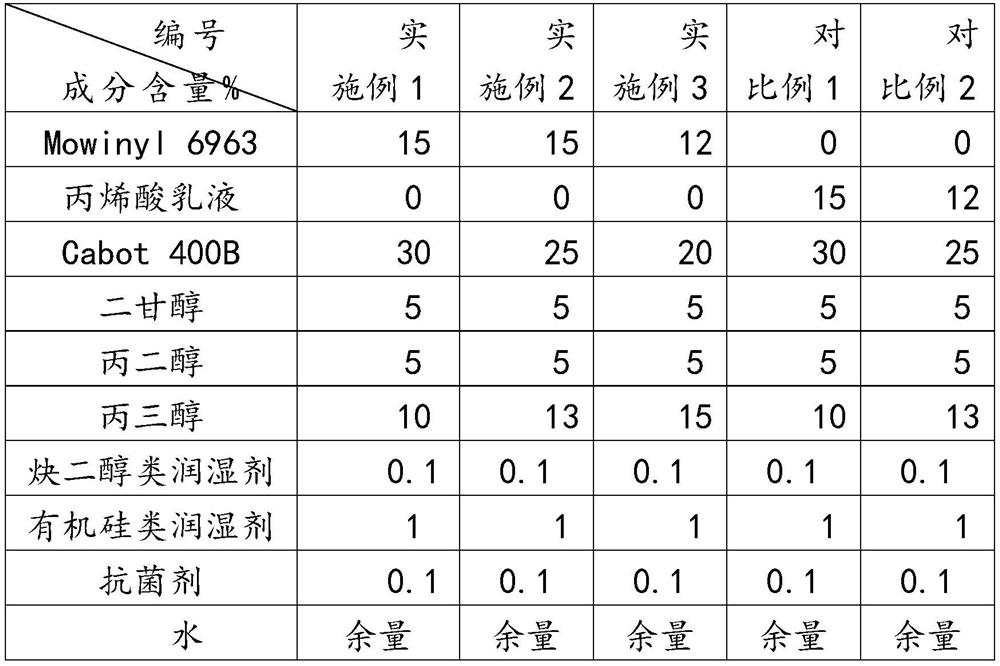

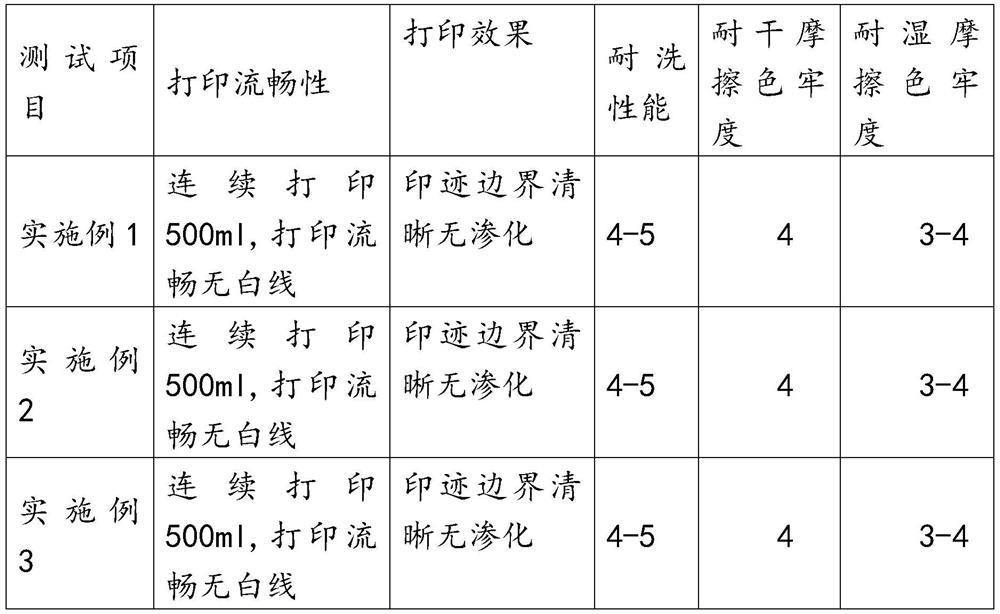

[0023] The environmentally friendly heat transfer ink of the present invention includes the following components: pigment paste, water-soluble organic solvent, styrene-acrylic polymer emulsion with a glass transition temperature of less than 0°C, surfactant and water, preferably, 100 parts by total weight In total, the environmentally friendly heat transfer ink includes 25-30 parts of pigment paste, 10-20 parts of water-soluble organic solvent, 15 parts of styrene-acrylic polymer emulsion, 0-2 parts of surfactant and the balance Of water. More preferably, the particle size of the pigment paste is preferably D50≤200nm and D99≤300nm. More preferably, the styrene-acrylic polymer emulsion is a water-dispersed styrene acrylic resin, and the water-soluble organic solvent is one or more of diethylene glycol, propylene glycol and glycerol. The environmentally friendly heat transfer ink also includes surfactants and antibacterial agents, wherein the surfactant is one or more of acetyle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com