Flannelette handicraft pyrography bar

A handmade and flannel technology, applied in textile and papermaking, fabric surface trimming, thorn pattern and other directions, can solve the problems of high production, high production difficulty, complex production process of flannel pattern, etc., and achieves convenient use, fast processing and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

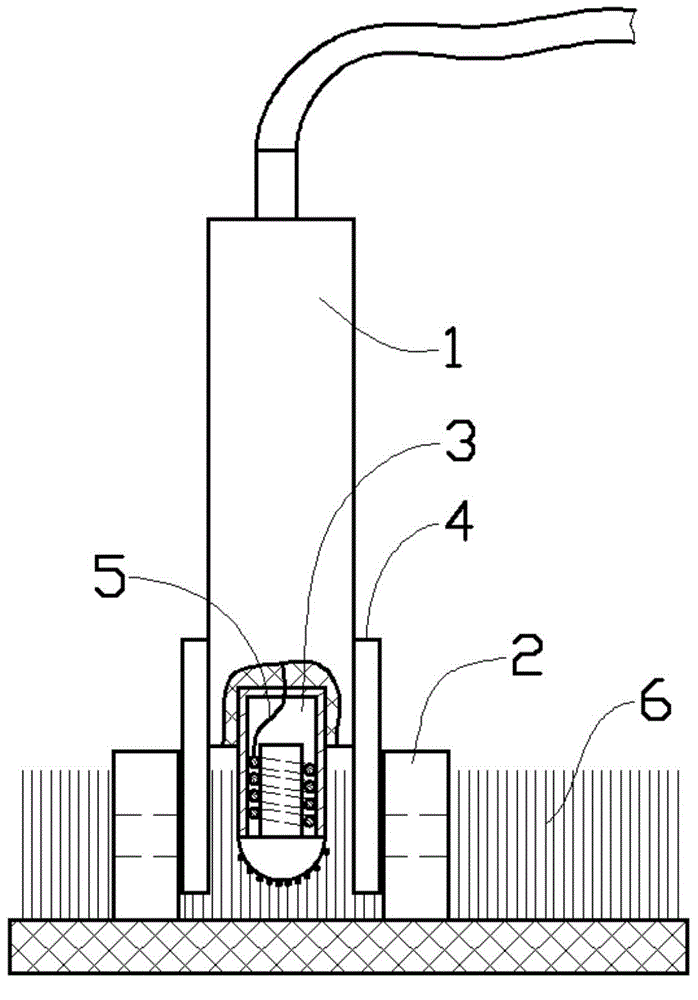

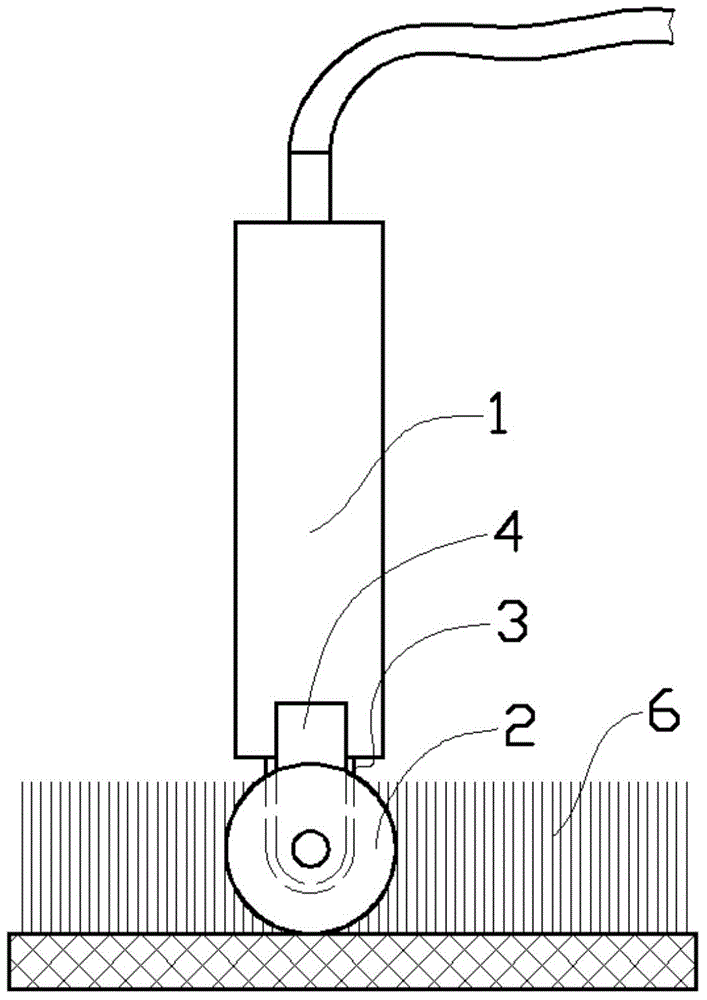

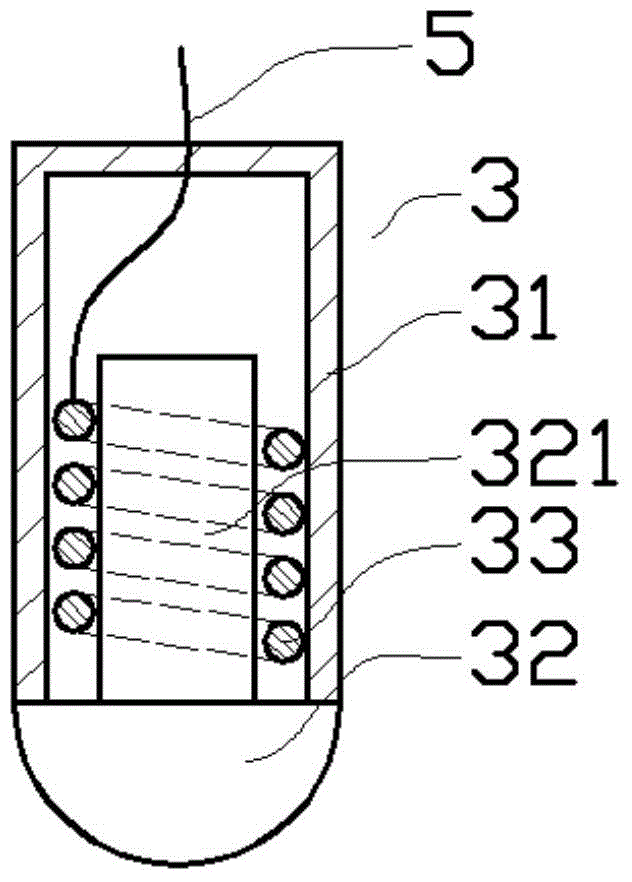

[0014] Such as figure 1 and figure 2 As shown in the embodiment, the flannelette manual heat transfer stick includes a handle 1, a roller 2, and a heating rod 3; the handle 1 is cylindrical and placed vertically during work. The diameter of the handle is convenient to hold It is better to live. Both sides of the lower part of the handle bar 1 are symmetrically equipped with connecting arms 4, and the outer sides of the two connecting arms 4 are symmetrically equipped with the rollers 2 that can rotate from the axis. The heating rod 3 is produced, the lower part of the heating rod 3 is spherical, and the bottom end of the heating rod 3 is 5-15 mm higher than the bottom end of the roller 2. The surfaces of 6 are close together, so that the heating rod 3 is 5-15 mm higher than the surface of the flannelette 6, specifically 5-15 mm higher than the weaving surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com