Patents

Literature

41results about How to "Good three-dimensional effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Three-dimensional printing image synthesizing method for optical grating

ActiveCN104539928ASimple processGood three-dimensional effectSteroscopic systemsOptical elementsImage synthesisSingle lens

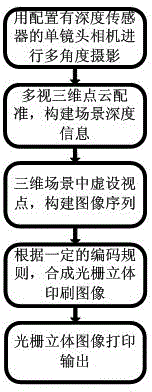

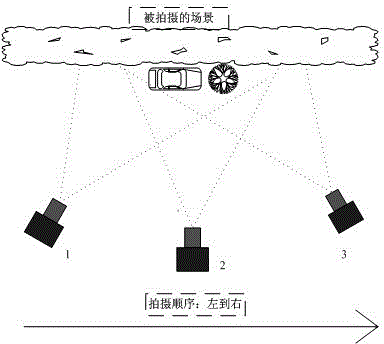

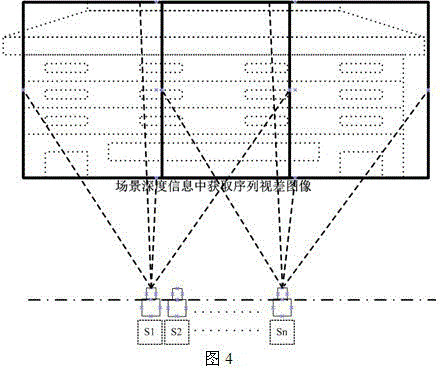

The invention discloses a three-dimensional printing image synthesizing method for an optical grating based on multi-view imaging of a depth transducer and an optical camera. Firstly, a single-lens camera with the depth sensor is used for obtaining a scene optical image and a corresponding depth image under multiple views; secondly, registering is carried out on three-dimensional point cloud under the multiple views, a redundancy space point is deleted, the depth information of a shooting scene is obtained, and a plurality of sequence optical parallax images are obtained according to a method for virtually setting a plurality of equal-interval view points in the three-dimensional space; finally, the optical grating three-dimensional printing image is synthesized according to an optical fiber three-dimensional coding mode. The image processing is carried out only through the technology, the depth information of the scene, the sequence optical parallax images and the optical grating three-dimensional synthesis image finally to be printed can be obtained in sequence, the whole process is convenient and fast, the three-dimensional effect of the optical grating three-dimensional image finally output is good, and the technology plays a significant role in popularization of the optical grating three-dimensional image.

Owner:WUHAN UNIV

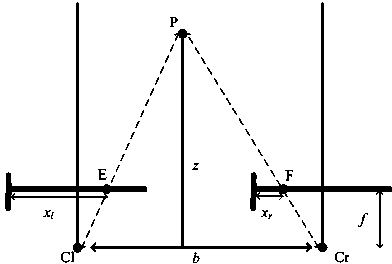

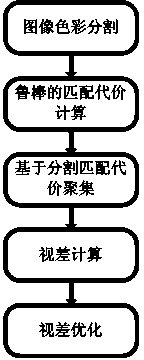

Optical grating three-dimensional printing image synthetic method based on binocular camera

ActiveCN103702103ASimple processGood three-dimensional effectSteroscopic systemsOptical elementsImage resolutionBinoculars

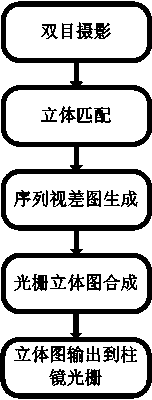

The invention provides an optical grating three-dimensional printing image synthetic method based on a binocular camera. The optical grating three-dimensional printing image synthetic method comprises the steps of using the binocular camera to shoot a scene so as to obtain a binocular image pair, wherein the binocular image pair comprises a left view and a right view; obtaining a binocular image depth map; constructing an image sequence, and taking the left view in the binocular image pair as a left-most sequence parallax image in the image sequence, and the right view in the binocular image pair as a right-most sequence parallax image in the image sequence to generate a plurality of sequence parallax images between the left view and the right view; compounding an optical grating three-dimensional image according to the image sequence; adjusting the resolution of the optical grating three-dimensional image, and outputting the optical grating three-dimensional image by taking a printer as output equipment and a lenticular grating as a carrier. The instant output with individuation and convenience of a three-dimensional printing product is realized, and a better three-dimensional effect can be observed by naked eyes for the optical grating three-dimensional image obtained by using the method.

Owner:WUHAN UNIV

Manufacturing method for three-dimensional paper-cut picture

InactiveCN101734086AGood three-dimensional effectIncrease productivityOutline designsDecorative surface effectsPaper sheetPaper cut

The invention relates to a manufacturing method for three-dimensional paper-cut picture. A paper-cut picture designed in a computer is taken as the base picture, the overall size of the part to be cut is gradually made into a series of similar or basically similar pictures according to the needed three-dimensional effect, the picture information is converted into a program to control a plasma cutter or a laser cutter to cut the paper, in order to avoid the paper from being burnt by high light intensity, the paper is soaked in water before cutting and smeared with paste three times with a specific silk mesh plate. The outside edge of the first similar cut paper conforming to the size change of the cut part of the base picture cut paper is aligned with the outside edge of the base picture cut paper, pressed on the pasted surface of the base picture cut paper by the front face, pressed by the silk mesh plate and smeared with paste continuously, and the rest is deduced by analogy, so that all the similar cut paper is mounted with the same method in the sequence of the gradual change of the cut size, and a three-dimensional layer cut paper is made by repeatedly mounting; and then backing paper is stuck on the back face of the cut paper by known mounting technique for traditional Chinese painting to finish the paper-cut picture. The method is favorable for mass production and has good admiration effect.

Owner:李国昌

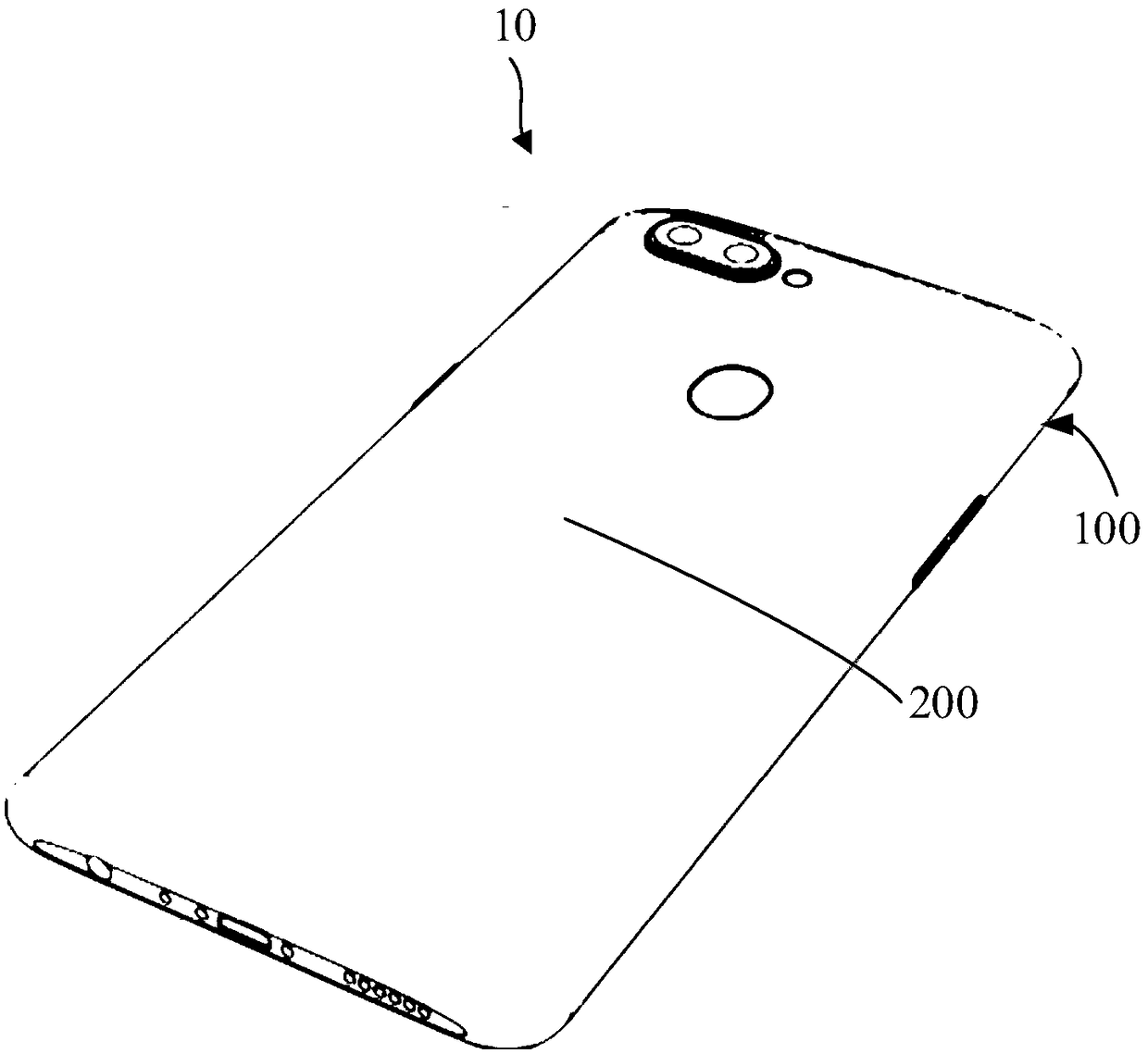

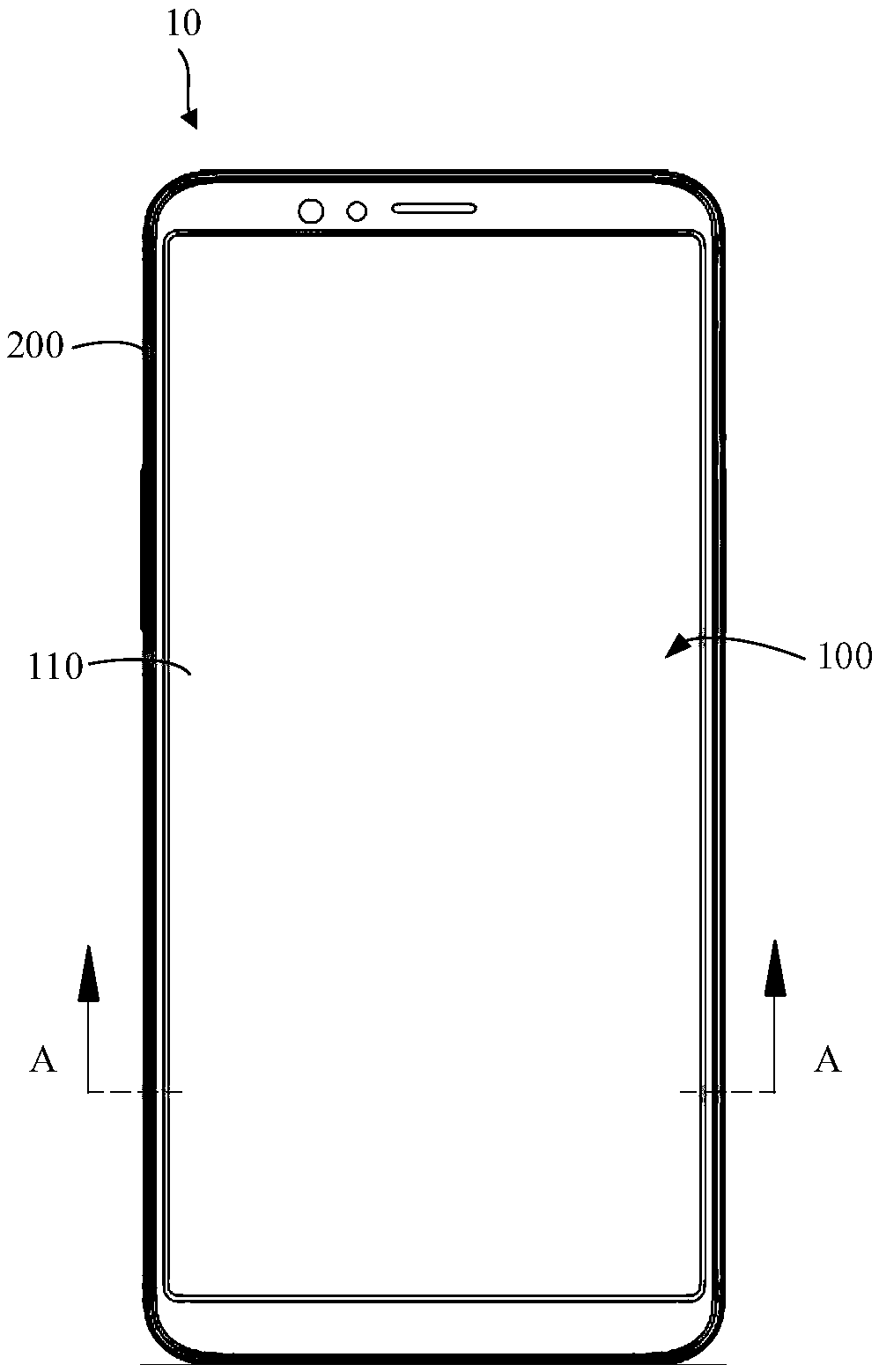

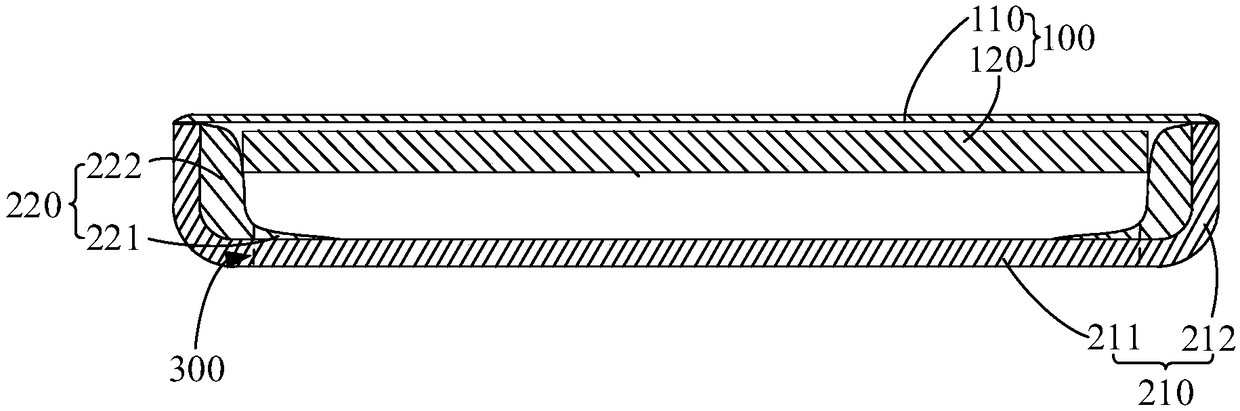

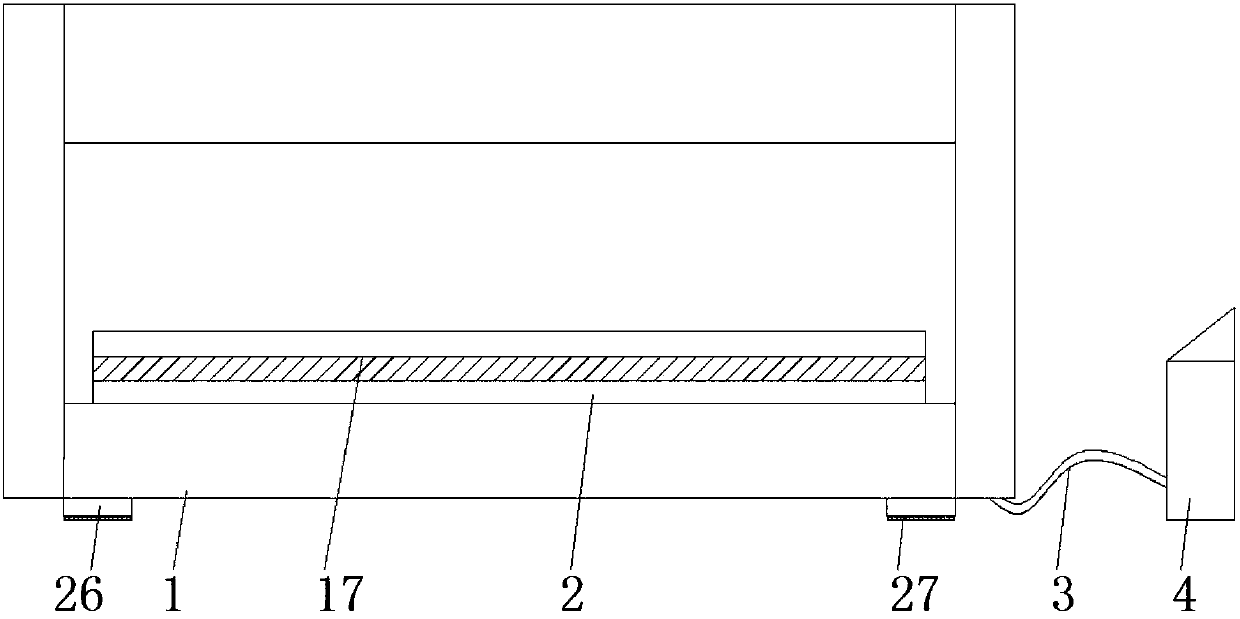

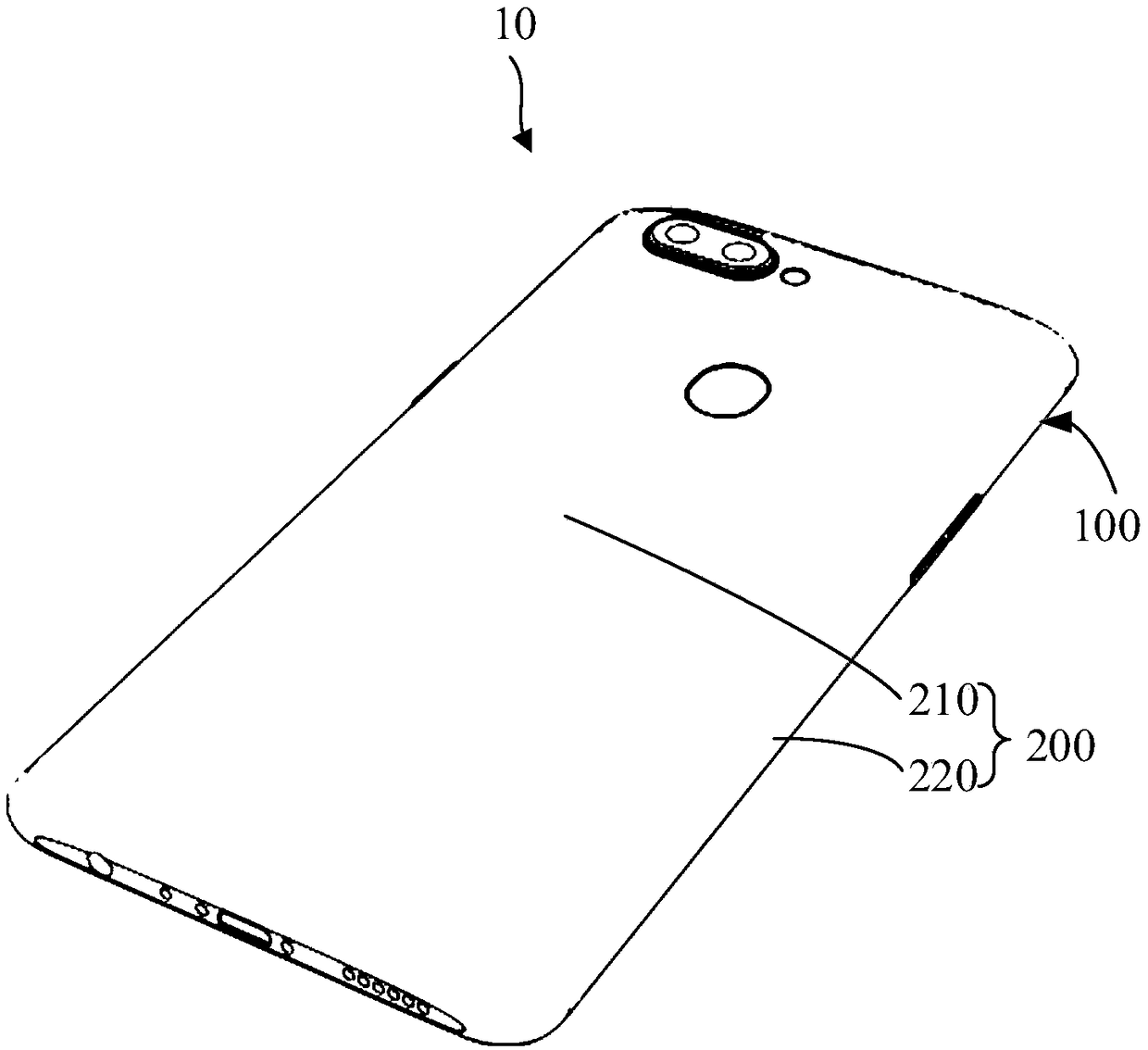

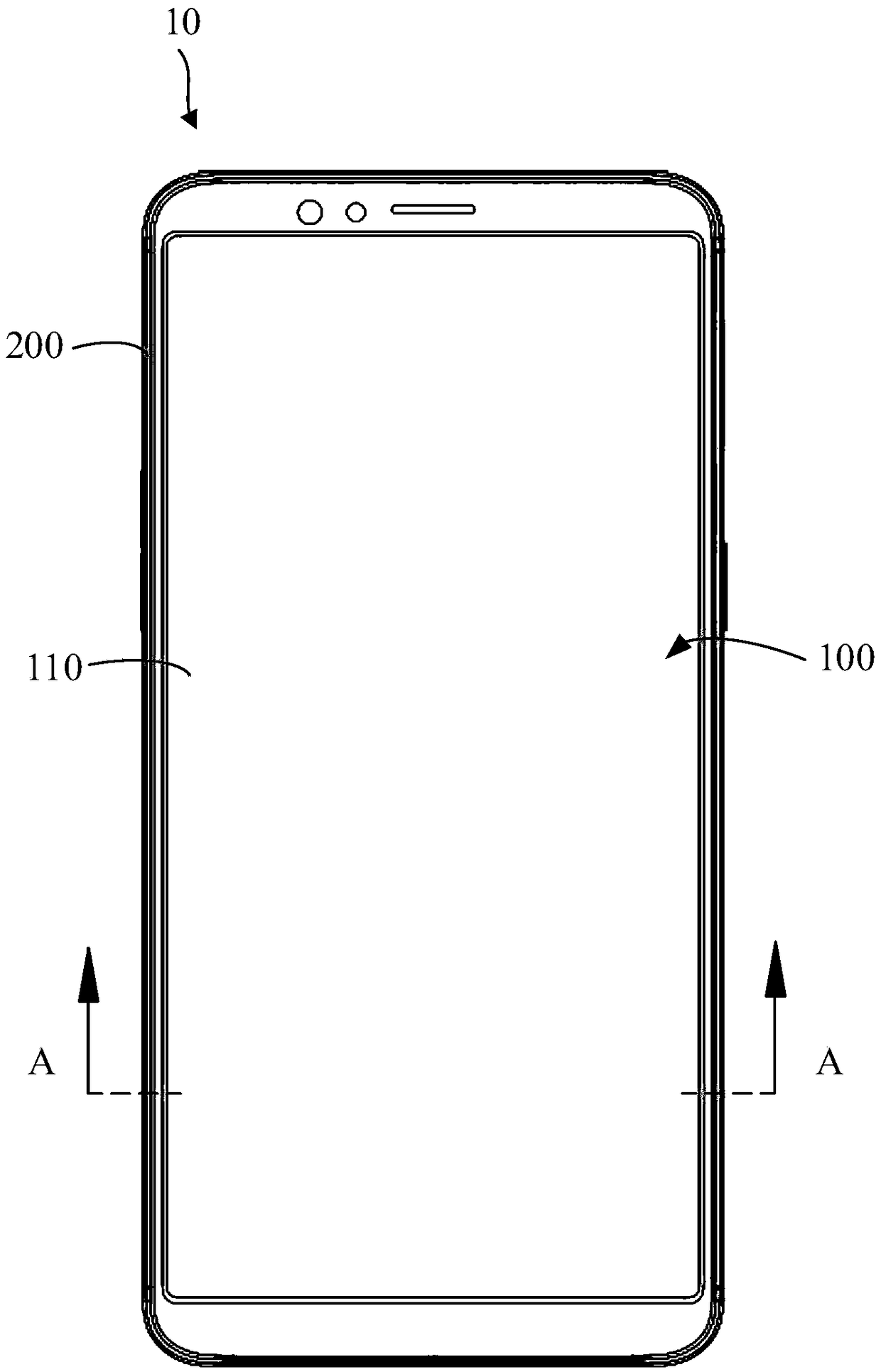

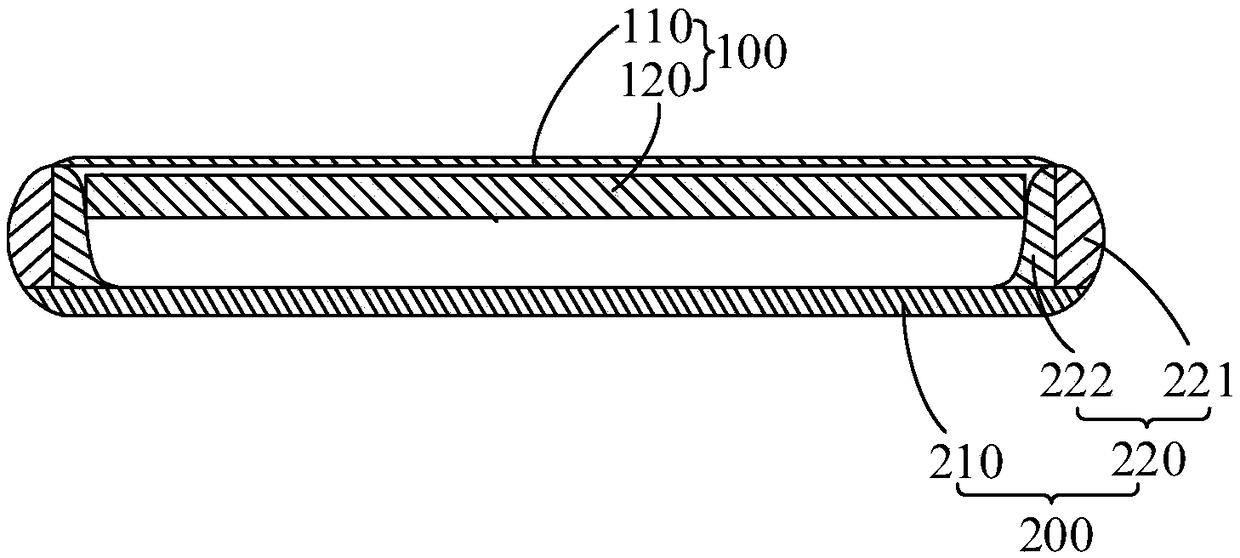

Shell, electronic device and manufacturing method of shell

ActiveCN108769302AGood three-dimensional effectReduce production difficulty and costTelephone set constructionsCeramicEngineering

The invention provides a shell, an electronic device with the shell and a manufacturing method of the shell. The shell comprises an outer shell piece and an inner shell piece; the inner shell piece isaffixed to the inner side of the outer shell piece; the outer shell piece comprises an outer connecting part and an outer wall part; the outer connecting part is in the shape of a plate, and the outer wall part is located at the edge of the outer connecting part, so that the outer shell piece is in the shape of an open box, and the outer connecting part and the outer wall part are integrally shaped; the inner shell piece comprises an inner wall part and an inner connecting part; the inner wall part and the inner connecting part are integrally shaped, the inner connecting part covers at leastpart of the outer connecting part, and the inner wall part covers the outer wall part; wherein the outer shell part is made of glass or ceramics, the inner shell part is made of a transparent macromolecule material, and the thickness of the location where the outer wall part and the inner wall part joined together is greater than that of the outer connecting part and the inner connecting part. Through the technical scheme provided by the invention, a shell with thick side wall part, thin main body and completely glass or ceramic outer surface is provided. The shell has good stereoscopic effectand attractive appearance.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Printing process of UV flash three-dimensional pyrography

InactiveCN107443942AStrong concave-convex feelGood three-dimensional effectOther printing apparatusPrinting after-treatmentCartonPrinting ink

The invention discloses a printing process of UV flash three-dimensional pyrography, which is used for printing on cartons. The printing process comprises the following steps of (1) plating silver: partially plating silver on the cartons; (2) calibrating: determining that the gilding position and the printing position are kept consistent through the registration of a positioning film; (3) printing patterns: partially printing patterns on the cartons with printing ink, wherein the registration error of the printing patterns is less than or equal to 0.05 mm; (4) performing matte printing: performing matte printing on full pages of the cartons; and (5) glazing: registering gilding and printing contents, and glazing with UV varnish. The printing process of the UV flash three-dimensional pyrography has the following advantages that (1) the visual stereoscopic effect of the surfaces of the graphic cartons is good, and the display effect is good; (2) the UV flash three-dimensional pyrography has a strong concave-convex feeling.

Owner:昆山科望快速印务有限公司

Surface treatment process (fluorine-carbon spraying) for carrying out lasers on metal surface

InactiveCN102423753AExtend the lifespanGood three-dimensional effectPretreated surfacesSpecial surfacesWeather resistanceSurface finishing

The invention provides a surface treatment process (fluorine-carbon spraying) for carrying out lasers on a metal surface. According to the process, the surface of a product is sprayed for four times and dried for four times and textures on the surface are etched on a substrate surface through the lasers, so that the textures on the product surface, and grooves and bulges on the surface can be permanently represented; and a fluorine-carbon painting which is famous for weather resistance is sprayed on the product surface and the service duration of the product is further prolonged, so that the product manufactured by the process has the advantages of more obvious surface stereoscopic effects, wear resistance and vividness, and can be acceptable in the conversion between space and time, therefore, the prolonged, durable, economical and substantial effects can be achieved.

Owner:许浩洪

Production technology of foaming bronzing painting craft painting

ActiveCN102627051AGood three-dimensional effectGood thickness changeDecorative surface effectsSpecial ornamental structuresBronzingMechanical engineering

The present invention relates to a production technology of a foaming bronzing craft painting, and solves defects, in prior art, of individual foaming process or bronzing process, and single painting effect of a produced craft painting. The technology comprises steps of: composing; fixing printing fabrics on a base; pulping; carrying out multicolour printing of foaming slurry and bronzing slurry simultaneously on th printing fabrics; carrying out high temperature foaming; and carrying out net suspension treatment on determined net suspension parts. The foaming process and bronzing process are conducted simultaneously to finish craft painting production at one time and enable the painting to have double effects of foaming and bronzing, as well as good stereo perception and texture effect of changing thickness.

Owner:YIWU WADOU PICTURE

Method for compressing three-dimensional image video sequence

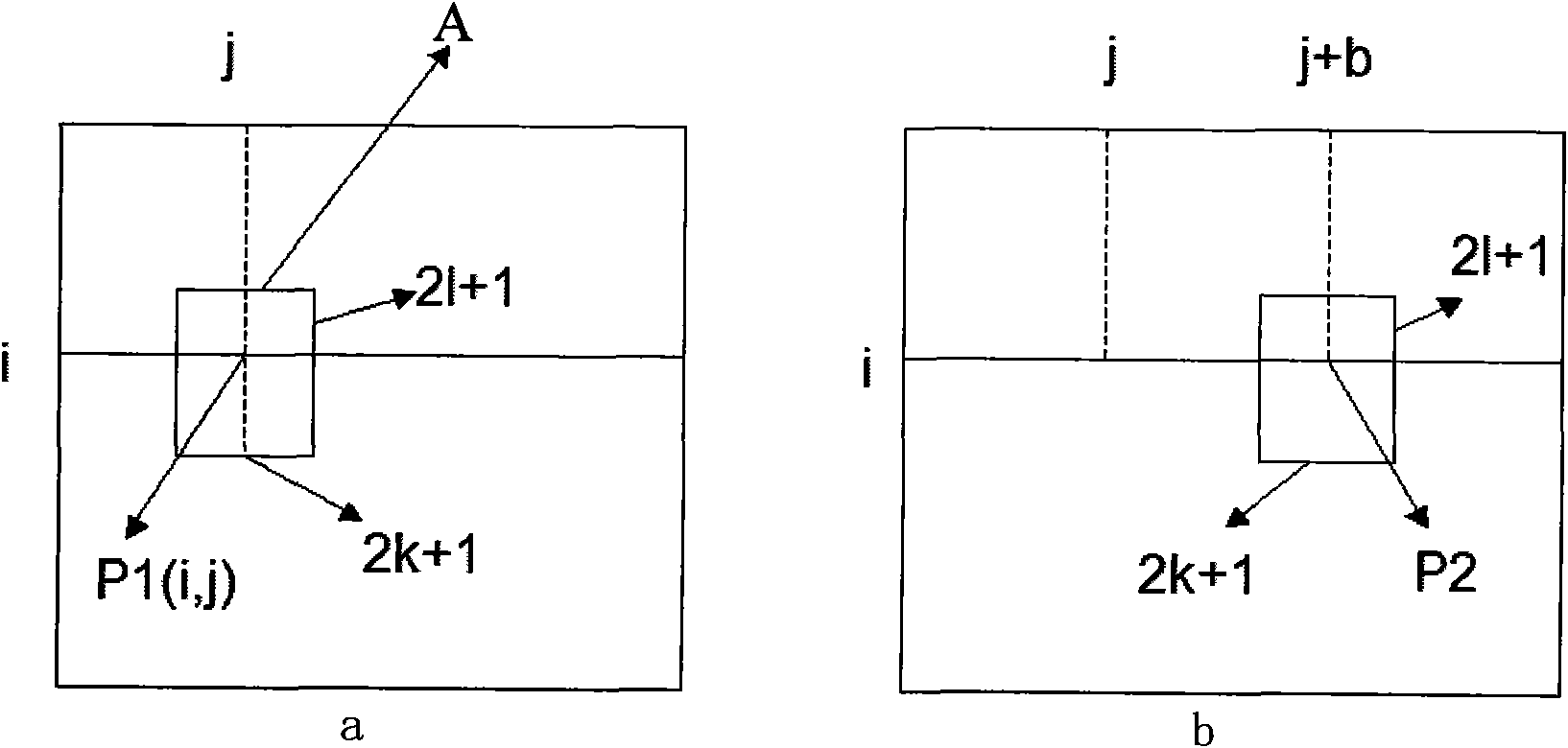

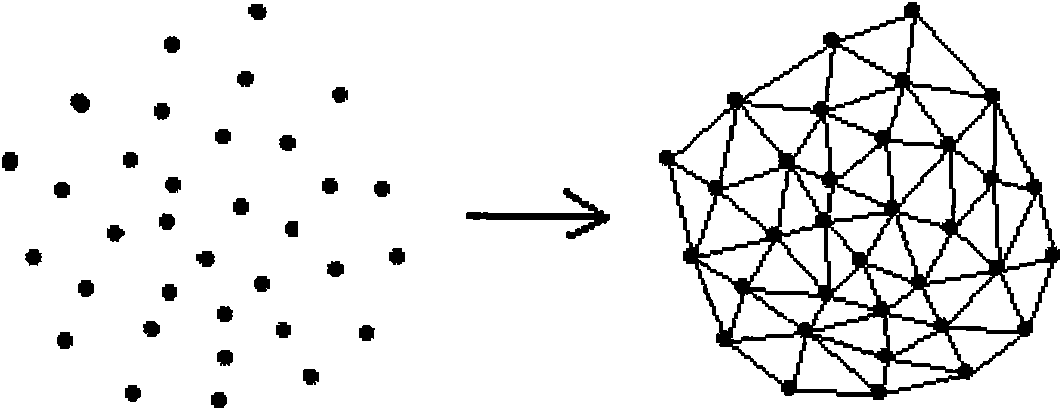

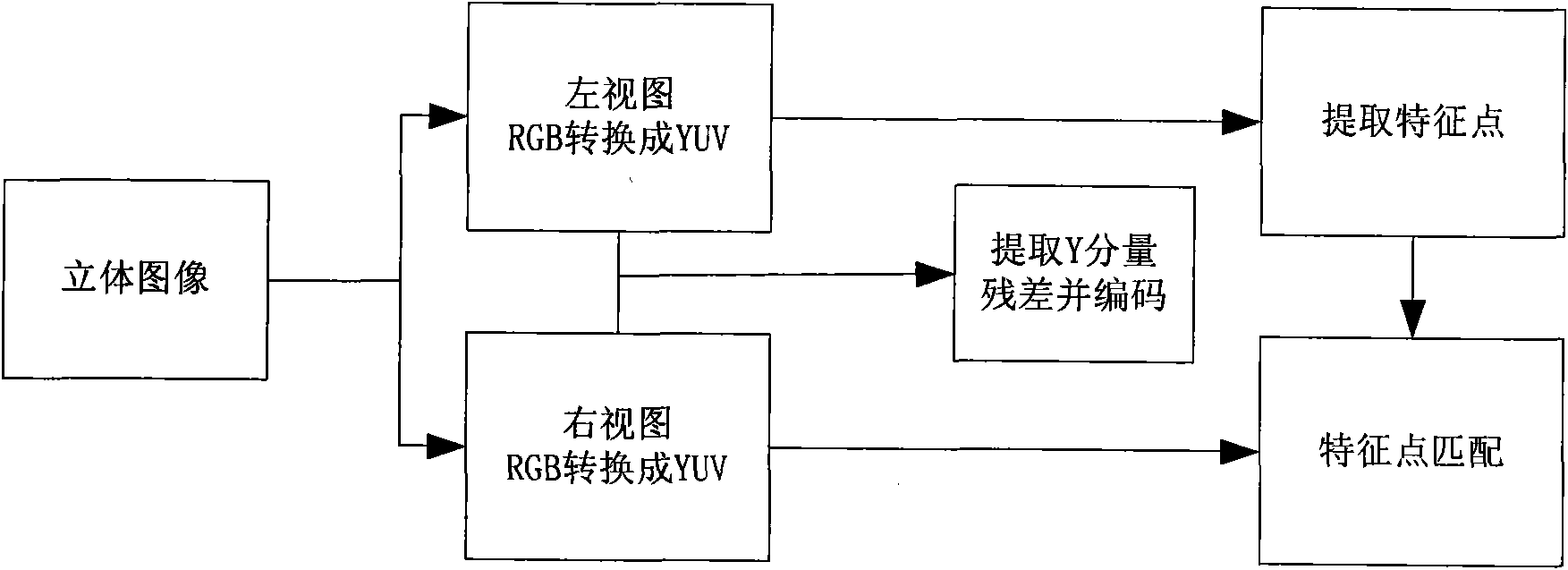

InactiveCN101610422AReduce data volumeGood three-dimensional effectTelevision systemsDigital video signal modificationJPEGPoint match

The invention relates to a method for compressing three-dimensional image video sequence, comprising left view L and right view R of three-dimensional image are respectively converted into YUV4:2:0; feature points of the left view L are extracted, and then the left view L is processed by Delaunay triangular mesh subdivision; points matched with the feature points of the left view L are found out in the right view R; hollow triangular mesh of the right view R is set up, and right view R' is filled out; residual information Y' of Y component between the original right view R and the filled out right view R' is then extracted; DCT transformation as well as quantization and entropy coding are carried out, and a JPEG method is used for compressing the left view L. According to the information of the matched feature point set of the left and the right views, every triangle in the left view is treated by affine transformation; the YUV information of the left view and the right view which is newly set up is transformed into RGB information, left and right three-dimensional diagram pairs can be obtained after being uncompressed and then transformed into three-dimensional image according to the display way. The method reduces the data volume of the three-dimensional image, and the three-dimensional image which is decoded and restored has good three-dimensional effect, no uncomfortable feeling and clear image. After being decoded, the image has higher similarity with the original image.

Owner:TIANJIN UNIV

Equipment and method for producing gradient discoloration fabrics

InactiveCN107829244ATo achieve the effect of gradient movement up and downGood outstandingMechanical cleaningPressure cleaningBristleCoupling

The invention provides a device and method for producing gradient color cloth, and relates to the field of textile equipment. The equipment and method for producing gradient-colored fabrics include a gradual-change depilation machine housing, and a first rotating mechanism is fixedly installed on one side of the inner wall of the gradient de-burring machine housing. One end of the inner wall of the hair machine housing is fixedly connected with a rotating rod through a shaft coupling. The equipment and method for producing gradient color cloth, through the third telescopic mechanism provided inside the casing of the gradient deburring machine, can effectively achieve the effect of placing the plate to move up and down gradually under the expansion and contraction of the third telescopic mechanism, thereby It makes the cloth achieve the effect of gradual change and one color when bristling the bristled cloth, changing the traditional phenomenon that the whole leather is one color, making the cloth more prominent when the gradient color is displayed, and the effect is more obvious, which solves the problem of the current cloth The problem that the viewing performance is relatively poor when making clothes with gradient colors.

Owner:SHAOXING JIEMEIDA TEXTILE CO LTD

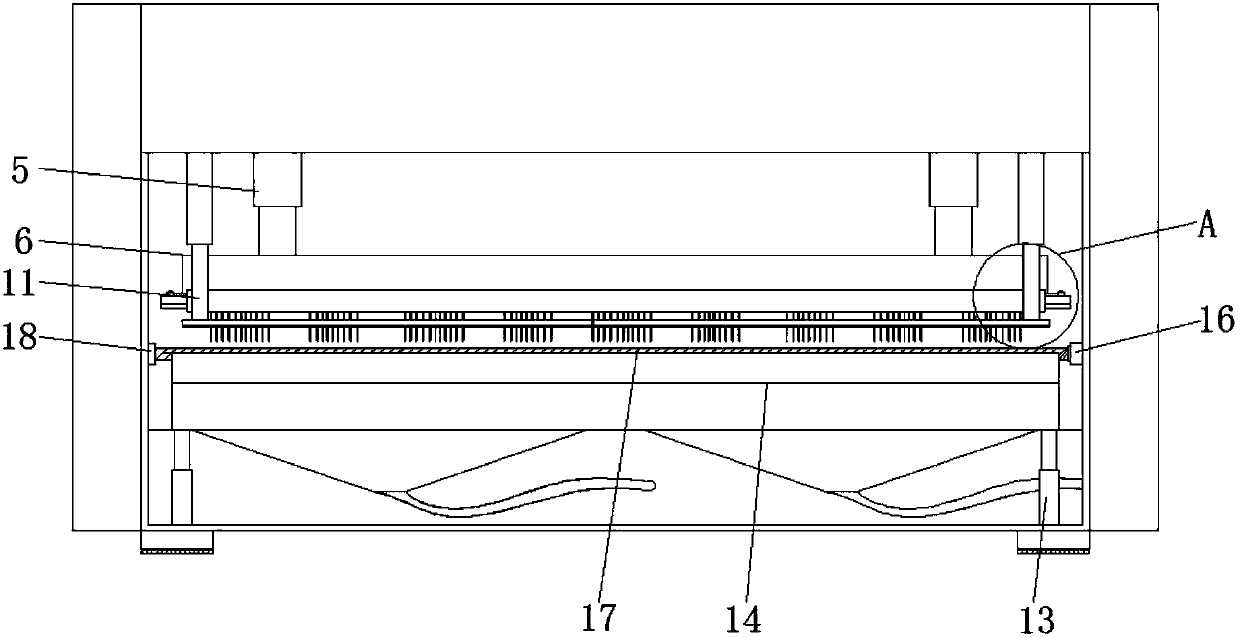

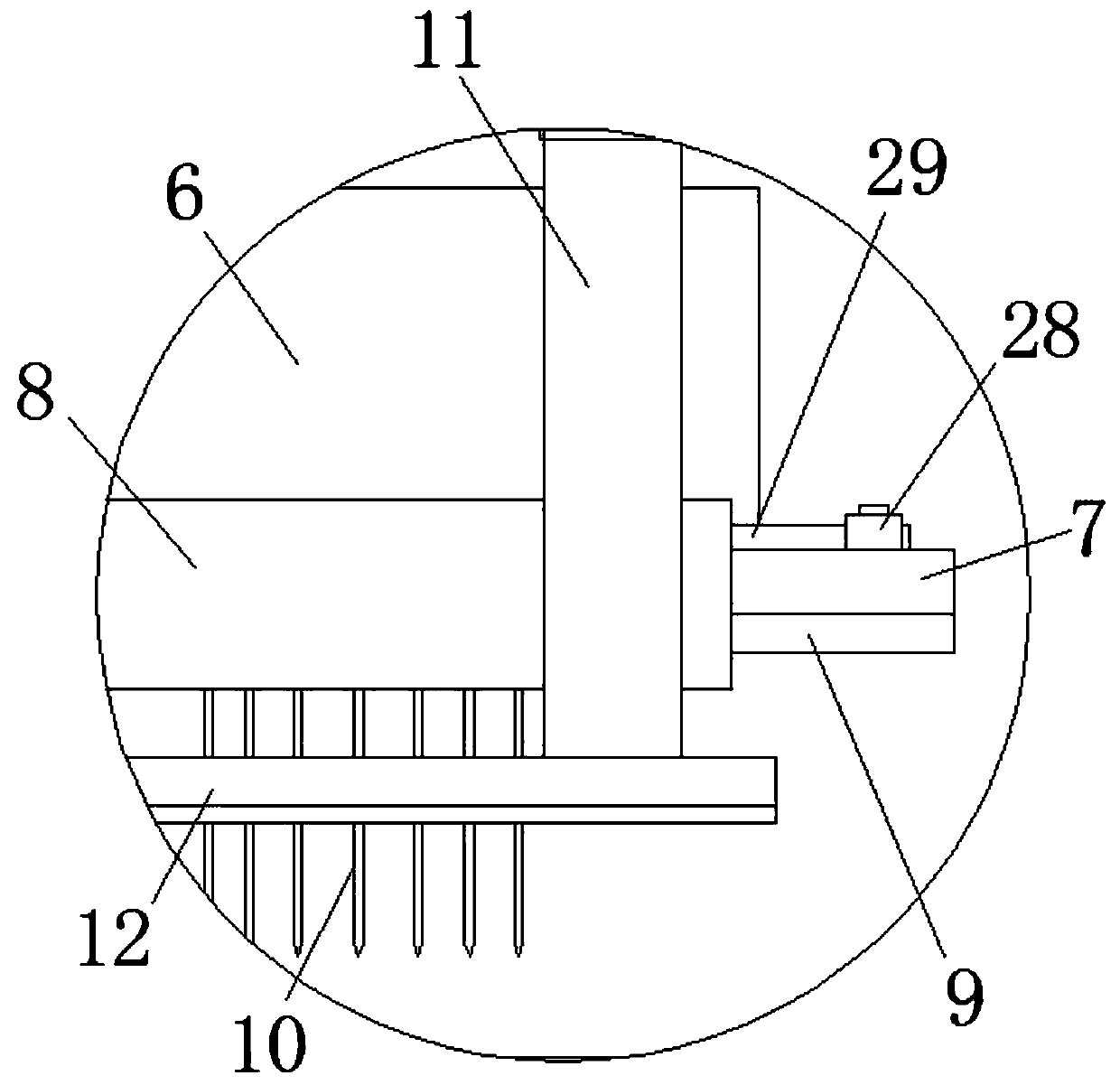

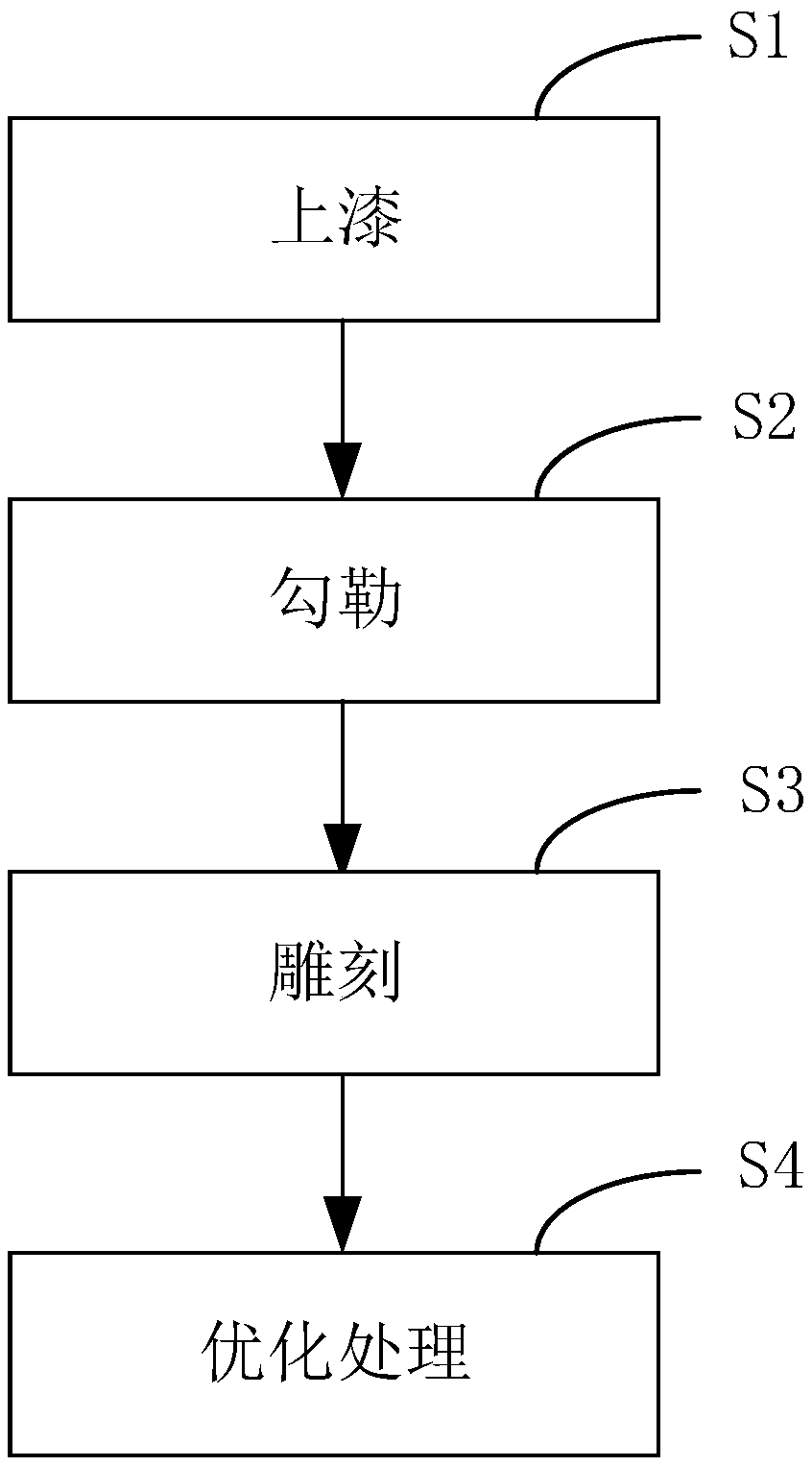

Colorful wood shadow sculpture and manufacture method

ActiveCN108973501AHigh artistic valueStrong three-dimensional senseDecorative surface effectsSpecial ornamental structuresColor depthMaterials science

The invention relates to the technical field of artware sculptures, in particular to a colorful wood shadow sculpture and a manufacture method. The manufacture method comprises the following steps: lacquering, drawing the outline, sculpturing and carrying out optimal processing. The step of lacquering is characterized in that the plate surface of a plate material is covered with a paint layer, andthe paint layer gradually darkens from inside to outside; the step of drawing the outline is characterized in that the outline of a pattern is drawn on the surface of the paint layer; the step of sculpturing is characterized in that a graver is used for sculpturing the surface of the paint layer according to the outline, the sculpturing depth of the graver is regulated according to the color depth of the pattern to realize different light and shade effects, different sculpturing angles are applied to the lines of the pattern to realize various different reflection effects of ray; the step ofoptimal processing is characterized in that luminance, shade and texture are optimized. According to the arrangement, the manufacture method for the colorful wood shadow sculpture is simple, is easy in selecting materials and is favorable for reducing cost and improving manufacture efficiency. In addition, the colorful wood shadow sculpture can show an obvious three-dimensional effect and strong stereoscopic impression and is favorable for improving the own artistic value of artware.

Owner:邢志鹏

Watercolor block printing blanked stamping process

InactiveCN103587328AGood three-dimensional effectImprove the three-dimensional effectDecorative surface effectsPattern printingStamping processComputer engineering

The invention discloses a watercolor block printing blanked stamping process, which comprises the following steps of 1) preparing watercolor block printing base timber; 2) drawing needed patterns on the upper surface of the watercolor block printing base timber; 3) etching to remove the surface base timber except the lines of patterns; 4) cutting the surplus base timber of the base timber with the three-dimensional patterns obtained in step 3) along the outer edge of each pattern to the position which is 1cm away from the outer edge of the pattern, thus obtaining a watercolor block printing version; 5) selecting the needed watercolor block printing version from step 4), printing colors corresponding to the patterns on the watercolor block printing version, and covering the watercolor block printing version by utilizing a piece of wetted Chinese art paper; 6) covering the Chinese art paper in step 5) by utilizing a felt, and brushing the felt for 3 to 5 times along a single oblique direction by utilizing a brush rake; 7) removing the felt in the step 6), lifting the Chinese art paper to be away from the watercolor block printing version, and airing the Chinese art paper for three hours; 8) mounting. The pattern indentation on the watercolor block printing version is pressed onto the wetted Chinese art paper through the brush rake, so that the colorful and fluctuated patterns can be formed.

Owner:HANGZHOU SHIZHUZHAI PRINT ART

Method for etching photo on marble

The invention relates to a method for etching a photo on marble, which can originally reflect an etched object and comprises the following steps of: outputting an image produced by scanning a photo which needs to be manufactured into a film with 25 to 40 meshes of dot grid; dissolving shell-lac by absolute ethyl alcohol (C2H5OH), and then evenly mixing to obtain a shell-lac photosensitive resist; evenly coating the photosensitive resist on the surface of the marble, on which the photo needs to be etched; tightly sticking the film on the surface of the marble; irradiating for 2 min under ultraviolet lamp light; then developing with alcohol until the image of the film is developed on the surface of the marble; printing off stone with the image, and etching by adopting corrosive liquid; after etching, washing the photosensitive resist on the stone by weak base water (NaOH and H2O) prepared in the volume ratio of 1:100, and then washing the residual base water by clear water; spraying pigments to the etched surface of the marble; after the pigments are completely dried, lightly rubbing out the convex pigments by a millstone; and when the convex pigments are completely rubbed out and only the pigments on a concave surface are left, obtaining a clear black-and-white photo.

Owner:金立民

Method for mounting paper-cut picture

InactiveCN101734087AGood three-dimensional effectIncrease productivityOutline designsDecorative surface effectsPaper sheetPaper cut

The invention relates to a method for mounting a paper-cut picture, which comprises the following steps of: a, drawing a paper-cut figure in a computer, transferring figure information to a plasma cutting machine or a laser cutting machine to cut the figure, soaking a stack of paper needed to be cut in water, clamping the paper full of water by two pieces of sheets, extruding remained water, putting the paper on a cutting board of the plasma cutting machine or the laser cutting machine, and cutting the figure after adjusting light intensity and speed; b, naturally drying the paper in the air or mechanically air drying or baking; c, putting the facade of the paper-cut on a plastic cloth, stacking a screen plate on the reverse side of the paper-cut, uniformly brushing paste on the screen plate, and removing the screen plate after brushing; d, adhering backing paper according to the mounting process of a known traditional Chinese painting to form the paper-cut picture; and e, brushing the paste on the peripheral edges of the reverse side of the solid paper-cut picture which is adhered with the backing paper, positioning the paper-cut picture and mounting sides, axes or a picture frame after naturally drying the paper in the air or air drying or baking. The method is suitable for industrialized production of paper-cut handicrafts in batches and has the advantages of good three-dimensional effect, low cost, convenient carrying and good appreciation.

Owner:李国昌

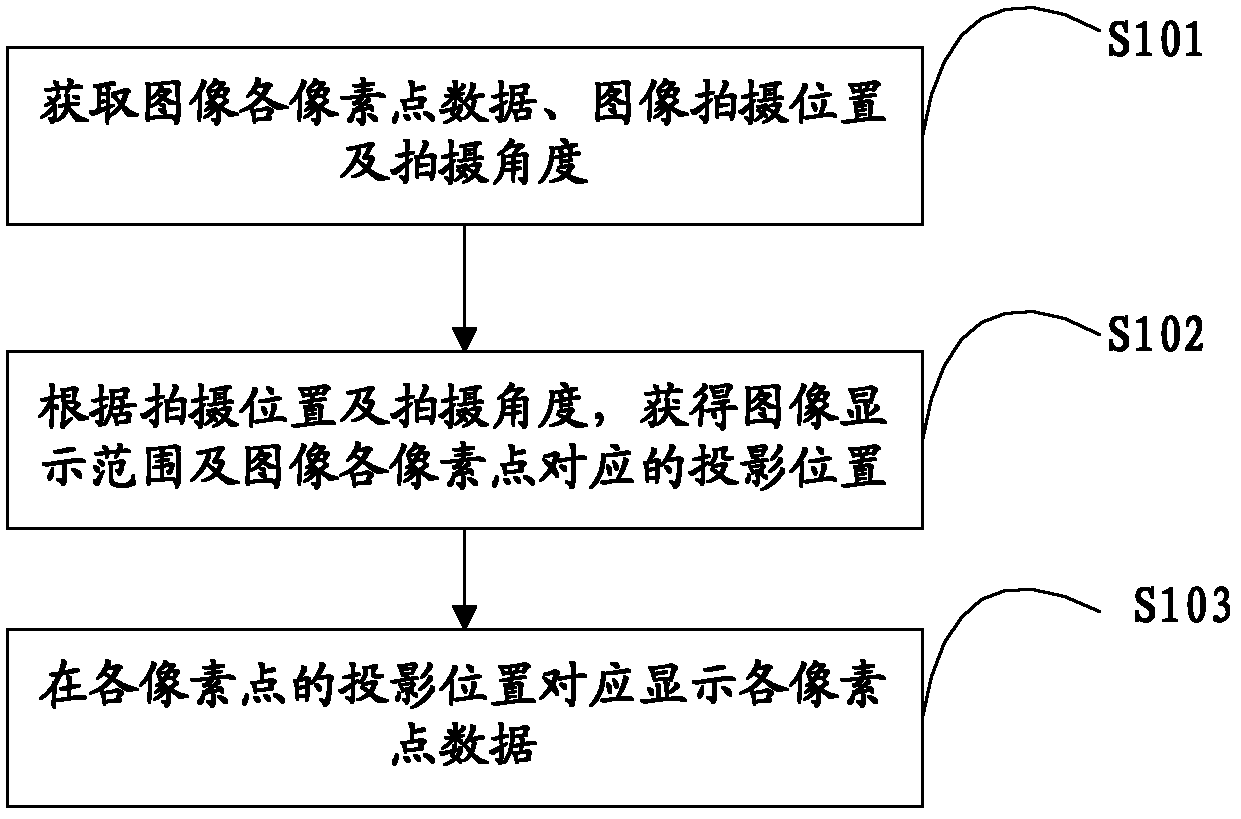

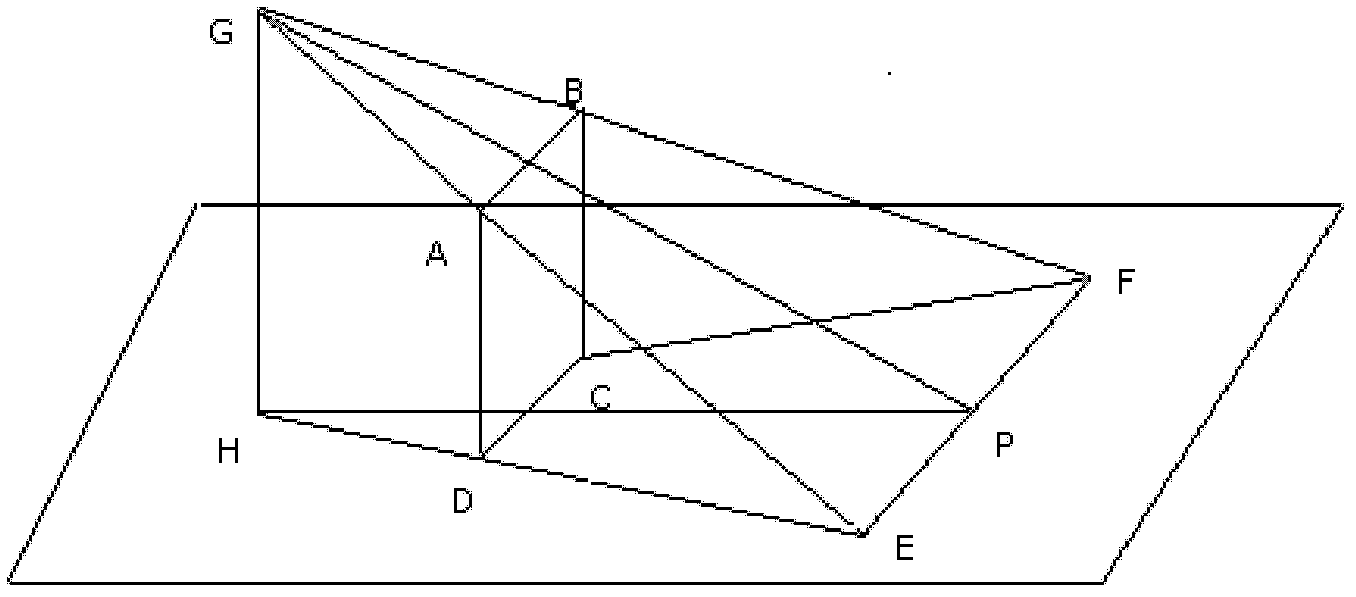

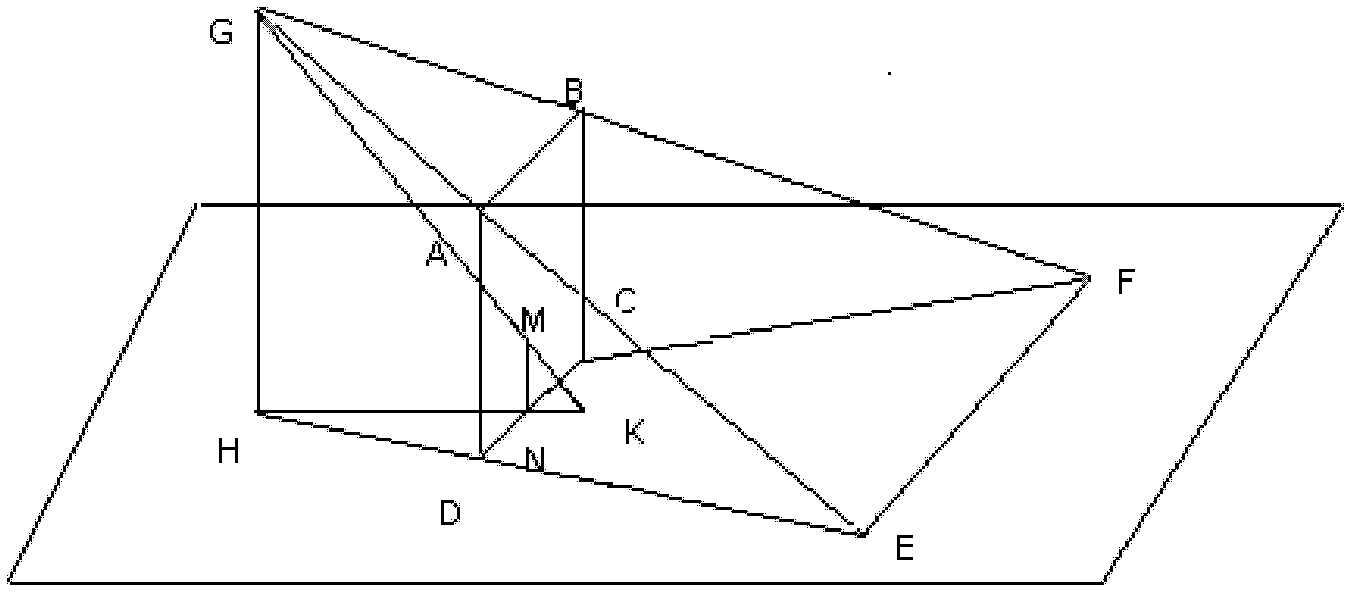

Method and device for displaying three-dimensional image

ActiveCN102427541AGood three-dimensional effectEasy to watchSteroscopic systemsTransmission lineComputer graphics (images)

The invention is applied to the field of image processing, providing a method and device for displaying a three-dimensional image. The method comprises the following steps of: acquiring each pixel point data, the shooting position and the shooting angle of an image; acquiring the display range of the image and the projection position corresponding to each pixel point of the image; and correspondingly displaying each pixel point data at the projection position of each pixel point. According to the method and device disclosed by the invention, the image is subjected to extension processing by adopting a mode of inclined overlook shooting and non-verticality of a display surface to the watching view during display, so that a looker can watch the three-dimensional image within a specified display range by using a two-dimensional display. The problems that the three-dimensional image cannot be displayed by using a two-dimensional display and 3D glasses are required to be worn and the requirement on a transmission line is high in a traditional 3D display technology are solved.

Owner:SHENZHEN SKYWORTH RGB ELECTRONICS CO LTD

Ceramic decorative material, ceramic decoration and ceramic decoration method thereof

The invention discloses a ceramic decorative material, belonging to the technical field of ceramic decoration. The expansion coefficient of the ceramic decorative material is 40-65 multiplied by 10, and the baking temperature thereof is 750 DEG C-900 DEG C; and in the components, the sum of alkali metals such as Na2O, K2O and Li2 is 0-12%, and the sum of alkali metals such as CaO, BaO, MgO and SrO is 0-8%. The invention also discloses a ceramic decoration method and ceramic decoration obtained by the decoration method. The method adopts processes of mould pressing and plastic moulding or printing ink point extruding to directly or indirectly adhere the ceramic decorative material matched with the expansion coefficient of ceramic glaze material to a glaze fired glaze layer, and the ceramic decorative material is baked at 750 DEG C-900 DEG C to form smooth projections which can be transparent, white and other colors, and also can have fluorescent or noctilucent effect. The invention combines ceramic decorative images or modeling design, has strong stereoscopic impression and the special effect of adding the finishing touch, improves the decoration artistic effects of ceramics, and increases the added value of ceramic products.

Owner:SHENZHEN YONG FENG YUAN IND

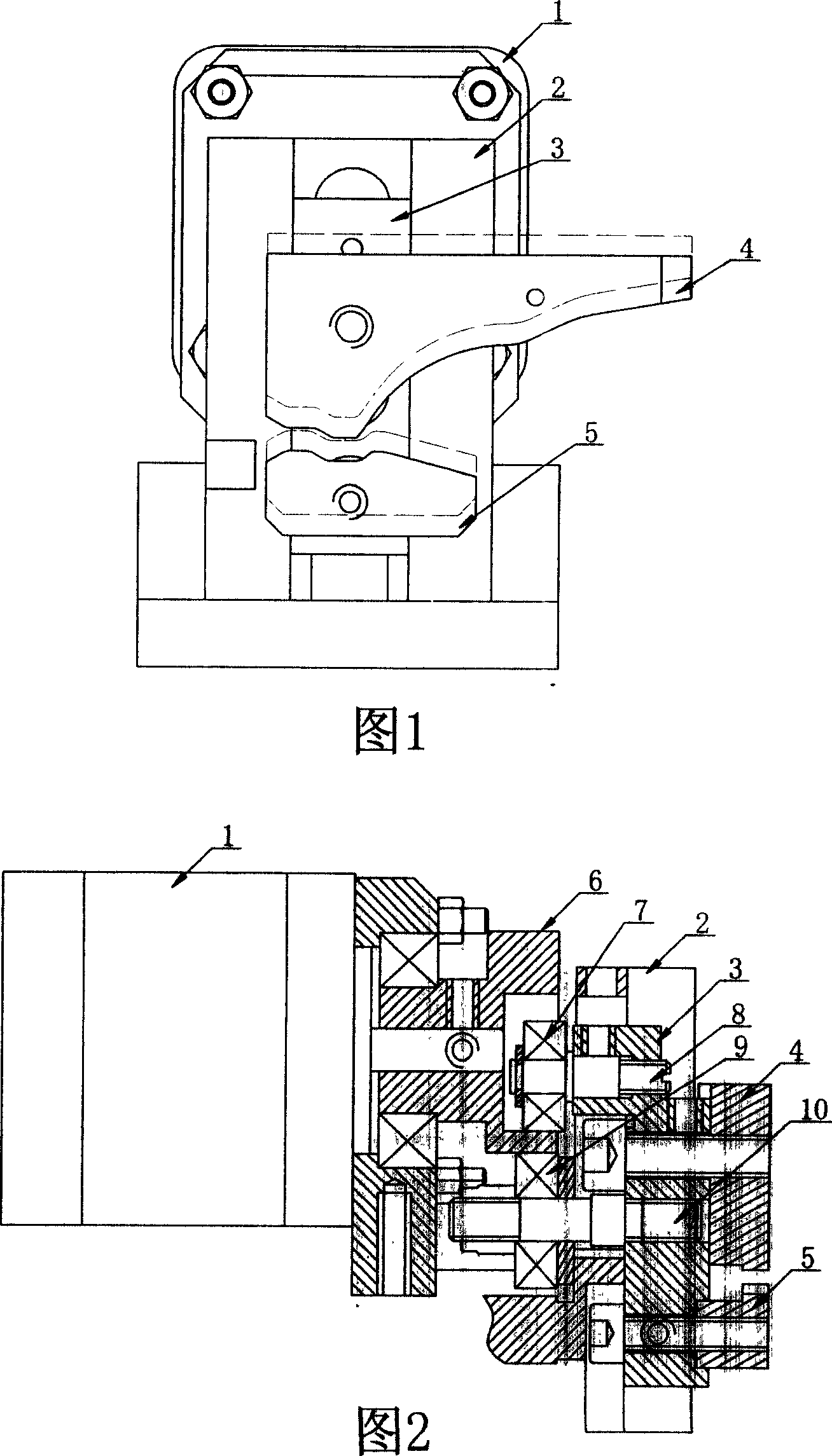

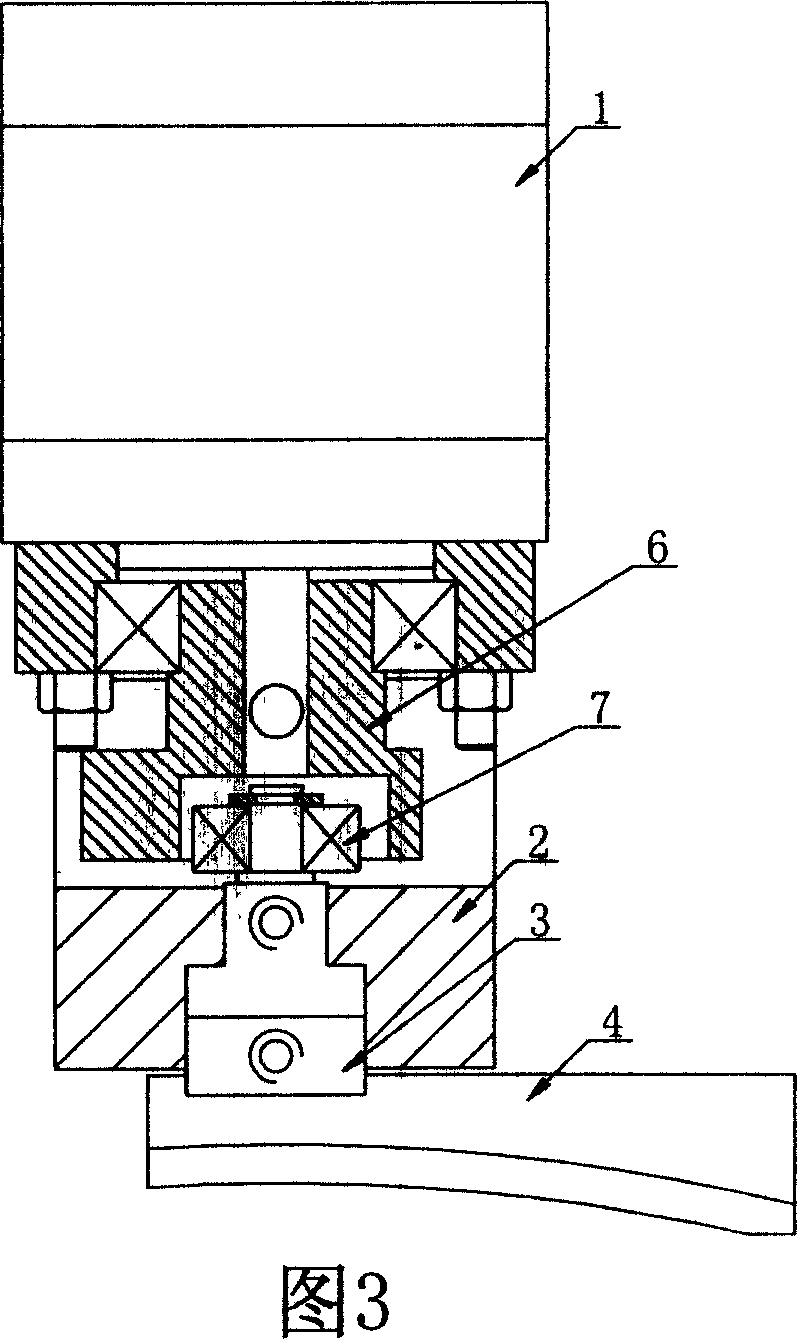

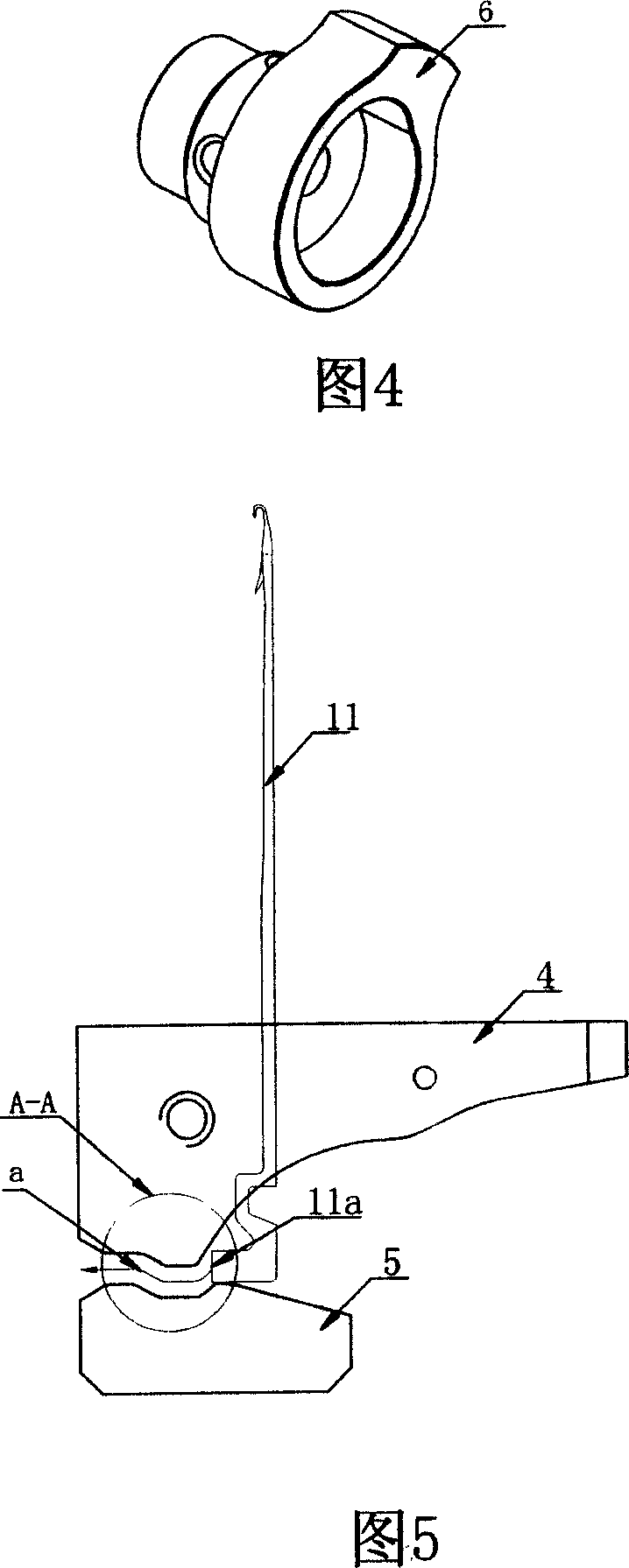

Texture regulator of seamless knitter

The texture regulator of seamless knitter includes a driving step motor, a texture regulating triangular mechanism, a double guard cam connected to the rotation shaft of the step motor, an inner bearing and an outer bearing. The texture regulating triangular mechanism includes a sliding block, a triangular texture dressing cam and a texture needle lifter. The present invention has small regulation interval, fast response, timely texture change and capacity of obtaining excellent 3D effect.

Owner:孙平范

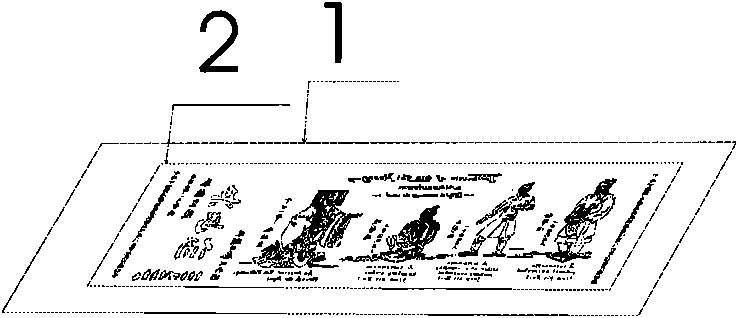

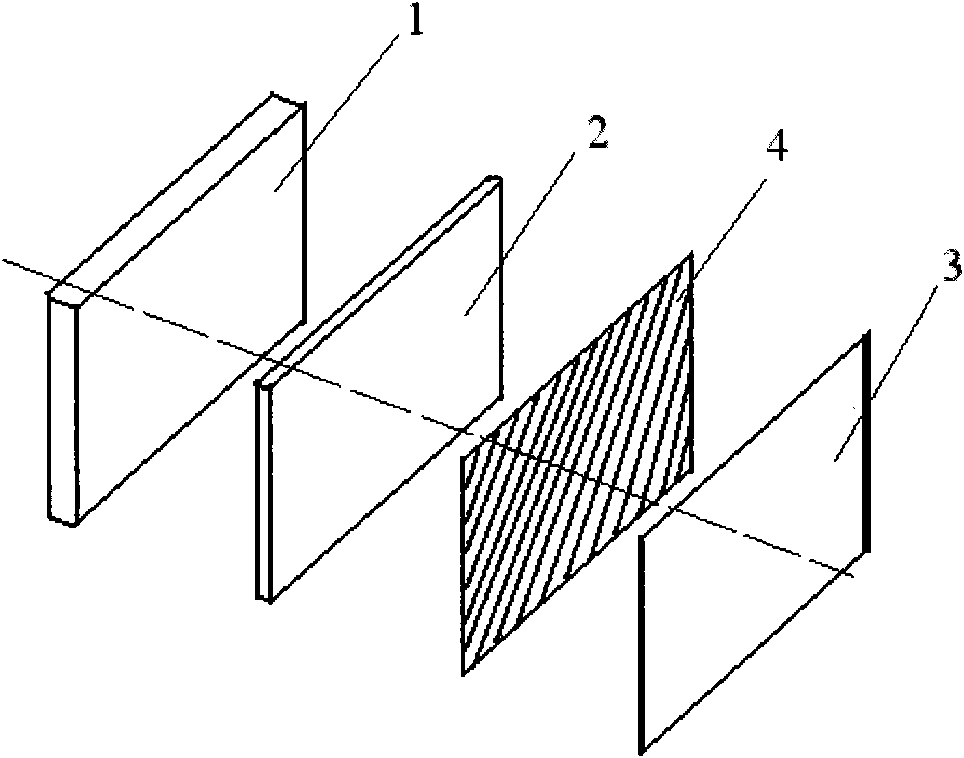

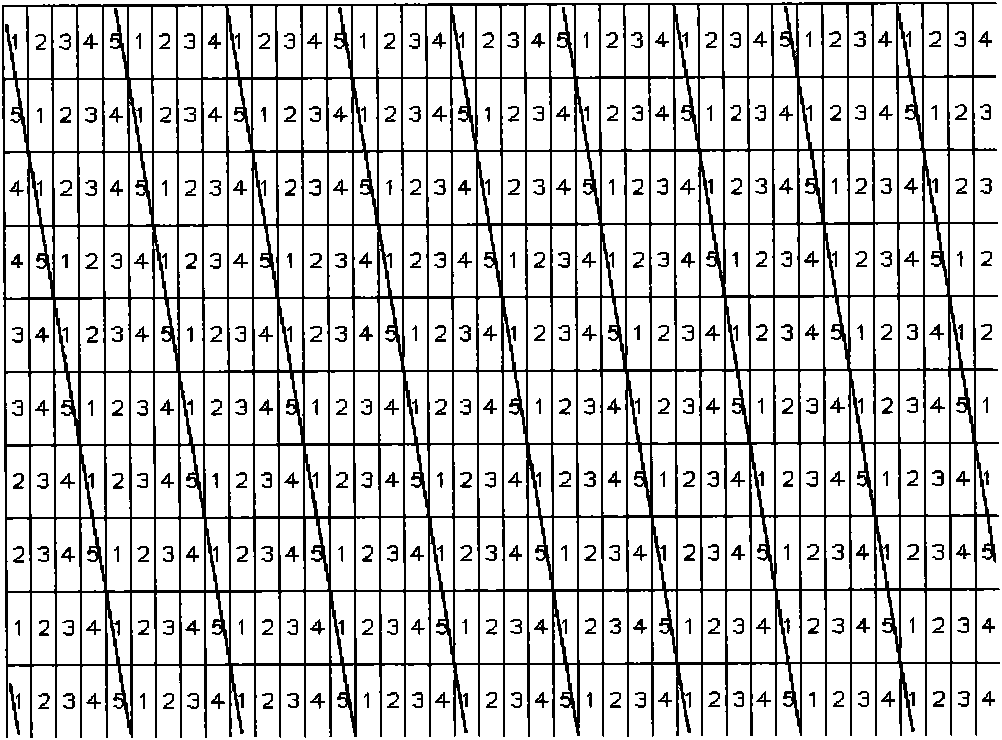

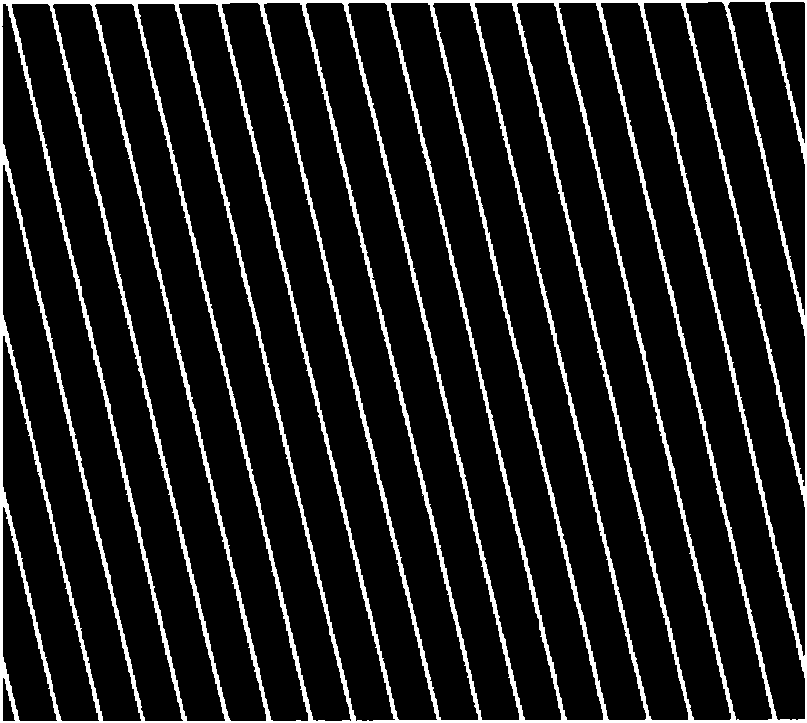

Naked-eye three-dimensional picture, animation and motion picture manufacturing method and picture synthesis apparatus

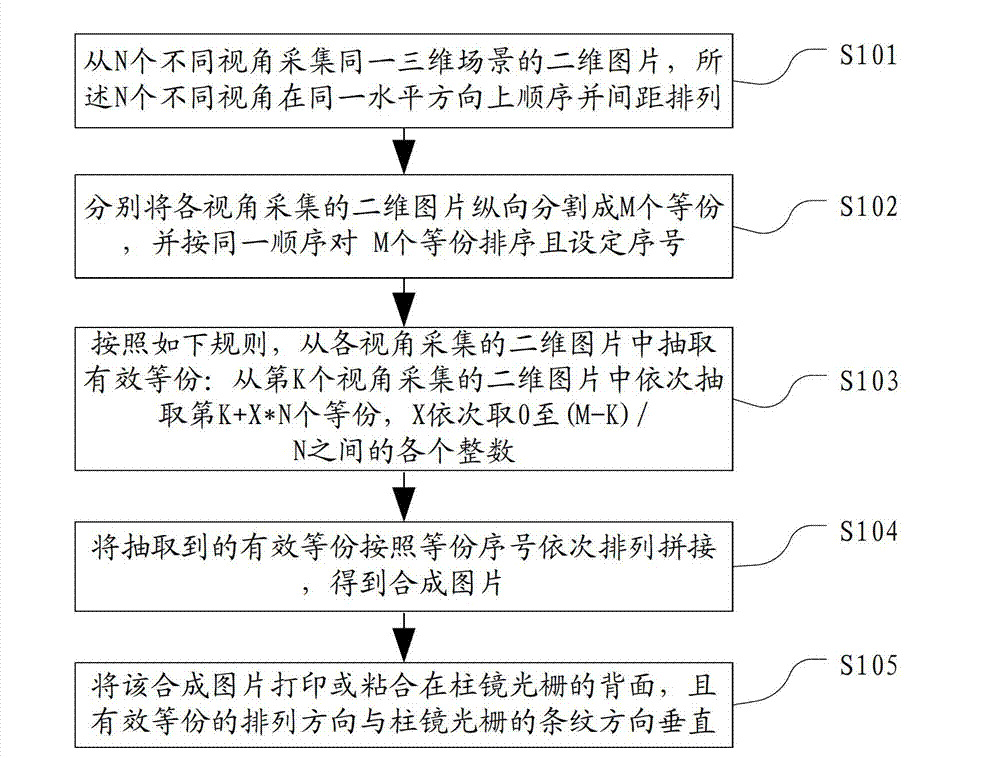

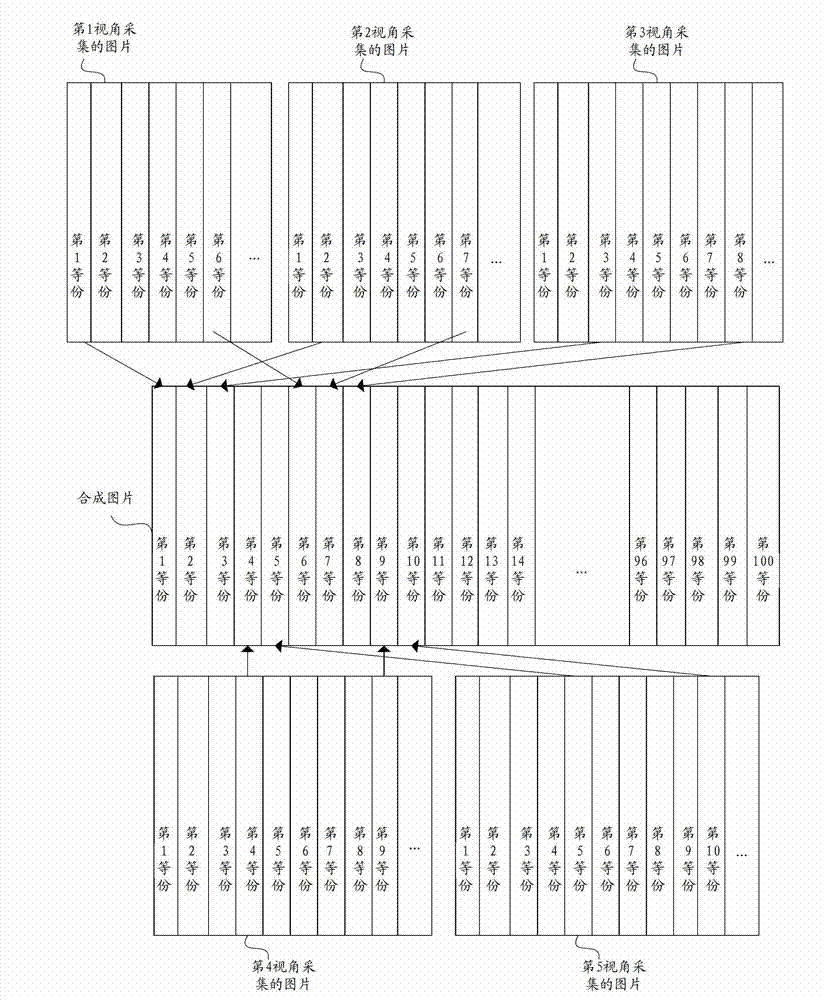

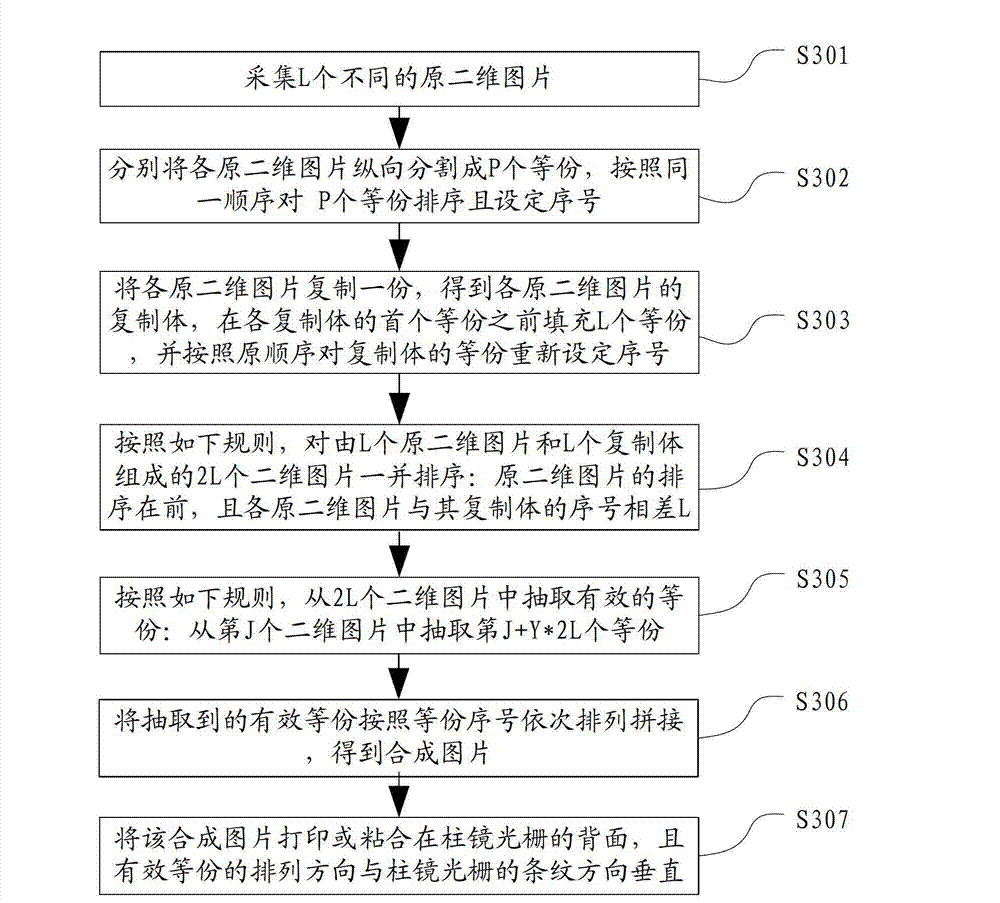

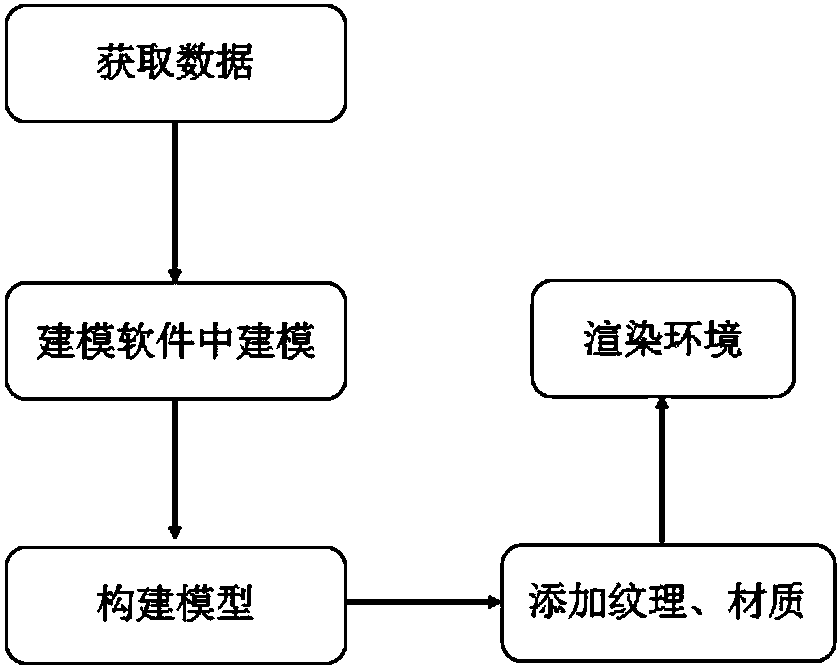

ActiveCN103714566AThe production process is simpleGood three-dimensional effectAnimation3D modellingAnimationGrating

The invention discloses a naked-eye three-dimensional picture, animation and motion picture manufacturing method and a picture synthesis apparatus. The naked-eye three-dimensional picture manufacturing method comprises acquiring two-dimensional pictures of the same three-dimensional scene from N different visual angles, vertically segmenting the two-dimensional pictures acquired from the visual angles into M equal parts respectively, according to the same sequence, ordering the M equal parts and setting sequence numbers, and according to the following rules, extracting effective equal parts from the two-dimensional pictures acquired from the visual angles: successively extracting a (K+X*N)th equal part from the two-dimensional pictures acquired from a Kth visual angle, wherein 1<=K<=N, and X is an integer successively taken from a range from 0 to (M-K) / N; successively arranging and splicing the extracted effective equal parts according to the sequence numbers of the equal parts to obtain a synthesized picture; and printing or adhering the synthesized picture on the back surface of a lenticular grating, the arranging direction of the effective equal parts being vertical to the striped direction of the lenticular grating. By using the technical scheme, the problems of complex and time-consuming three-dimensional manufacturing process and poor effects are solved.

Owner:SHENZHEN SILKROAD DIGITAL VISION

Process for performing glass printing by using three-dimensional ink

The invention discloses a process for performing glass printing by using three-dimensional ink. The process comprises the following steps of: cleaning a plate; laying the three-dimensional ink on the plate; baking for forming; cooling; printing a coating; baking; finishing; and the like. The process for performing glass printing by using three-dimensional ink provided by the invention is environment-friendly and efficient, can show a highly three-dimensional forming effect and can realize large-scale batch production in production practice.

Owner:FOSHAN CITY GREEND CHEM

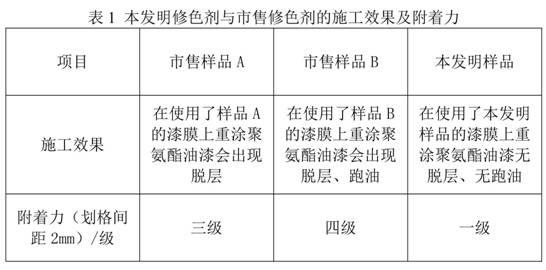

Single-component woodware color modifier easy to construct and preparation method thereof

InactiveCN102675987AGood three-dimensional effectDoes not affect adhesionCoatingsOrganosolvEthylic acid

The invention discloses a single-component woodware color modifier easy to construct and a preparation method of the single-component woodware color modifier. The color modifier comprises the following compositions in percent by weight as follows: 80-87% of organic solvent, 1.8-3% of aldehyde ketone resin, 1.2-2% of acetate solvent, and 10-15% of color concentrate solution, wherein the color concentrate solution is obtained by dissolving a color concentrate into the organic solvent, and the mass concentration of the color concentrate solution is 0.01-49%. The detection and trial prove that the single-component woodware color modifier has excellent tinting strength and does not affect the adhesive force of a coating; in the construction, the smell is small, the construction can be carried out easily, no spraying operation is needed, and the brushing and coating operations can be carried out only by a worker; particularly after the construction, the texture of wood is clear, the three-dimensional layered effect is excellent, the coloring effect can also be easily mastered by a construction worker, and the construction is quick and convenient.

Owner:广东花王涂料有限公司

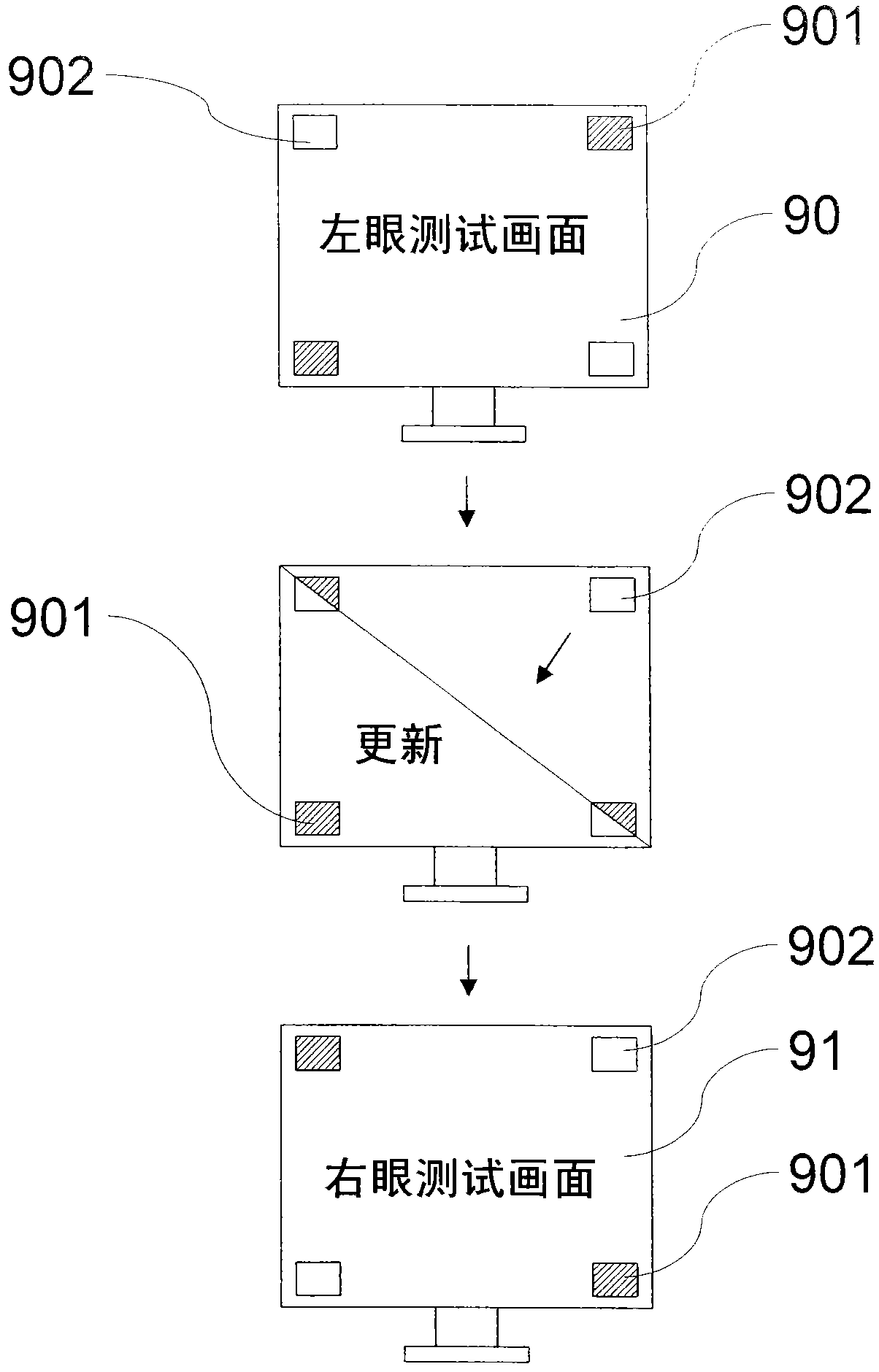

Adjustment system of three-dimensional (3D) display synchronous signals

InactiveCN102387376AGood three-dimensional effectImprove the three-dimensional effectSteroscopic systemsOptical elementsDisplay deviceEngineering

The invention discloses an adjustment system of three-dimensional (3D) display synchronous signals, which comprises a 3D signal transmitter, a pair of first sensors, a shutter glasses test seat, a pair of light sources, a pair of second sensors, a pair of shutter glasses and a calibrator. The 3D signal transmitter is arranged in a displayer or is externally connected to the displayer and provides a series of 3D synchronous signals according to vertical synchronous signals of the displayer, and a first color pattern and a second color pattern are arranged on a pair of angles on each image signal. The pair of first sensors is arranged on a pair of angles of the displayer and corresponds to the first color pattern and the second color pattern, the shutter glasses test seat is arranged in front of the displayer and provided with a placement face, and the pair of light sources is placed on the left side and the right side of the front edge of the shutter glasses test seat. The pair of second sensors is placed on the other side of the shutter glasses test seat and arranged opposite to the left light source and the right light source, the pair of shutter glasses is placed between the two light sources and the second sensors, and the calibrator is arranged on the displayer and electrically connected with the 3D signal transmitter.

Owner:DANIC INDAL

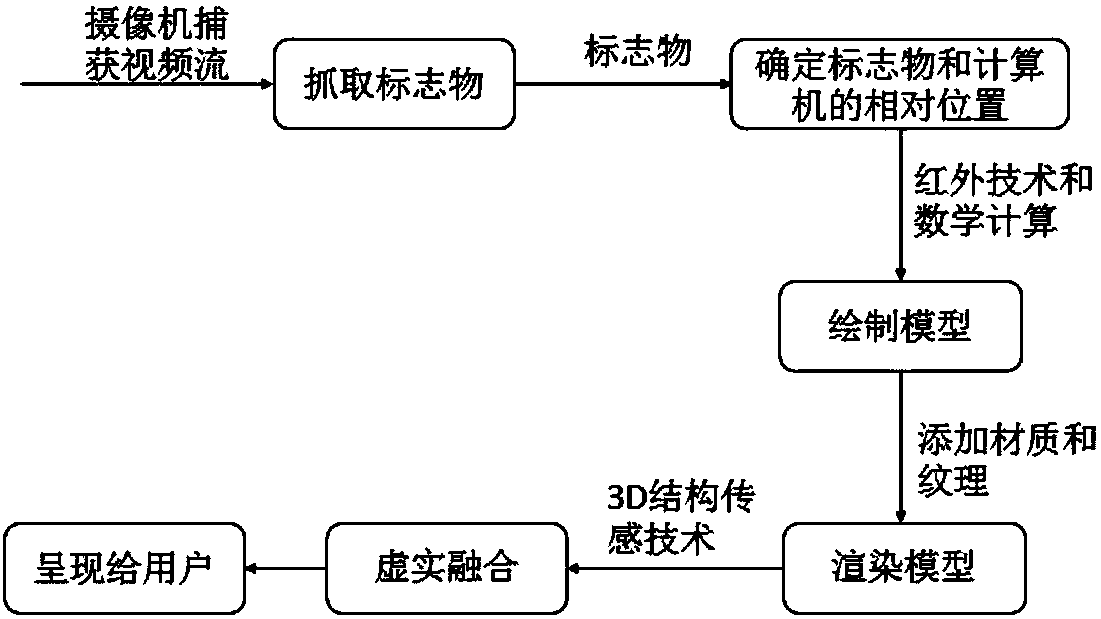

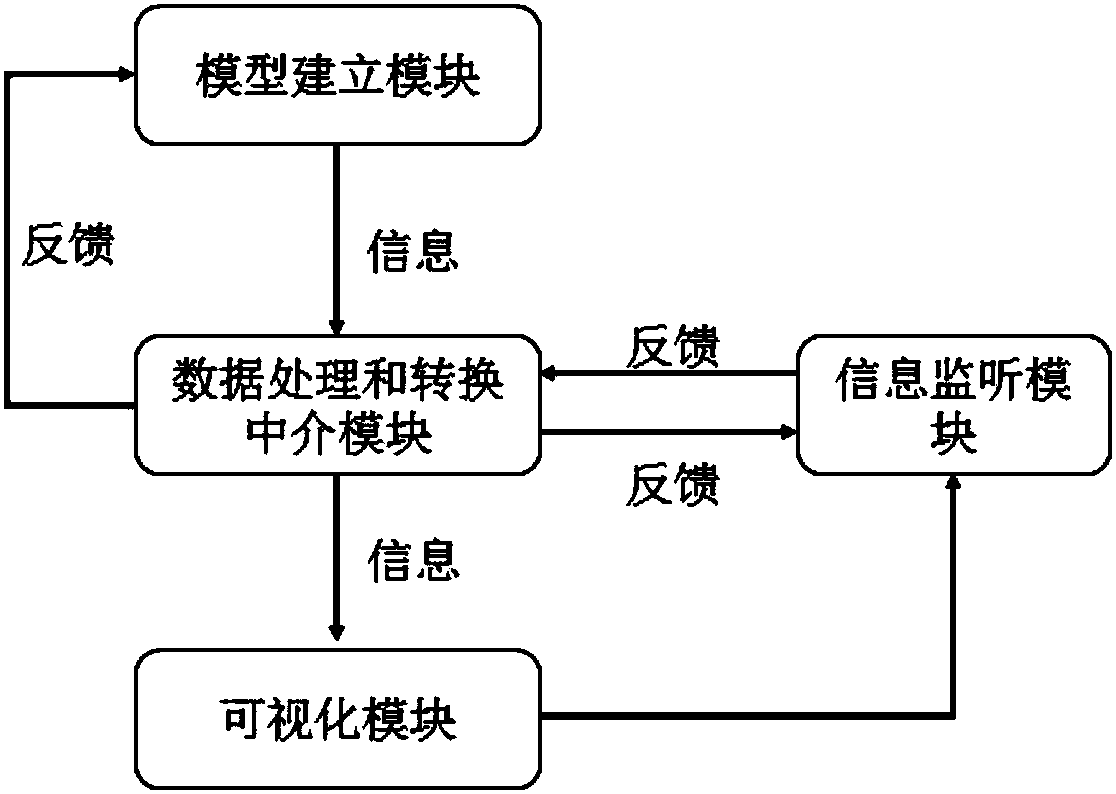

Generation method and system for multi-person interactive three-dimensional virtual environment

PendingCN108279768AImprove richness and funGood three-dimensional effectInput/output for user-computer interactionGraph readingInformation monitoringData processing

The invention relates to a generation method and system for a multi-person interactive three-dimensional virtual environment. The system comprises an information monitoring module, a visualization module, a data processing and conversion mediation module and a model establishing module, wherein the information monitoring module is used for acquiring video information and voice information, generating an interaction instruction through user operation and sending the interaction instruction to the data processing and conversion mediation module; the data processing and conversion mediation module feeds the received information, fed back by the information monitoring module, back to the model establishing module, the model establishing module returns the environment finally rendered accordingto the instruction to the data processing and conversion mediation module, and after the data processing and conversion mediation module fuses a virtual environment model and a real scene, the fusedvirtual environment model and real scene are sent to the visualization module; and the visualization module displays the whole scene to a user. Through the generation method and system, the richness and interestingness of multi-person interaction are improved, interaction content is expanded, the displayed stereo effect is better, and the immersion and experience of the user are deeper.

Owner:深圳市诺诺易购网络科技有限公司

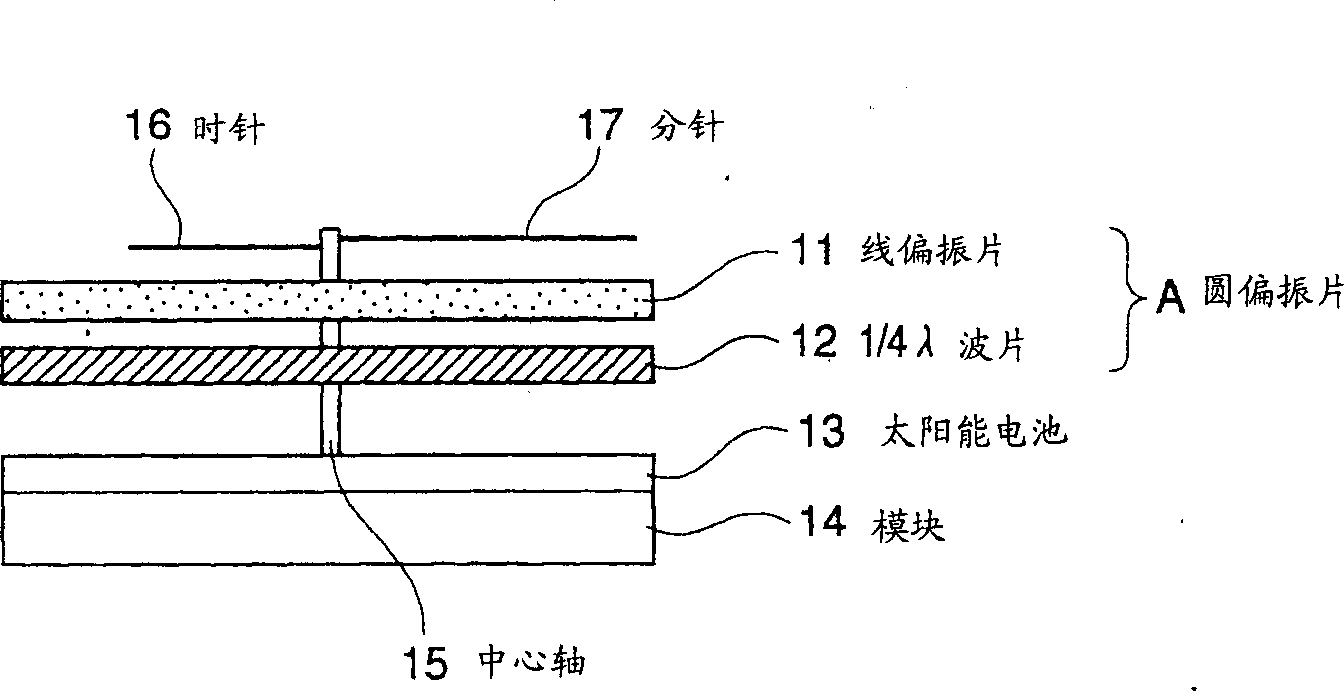

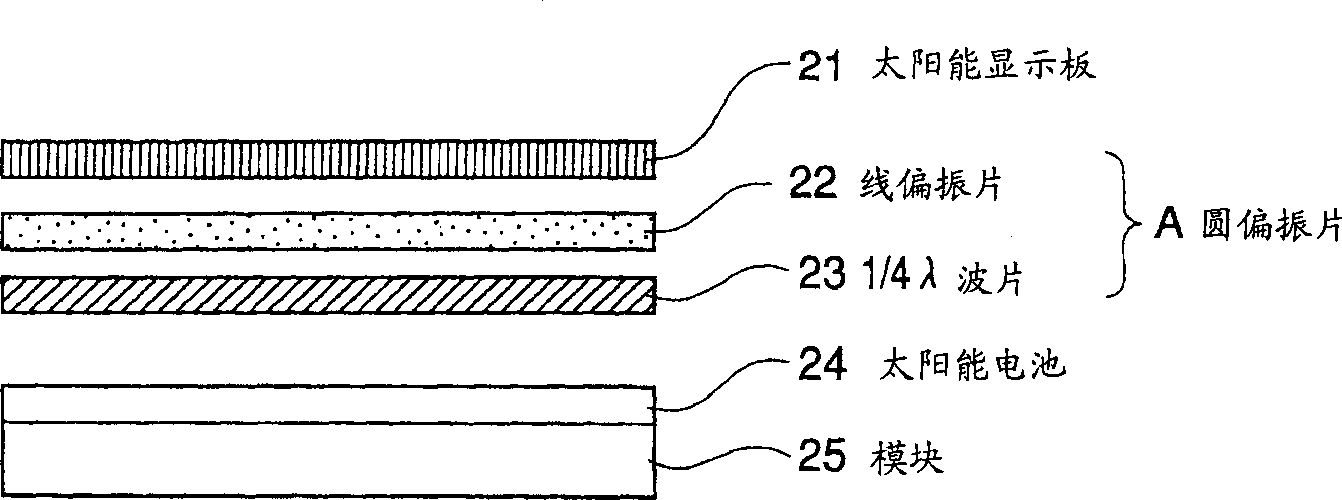

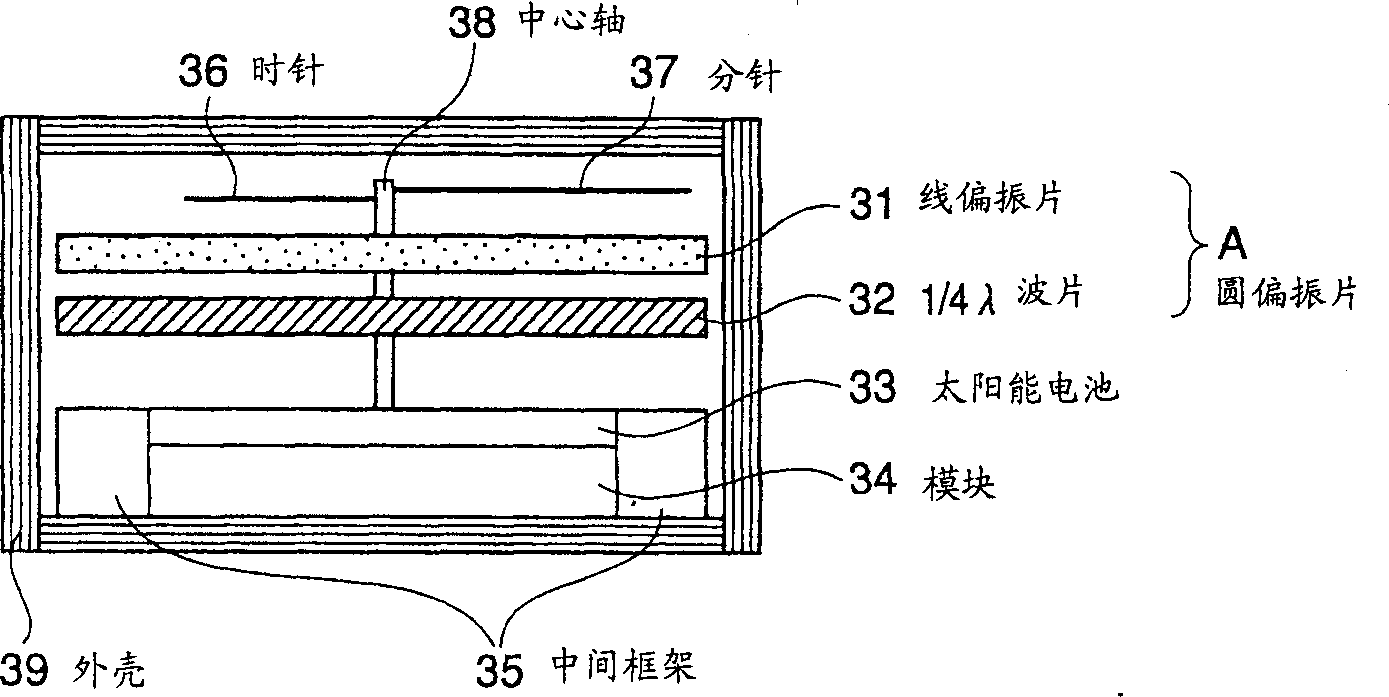

Display device of electronic apparatus provided with solar cell

InactiveCN1343375AHue is not affectedExcellent toneVisual indicationElectric windingDisplay boardDisplay device

In a display device for an electronic apparatus, a circular polarizing plate constituted by a linear polarizing plate 42 and a 1 / 4 lambda plate 43 is provided between a solar display board 41 and a middle frame 46 for fixing a module 45 having a solar cell 44 to an outer case. As a result, a boundary line between the middle frame 46 and the solar cell 44, a gate track generated through injection molding of the middle frame 46, and furthermore, a solar cell element dividing line of the solar cell 44 cannot be seen. Consequently, a variation in design of the solar display board 41 can be increased. Moreover, the color of the solar display board 41 is deepened so that a feeling of high quality can be obtained as goods, and the provision of the middle frame can provide various external shapes of a watch in respect of the design.

Owner:CITIZEN WATCH CO LTD

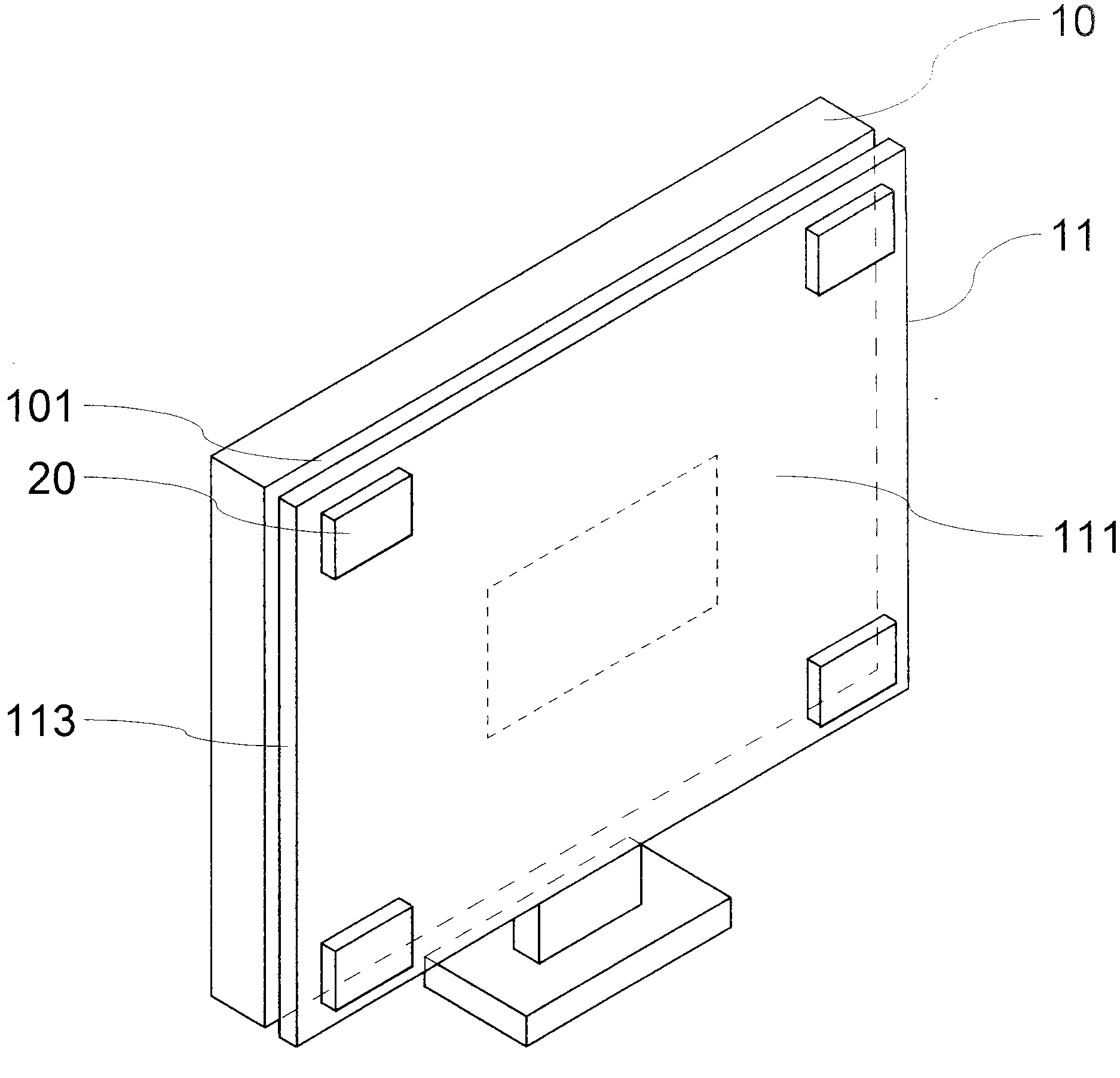

Flat three-dimensional digital photo frame

ActiveCN102087815AGood three-dimensional effectImprove the three-dimensional effectIdentification meansOptical elementsDot pitchParallax

The invention discloses a flat three-dimensional digital photo frame which comprises a display screen, a grating, a glass board and a shell, wherein the glass board and the grating which is designed according to a visual angle of 4.5 are adhered together; the distance between the display screen and the grating is d; W is the double-eye distance of a person, D is the viewing distance between the person and the flat three-dimensional digital photo frame, and S is the dot pitch of the display screen; and the display screen and the adhered grating and glass board are arranged together on the shell. The grating which is designed according to the visual angle of 4.5 is adopted in the invention, and the distance between the grating and the display screen is set into a specific distance d; after the specific picture or video with a visual angle of 5 passes through the grating, the left eye and the right eye of a viewer respectively view the pictures of two adjacent visual angles; the parallaxis obtained in double eyes, and the three-dimensional effect is formed by the brain of a person, therefore, the more favorable three-dimensional effect is realized under the condition of adopting thefewer-visual angle grating, and the problems existing in the prior art are solved.

Owner:北京优科朗润科技有限公司

Hem making process for leather garment

InactiveCN101720995AGood three-dimensional effectStable flowClothes making applicancesPolyesterPulp and paper industry

The invention discloses a hem making process for leather garment. The hem making process comprises the following steps of: 1) binding and ironing lining cloth on the bottom of the back side of the leather flap; 2) according to the set size, edge-folding, ironing and shaping the bottom; and 3) using a special hem making machine to complete the hem making operation of the bottom undergoing the edge-folding, ironing and shaping. The lining cloth materials used in the step 1 are the woven light-weight material twill lining cloth which is made of 100 percent polyester, the width of the bound and ironed lining cloth is 2 centimeters more than double of the seam folding edge, and the binding and ironing temperature is between 110 and 120 DEG C. The ironing shaping temperature is 130 DEG C. In the process, due to the binding and ironing of the lining cloth, the bottom is not rigid and frothed, and has the same softness as other parts of the leather garment, the leather garment is made to have good stereoscopic impression, the appearance line is smooth, and simultaneously the cloth in the leather garment is prevented from falling out, and the product quality is ensured.

Owner:TIANJIN YINGDAK

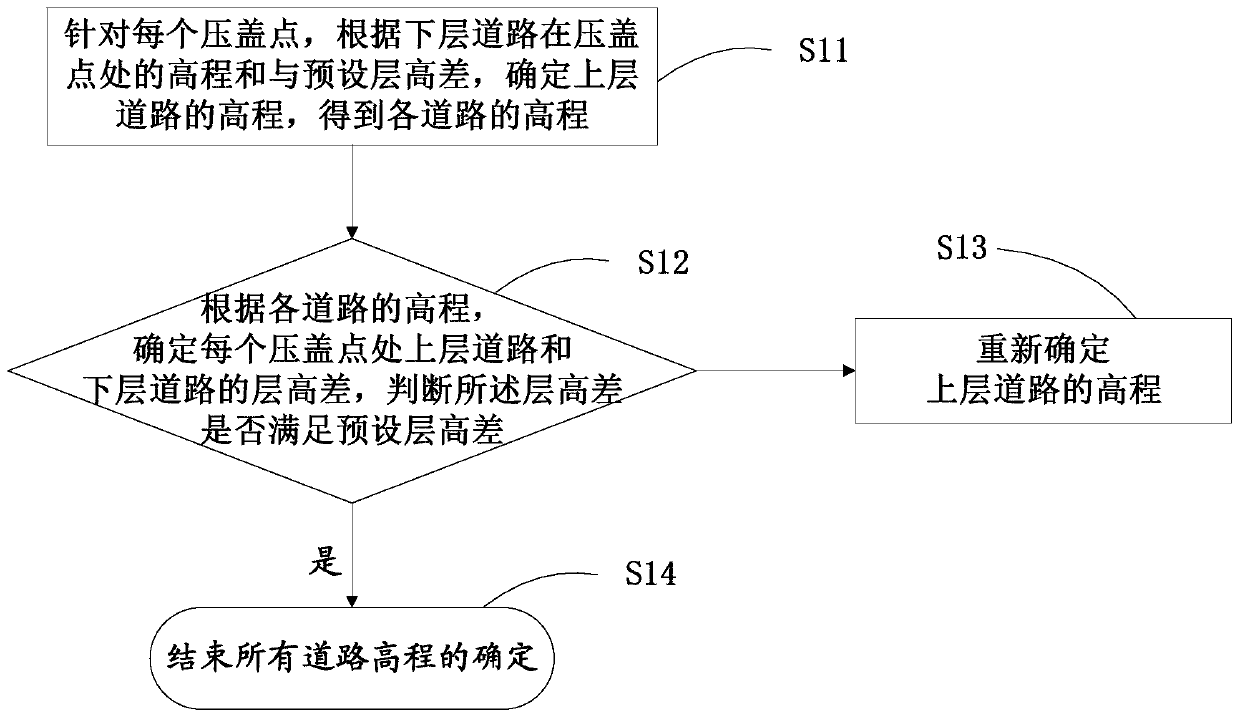

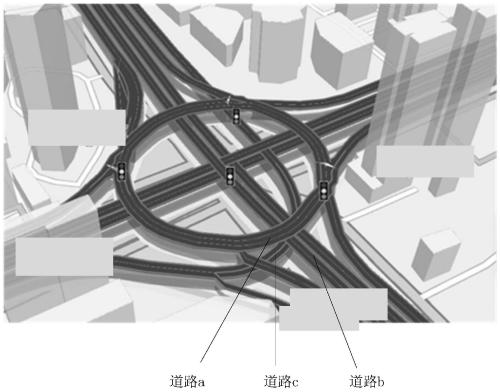

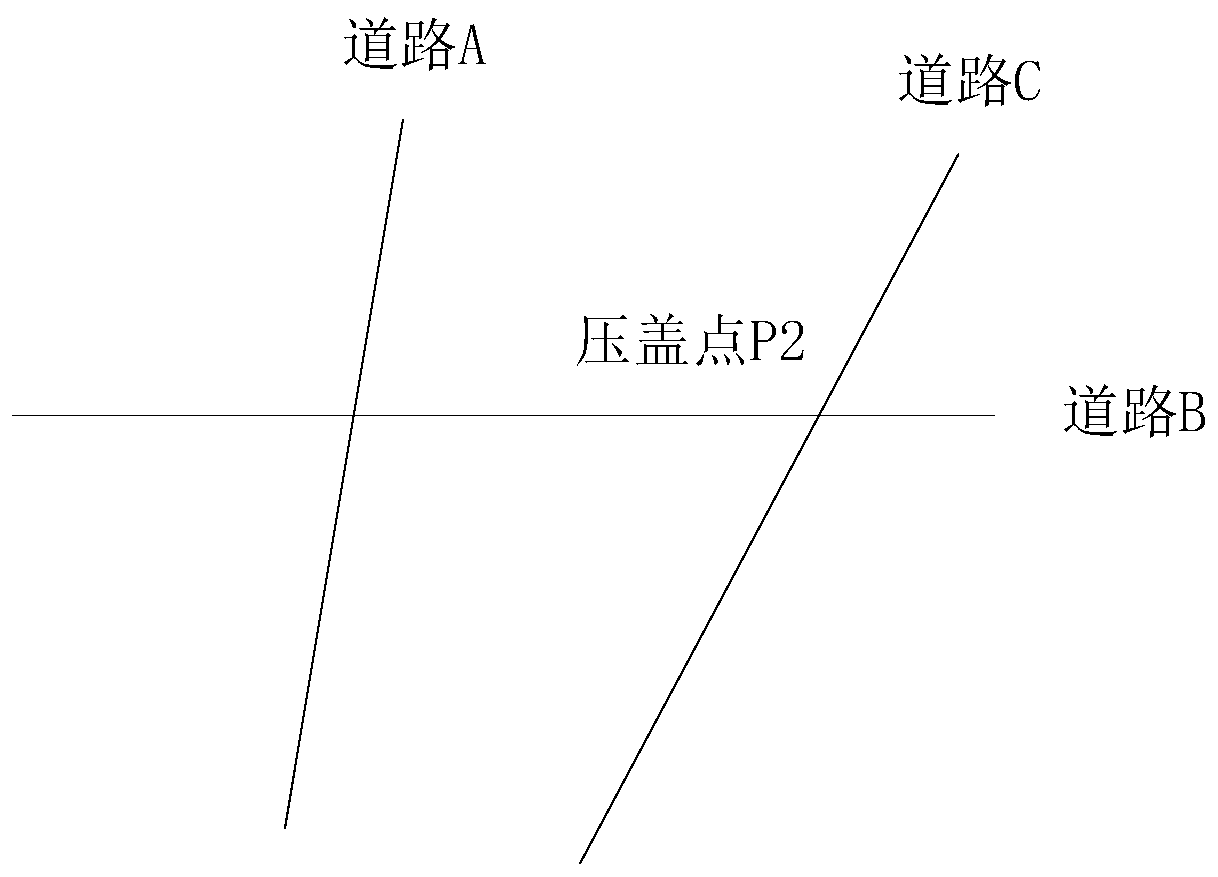

Method and device for determining road elevation

ActiveCN111501496AStrong simulationGood three-dimensional effectGeometric CADRoads maintainenceEnvironmental geologyMechanical engineering

The invention discloses a method and a device for determining road elevation. The method comprises the steps that for each gland point, the elevation of an upper-layer road is determined according tothe sum of the elevation of a lower-layer road at the gland point and the preset height difference, and the elevation of each road is obtained; wherein the cover pressing points are intersection points of the upper-layer road and the lower-layer road which have a cover pressing relationship on a two-dimensional plane; according to the elevation of each road, a judgment is made that the height difference between the upper-layer road and the lower-layer road at each gland point, and a judgment is made as to whether the height difference meets the preset height difference or not; if not, the elevation of the upper road is re-determined; wherein the height difference between the upper-layer road and the lower-layer road corresponding to all the re-determined gland points meets the preset height difference. The elevation of each road can be reasonably simulated, and three-dimensional display of each road is realized; meanwhile, the data acquisition cost is low, and the updating real-time performance is high.

Owner:ALIBABA GRP HLDG LTD

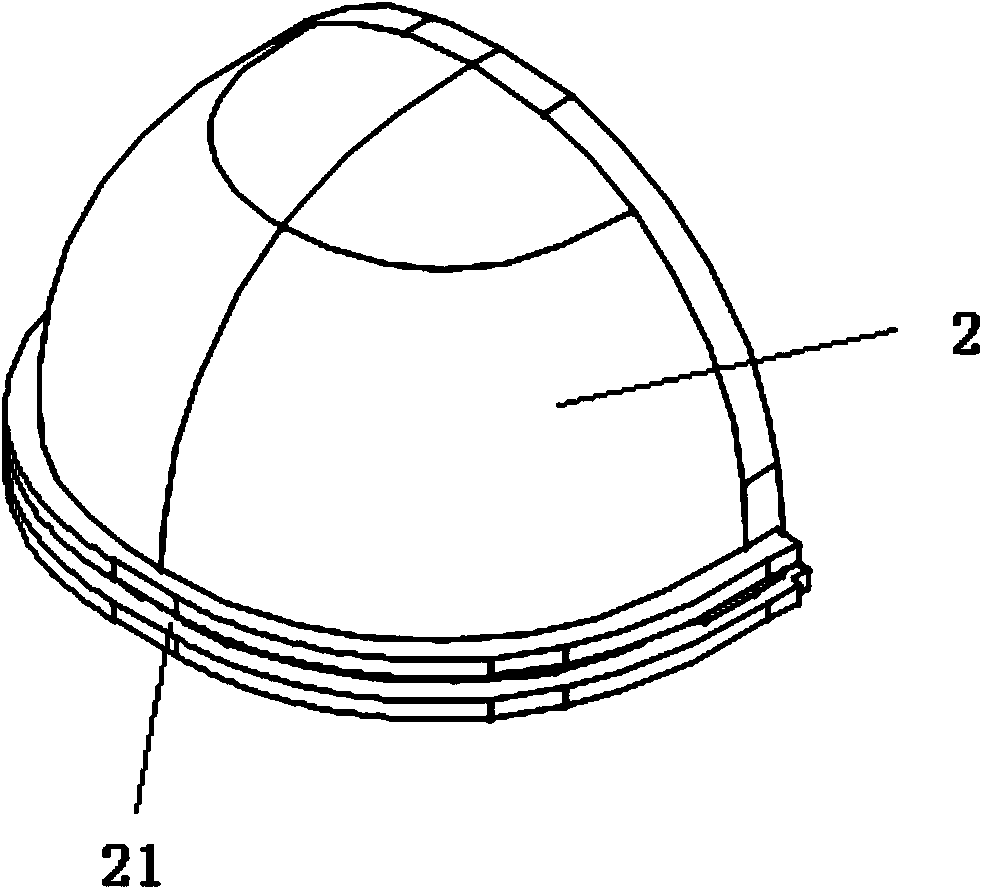

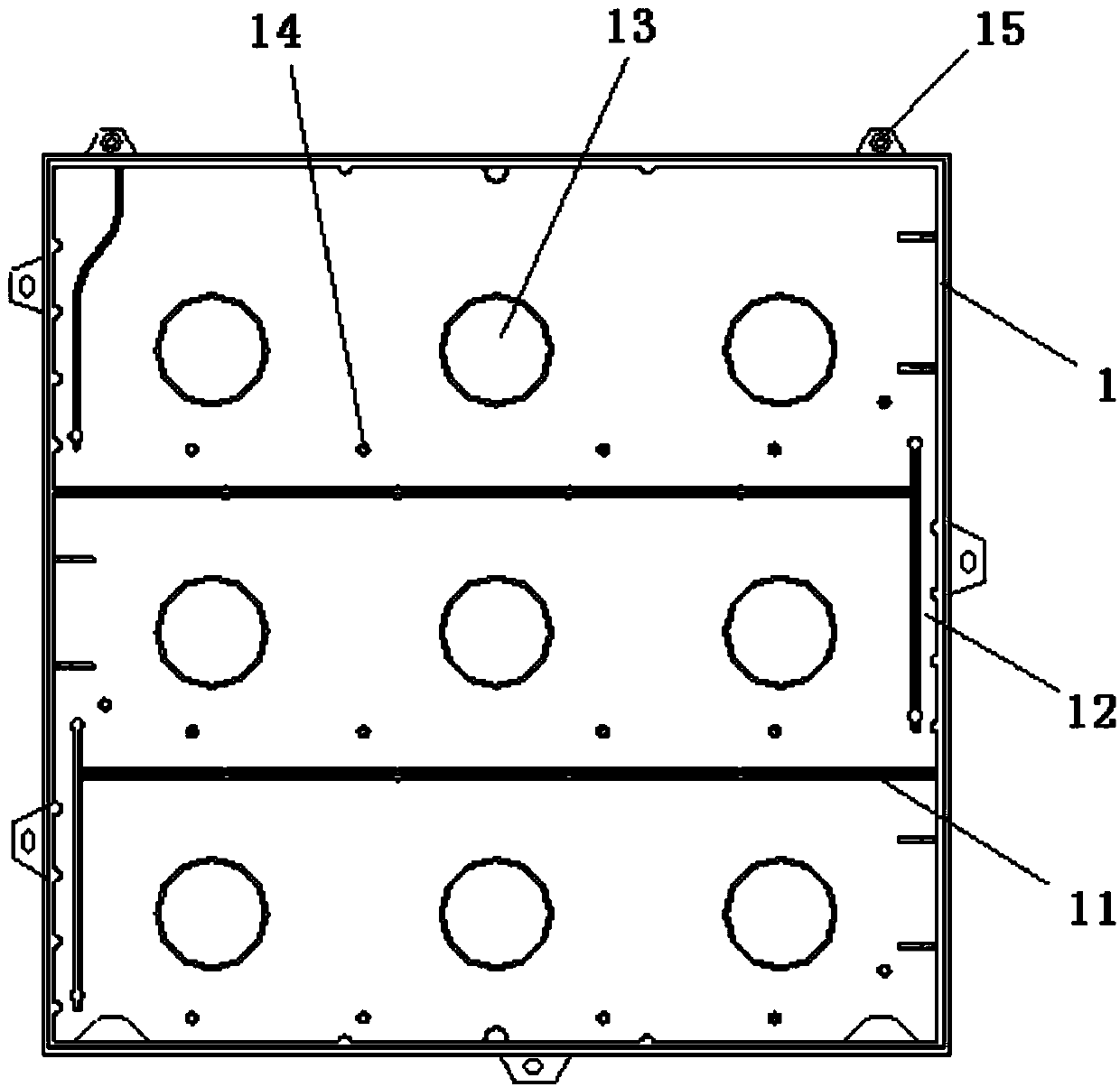

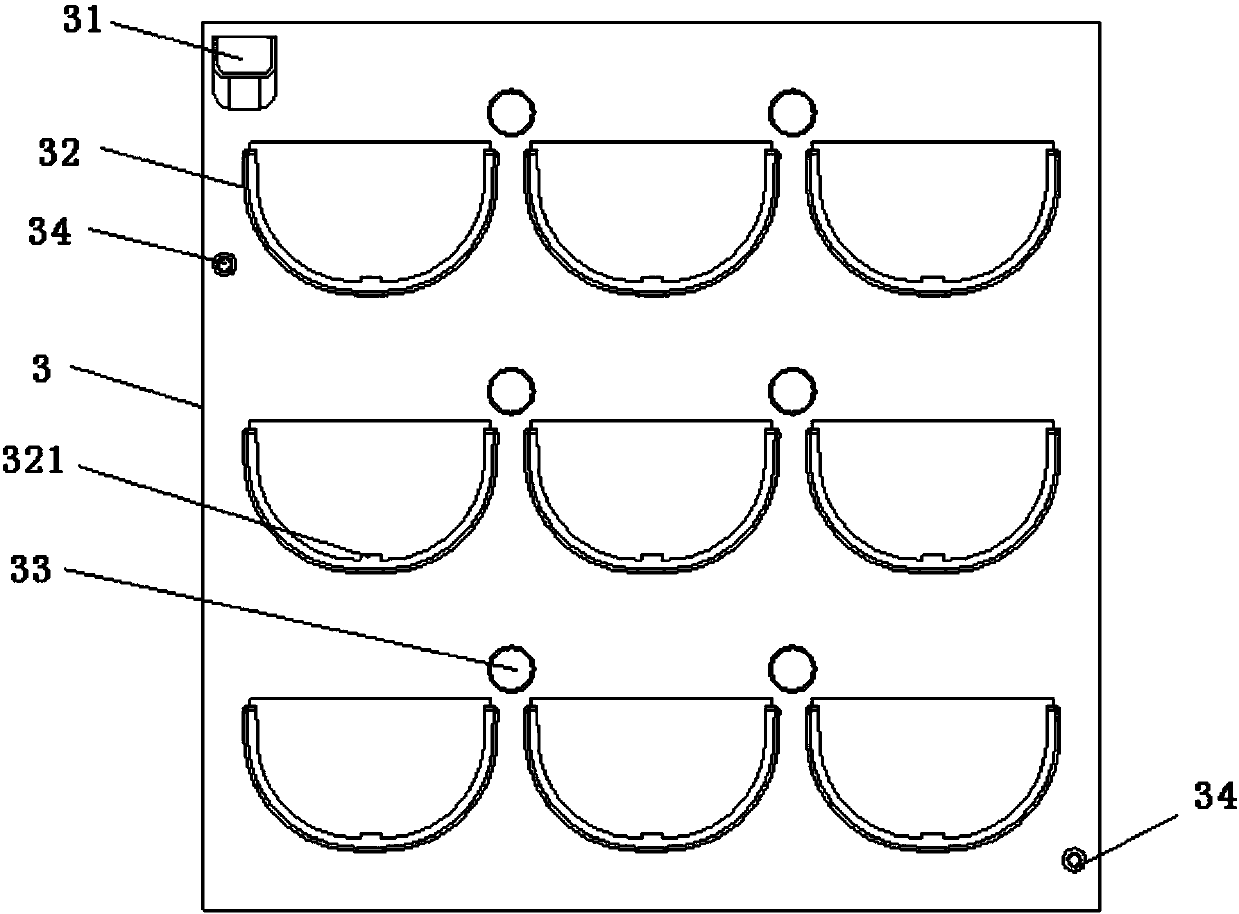

Wall-mounted long-acting plant growing module

InactiveCN103548603ASimple structureGood three-dimensional effectReceptacle cultivationFront coverEngineering

The invention discloses a wall-mounted long-acting plant growing module, which comprises a bottom plate, plant growing bowls and a front cover, wherein the bottom plate is provided with multiple layers of water channels and multiple layers of drainage channels, each plant growing bowl is provided with a clamping groove, the front cover is provided with a water filling port and a plurality of growing bowl clamping edges, wherein the water outlet end of each layer of drainage channel is communicated with the water inlet end of the corresponding water channel, the water outlet end of each layer of water channel is communicated with the water inlet end of the corresponding drainage channel, the peripheries of the front cover and the bottom plate are hermetically connected, the clamping grooves of the plant growing bowls are clamped with the growing bowl clamping edges, and the water filling port is communicated with the water inlet end of the drainage channel at the topmost layer. The wall-mounted long-acting plant growing module is simple in structure, can be randomly placed on a wall, is not limited by water resources and free of water leakage, is only 3.5cm in thickness, ensures moisture and nutriment required by growth of a plant, realizes convenience in hanging anywhere for plant decoration and is good in three-dimensional effect.

Owner:武汉绿色飞扬生态环保科技有限公司

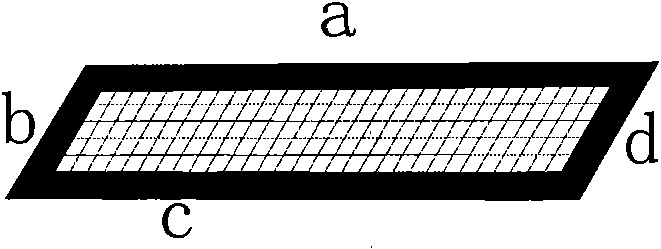

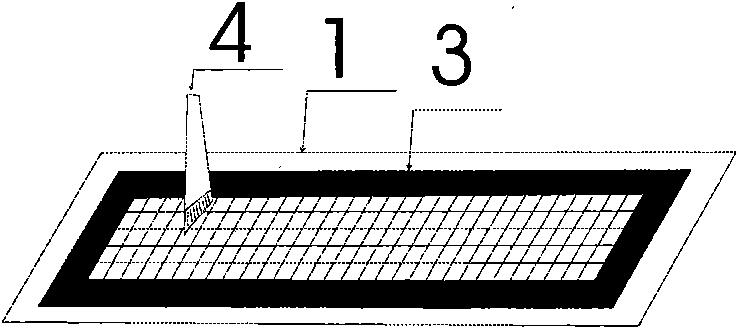

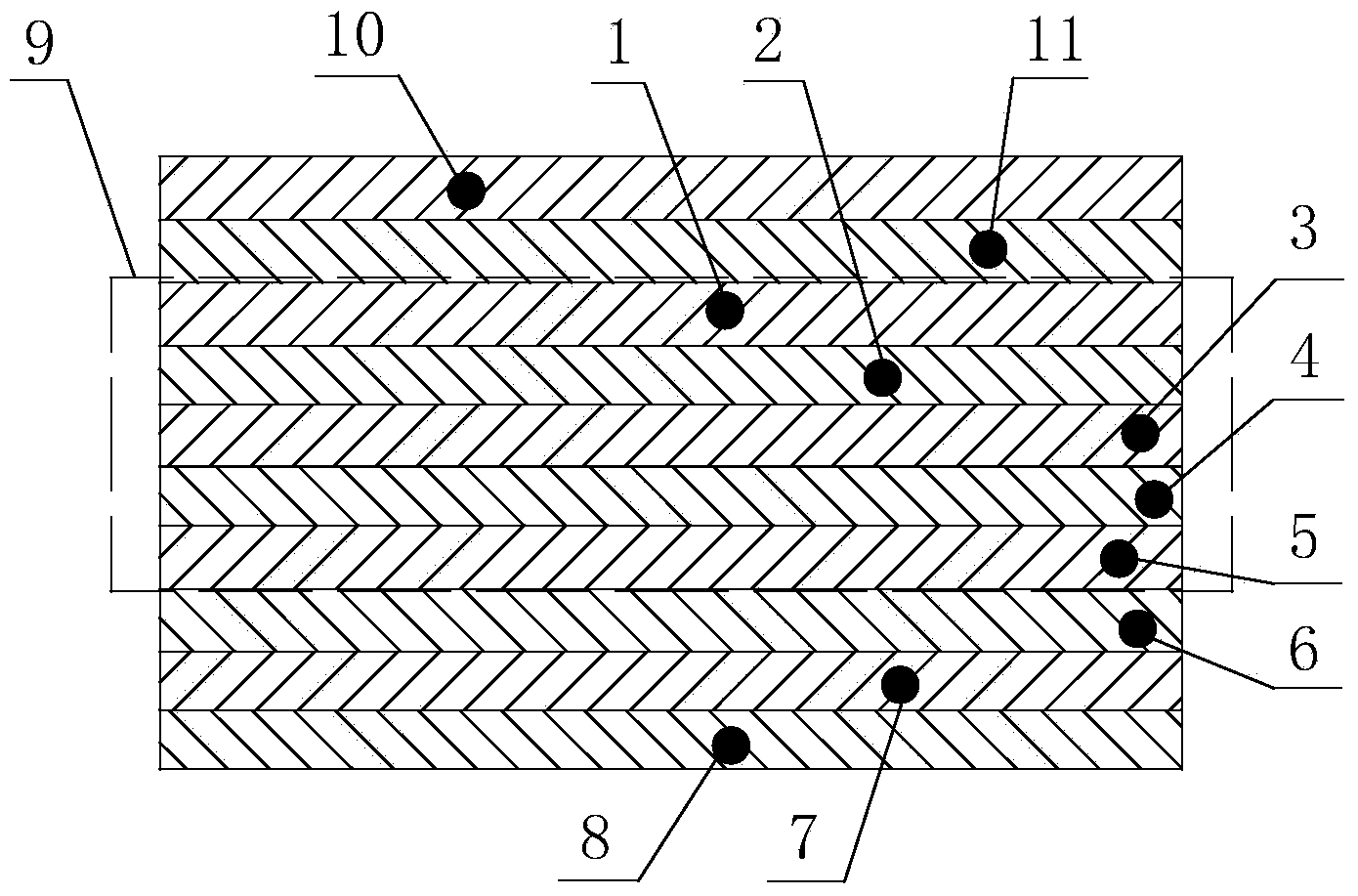

Matte three-dimensional cold-laminating composite paper

InactiveCN103898805AGood three-dimensional effectImprove the three-dimensional effectFlexible coversWrappersCoatingPulp and paper industry

The invention belongs to the technical field of packaging materials and particularly relates to composite paper and a preparation method thereof. The matte three-dimensional cold-laminating composite paper is characterized by consisting of a gloss oil layer (10), a matting layer (11), a three-dimensional cold-laminating film layer (9), an adhesive layer (6), a paper layer (7) and a back adhesive coating layer (8), wherein the gloss oil layer (10), the matting layer (11), the three-dimensional cold-laminating film layer (9), the adhesive layer (6), the paper layer (7) and the back adhesive coating layer (8) are sequentially combined into a whole. The composite paper has a good three-dimensional effect and has a matting function.

Owner:HUBEI FUSHI MATERIAL SCI & TECH

Reversely graved three-dimensional head portrait manufacturing method

InactiveCN101941350AEnhance the sense of depthGood three-dimensional effectOrnamental structuresModel makingRoughcastEngineering

The invention discloses a reversely graved three-dimensional head portrait manufacturing method which comprises the steps of head portrait preparation, blank preparation, impression, deep graving and engraving, reverse female die manufacturing, grouting, air exhausting, condensation molding, coloring, coating and the like. The method specifically comprises the followings steps of: impressing a concave head portrait on an oil blank material; deepening the lines of the concave head portrait by using a graver, wherein the engraved lines are deepened by 3-8% compared with the original lines; manufacturing a model, injecting molding rubber in the model provided with the model, and inverting the female die of the head portrait; and injecting glass slurry for condensation molding after opening the female die, and coloring and coating the molded blank to obtain the finished product. The invention enables the concave head portrait to achieve the convex three-dimensional head portrait effect toward the direction opposite to the concave by using spatial fluctuations and human visual illusion through the methods of reversely graving the concave head portrait and deepening graving depth, and thus, the head portrait is life-like and vivid.

Owner:李金成

Artistic coating with three-dimensional pearlescent effect

ActiveCN112341877ARealize three-dimensional effectStrong stain resistanceAntifouling/underwater paintsPaints with biocidesPolymer sciencePolymer chemistry

The invention discloses an artistic coating with three-dimensional pearlescent effect, and preparation and application thereof. The artistic coating is prepared from the following raw materials in parts by weight: 10-60 parts of acrylic copolymer emulsion; 0.1-5 part by weight of a rheological additive; 0.1-0.6 part by weight of a dispersing agent; 0.1-0.6 part by weight of a wetting agent; 2-10 parts by weight of a coalescing agent; 1-5 parts by weight of an antifreeze agent; 0.1-0.5 part by weight of a defoaming agent; 0.1-0.5 part by weight of a pH regulator; 1-40 parts by weight of water;3-10 parts by weight of a wax emulsion auxiliary agent; and 10-20 parts by weight of a pearlescent effect material, wherein the pearlescent effect material is natural or synthetic mica pearlescent, and the particle size of the pearlescent effect material is 10-100 microns. Compared with the prior art, the coating has the advantages of simple construction, realization of spot coating, batch coatingand roller coating, realization of the three-dimensional effect of the pearlescent art paint, fine hand feeling, and realization of protection, decoration and beautification effects through random matching with routine aqueous color pastes when the pearlescent art paint is applied to interior wall decoration construction.

Owner:GUANGDONG MAYDOS BUILDING MATERIALS LTD CO

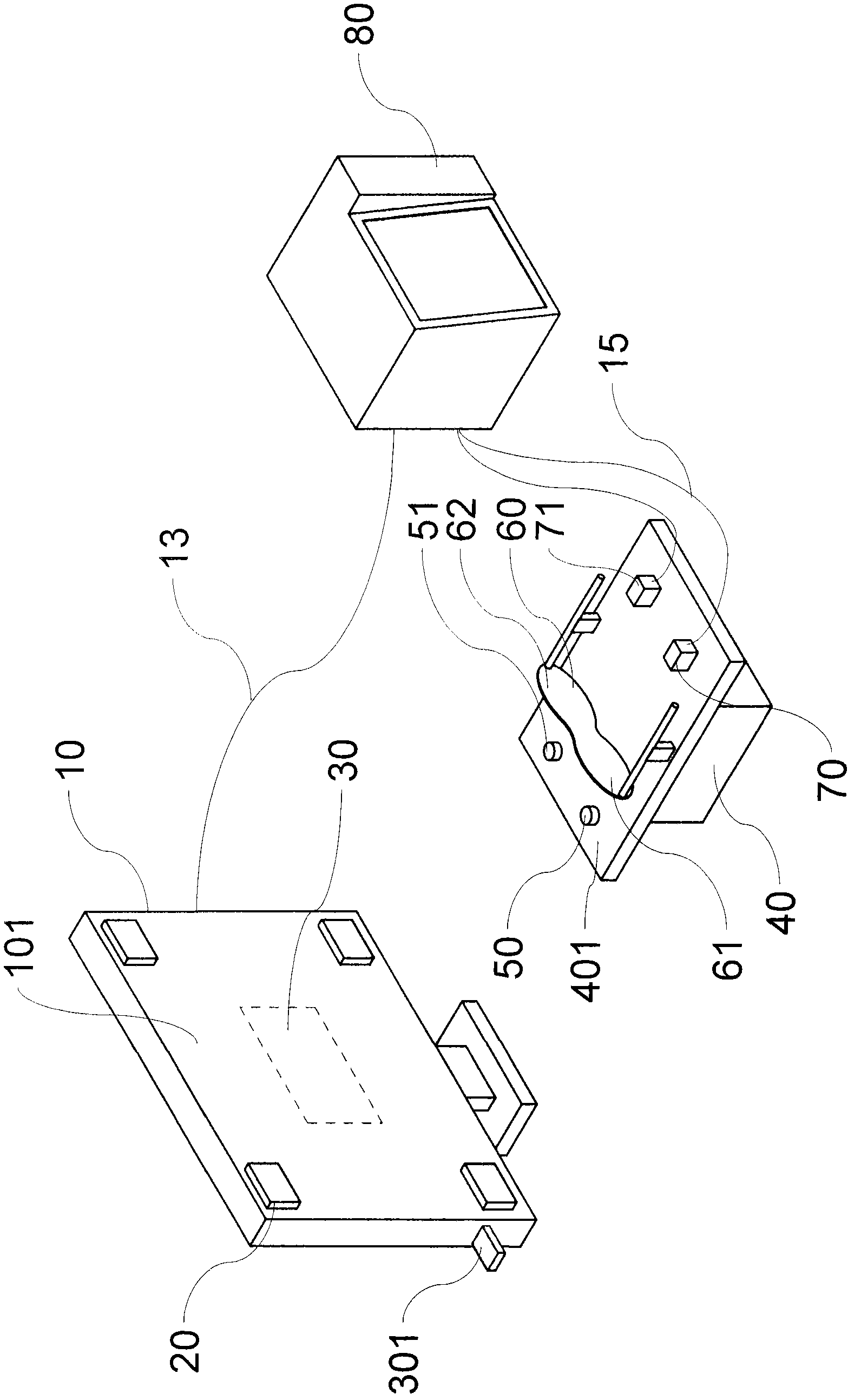

Shell, electronic device and shell manufacturing method

InactiveCN108737599AGood three-dimensional effectReduce production difficulty and costTelephone set constructionsEngineeringPolymer

The invention provides a shell, a shell manufacturing method, and an electronic device with the shell. The shell comprises a main body part and a sidewall part; the main body part is made of glass orceramic and is platy; the sidewall part is located at the edge of the main body part, thereby enabling the shell to be an opened box, and the thickness of the sidewall is greater than the thickness ofthe main body part; the sidewall part comprises an outer wall part and an inner wall part, the inner wall part is fixed on the main body part, and the outer wall part is attached to the outer surfaceof the inner wall part; the outer wall part is made of the glass or the ceramic, and the inner wall part is composed of transparent polymer material. Through the above technical scheme, the shell with a thick sidewall part and a thin main body can be obtained, and the shell is an opened box.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com