Texture regulator of seamless knitter

A density adjustment and knitting machine technology, applied in knitting, weft knitting, textiles and papermaking, etc., can solve the problems of small adjustment gap, inability to obtain three-dimensional effect, slow response speed, etc., and achieve small adjustment gap and good three-dimensional Effect, fast response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

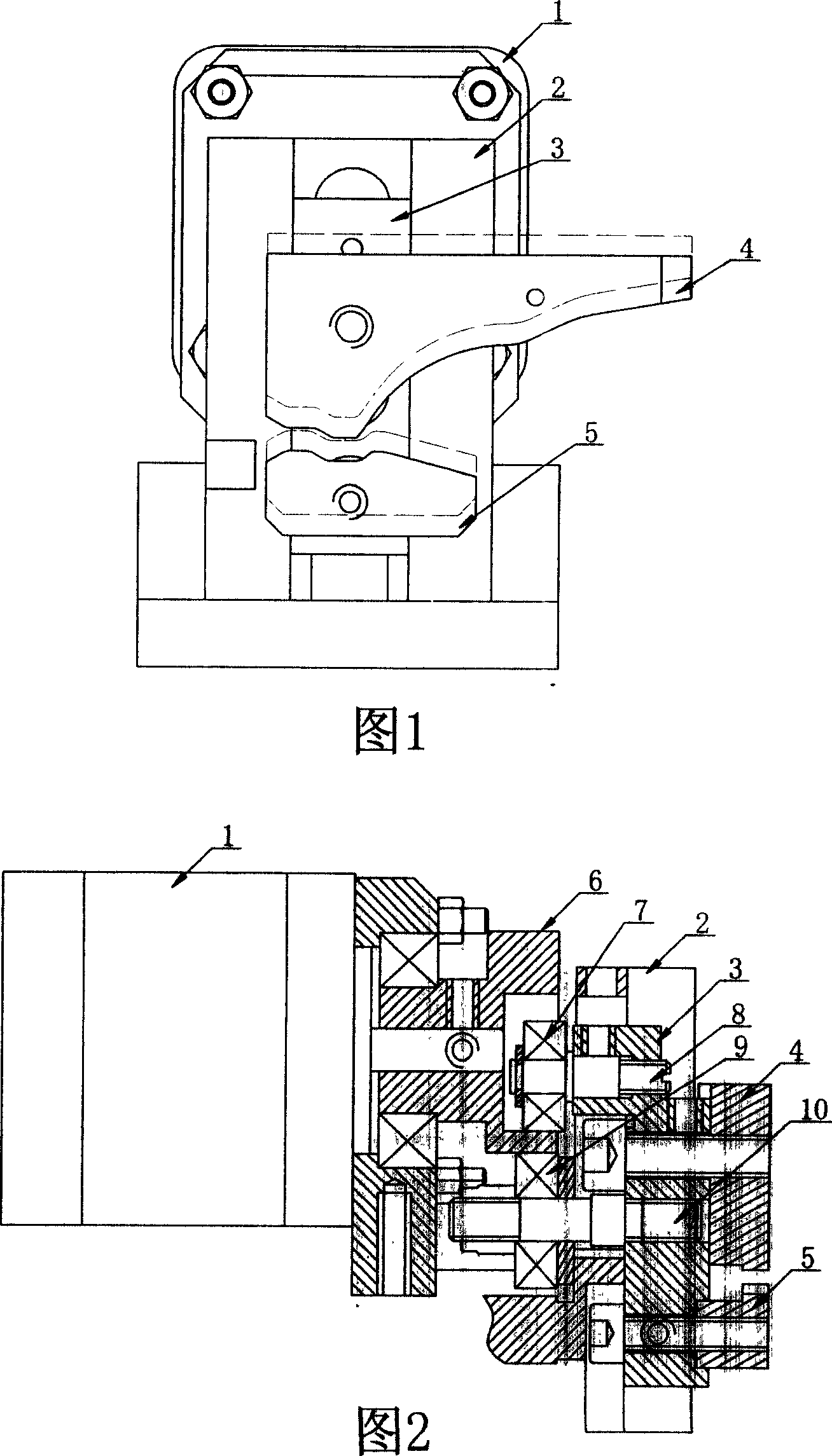

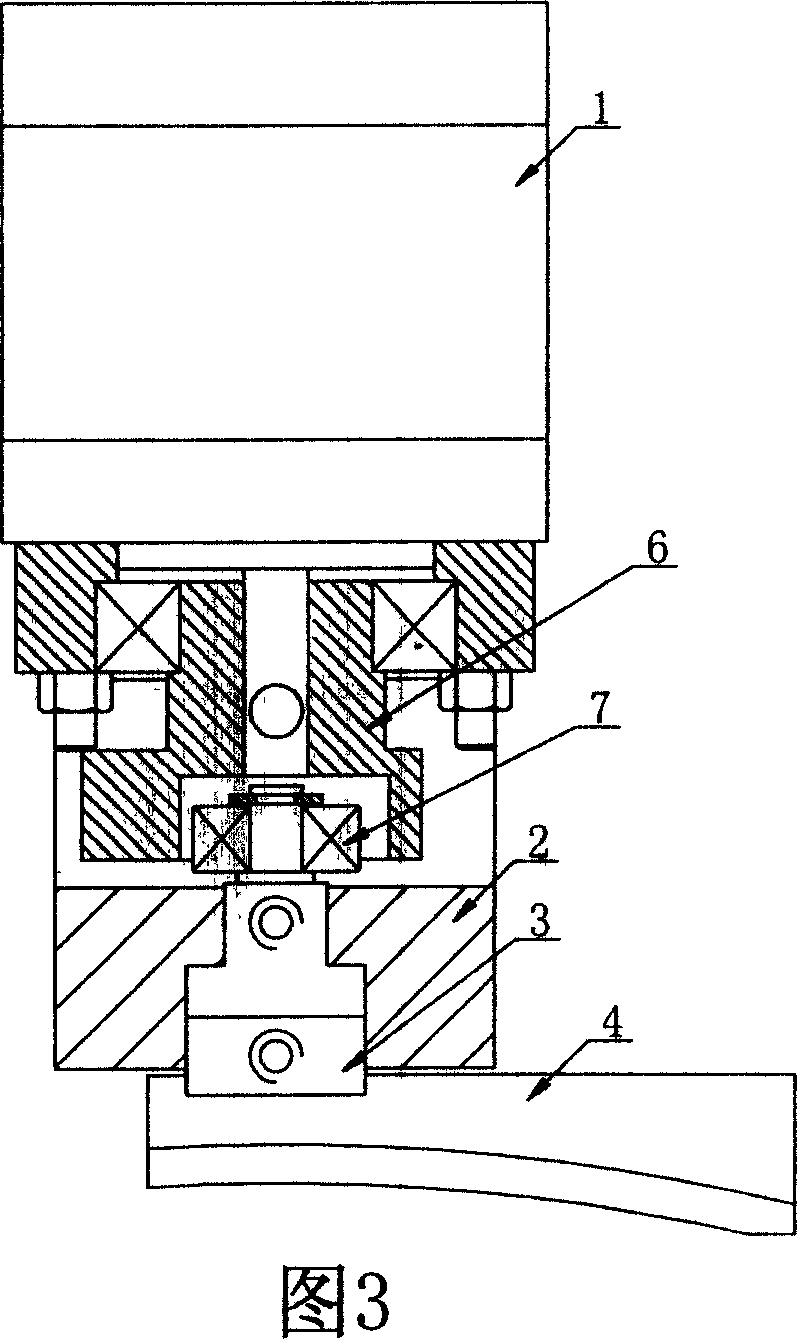

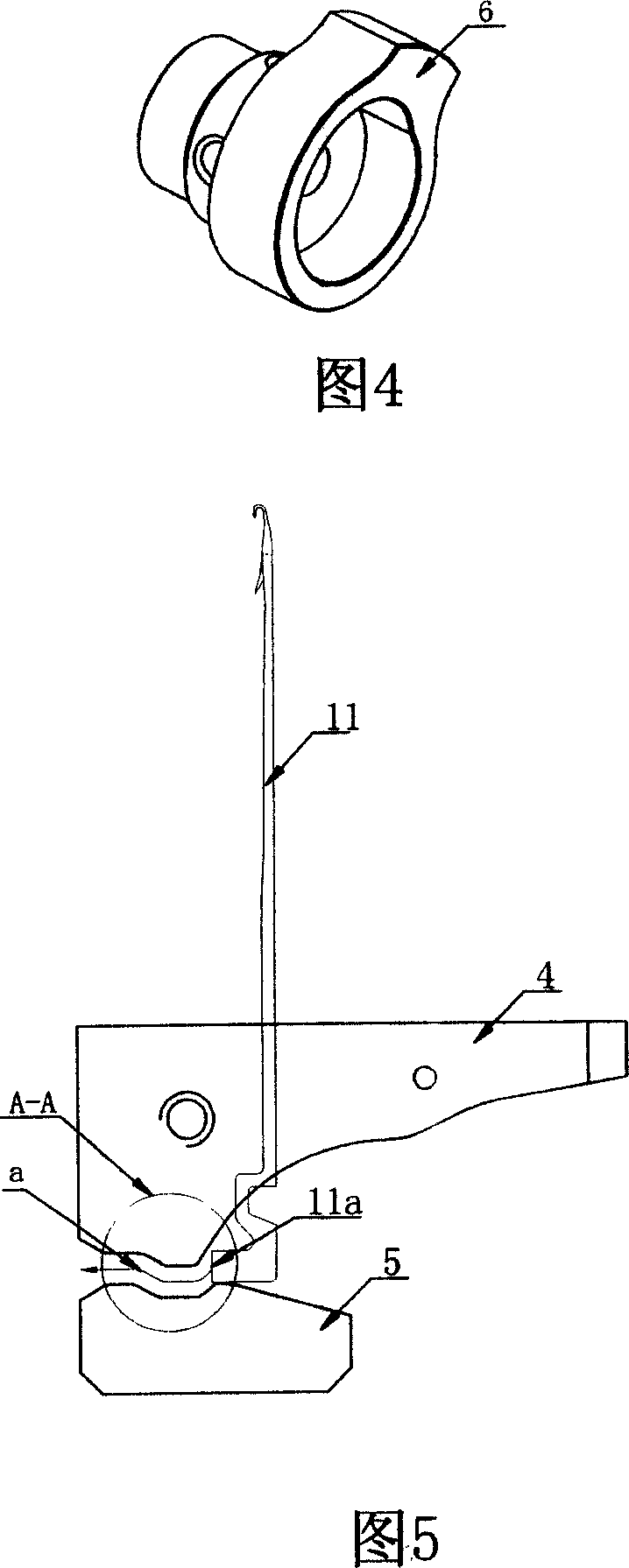

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

[0023] Referring to Figures 1 to 9, a density adjustment device for a seamless knitting machine includes a stepping motor 1 for driving and a density triangle mechanism, and the density adjustment device also includes a double-yoke cam 6, and the double-yoke cam 6 is fixedly connected with the rotating shaft of the stepper motor 1, the inner and outer bearings 7 and outer bearings 9 of the double-yoke cam 6 are respectively provided; Needle setting triangle 5, the inner bearing 7 is connected with the density triangle slider 3 through the eccentric shaft 8, the outer bearing 9 is connected with the density triangle slider 3 through the shaft pin 10, and the density needle pressing triangle and 4 density starting Needle triangle 5 is installed on the density triangle slide block 3, and density triangle slide block 3 is located in the density triangle seat 2.

[0024] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com