Titanium carbide in-situ growth CNTs three-dimensional composite with polydopamine serving as transition layer and preparation method thereof

A technology of polydopamine and in-situ growth, applied in the direction of titanium carbide, carbide, nanotechnology for materials and surface science, etc., can solve the problem of high price, and achieve the effect of low equipment requirements, high quality and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

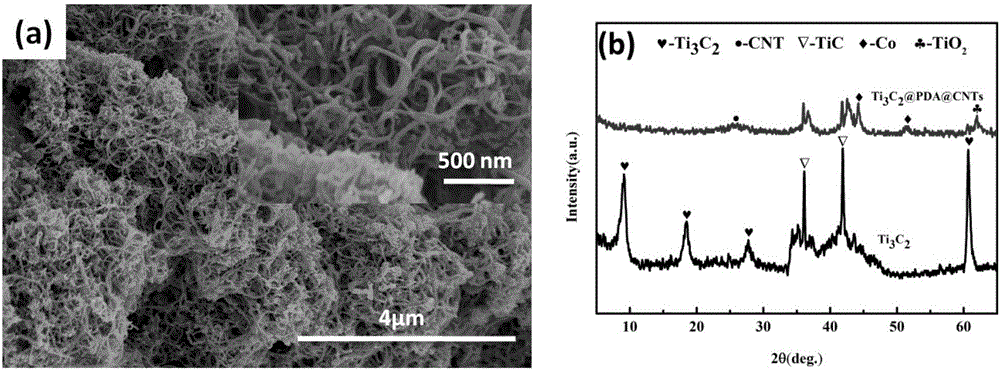

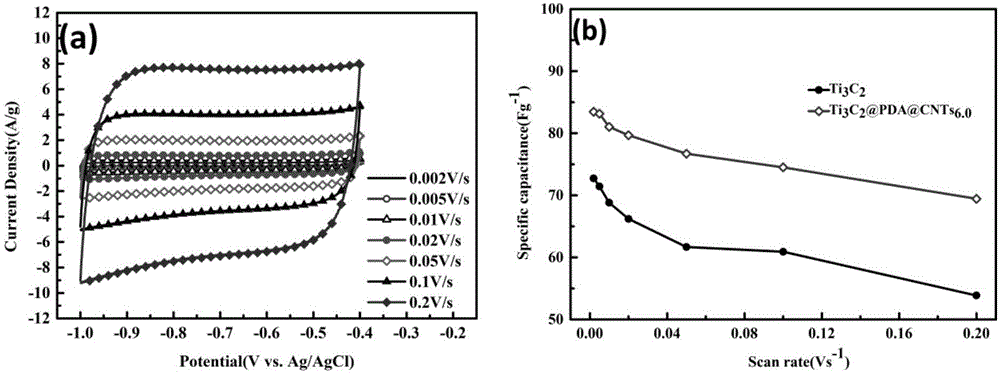

[0043] (1) Ti 3 C 2 Preparation of @PDA composite materials;

[0044] First, 500mg of Ti 3 C 2 Ultrasonic dispersion of nano powder in 300mL ultrapure water, ultrasonic 30min; 1.0g dopamine hydrochloride dissolved in 100mL ultrapure water, add the above solution, stir at room temperature under light-shielding conditions for 1h; then add 100mL Tris-buffer (50mmolL -1 , pH=8.5), stirred at room temperature for 24 hours under light-shielding conditions; centrifuged the obtained mixed solution, washed with deionized water until the supernatant was clear, transferred it to a freeze dryer, and took it out after 48 hours to obtain Ti 3 C 2 @PDA.

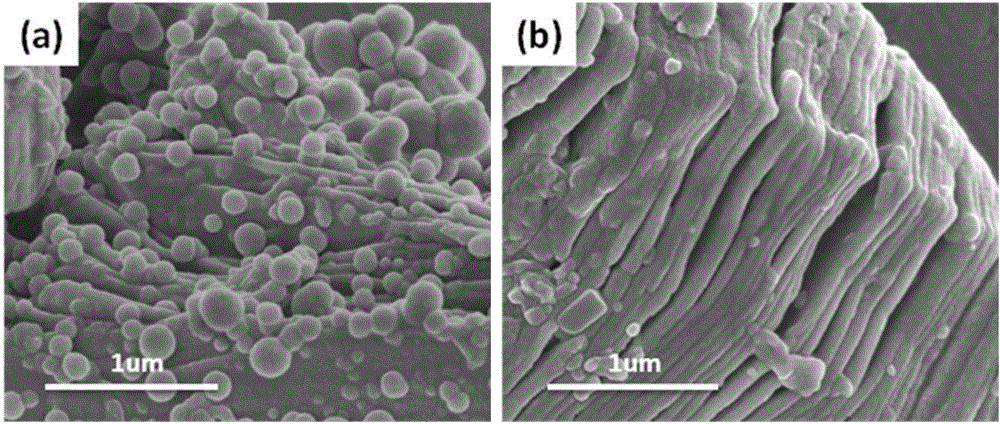

[0045] (2) Ti 3 C 2 Preparation of @PDA@CNTs three-dimensional composite materials;

[0046] First, 300mg of Ti 3 C 2 @PDA nanopowder, add to 200mL ultrapure water, ultrasonically disperse for 30min; then, add 0.29g Co(NO 3 ) 2 ·6H 2 O, stirred at room temperature for 4 hours; secondly, 6.0 g of urea was added, and the above mi...

Embodiment 2

[0049] (1) Ti 3 C 2 Preparation of @PDA composite materials;

[0050] First, 500mg of Ti 3 C 2 Ultrasonic dispersion of nano powder in 150mL ultrapure water, ultrasonic 30min; 0.5g dopamine hydrochloride dissolved in 50mL ultrapure water, add the above solution, stir at room temperature under light-shielding conditions for 1h; then add 50mL Tris-buffer (50mmolL -1 , pH=8.5), stirred at room temperature for 24 hours under light-shielding conditions; centrifuged the obtained mixed solution, washed with deionized water until the supernatant was clear, transferred it to a freeze dryer, and took it out after 48 hours to obtain Ti 3 C 2 @PDA.

[0051] (2) Ti 3 C 2 Preparation of @PDA@CNTs three-dimensional composite materials;

[0052] First, 300mg of Ti 3 C 2 @PDA nanopowder, add to 200mL ultrapure water, ultrasonically disperse for 30min; then, add 0.29g Co(NO 3 ) 2 ·6H 2 O, stirred at room temperature for 4 hours; secondly, 6.0 g of urea was added, and the above mixe...

Embodiment 3

[0054] (1) Ti 3 C 2 Preparation of @PDA composite materials;

[0055] First, 500mg of Ti 3 C 2 Ultrasonic dispersion of nano powder in 75mL ultrapure water, ultrasonic 30min; 0.25g dopamine hydrochloride dissolved in 25mL ultrapure water, add the above solution, stir at room temperature under light-shielding conditions for 1h; then add 25mL Tris-buffer (50mmolL -1 , pH=8.5), stirred at room temperature for 24 hours under light-shielding conditions; centrifuged the obtained mixed solution, washed with deionized water until the supernatant was clear, transferred it to a freeze dryer, and took it out after 48 hours to obtain Ti 3 C 2 @PDA.

[0056] (2) Ti 3 C 2 Preparation of @PDA@CNTs three-dimensional composite materials;

[0057] First, 300mg of Ti 3 C 2 @PDA nanopowder, add to 200mL ultrapure water, ultrasonically disperse for 30min; then, add 0.29g Co(NO 3 ) 2 ·6H 2 O, stirred at room temperature for 4 hours; secondly, 6.0 g of urea was added, and the above mixe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com