A method of separating carbon dioxide

A carbon dioxide and a part of the technology, applied in the field of gas absorption and separation, can solve the problems of small absorption capacity of absorbent, low sensitivity of device operation, high absorption and regeneration energy consumption, etc., and achieve simple control scheme, improve operation flexibility and reduce operation cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

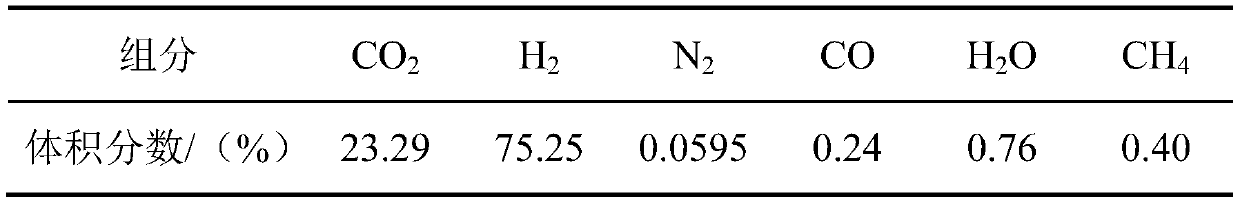

[0054] In the present embodiment, the size of the packing area of the absorption tower (from the top of the tower to the bottom of the tower, the same below) is: (including the part of the rotating body), the tower height is 40000mm, and the bottom of the absorption tower is equipped with The rotating body; the size of the sieve plate of the desorption tower is: The height of the tower is 33000mm. The theoretical plate number of the absorption tower is 10, and the theoretical plate number of the desorption tower is 8. The composition of the mixed gas is shown in Table 1. The composition of the absorption liquid: 100 parts by weight of desalinated water, 69.0 parts by weight of MDEA, 3.44 parts by weight of piperazine as an activator, 0.02 parts by weight of emulsified silicone oil as a defoamer, and 0.01 part by weight of potassium metavanadate as a corrosion inhibitor.

[0055] Table 1 Mixed gas composition

[0056]

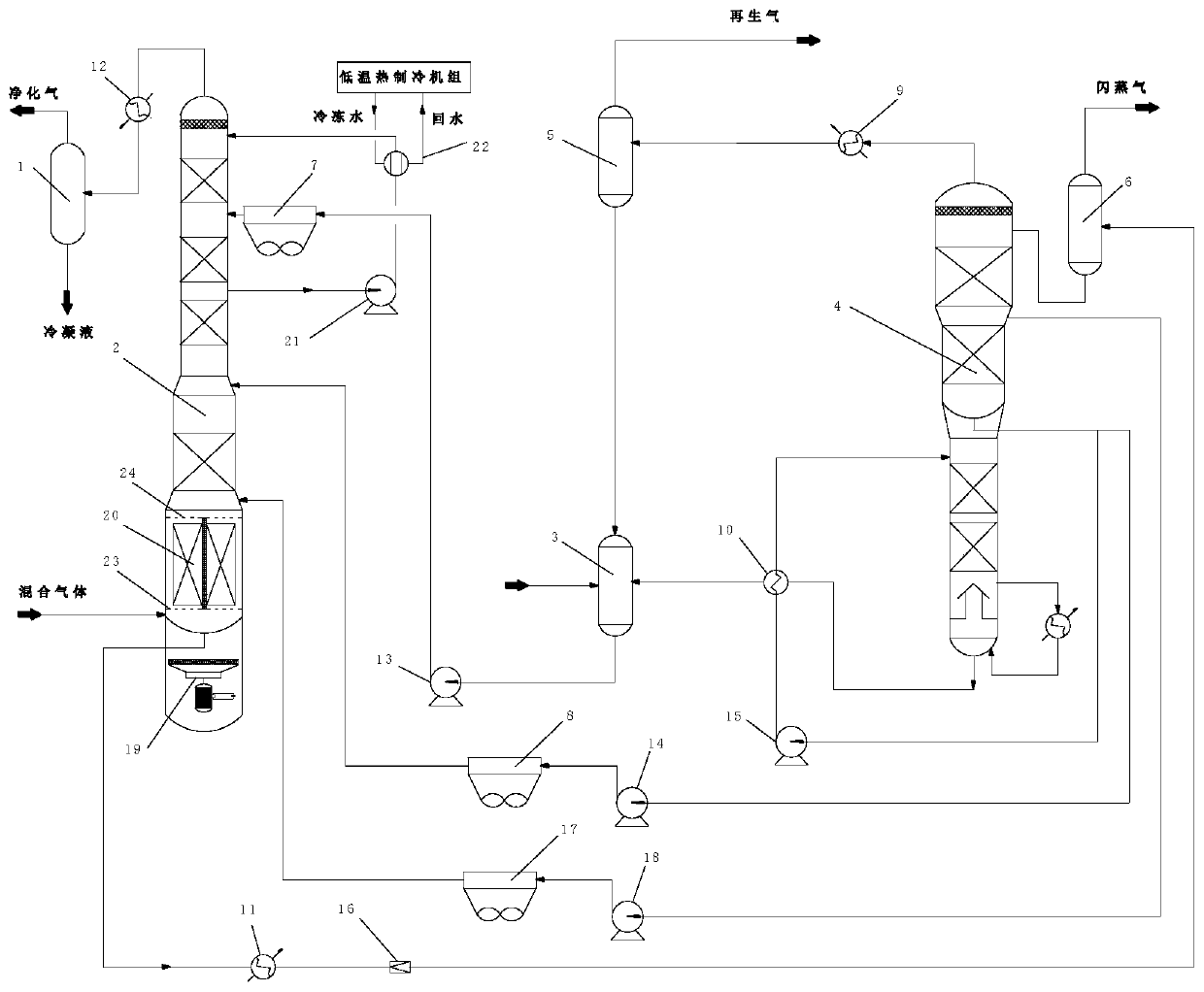

[0057] like figure 1 As shown, the carbon d...

Embodiment 2

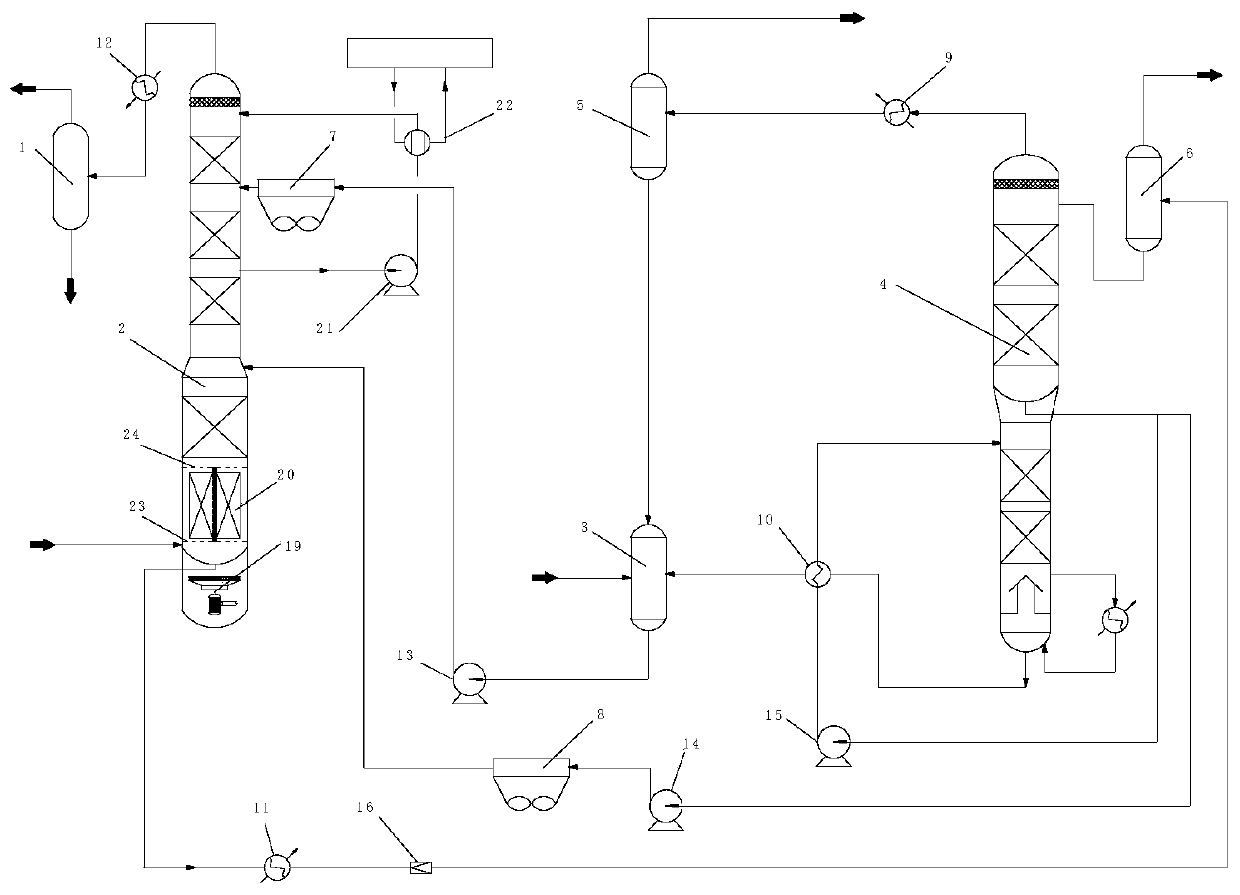

[0067] like figure 2 As shown, the present embodiment adopts the device and method of Embodiment 1, and the difference is that two towers and two stages of absorption and desorption processes are adopted, that is, the method of the present embodiment does not include the 9000mm position from the desorption tower to the tangent line on the top of the tower. The step of taking out the second semi-lean liquid and sending it to the absorption tower to continue absorbing carbon dioxide. Reach and embodiment 1 substantially identical purification gas CO in the present embodiment 2 In terms of removal performance, various process parameters of carbon dioxide separation are listed in Table 2.

[0068] Table 2 Performance indicators of purified gas and process parameters of carbon dioxide separation

[0069]

[0070] * Regeneration = mol CO 2 / mol MDEA

[0071] It can be seen from Table 2 that the absorption capacity of the two-tower three-stage absorption and desorption proces...

Embodiment 3

[0073] In the present embodiment, the size of the packing area of the absorption tower (from the top of the tower to the bottom of the tower, the same below) is: (including the part of the rotating body), the tower height is 20000mm, and the bottom of the absorption tower is equipped with The rotating body; the size of the sieve plate of the desorption tower is: The tower height is 23000mm. The number of theoretical plates of the absorption tower is 8, and the number of theoretical plates of the desorption tower is 7.

[0074] The composition of the mixed gas is shown in Table 3. The composition of the absorbing liquid is the same as in Example 1.

[0075] Table 3 Mixed Gas Composition

[0076]

[0077] like figure 2 As shown, the carbon dioxide separation method in this embodiment adopts two-tower two-stage absorption and two-stage desorption processes:

[0078] a. will contain 26.0% (volume fraction), temperature is 60 ℃, the mixed gas that pressure is 2.4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com