Manufacturing method for three-dimensional paper-cut picture

A production method and three-dimensional technology, which can be applied to special patterns, special decorative structures, patterns characterized by outlines, etc., can solve the problems of inability to mass-produce process products, difficult to paste or mount, and paper-cuts that are not suitable for carrying and storage, etc. Achieve the effect of good three-dimensional effect, low cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

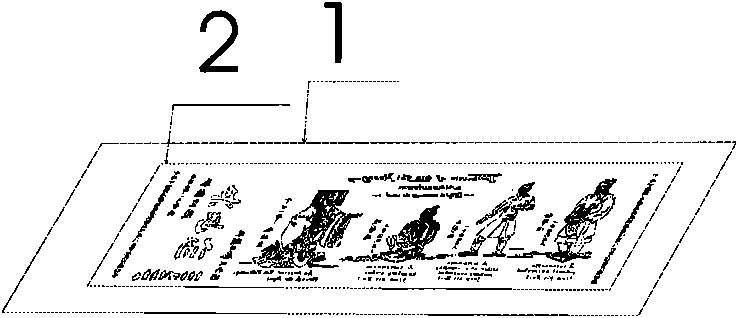

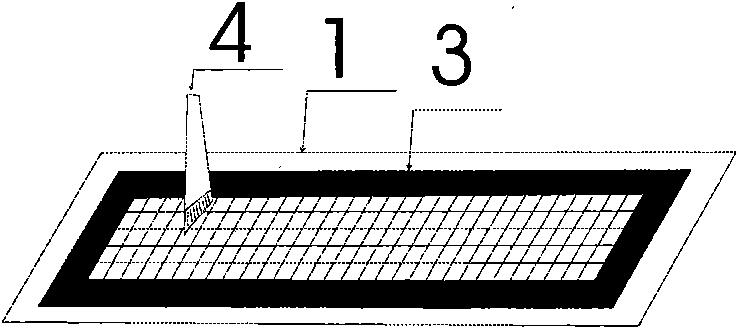

[0031] Embodiment 1 is the making method of a three-dimensional paper-cut painting similar to the black and white contrast of traditional Chinese painting: 1), make the required terracotta warriors and horses paper-cut graphics in the computer as the base figure 1 According to the required three-dimensional size, gradually reduce the size of the part that needs to be cut by 1mm to make 7 similar graphics, or increase the size of the part that needs to be kept by 1mm to make 7 similar graphics. The terracotta warriors of graphics convert the graphic information into programs and transmit them to the plasma cutting machine or laser cutting machine that can be controlled by the program. Cutting; In addition, use rice paper with the same size as the surface to be cut to draw traditional Chinese paintings, and stack each 50 sheets neatly into 8 stacks, soak them in clean water, let all the paper soak in water, and then use two pieces The sheet material larger than the surface of th...

Embodiment 2

[0037] Embodiment 2 is the preparation method of the color three-dimensional paper-cut handicraft painting of color change, and many of its methods are the same as embodiment 1, and the difference is: paper-cut has colored paper, and when soaking, the colored paper is soaked in the color water of corresponding color , to prevent the paper from fading in soaking. In order to form a three-dimensional paper-cut painting with color gradients, similar paper-cuts of different sizes are made with color-gradient paper or made of paper of the same color and soaked in different pigment waters with color differences that can form color gradients. In this way, the color also changes with the gradual change of the paper-cut layer, giving people a modernized aesthetic feeling.

Embodiment 3

[0038] The three-dimensional paper-cut painting of color gradient of embodiment 3, it is after the three-dimensional paper-cut painting of white is made by the method for embodiment 1, paints the color of color transformation with a pen.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com