Single-component woodware color modifier easy to construct and preparation method thereof

A single-component, color-repairing agent technology, applied in the direction of coating, etc., can solve the problems that the surface of concave and convex parts cannot be sprayed evenly, is not easy to rework and repair, and affects the decoration effect, etc., to achieve high-grade beautifying furniture decoration effect and good three-dimensional layering effect , The effect of reducing the technical difficulty of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

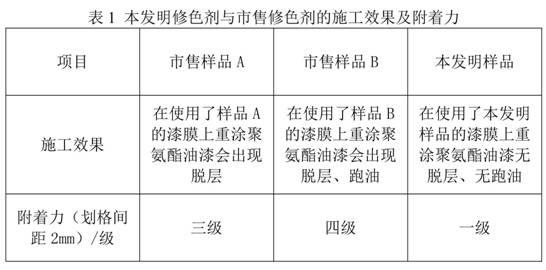

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] An easy-to-apply one-component transparent wood finish (black walnut color), which contains the following components by weight percentage:

[0027] Ethylene glycol monobutyl ether 84.5%,

[0028] Aldehyde and ketone resin 3%,

[0029] Butyl acetate 2%,

[0030] Black fine solution 6.2%,

[0031] Red essence solution 0.4%,

[0032] Yellow essence solution 3.9%;

[0033] Wherein, the mass concentration of red essence solution, black essence solution, and yellow essence solution is 45%.

[0034] The preparation method of above-mentioned one-component transparent woodware repairing agent comprises the following steps:

[0035] 1) Dissolve black essence, red essence and yellow essence in ethylene glycol monobutyl ether respectively to make red essence solution, black essence solution and yellow essence solution;

[0036] 2) dissolving the aldehyde and ketone resin in an acetate solvent, and stirring evenly to obtain the aldehyde and ketone resin solution;

[0037] 3) ...

Embodiment 2

[0039] An easy-to-apply one-component transparent wood finish (dark brown), containing the following components in weight percent:

[0040] Ethylene glycol monobutyl ether 84.5%,

[0041] Aldehyde and ketone resin 1.8%,

[0042] Butyl acetate 1.2%,

[0043] Black fine solution 5.7%,

[0044] Red essence solution 4.6%,

[0045] Yellow essence solution 2.2%;

[0046] Wherein, the mass concentration of black essence solution, red essence solution, and yellow essence solution is 40%.

[0047] The preparation method is the same as in Example 1.

[0048] The preparation method of above-mentioned one-component transparent woodware repairing agent comprises the following steps:

[0049] 1) Dissolve black essence, red essence and yellow essence in butyl carbitol respectively to make red essence solution, black essence solution and yellow essence solution;

[0050] 2) dissolving the aldehyde and ketone resin in an acetate solvent, and stirring evenly to obtain the aldehyde and ke...

Embodiment 3

[0053] An easy-to-apply one-component transparent wood finish (mahogany color), which contains the following components by weight percentage:

[0054] Ethylene glycol monobutyl ether 67.7%,

[0055] Polyol Dibasic Esters (EGDA) 15%,

[0056] Aldehyde and ketone resin 3%,

[0057] Butyl acetate 2%

[0058] Black essence solution 1%,

[0059] Red essence solution 8%,

[0060] Yellow essence solution 3.3%;

[0061] Wherein, the mass concentration of black essence solution, red essence solution, and yellow essence solution is 20%.

[0062] The preparation method of above-mentioned one-component transparent woodware repairing agent comprises the following steps:

[0063] 1) Dissolve black essence, red essence and yellow essence in ethylene glycol monobutyl ether respectively to make red essence solution, black essence solution and yellow essence solution;

[0064] 2) dissolving the aldehyde and ketone resin in an acetate solvent, and stirring evenly to obtain the aldehyde an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com