Dyeing method of wool fibers

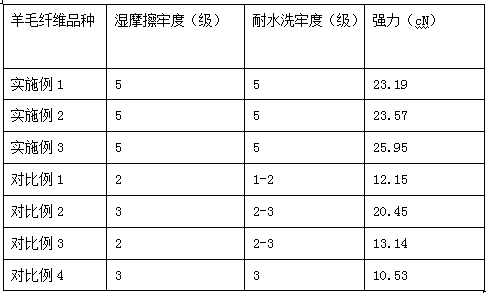

A wool fiber and dyeing method technology, applied in the field of textile dyeing, can solve the problems of reduced fiber strength, long dyeing time, loss of wool fiber strength, etc., and achieves the effect of reducing the loss of strength, good wet rubbing fastness, and improving quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for dyeing wool fibers, comprising the following steps:

[0026] (1) Pretreatment of wool fibers, as follows:

[0027] (1.1) Propolis, ethanol and water were stirred and mixed according to the mass ratio of 1:20:40, after microwave treatment at 500W power for 15min, wool fiber was added according to the bath ratio of 1:40, soaked for 1h, then ultrasonically treated for 20min, and then added with ethanol The yeast aqueous solution with twice the volume and 1% mass concentration was ultrasonically treated for 30min; wherein, the ultrasonic treatment conditions were: ultrasonic power 300W, ultrasonic frequency 40KHz;

[0028] (1.2) The wool fiber obtained in step (1.1) was fumigated with rice-washing water for 60 minutes at 75°C, and then soaked in ethanol solution with a volume concentration of 20% for 30 minutes;

[0029] (1.3) Wash the wool fiber obtained in step (1.2) with water for 5 times, and then vacuum dry it at 40°C for 6h;

[0030] (2) Dip-dyeing: Mix...

Embodiment 2

[0036] A method for dyeing wool fibers, comprising the following steps:

[0037] (1) Pretreatment of wool fibers, as follows:

[0038] (1.1) Propolis, ethanol and water were stirred and mixed according to the mass ratio of 1:20:40. After microwave treatment at 500W power for 20min, wool fiber was added according to the bath ratio of 1:40, soaked for 2h, then ultrasonically treated for 40min, and then ethanol was added. The yeast aqueous solution with 2 times the volume and 3% mass concentration was ultrasonically treated for 40min; wherein, the ultrasonic treatment conditions were: ultrasonic power 300W, ultrasonic frequency 40KHz;

[0039] (1.2) The wool fiber obtained in step (1.1) was fumigated with rice-washing water at 90°C for 40min, and then soaked in an ethanol solution with a volume concentration of 20% for 50min;

[0040] (1.3) Wash the wool fiber obtained in step (1.2) with water for 8 times, and then vacuum dry it at 40°C for 8h;

[0041] (2) Dip dyeing: Mix dye,...

Embodiment 3

[0047] A method for dyeing wool fibers, comprising the following steps:

[0048] (1) Pretreatment of wool fibers, as follows:

[0049] (1.1) Propolis, ethanol and water were stirred and mixed according to the mass ratio of 1:20:40. After microwave treatment at 500W power for 17min, wool fiber was added according to the bath ratio of 1:40, soaked for 1.5h, and then ultrasonically treated for 30min, and then added The yeast aqueous solution with 2 times the volume of ethanol and a mass concentration of 2% was ultrasonically treated for 35 minutes; wherein, the ultrasonic treatment conditions were: ultrasonic power 300W, ultrasonic frequency 40KHz;

[0050](1.2) The wool fibers obtained in step (1.1) were fumigated with rice-washing water at 80°C for 50 minutes, and then soaked in an ethanol solution with a volume concentration of 20% for 40 minutes;

[0051] (1.3) Wash the wool fiber obtained in step (1.2) with water for 6 times, and then vacuum dry it at 40°C for 7h;

[0052]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com