A kind of preparation method and application of active hydrophilic type formaldehyde-free color fixing agent

A formaldehyde-free color-fixing agent, hydrophilic technology, applied in dyeing, textiles and papermaking, etc., can solve the problems of poor hydrophilicity, poor hydrophilicity, resource consumption, etc., and achieve good color fastness to washing, Good hydrophilic performance, little effect of hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

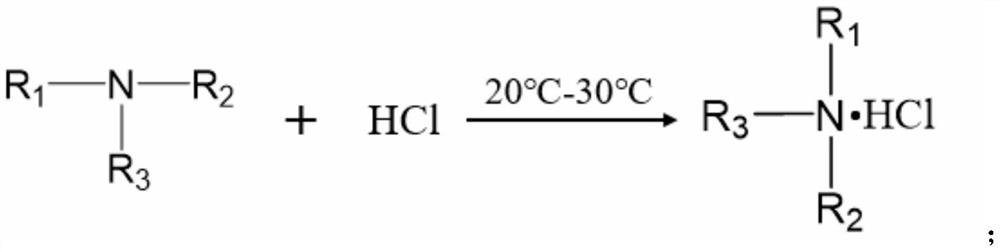

[0024] (1) Preparation of intermediate products:

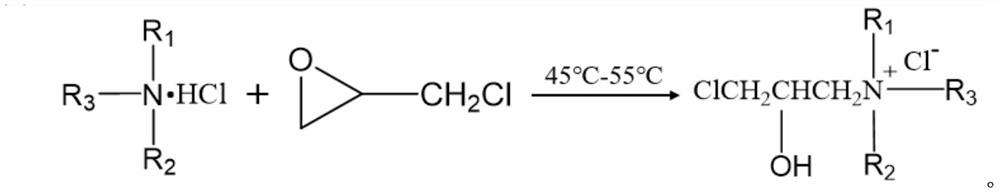

[0025] Add 28 parts of concentrated hydrochloric acid (37%) into the reaction flask, stir, slowly add 50 parts of trimethylamine solution (33%) dropwise, and control the temperature at 20-30°C; Finally, use trimethylamine solution to adjust the pH of the solution to 3~4; then raise the temperature to 45°C, slowly add 22 parts of epichlorohydrin (ECH) dropwise, control the temperature at 45~55°C, and keep the temperature for 1.0~2.5h after dropping Until it becomes a homogeneous solution, finally adjust the pH value to 7-8 with a trimethylamine solution, and cool down to obtain an intermediate product with a solid content of 48% for later use.

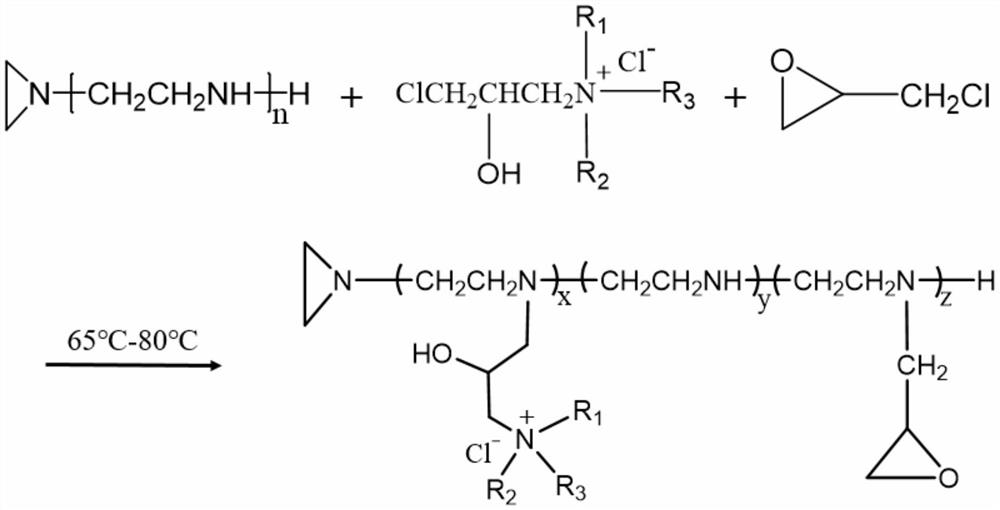

[0026] (2) Preparation of hydrophilic formaldehyde-free color fixing agent: add 16 parts of intermediate product of step (1), 12 parts of polyethyleneimine (linear type, molecular weight 600) and 56 parts of deionized water, stirred, and slowly dropwise added 16 parts of epichlorohydri...

Embodiment 2

[0028] (1) preparation of intermediate product: same as example 1;

[0029] (2) Preparation of hydrophilic formaldehyde-free color fixing agent: add 34 parts of intermediate products of step (1), 7.5 parts of polyethyleneimine (linear type, molecular weight 600) and 52 parts of deionized Water, stirred, and slowly added dropwise 6.5 parts of epichlorohydrin (ECH), and the temperature was controlled at 20-40°C. After dripping and keeping warm for 5-7 hours, the temperature is controlled at 65-80°C, and finally the pH value is adjusted to 6-7 with glacial acetic acid, and the temperature is lowered to obtain a hydrophilic formaldehyde-free color-fixing agent.

Embodiment 3

[0031] (1) preparation of intermediate product: same as example 1;

[0032] (2) Preparation of hydrophilic formaldehyde-free color fixing agent: add 33 parts of intermediate product of step (1), 8 parts of polyethyleneimine (linear type, molecular weight 10000) and 52.4 parts of deionized Water, stirred, slowly added 6.6 parts of epichlorohydrin (ECH) dropwise, and the temperature was controlled at 20-40°C. After dripping and keeping warm for 5-7 hours, the temperature is controlled at 65-80°C, and finally the pH value is adjusted to 6-7 with glacial acetic acid, and the temperature is lowered to obtain a hydrophilic formaldehyde-free color-fixing agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com