Patents

Literature

36results about How to "Good color fastness to rubbing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

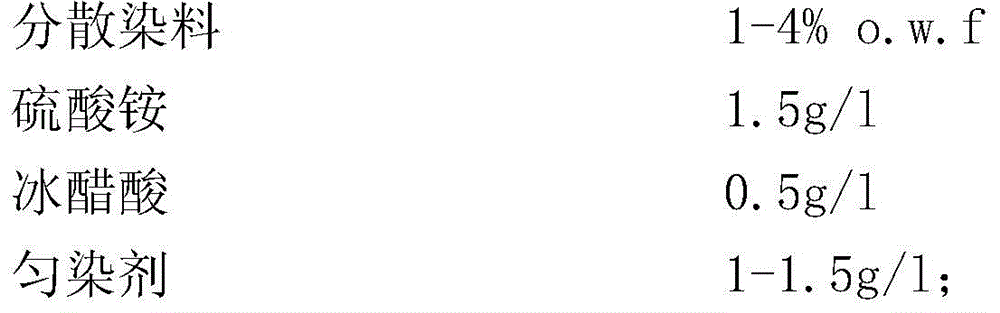

Preparation method of superfine fiber suede leather and prepared superfine fiber suede leather

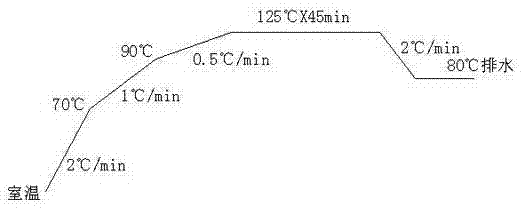

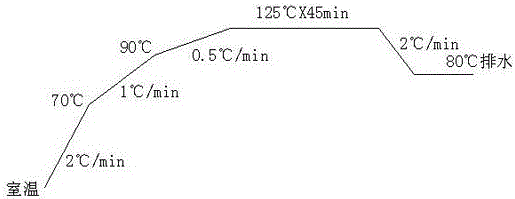

The invention discloses a preparation method of a superfine fiber suede leather and the prepared superfine fiber suede leather. The preparation method comprises the following steps that: a buffed base cloth is subject to dyeing with the effect of a dye containing an azo structure and molecules with polar groups and the effect of auxiliary agents, then after-treatment is carried out, wherein, the dyeing is carried out at room temperature with the heating rate of 0.5 DEG C / min-1.5 DEG C / min and the dyeing temperature of 90-130 DEG C. The preparation method is simple, the prepared superfine fiber suede leather has two-color tone, can satisfy the requirements of processing various kinds and smallot superfine fiber suede leather and increase the colors and patterns of the product, satisfying the requirements that the consumer goes after fashion and personality.

Owner:HUAFON MICROFIBER SHANGHAI

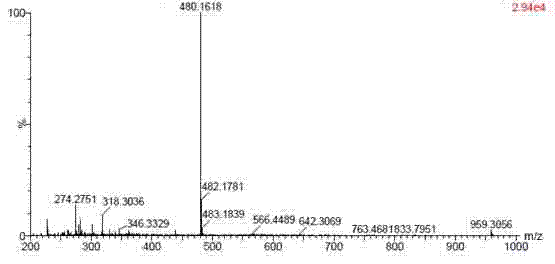

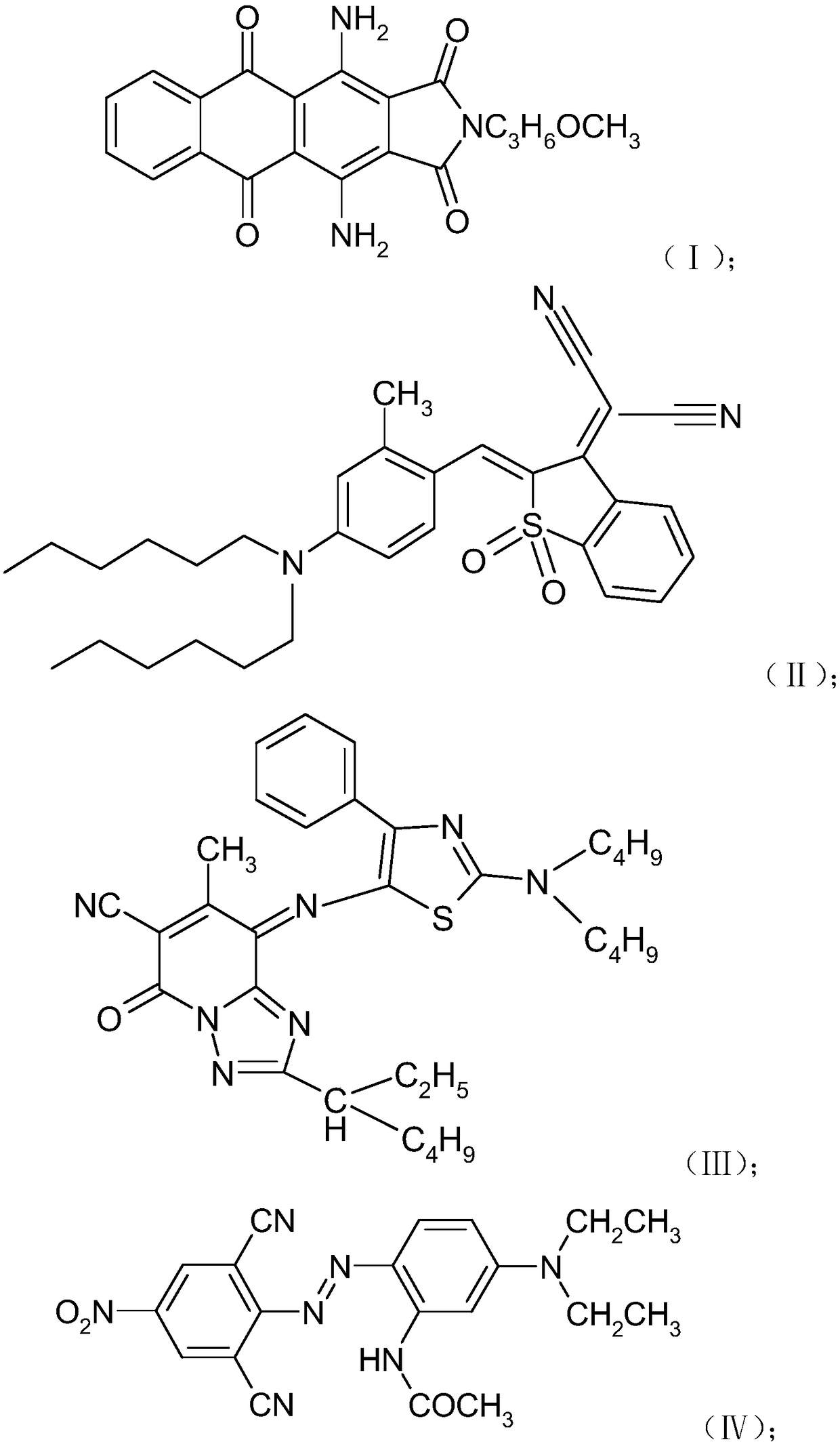

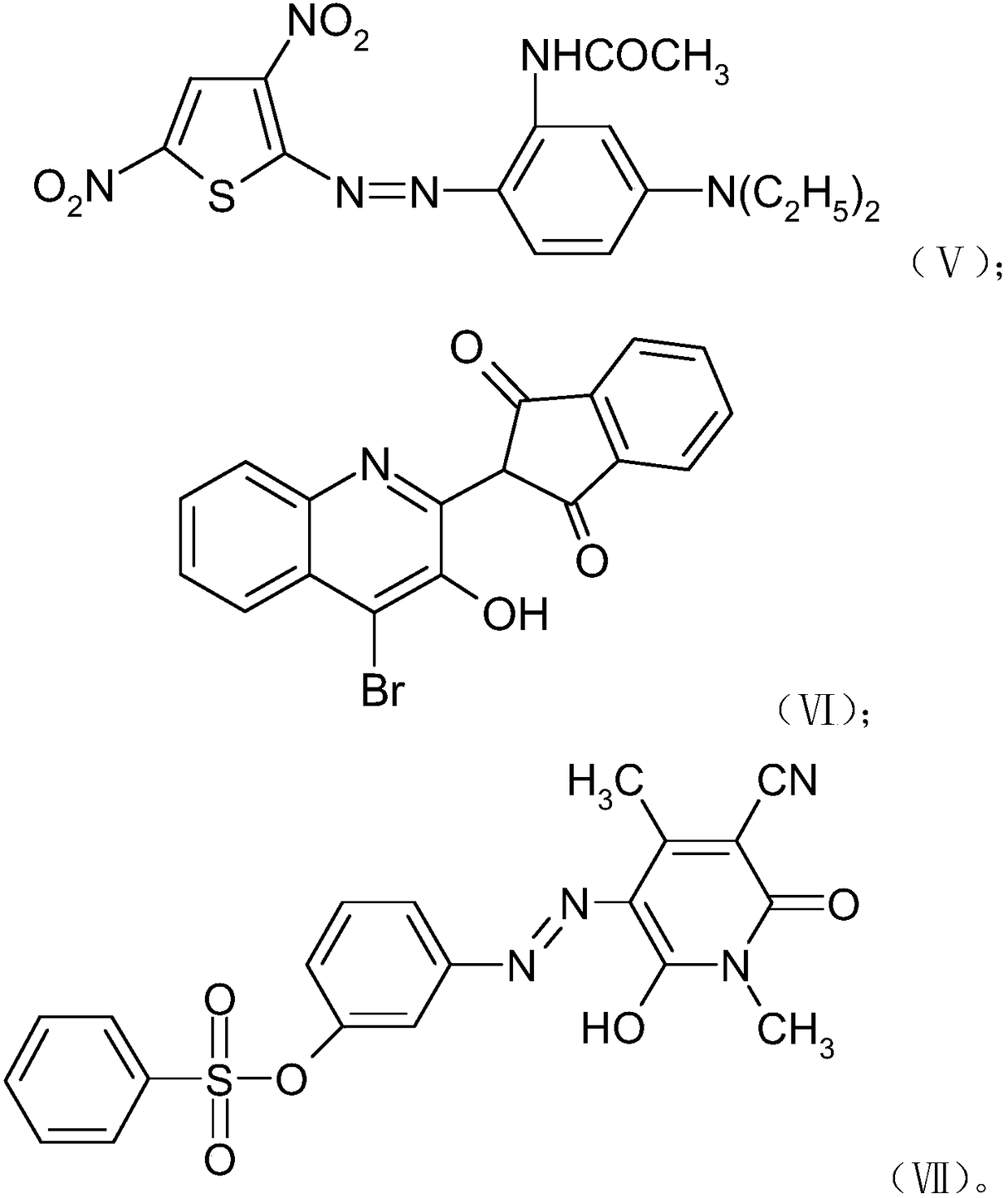

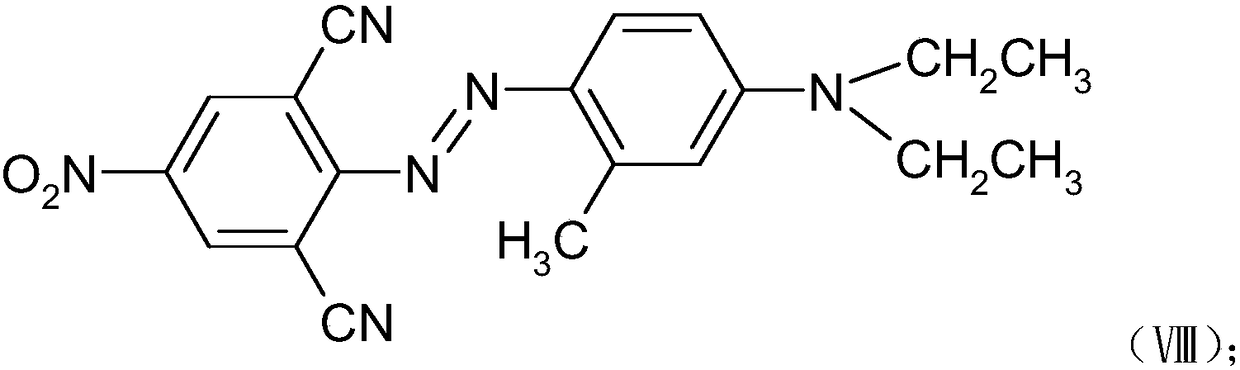

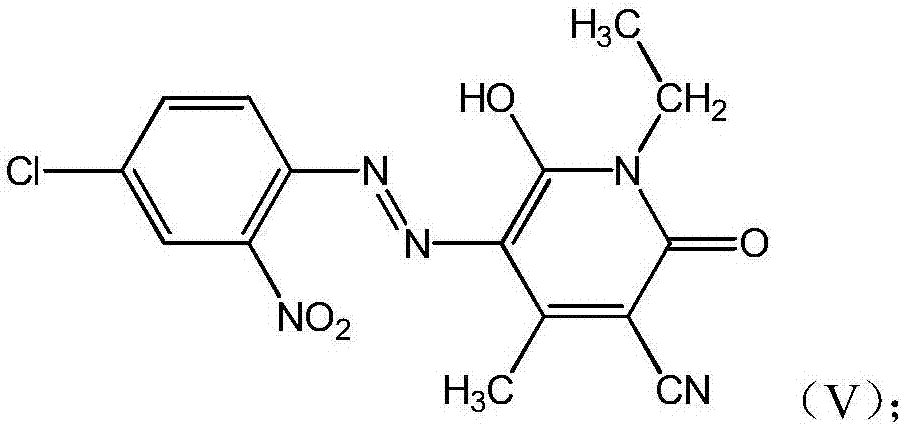

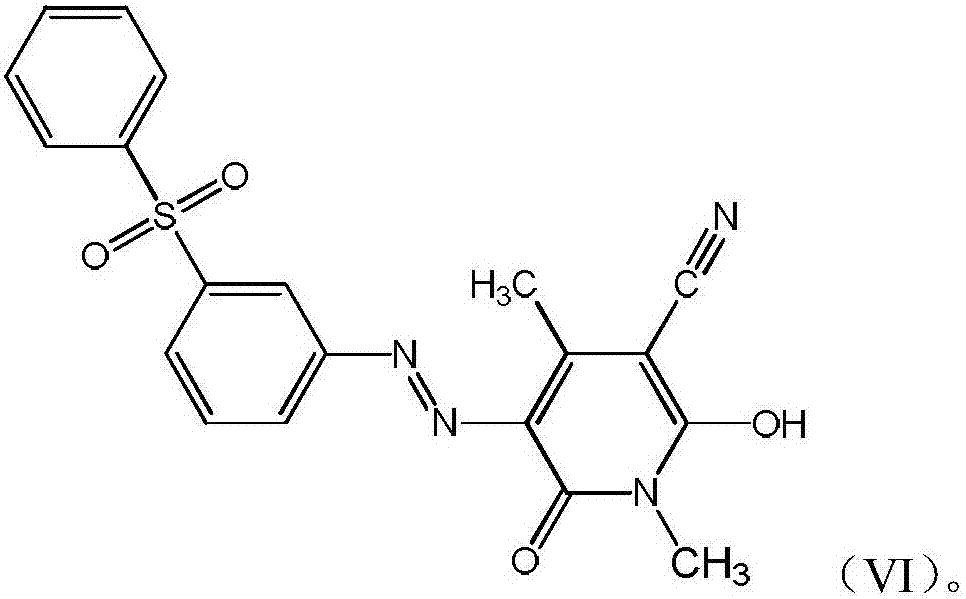

Monoazo compound as well as preparation method and application thereof

ActiveCN102603572AImprove washing fastnessGood fastness to sublimationAzo dye preparationPreparation by cyanide reactionColour fastnessDisperse dye

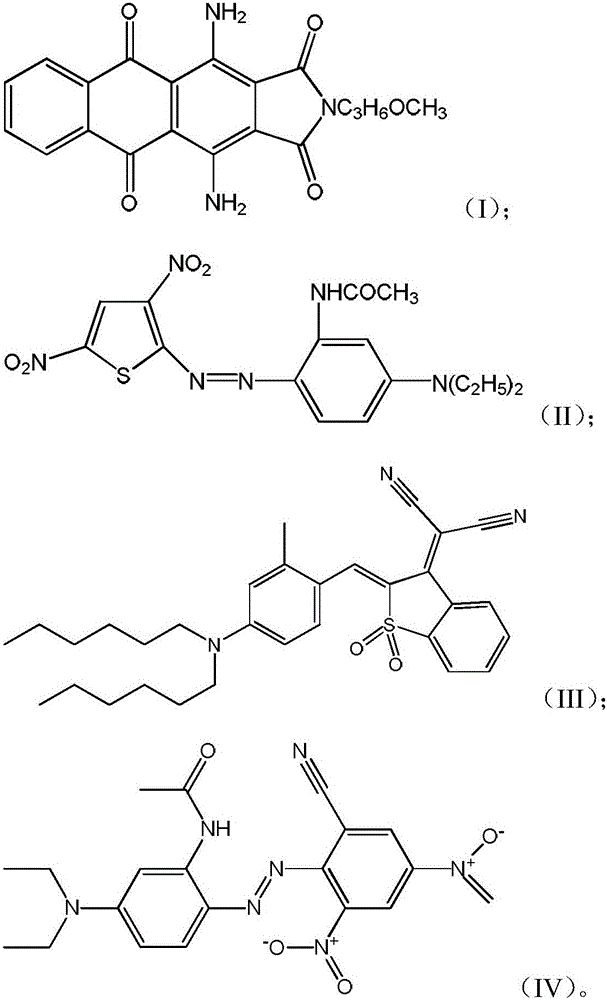

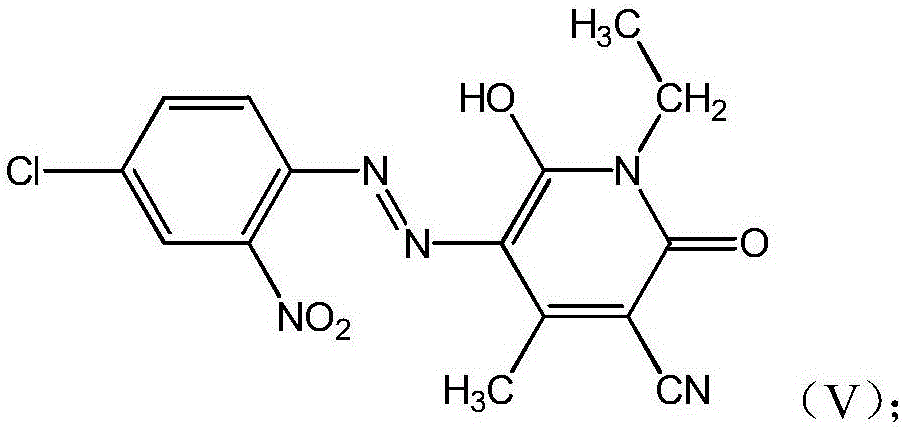

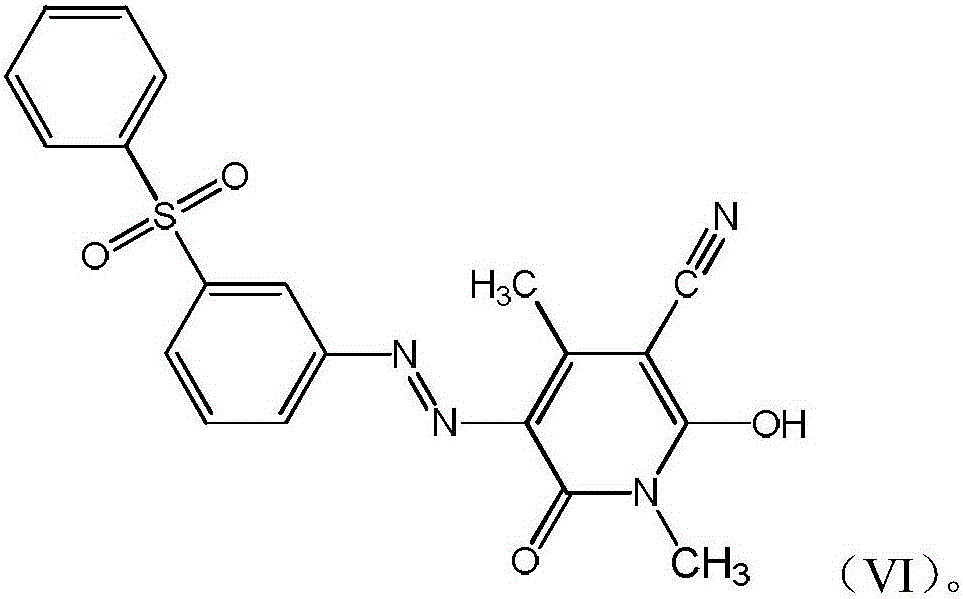

The invention relates to the technical field of disperse dyes and provides a monoazo compound as well as a preparation method and application thereof for the purposes of solving the problems that dyeing is carried out on fabrics such as terylene and superfine fiber so as to obtain very deep color and excellent washing resistance fastness and sublimation resistance fastness. The monoazo compound has a general formula (I). When the monoazo compound is dyed on fabrics such as terylene and superfine fiber, the obtained fabrics have very deep color, excellent washing resistance fastness and sublimation resistance fastness, friction resistance color fastness and light fastness and good color fixation rate in dip dyeing. The monoazo compound provided by the invention is also suitable for compounding of mixed tones with other disperse dyes.

Owner:HANGZHOU JIHUA JIANGDONG CHEMICAL CO LTD

Disperse dye composition and preparing method thereof

ActiveCN105860581AGood color fastness to lightGood color fastness to sublimationOrganic dyesMonomerDisperse dye

The invention discloses a disperse dye composition capable of improving strength and a preparing method thereof. The disperse dye composition comprises, by weight, 0.1-100 parts of C.I. disperse blue60, 0.1-50 parts of C.I. disperse green9, 0.1-50 parts of C.I. disperse blue354, 0.1-10 parts of C.I. disperse blue165 and 0.1-5 parts of disperse yellow. The preparing method of the disperse dye includes the following steps that 1, C.I. disperse blue60, C.I. disperse green9, C.I. disperse blue354, C.I. disperse blue165 and disperse yellow are taken according to the formula amount and mixed to obtain a mixed dye, wherein the disperse yellow is selected from C.I. disperse yellow211 and / or C.I. disperse yellow114; 2, water is added into the mixed dye obtained in the step 1, the weight dosage ratio of the mixed dye to the water is 1:(2-20), the mixture is mixed, and mixed slurry is obtained; 3, the mixed slurry obtained in the step 2 is sprayed and dried, and the disperse dye composition is obtained.

Owner:ZHEJIANG OUYA CHEM CO LTD

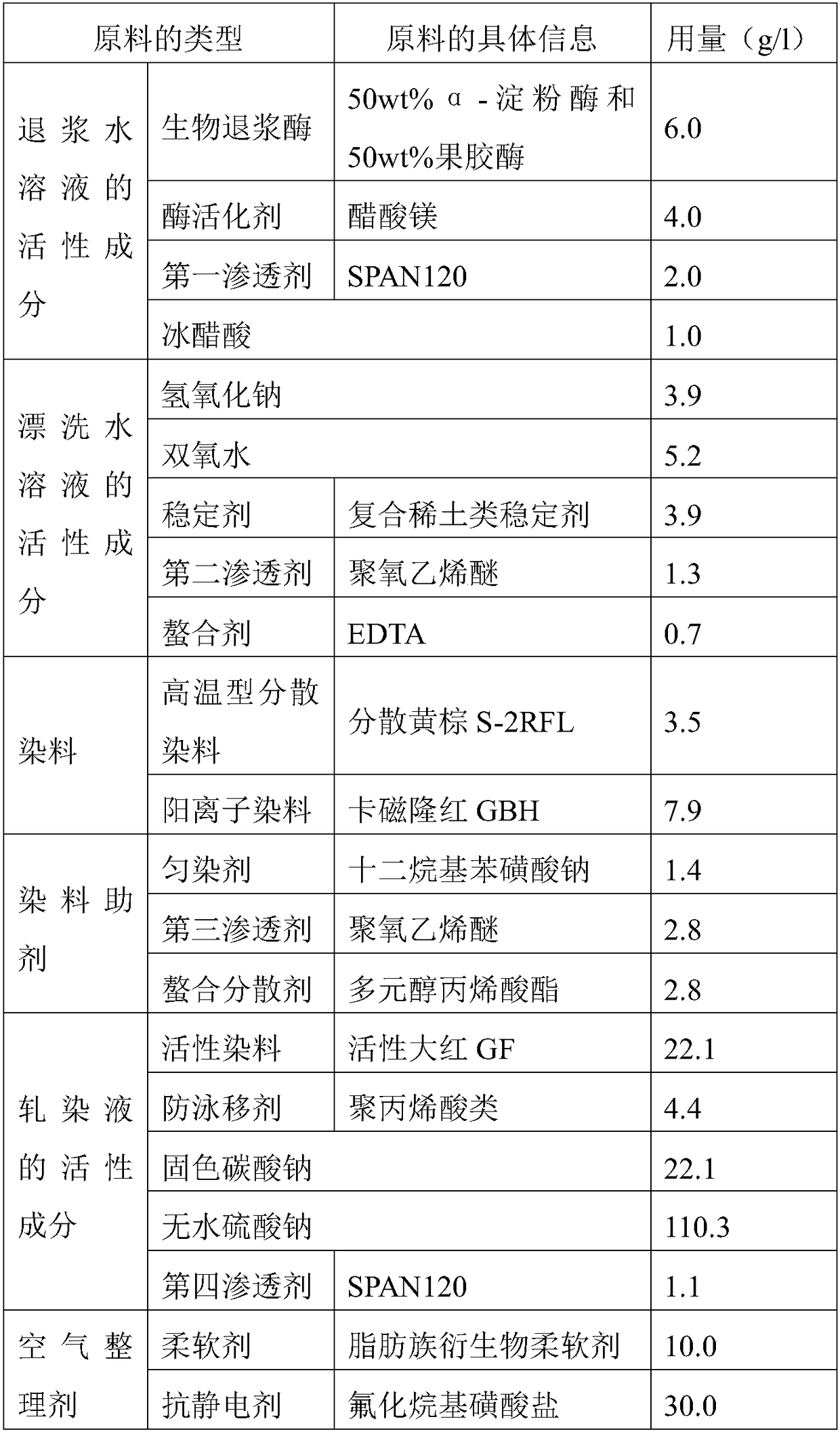

Dyeing and finishing process of coffee-yarn blended and knitted fabric

ActiveCN104727163ARealize medium and dark double dyeing processAccelerated adsorption and dispersionFibre treatmentDyeing processColour fastnessYarn

The invention discloses a dyeing and finishing process of a coffee-yarn blended and knitted fabric. The dyeing and finishing process is characterized by comprising the following steps: preparing grey fabric, pretreating, dyeing, soaping, softening and carrying out after finishing, wherein a mild pre-treatment degreasing process is adopted; and an active double-dyeing process of firstly dyeing, dispersing and dyeing is adopted to dye, so that the difficulty in dying with the same color of the blended and knitted fibers is solved; through control on a finishing agent and the amount of the finishing agent in the after finishing process of the coffee-yarn blended and knitted fabric, the problems of same color and different colors in the dyeing process of the coffee-yarn blended and knitted fabric are solved; good air permeability and relatively good rubbing fastness are obtained; and meanwhile, a plurality of efficacies that the coffee-yarn blended and knitted fabric is capable of absorbing stink, removing an odor, storing heat, keeping warm, absorbing moisture and drying quickly in an far infrared manner are taken into account.

Owner:浙江七色彩虹科技有限公司

Economical dispersion dye mixture

InactiveCN108727866AGood color fastness to washingGood color fastness to rubbingOrganic dyesDisperse dyeDisperse yellow

The invention discloses an economical dispersion dye mixture. 1000 parts of dispersion dye mixtures are prepared from the following ingredients in parts by weight: 0.1 to 800 parts of C.I. disperse blue 60, 20 to 200 parts of C.I. disperse blue 354 and / or disperse color blue B, 0.1 to 20 parts of C.I. disperse blue 165, 0.1 to 70 parts of C.I. disperse green 9, 0.1 to 5 parts of C.I. disperse yellow 64 and / or C.I. disperse yellow 114, 175 to 800 parts of dispersing agents MF and / or dispersing agents NNO and 0.1 to 5 parts of EDTA-2Na or EDTA-4Na. The economical dispersion dye mixture has thecharacteristics of high washing resistant color fastness, rubbing resistant color fastness, light resistant color fastness and sublimation color fastness, and is applicable to the dyeing effect requirement of various fiber fabrics; the production cost is low; the economical dispersion dye mixture is applicable to large-scale production.

Owner:绍兴金绿洲新材料科技有限公司

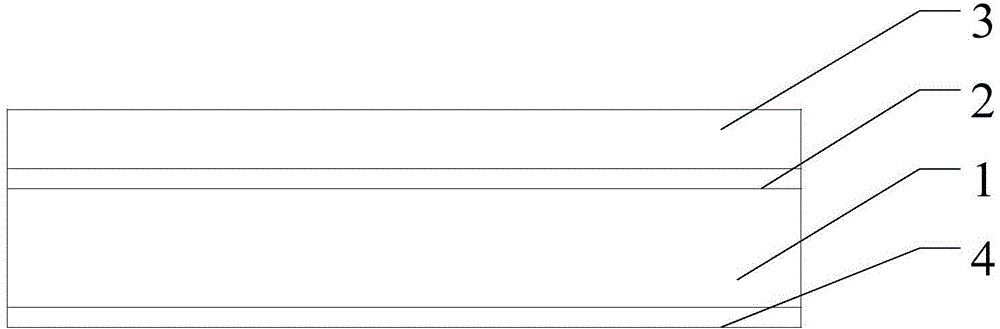

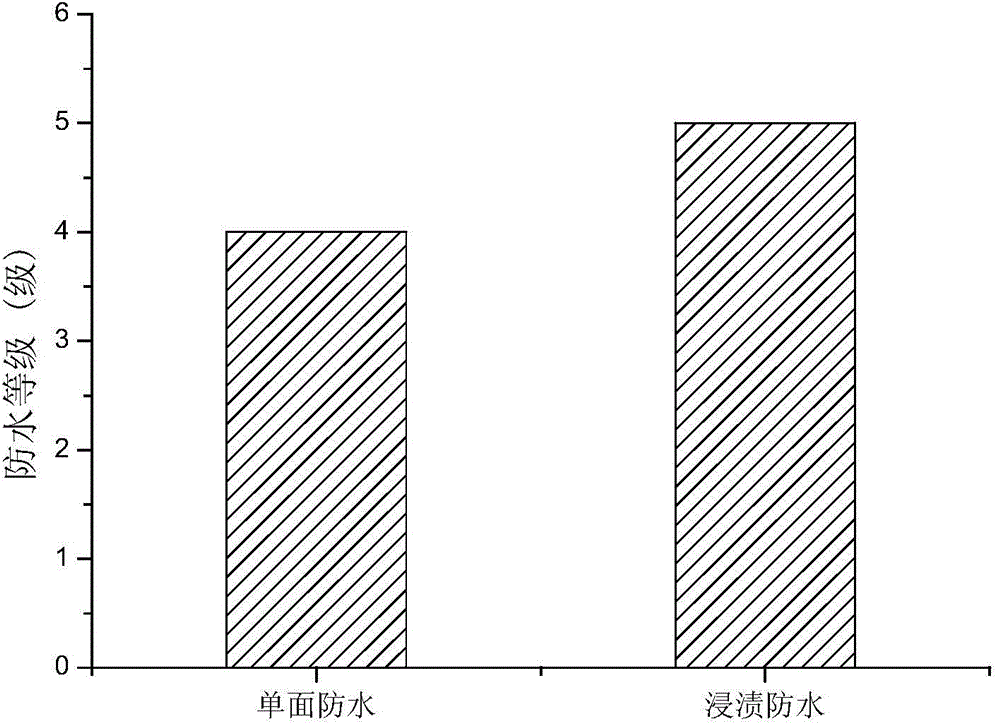

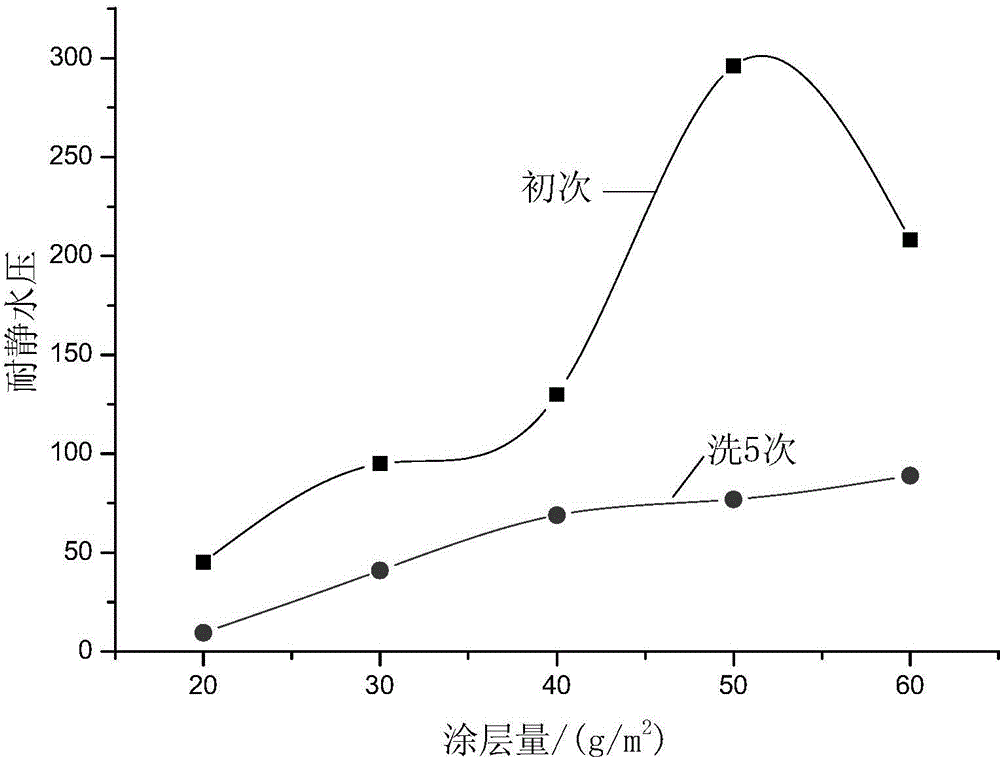

Waterproof composite coated fabric and production technology thereof

InactiveCN104985889AGood color fastness to rubbingGood color fastness to sea waterSynthetic resin layered productsBagsWear resistantEngineering

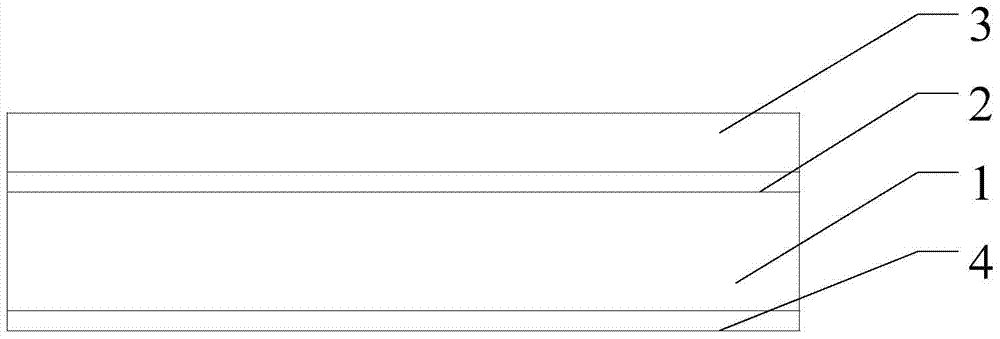

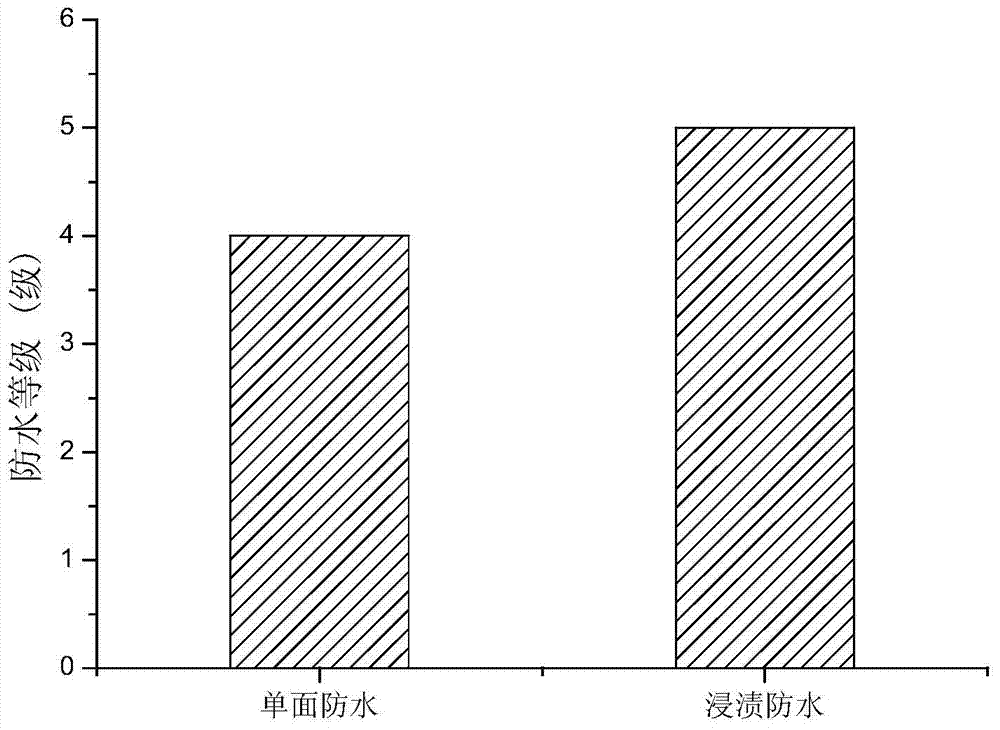

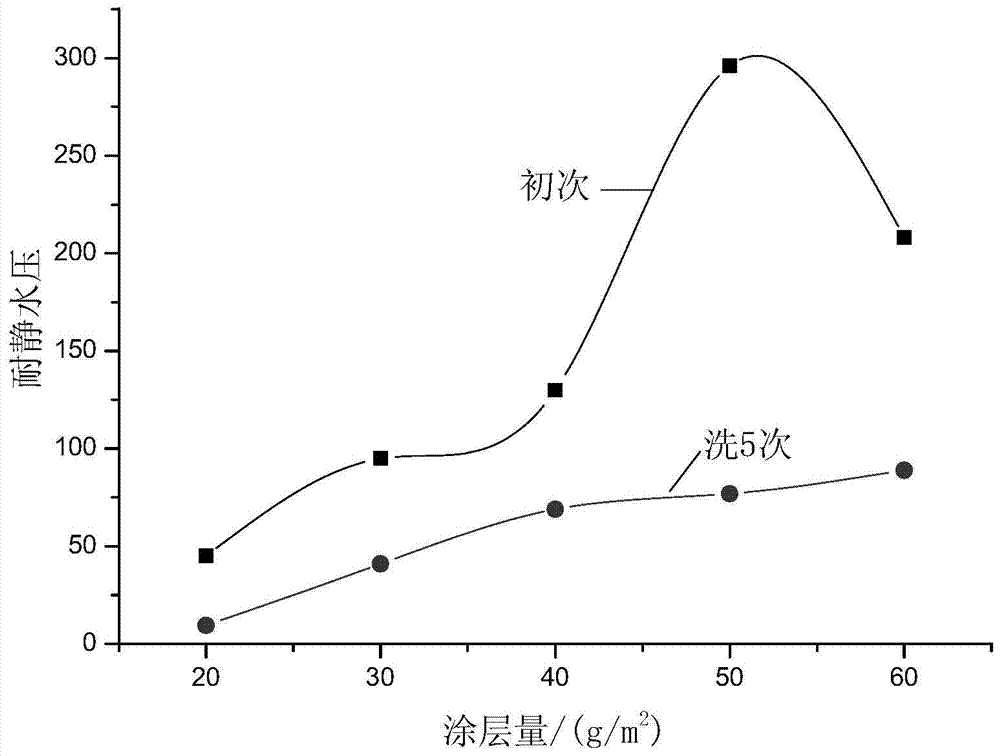

The invention provides waterproof composite coated fabric. The waterproof composite coated fabric comprises a nylon fabric layer, a first glue coated layer, a TPU film layer and a second glue coated layer, the first glue coated layer and the second glue coated are arranged at the two sides of the nylon fabric layer respectively, and the TPU film layer is arranged at the other side of the first glue coated layer; glue in the first glue coated layer and in the second glue coated layer comprises, by weight, 50-100 parts of crude glue, 10-30 parts of solvent and 5-10 parts of bridging agents. According to the waterproof composite coated fabric and a production technology thereof, the fabric has the comprehensive performances of being high-performance waterproof, wear resistant, tear resistant and stretch resistant at the same time, the fabric can be effectively applicable to the shell fabric of load carrying equipment of naval crews, the fabric can withstand heavy waves or heavy rainstorm weather as well as frequent stress and tensile deformation on account of drawing and pulling, and the fabric is quite worthy of application and popularization.

Owner:NAVY MEDICINE RES INST OF PLA +1

Method for dyeing fabric by using natural blue pigment

ActiveCN106498767ABright and brightGood color fastness to rubbingMicroorganismsMicroorganism based processesFermentationRubbing

The invention discloses a method for dyeing a fabric by using natural blue pigment. The method for dyeing the fabric by using the natural blue pigment includes following steps: using strains for fermenting the blue pigment, obtaining fermentation liquor, and then extracting the blue pigment so as to obtain blue pigment powder; preparing dye liquor from the blue pigment powder and water, raising temperature of the dye liquor to 35-45 DEG C, placing the fabric in the dye liquor, keeping the fabric in the dye liquor for 10-20min, and then adding sodium chloride, keeping for 10-20min, and next heating the dye liquor to 75-85 DEG C by using temperature of 0.5-5 DEG C, adding sodium carbonate, keeping temperature for 30-60min at temperature of 75-85 DEG C, and then cooling the fabric, and finally completing dyeing of the fabric after washing the fabric with cool water and drying the fabric. The method for dyeing the fabric by using the natural blue pigment extracts the blue pigment, uses the blue pigment as natural pigment obtained through microbial fermentation, and endows the pure cotton fabric with antibacterial performance in dyeing, and the fabric is bright and colorful in color, and has good color fastness to rubbing. The dyeing method is easy to operate and implement, facilitates industrial production, and has a wide application prospect.

Owner:JIAXING UNIV

Extraction method and dyeing method of natural blue pigment

InactiveCN106497980ABright and brightGood color fastness to rubbingNatural dyesDyeing processColour fastnessFermentation broth

The invention discloses an extraction method and dyeing method of natural blue pigment. The method includes the steps of: fermenting blue pigment with a strain to obtain fermentation broth, then extracting blue pigment to obtain blue pigment powder; making the blue pigment powder and water into a dye liquid, heating the dye liquid to 35-45DEG C, putting the fabric in the dye liquid for 10-20min, then adding sodium chloride and maintaining the state for 10-20min, then performing heating to 75-85DEG C from 0.5-5DEG C, adding soda ash, conducting heat preservation at 75-85DEG C for 30-60min, then performing cooling, and carrying out cold water washing and drying, thus finishing fabric dyeing. The blue pigment extracted by the method provided by the invention serves as a natural pigment produced by microbial fermentation, endows pure cotton fabrics with antibacterial properties while dyeing, is bright in color, and has good color fastness to rubbing. The dyeing method provided by the invention is easy to operate and implement, and is easy for industrial production, thus having broad application prospects.

Owner:JIAXING UNIV

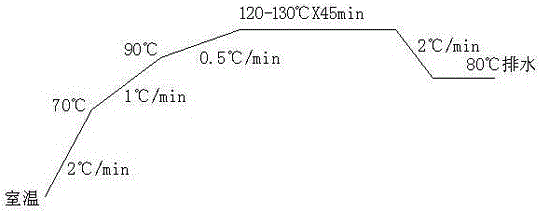

Dyeing process of fire retardant fibers

ActiveCN105714575AImprove parallelismGreat production valueHeat resistant fibresDry-cleaning apparatus for textilesFiberWater baths

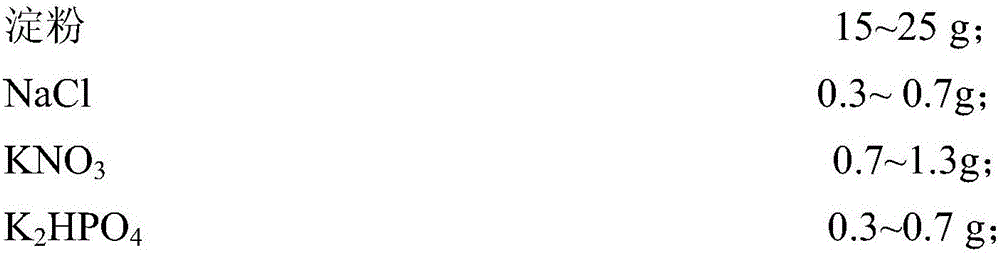

The invention aims at providing a dyeing process of fire retardant fibers. The dyeing process comprises the following steps: step 1, desizing: adding the fire retardant fibers into a desizing eater solution at 50-60 DEG C, keeping the heat and washing with water; step 2, rinsing: adding the fire retardant fibers subjected to the desizing into a rising water solution at 95-100 DEG C, keeping the heat and washing with the water; step 3, dehairing: taking the rinsed fire retardant fibers and removing hairs on the surfaces of the fire retardant fibers; step 4, dyeing: taking the unhaired fire retardant fibers and adding the unhaired fire retardant fibers into water at 15-35 DEG C; gradually heating a water bath to 100-102 DEG C; adding dyestuff when the water bath is 68-71 DEG C and adding a dyestuff auxiliary agent when the water bath is 95-100 DEG C; keeping the heat at 100-102 DEG C for 0.5-1 hour; gradually heating the water bath to 130-135 DEG C and keeping the heat at 130-135 DEG C for 0.5-1 hour; gradually cooling the water bath to 75-80 DEG C; taking out the fire retardant fibers and soaping at 75-80 DEG C for 0.1-0.5 hour; and step 5, finishing: taking the dyed fire retardant fibers and sequentially carrying out air finishing and full decatizing finishing on the dyed fire retardant fibers. The dyeing process has the advantage that the dyeing effect is improved.

Owner:HANGZHOU ZHUODA PRINTING & DYEING CO LTD

Aqueous pigment ink composition

The invention relates to an aqueous pigment ink composition. The aqueous pigment ink composition comprises: 15 wt%-30 wt% of an aqueous pigment dispersion, 10 wt%-50 wt% of glycerol, 0.5 wt%-1 wt% ofsurfactant, antibacterial agent with the amount greater than 0 wt% and less than 0.1 wt%, defoamer with the amount greater than 0 wt% and less than 0.1 wt%, 10 wt%-20 wt% of adhesive and water. The aqueous pigment ink composition of the invention has suitable physical properties such as average particle size, viscosity, surface tension and acid-base number, can be applied to a digital printing machine, has better operation effect, and ensures that the formed printing has better quality; moreover, when the ink is applied to the fabric, the ink will have a better color fastness, and even after illumination, immersion, soaping or rubbing, the ink will not fall off from the fabric significantly, and the printing formed by the aqueous pigment ink composition can have a better quality.

Owner:DOUBLE BOND CHEM IND

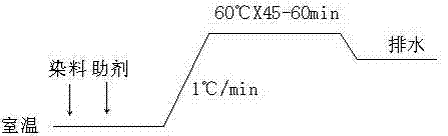

A kind of reactive dye exhaust dyeing process of cotton fabric

ActiveCN106245369BHigh color fixing rateIncrease profitBiochemical treatment with enzymes/microorganismsDyeing processThermal insulationRoom temperature

Owner:ANHUI YAYUAN PRINTING & DYEING CO LTD

Polypropylene resin for melt-blown fabric production and preparation method thereof

The invention discloses polypropylene resin for melt-blown fabric production and a preparation method thereof, and relates to the technical field of materials for melt-blown fabric production. The polypropylene resin is prepared from the following raw materials: polypropylene resin, a silver ion aqueous solution, waterborne aziridine, waterborne polyurethane, a compatilizer, a weather-proof agent and an antioxidant. The preparation method comprises the following steps: stirring and mixing raw materials in a stirrer to obtain a mixed material; putting the mixed material into a double-screw extruder for plasticizing extrusion, cooling to obtain a hardened material, granulating, sieving, cooling and drying. The melt-blown fabric has the effect of inhibiting the growth of bacteria and viruses, and solves the problem that the mask and other products made of the existing melt-blown fabric cannot be repeatedly used due to no effect of inhibiting the growth of bacteria and viruses, and therefore the resource waste is caused.

Owner:广西德福莱医疗器械有限公司

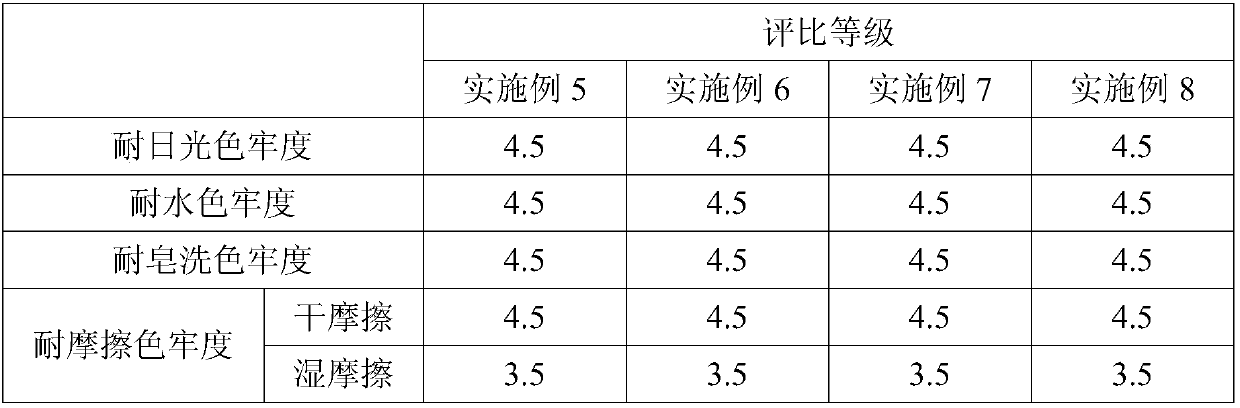

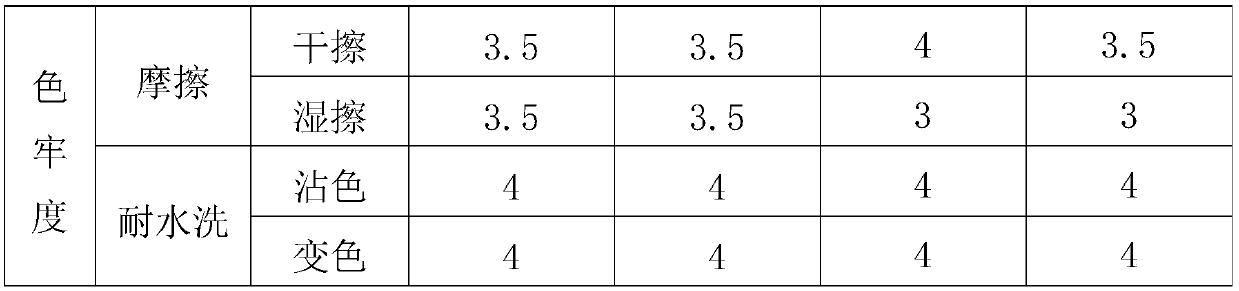

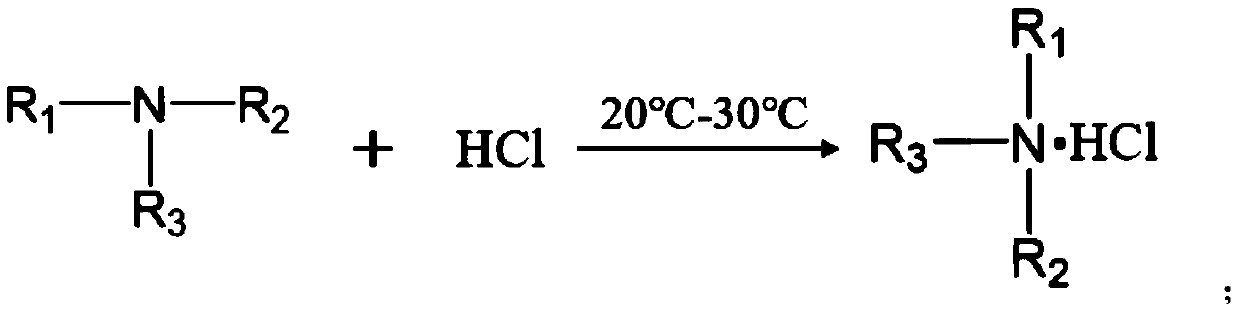

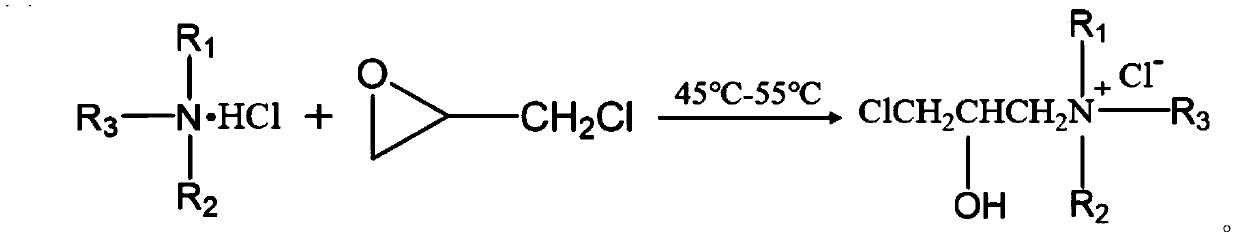

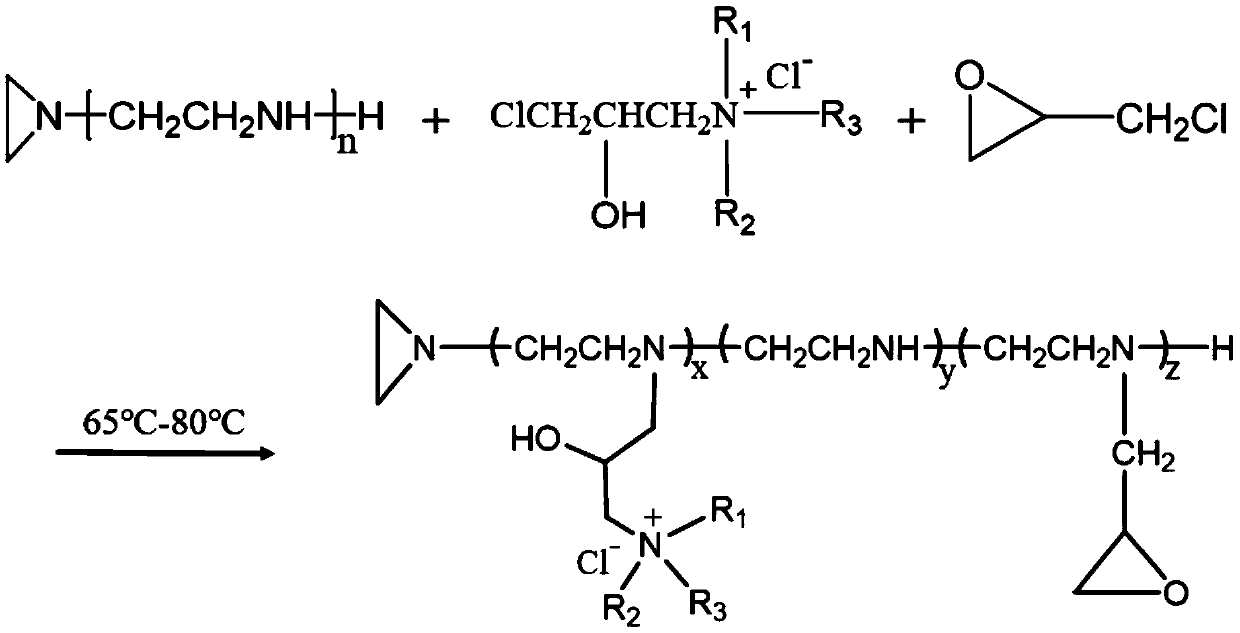

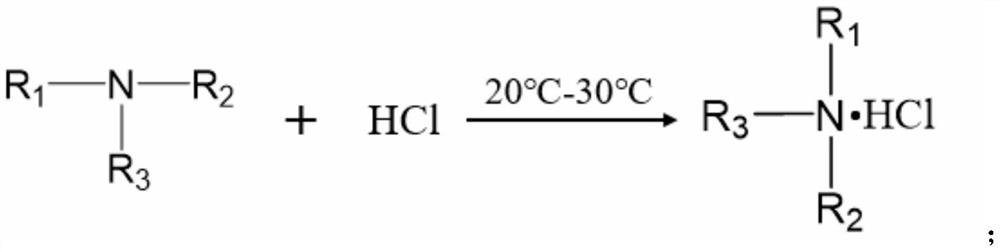

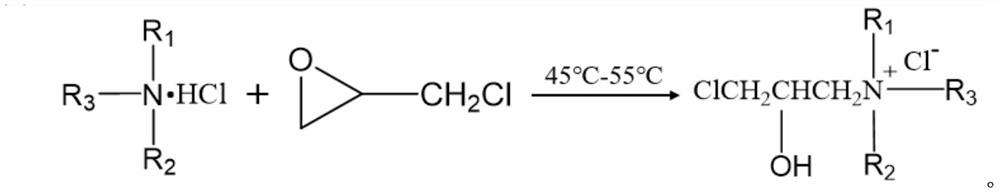

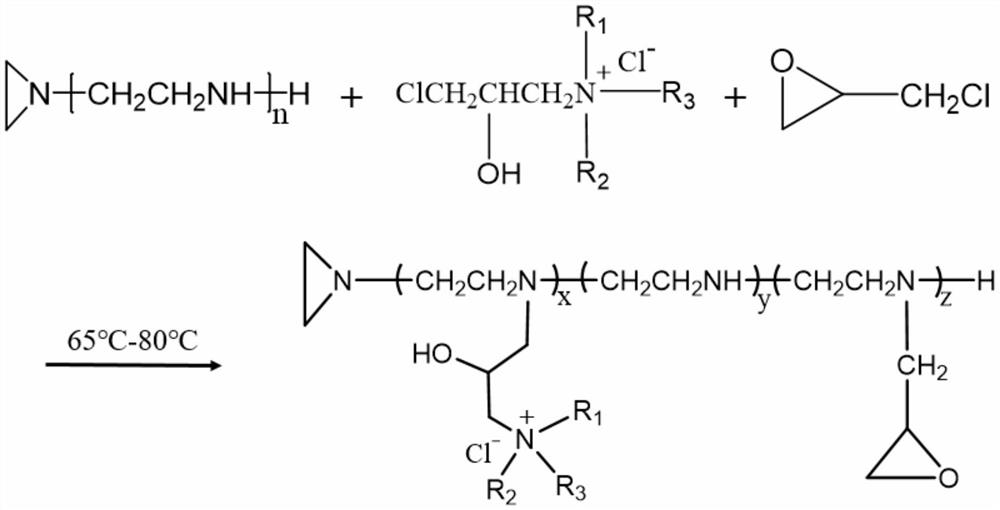

Preparation method and application of active hydrophilic formaldehyde-free color fixing agent

ActiveCN111138662AGood color fixing effectImprove hydrophilicityDyeing processMaterials scienceChemistry

The invention relates to a preparation method of an active hydrophilic formaldehyde-free color fixing agent. The preparation method comprises the following steps: S1) stirring concentrated hydrochloric acid, slowly dropwise adding tertiary amine, carrying out a heat-preserved reaction, and regulating the pH value of the obtained solution to 3-4 by using tertiary amine; S2) carrying out heating to45 DEG C, slowly and dropwise adding epoxy chloropropane, keeping a temperature at 45-55 DEG C, conducting a reaction for 1.0-2.5 hours under a heat preservation condition so as to obtain a homogeneous solution, regulating the pH value, and performing cooling to obtain an intermediate product; and b) adding the intermediate product, polyethyleneimine and deionized water into a reaction bottle, slowly and dropwise adding epoxy chloropropane while stirring, carrying out a heat-preserved reaction at 20-40 DEG C for 5-7 hours, regulating the pH value to 6-7, and performing cooling to obtain the hydrophilic color fixing agent. The hydrophilic formaldehyde-free color fixing agent disclosed by the invention has a relatively high cation degree and reactive epoxy groups, and also has good hydrophilicity and color fixing effect; and after a cotton fabric is subjected to color fixing treatment with the agent, the washing fastness of the fabric reaches level 3-5 and accords with the national regulation that hygroscopicity is within 5 seconds in China, the finishing of a subsequent procedure can be reduced, and the use requirements of printing and dyeing plants are met.

Owner:DYMATIC CHEM

Processing process of high-count and high-density corn fiber fabric

InactiveCN107488924AGood color fastness to washingGood color fastness to rubbingTextile storage in superimposed formBiochemical fibre treatmentFiberColour fastness

The invention discloses a processing process of a high-count and high-density corn fiber fabric and relates to the technical field of textile. The processing process comprises the following steps of 1) corn fiber selection and pretreatment; 2) cotton opening and cleaning procedure; 3) cotton carding procedure; 4) drawing procedure; 5) rough sanding procedure; 6) spinning procedure; 7) warp sizing and desizing procedure; 8) weaving procedure; 9) dyeing procedure; and 10) antibacterial finishing procedure. The processing process provided by the invention is reasonable in design and avoids the electrostatic phenomenon and the cotton sliver breaking phenomenon; and the prepared fabric is high in count and density, good in colour fastness to washing, small in washing size change and excellent in mechanical performance and friction resistance.

Owner:安徽三宝棉纺针织投资有限公司

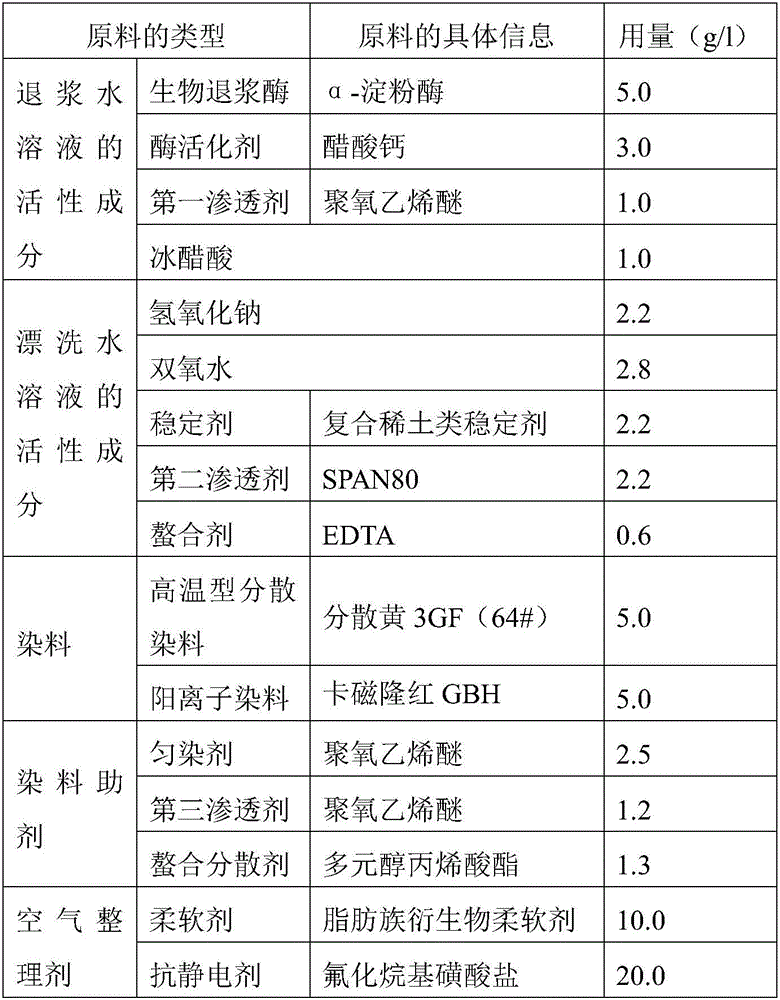

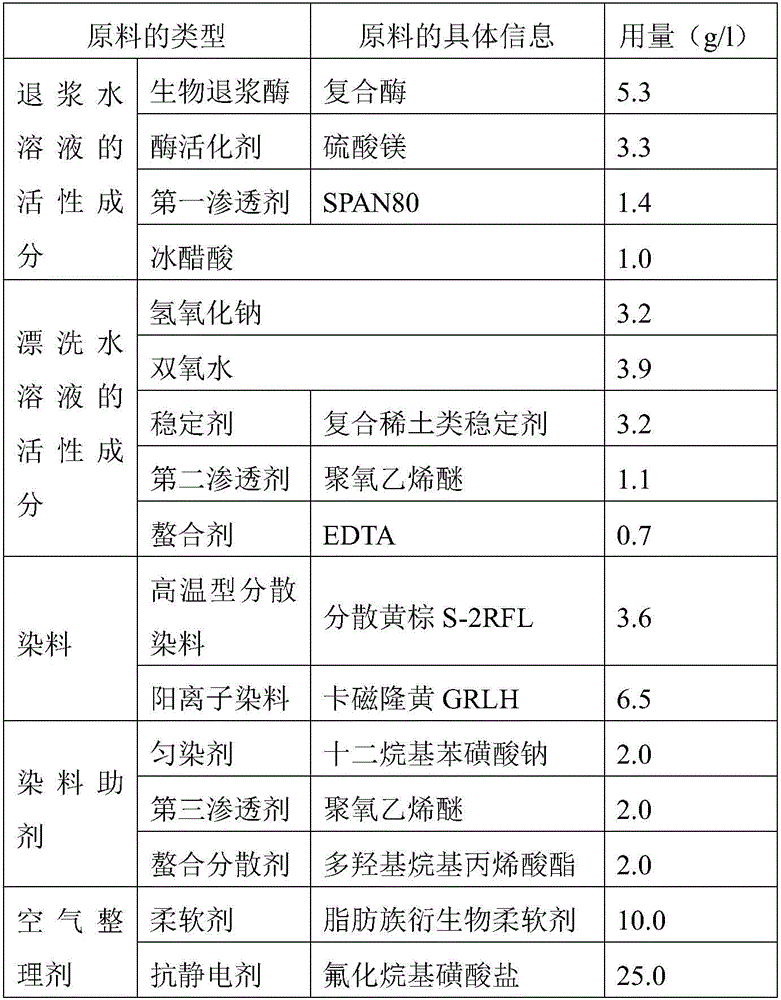

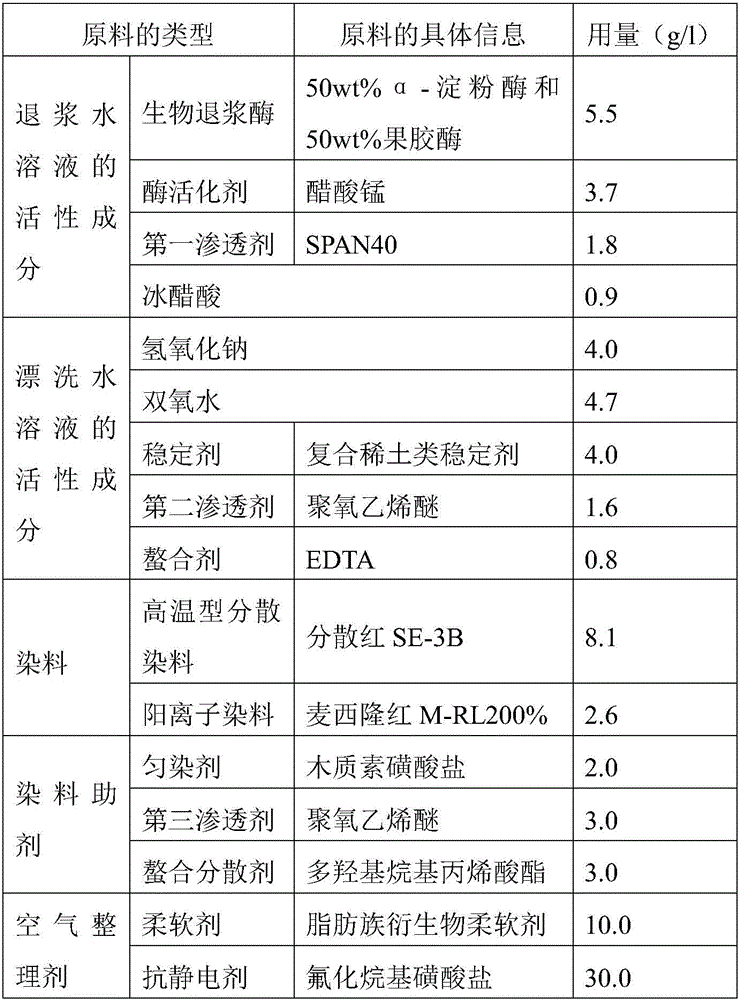

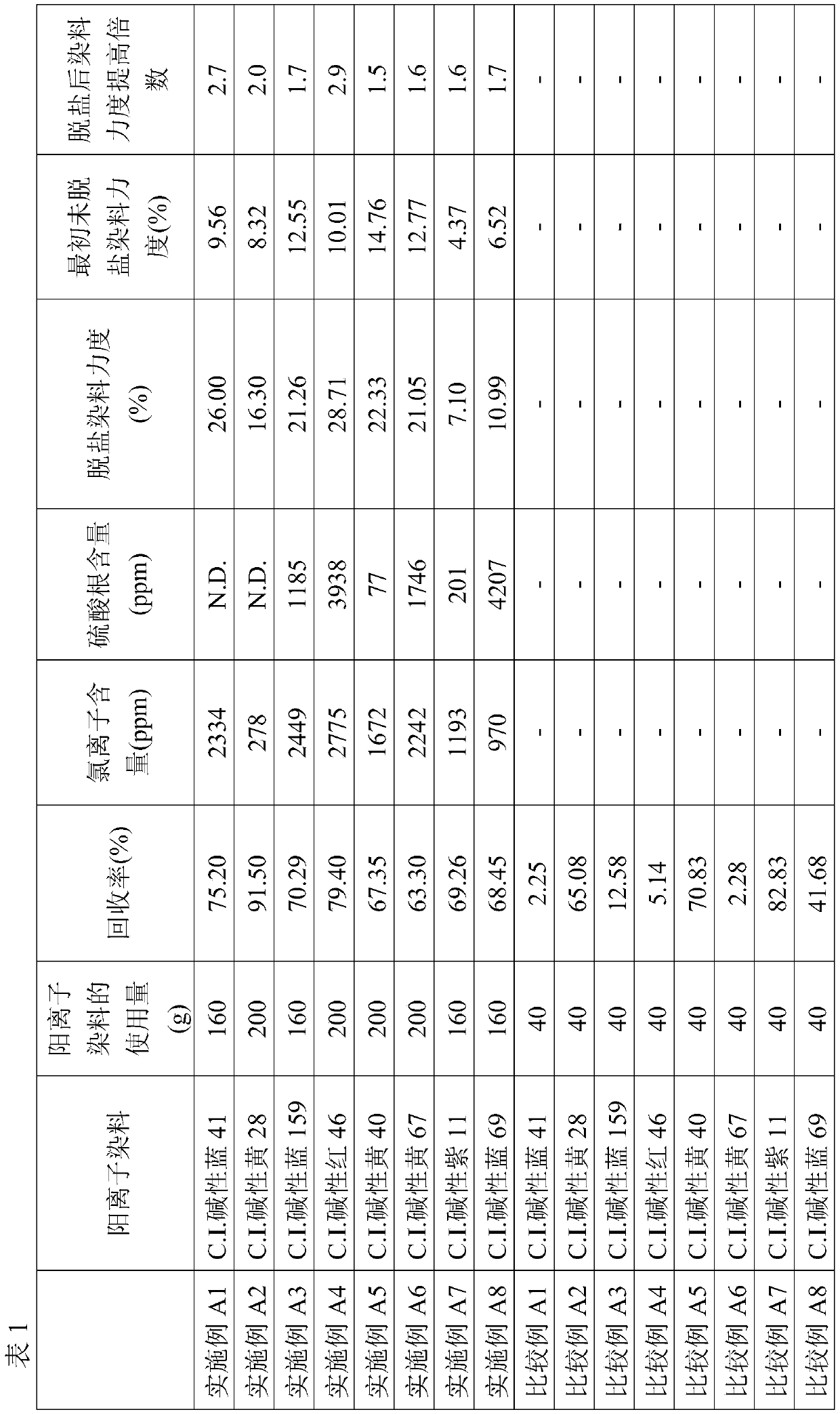

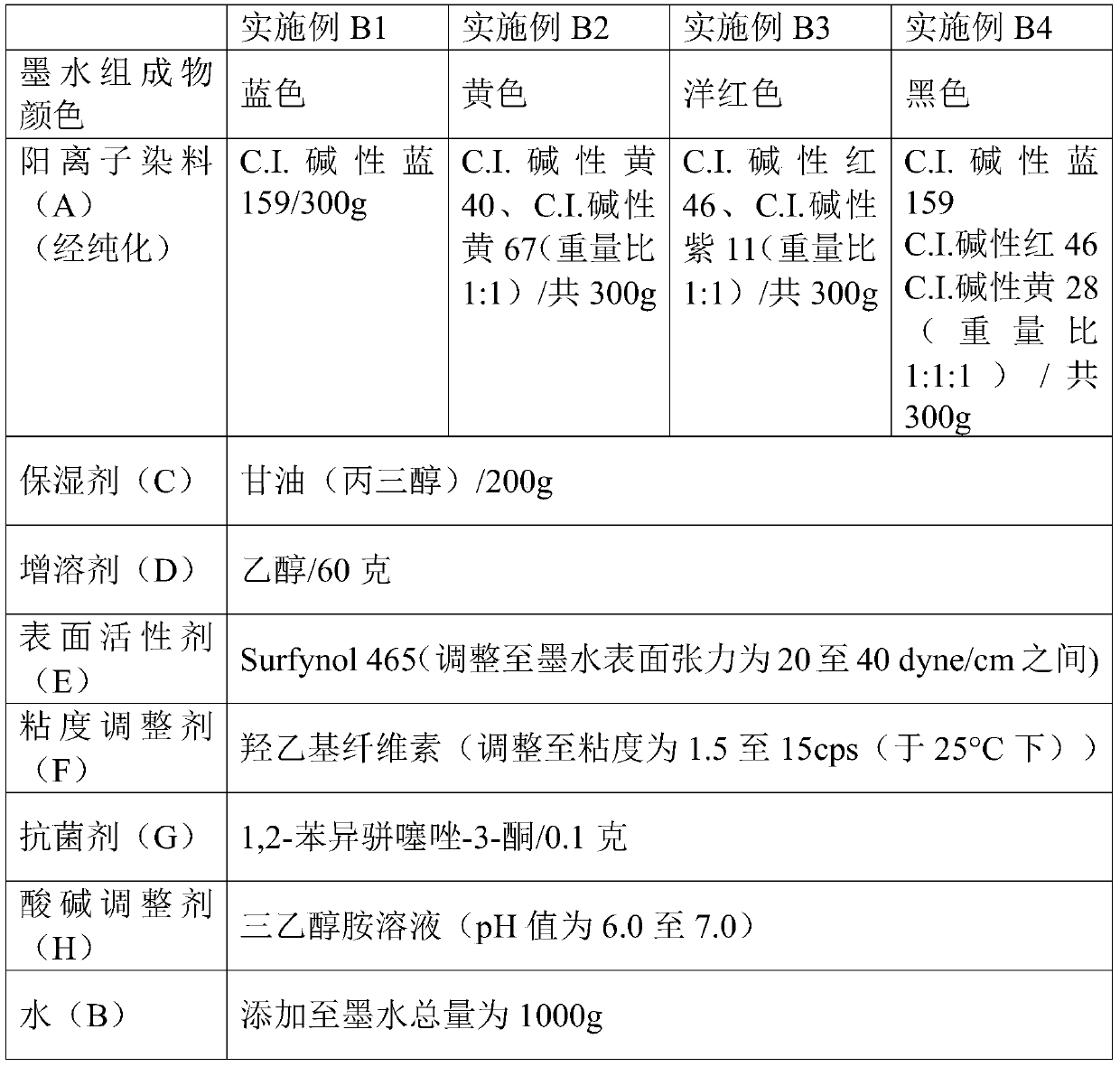

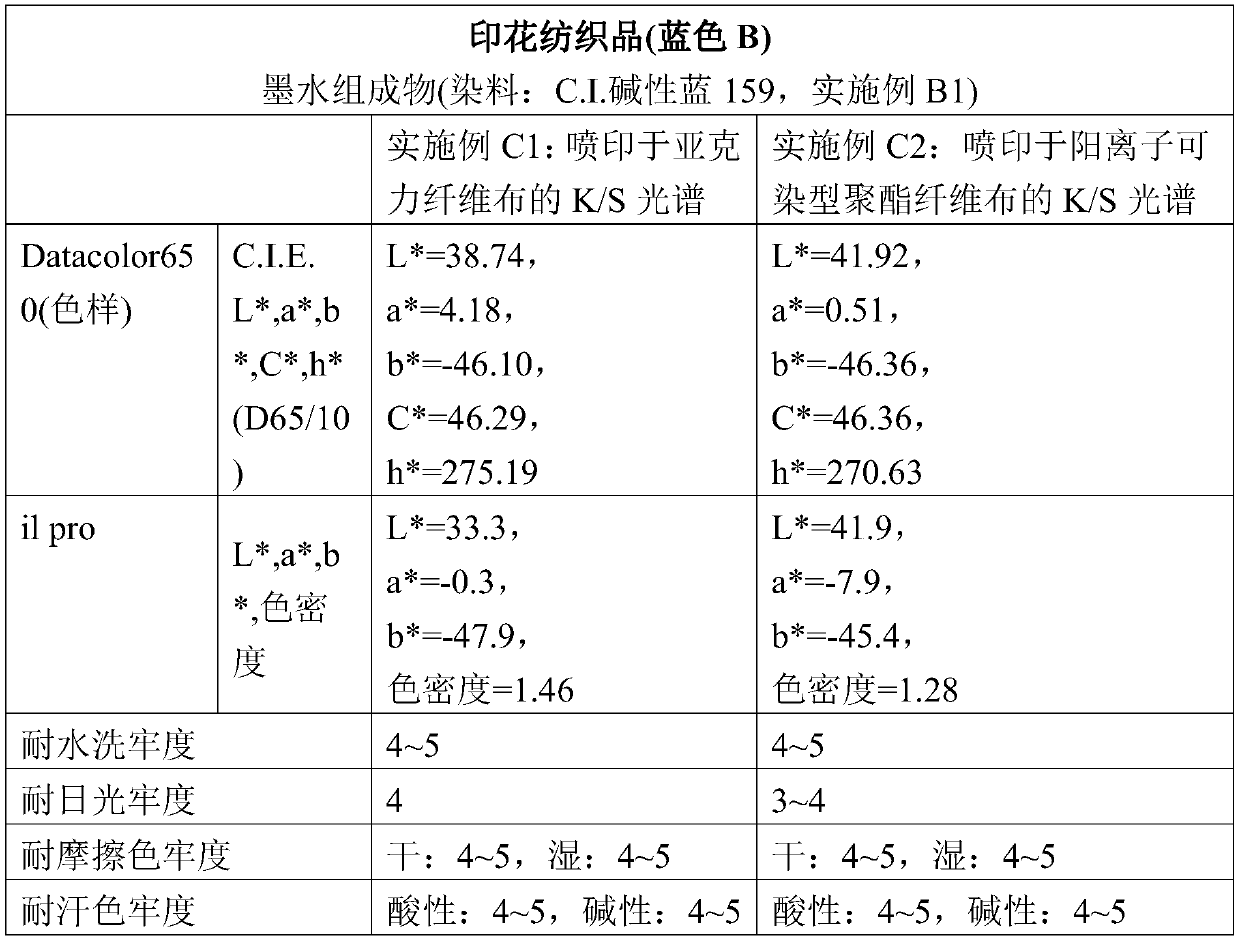

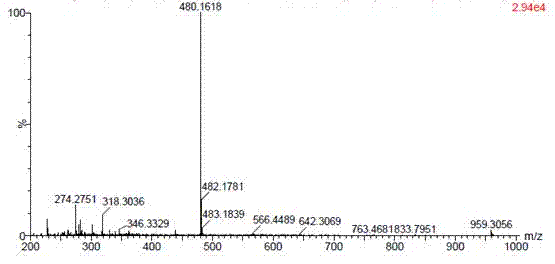

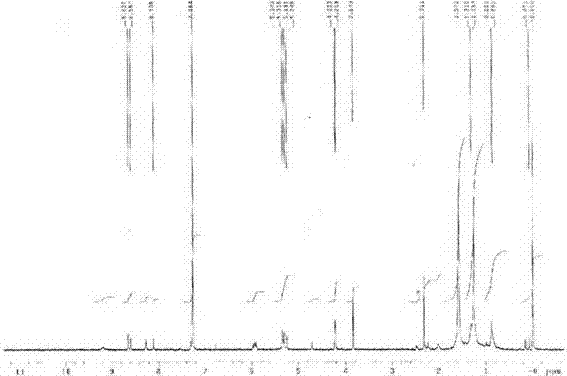

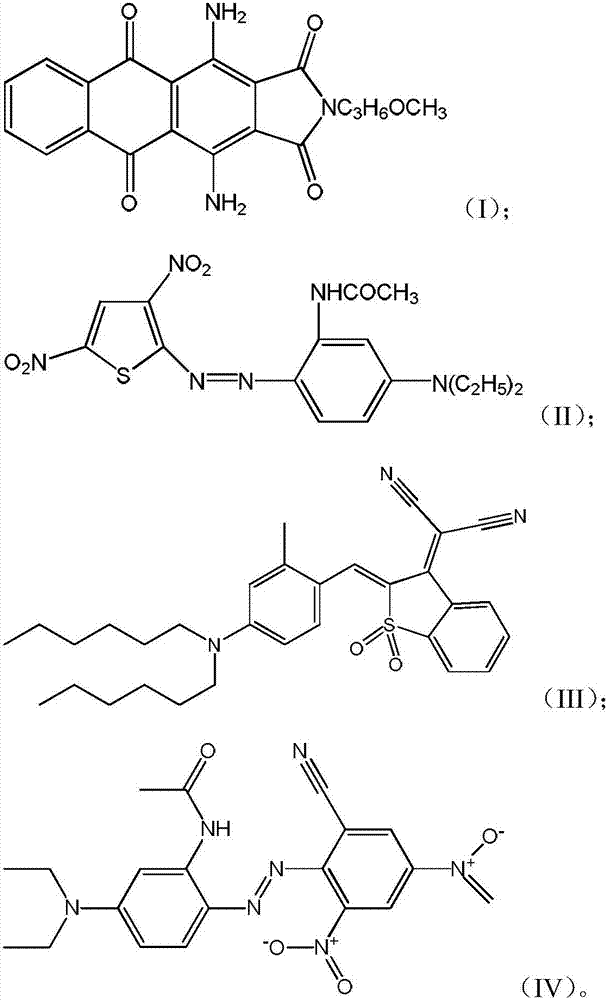

Cationic dye ink composition for digital inkjet and method for manufacturing printed textiles

InactiveCN110872789AGood combination stabilityImprove washing fastnessBiochemical fibre treatmentFibre typesTextile printerPolymer science

The invention provides a cationic dye ink composition for digital inkjet and a method for manufacturing printed textiles. The cationic dye ink composition for digital inkjet includes at least one cationic dye, water, and at least one organic solvent as a humectant.

Owner:T&T IND

Monoazo compound as well as preparation method and application thereof

ActiveCN102603572BImprove washing fastnessGood fastness to sublimationAzo dye preparationPreparation by cyanide reactionColour fastnessDisperse dye

Owner:HANGZHOU JIHUA JIANGDONG CHEMICAL CO LTD

A kind of disperse dye composition and preparation method thereof

ActiveCN105860581BGood color fastness to washingGood color fastness to rubbingOrganic dyesDisperse dyeSpray dried

The invention discloses a disperse dye composition capable of improving strength and a preparing method thereof. The disperse dye composition comprises, by weight, 0.1-100 parts of C.I. disperse blue60, 0.1-50 parts of C.I. disperse green9, 0.1-50 parts of C.I. disperse blue354, 0.1-10 parts of C.I. disperse blue165 and 0.1-5 parts of disperse yellow. The preparing method of the disperse dye includes the following steps that 1, C.I. disperse blue60, C.I. disperse green9, C.I. disperse blue354, C.I. disperse blue165 and disperse yellow are taken according to the formula amount and mixed to obtain a mixed dye, wherein the disperse yellow is selected from C.I. disperse yellow211 and / or C.I. disperse yellow114; 2, water is added into the mixed dye obtained in the step 1, the weight dosage ratio of the mixed dye to the water is 1:(2-20), the mixture is mixed, and mixed slurry is obtained; 3, the mixed slurry obtained in the step 2 is sprayed and dried, and the disperse dye composition is obtained.

Owner:ZHEJIANG OUYA CHEM CO LTD

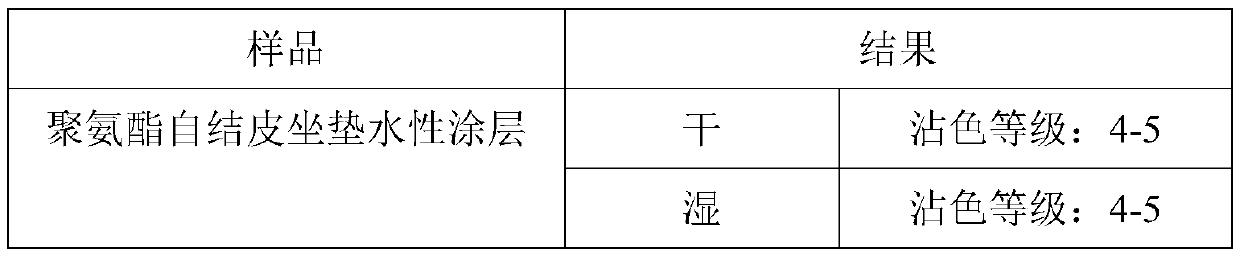

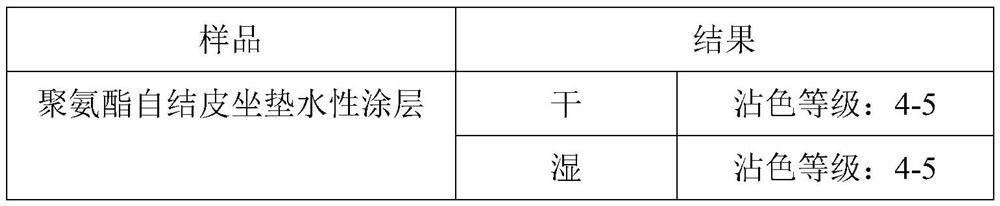

Polyurethane self-skinning cushion water-based coating and polyurethane self-skinning cushion

ActiveCN111072905AGood color fastness to rubbingGood resistance to reagentsPolyurea/polyurethane coatingsEpoxyPolymer science

The invention discloses a polyurethane self-skinning cushion water-based coating and a polyurethane self-skinning cushion. The coating is prepared from the following components in parts by mass: 66 to84 parts of water-based epoxy resin, 9 to 17 parts of hyperbranched polyethyleneimine and 5 to 20 parts of a water-based polyurethane prepolymer. The water-based coating has good adhesive force and flexibility and good color fastness to rubbing, reagent resistance, low temperature resistance and high temperature resistance, and the preparation method of the water-based coating has the advantagesof no toxicity, no pollution and no residue and has a wide application prospect in preparation of the polyurethane self-skinning cushion. The invention further provides a method for preparing the polyurethane self-skinning cushion by using the water-based coating, and the cushion prepared by the method has good wear resistance, antifouling property, chemical resistance, cleaning agent resistance and aging resistance, and can be produced on a large scale and widely used.

Owner:鹤山市鹤威科技发展有限公司

Aramid fiber antibacterial dyeing one-bath treatment method

The invention provides an aramid fiber antibacterial dyeing one-bath treatment method. The method comprises the following steps of S1, sequentially adding a carrier and sodium sulfate into a cationic dye to obtain a mixed solution; S2, adding silver nitrate into the mixed solution prepared in the step S1, adjusting the pH value to 3-5 after uniform stirring, and obtaining a dye liquor; and S3, putting an aramid fabric and the dye liquor obtained in the step S2 into a dyeing cup, putting the dyeing cup into a high-temperature dyeing machine, raising the temperature to 60-100 DEG C, keeping the temperature for 20-50 minutes until the carrier and the fabric act uniformly, after heat preservation is finished, increasing the temperature to 120-140 DEG C at the speed of 2 DEG C / min, dyeing for 50-80 min, and after dyeing is finished, cooling to 40 DEG C, soaping and drying. According to the method, aramid fiber is dyed by using the cationic dye, and the dye has positive charges, so that the dye mainly exists in a dye bath in an ionic form, but the main combination mode between the dye and the fiber is not an ionic bond, but hydrogen bonds, Van der Waals' force and the like, and the dyeing effect is obvious. Meanwhile, the dyed aramid fiber has good color fastness to rubbing, soaping fastness and better color fastness to sunlight.

Owner:NANTONG UNIVERSITY

A dyeing process of flame-retardant blended fiber

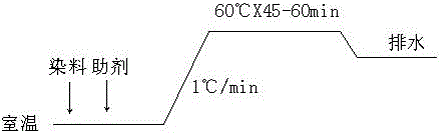

ActiveCN105908527BIncrease profitPromote infectionDry-cleaning apparatus for textilesDyeing processAcetic acidFiber

The invention aims to provide a dyeing process of flame-retardant mixed fiber. The dyeing process includes following steps: adding the flame-retardant mixed fiber into a desizing water solution of 50-60 DEG C, holding the temperature, and washing with water at 50-70 DEG C; adding the flame-retardant mixed fiber that is desized into a rinsing water solution of 95-100 DEG C, holding the temperature, and washing with water at 50-70 DEG C; unhairing; adding the flame-retardant mixed fiber that is unhaired into water of 15-35 DEG C, rising the temperature to 100-102 DEG C, adding dye at 68-71 DEG C, adding a dye auxiliary at 95-100 DEG C, and holding the temperature at 100-102 DEG C; rising the temperature to 130-135 DEG C, and holding the temperature at 130-135 DEG C; lowering the temperature to 75-80 DEG C; taking out the flame-retardant mixed fiber, and soaping the flame-retardant mixed fiber at 75-80 DEG C; taking the flame-retardant mixed fiber dyed for the first time, padding the flame-retardant mixed fiber in dye liquid, and air-drying at high temperature; padding the flame-retardant mixed fiber in color fixing liquid, and performing saturated steaming at high temperature; subjecting the flame-retardant mixed fiber after saturated steaming to water washing at 10-15 DEG C, acetic acid neutralizing, soaping at 85-90 DEG C and water washing at 15-35 DEG C sequentially; taking the flame-retardant mixed fiber after being dyed, and subjecting the flame-retardant mixed fiber to air finishing and full decatizing sequentially. The dyeing process has the advantage that dyeing effect is improved.

Owner:HANGZHOU ZHUODA PRINTING & DYEING CO LTD

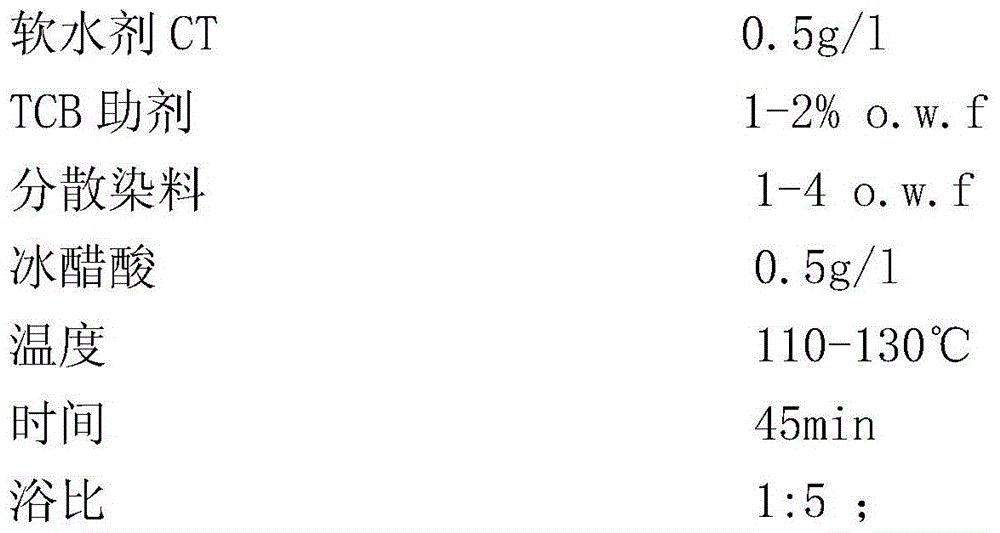

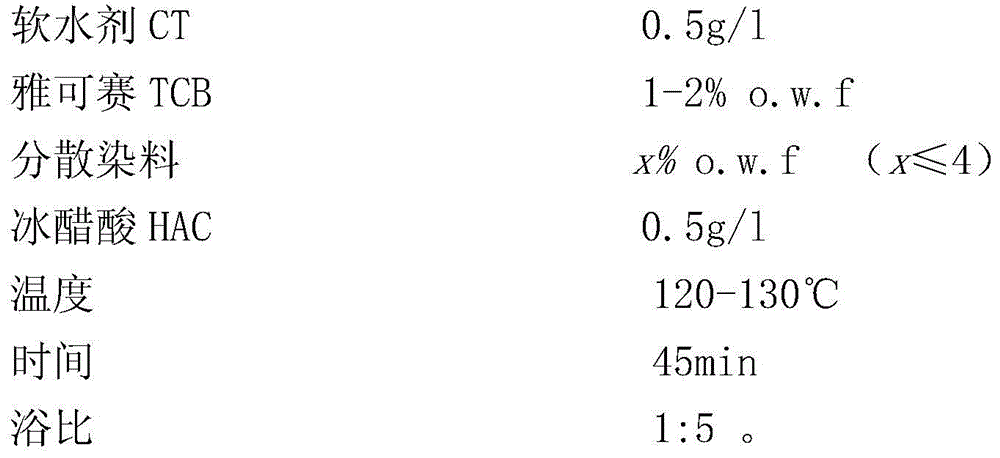

Dyeing and finishing process of coffee yarn pure spinning fabric

The invention discloses a dyeing and finishing process for a pure coffee yarn spun fabric. The dyeing and finishing process comprises the following working procedures: a pretreated dyeing one-bath process procedure, a soaping procedure, a softening procedure, and a moisture absorption and sweat releasing finishing procedure, wherein the unique TCB pretreated dyeing one-bath process is adopted; after dyeing, the soaping and softening treatment is adopted; meanwhile, in the moisture absorption and sweat releasing finishing procedure, a finishing agent is selected and blended, and the special moisture absorption and sweat releasing finishing process is adopted, so that the better air permeability and the better rubbing fastness can be achieved.

Owner:浙江七色彩虹科技有限公司

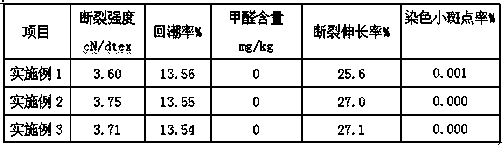

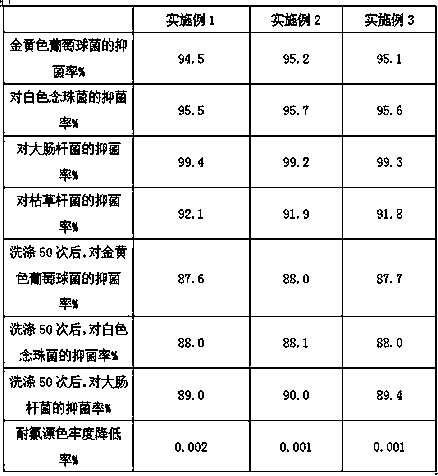

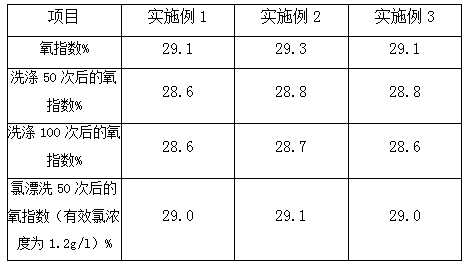

Silk fiber prepared by modifying plant extracts and preparation method of silk fiber

InactiveCN109811561ALow reduction rate of color fastness to chlorine bleachingHigh oxygen indexPhysical treatmentDyeing processChemistryRoom temperature

The invention provides a silk fiber prepared by modifying plant extracts. According to the silk fiber, the breaking strength is 3.60-3.75 cN / dtex, the elongation at break is 25.6-27.1%, the dye smallspeck rate is less the or equal to 0.001%, the bacteria inhibitive rate against bacillus subtilis is 91.8-92.1%, and the oxygen index after chlorine rinsing for 50 times is 29.0-29.1%. The invention further provides a preparation method of the silk fiber prepared by modifying the plant extracts. The preparation method comprises the steps of pretreatment and secondary treatment of the silk fiber, wherein the pretreatment comprises the steps that ultrasonic cleaning is carried out with deionized water and 1% of dilute hydrochloric acid for 10-15 min, then washing is carried out with ultrapure water, immersing is carried out at room temperature for 10-30 min, temperature is controlled at 25-50 DEG C and standing is carried out for 20-50 h. After the silk fiber is washed for 50 times, the bacteria inhibitive rate against staphylococcus aureus, candida albicans and escherichia coli is almost not reduced; and the flame retardant performance is good, and the oxygen index is reduced little after washing is carried out for 50 times and 100 times.

Owner:ZHONGKE TEXTILE RES INST QINGDAO CO LTD

Printing paste for polyvinyl chloride leaf handicraft and preparation method of printing paste

The invention discloses printing paste for a polyvinyl chloride leaf handicraft and a preparation method of the printing paste. The paste is formed by performing emulsification and polymerization on acrylic acid, acrylamide, butyl acrylate, acrylonitrile, hydroxyethyl methylacrylate, methyl methacrylate, 1,6-hexanediol diacrylate, styrene, alcohol polyoxyethylene ether (AEO 9), dodecylbenzene sulfonic acid and deionized water, and compounding with an anti-bleeding thickener, a wetting agent, a rheological agent and an anti-blocking agent. A film formed by the printing paste is strong in transparency, high in gloss and good in elasticity and oxidative resistance; and the printed polyvinyl chloride material is improved in folding resistance, and good in color fastness to rubbing and color fastness to washing.

Owner:LIAONING FIXED STAR FINE CHEM

A kind of preparation method and application of active hydrophilic type formaldehyde-free color fixing agent

ActiveCN111138662BGood color fixing effectImprove hydrophilicityDyeing processEpichlorohydrinBis epoxide

The invention relates to a preparation method of an active hydrophilic formaldehyde-free color fixing agent, a) preparation of an intermediate product: S1) stirring concentrated hydrochloric acid and slowly adding a tertiary amine dropwise, keeping warm for reaction, and adjusting the pH of the solution to 3 with the tertiary amine ~4; S2) Heating up to 45°C, slowly adding epichlorohydrin dropwise at a temperature of 45-55°C, keeping the temperature for 1.0-2.5h to reach a homogeneous solution, then adjusting the pH value, and cooling down to obtain an intermediate product; b) Intermediate product , polyethylenimine and deionized water into the reaction bottle, stirring slowly drop epichlorohydrin, 20 ~ 40 ℃, heat preservation reaction 5 ~ 7h, 65 ~ 80 ℃, adjust the pH value to 6 ~ 7, cool down Water color fixing agent. The hydrophilic formaldehyde-free color-fixing agent of the present invention has high cationicity and reactive epoxy groups, and has good hydrophilicity and color-fixing effect. The fastness reaches grades 3-5, and meets the national regulation on hygroscopicity within 5 seconds, which can reduce the finishing of subsequent processes and meet the needs of printing and dyeing factories.

Owner:DYMATIC CHEM

Polyurethane integral leather cushion water-based coating and polyurethane integral leather cushion

ActiveCN111072905BGood color fastness to rubbingGood resistance to reagentsPolyurea/polyurethane coatingsEpoxyPolymer science

The invention discloses a polyurethane self-skinned cushion water-based coating and a polyurethane self-skinned cushion. The invention provides a polyurethane self-skinned cushion water-based coating, which comprises the following components in parts by mass: 66-84 parts of water-based epoxy resin, 9-17 parts of hyperbranched polyethyleneimine, and water-based polyurethane prepolymer 5 to 20 copies. The water-based coating has good adhesion and flexibility, as well as color fastness to rubbing, resistance to reagents, low temperature resistance and high temperature resistance, and the preparation method of the water-based coating has the advantages of non-toxicity, no pollution and no residue, It has wide application prospects in the preparation of polyurethane self-skinned cushions; the present invention further provides a method for preparing polyurethane self-skinned cushions with water-based coatings, and the cushions prepared by the method have good wear resistance, antifouling, and Chemical, cleaning agent resistance, aging resistance, mass production and wide use.

Owner:鹤山市鹤威科技发展有限公司

Dyeing and finishing process of polyester acetate double-layer georgette fabric

ActiveCN113265886AGood color fastness to washingGood color fastness to rubbingFibre typesDyeing processDisperse dyeColour fastness

The invention relates to the technical field of fabric dyeing and finishing, in particular to a dyeing and finishing process of a polyester acetate double-layer georgette fabric. The dyeing and finishing process of a polyester acetate double-layer georgette fabric comprises the following steps of step 1, unwinding gray fabric; step 2, pretreatment; step 3, setting and leveling; step 4, gray fabric dyeing: raising the water temperature to 40-50 DEG C, running for 8-10 minutes, adding a dyeing and finishing aid, running for 10-20 minutes, adding glacial acetic acid, running for 10-20 minutes, adding a disperse dye, running for 10-20 minutes, fixing color, raising the temperature to 100-110 DEG C, keeping the temperature for 40-60 minutes, discharging water, washing with a 0.2-0.6 g / L reducing agent, raising the temperature to 85-95 DEG C, keeping the temperature for 10-20 minutes, cooling, soaping and discharging water; and step 5, softening, overfeeding and setting to obtain a finished product. The polyester acetate double-layer georgette fabric has the advantages of being comparable to real silk in hand feeling, soft, silky, uniform in color and luster and good in color fastness.

Owner:HAIYAN JIAYUAN PRINTING & DYEING

A kind of waterproof composite coated cloth and its production process

InactiveCN104985889BGood color fastness to rubbingGood color fastness to sea waterSynthetic resin layered productsBagsWear resistantEngineering

The invention provides waterproof composite coated fabric. The waterproof composite coated fabric comprises a nylon fabric layer, a first glue coated layer, a TPU film layer and a second glue coated layer, the first glue coated layer and the second glue coated are arranged at the two sides of the nylon fabric layer respectively, and the TPU film layer is arranged at the other side of the first glue coated layer; glue in the first glue coated layer and in the second glue coated layer comprises, by weight, 50-100 parts of crude glue, 10-30 parts of solvent and 5-10 parts of bridging agents. According to the waterproof composite coated fabric and a production technology thereof, the fabric has the comprehensive performances of being high-performance waterproof, wear resistant, tear resistant and stretch resistant at the same time, the fabric can be effectively applicable to the shell fabric of load carrying equipment of naval crews, the fabric can withstand heavy waves or heavy rainstorm weather as well as frequent stress and tensile deformation on account of drawing and pulling, and the fabric is quite worthy of application and popularization.

Owner:NAVY MEDICINE RES INST OF PLA +1

A kind of printing paste for polyvinyl chloride material handicraft leaves and preparation method thereof

The present invention is a polyvinyl chloride material handicraft leaf printing paste and a preparation method thereof, comprising acrylic acid, acrylamide, butyl acrylate, acrylonitrile, hydroxyethyl methacrylate, methyl methacrylate, 1,6-hexanedi Alcohol diacrylate, styrene, fatty alcohol polyoxyethylene ether AEO9, sodium dodecylbenzenesulfonate, deionized water, after emulsification, polymerization, compound anti-seepage thickener, wetting agent, rheological agent , Anti-clogging agent prepared. The film has strong transparency, high gloss, good elasticity and oxidation resistance, and the printed polyvinyl chloride material has improved folding resistance, good color fastness to rubbing, and good color fastness to washing.

Owner:LIAONING FIXED STAR FINE CHEM

Dyeing and finishing process of coffee yarn blended blended fabric

ActiveCN104727163BRealize medium and dark double dyeing processAccelerated adsorption and dispersionFibre treatmentDyeing processYarnColour fastness

The invention discloses a dyeing and finishing process of a coffee-yarn blended and knitted fabric. The dyeing and finishing process is characterized by comprising the following steps: preparing grey fabric, pretreating, dyeing, soaping, softening and carrying out after finishing, wherein a mild pre-treatment degreasing process is adopted; and an active double-dyeing process of firstly dyeing, dispersing and dyeing is adopted to dye, so that the difficulty in dying with the same color of the blended and knitted fibers is solved; through control on a finishing agent and the amount of the finishing agent in the after finishing process of the coffee-yarn blended and knitted fabric, the problems of same color and different colors in the dyeing process of the coffee-yarn blended and knitted fabric are solved; good air permeability and relatively good rubbing fastness are obtained; and meanwhile, a plurality of efficacies that the coffee-yarn blended and knitted fabric is capable of absorbing stink, removing an odor, storing heat, keeping warm, absorbing moisture and drying quickly in an far infrared manner are taken into account.

Owner:浙江七色彩虹科技有限公司

Preparation method of superfine fiber suede leather and prepared superfine fiber suede leather

The invention discloses a preparation method of a superfine fiber suede leather and the prepared superfine fiber suede leather. The preparation method comprises the following steps that: a buffed base cloth is subject to dyeing with the effect of a dye containing an azo structure and molecules with polar groups and the effect of auxiliary agents, then after-treatment is carried out, wherein, the dyeing is carried out at room temperature with the heating rate of 0.5 DEG C / min-1.5 DEG C / min and the dyeing temperature of 90-130 DEG C. The preparation method is simple, the prepared superfine fiber suede leather has two-color tone, can satisfy the requirements of processing various kinds and smallot superfine fiber suede leather and increase the colors and patterns of the product, satisfying the requirements that the consumer goes after fashion and personality.

Owner:HUAFON MICROFIBER SHANGHAI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com