Aqueous pigment ink composition

A technology of water-based pigments and compositions, applied in inks, applications, household appliances, etc., can solve the problems of easy pollution to the environment, large amount of colorant usage, high process cost, etc., and achieve good color fastness to sunlight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

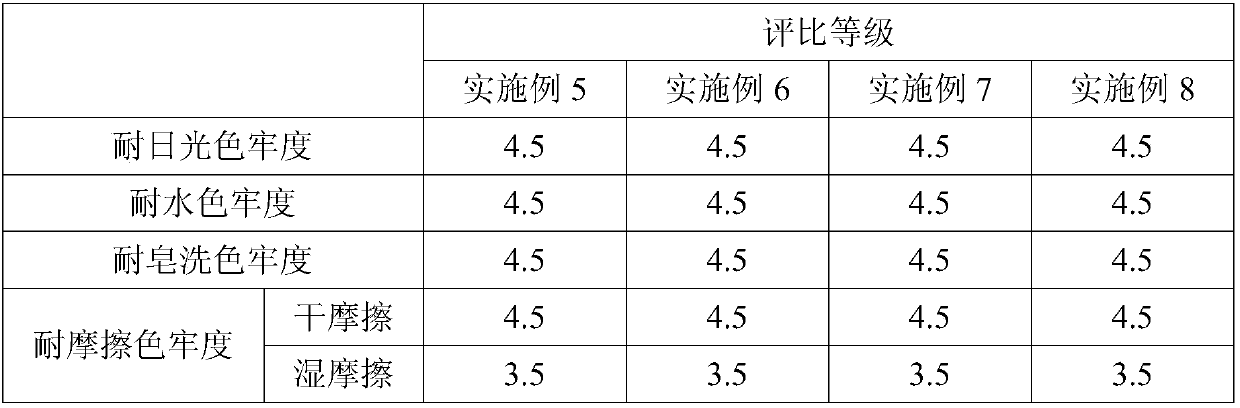

Examples

Embodiment 1

[0019] Embodiment 1: magenta water-based pigment ink composition

[0020] Prepare a magenta water-based pigment ink composition, which includes 30wt% pigment red 122 dispersion (15wt% pigment red 122 is dispersed in water), 15wt% glycerin, 10wt% polyurethane (polyurethane resin, as adhesive) (purchased from LIDYE CHMICAL), 0.08wt% of 1,2-benzisothiazol-3-one (as an antibacterial agent) (purchased from FOXIDE), 0.02wt% of organosiloxane (as a defoamer) (purchased from ) and 1wt% acetylene surfactant (purchased from NISSIN CHEMICAL), and the remaining components are water.

Embodiment 2

[0021] Embodiment 2: cyan water-based pigment ink composition

[0022] Prepare the cyan water-based pigment ink composition, which includes 25wt% pigment blue 15:4 dispersion (20wt% pigment blue 15:4 is dispersed in water), 43.9wt% glycerol, 10wt% polyurethane adhesive, 0.08wt% 1,2-benzisothiazol-3-one, 0.02wt% organosiloxane and 1wt% acetylene surfactant, and the rest is water.

Embodiment 3

[0023] Embodiment 3: yellow aqueous pigment ink composition

[0024] Prepare the yellow water-based pigment ink composition, which includes 30wt% pigment yellow 155 dispersion (20wt% pigment yellow 155 is dispersed in water), 43.9wt% glycerin, 10wt% acrylic polymer colloid dispersion (as adhesive) (purchased from LUBRIZOL), 0.08wt% of 1,2-benzisothiazol-3-one, 0.02wt% of organosiloxane and 1wt% of acetylene surfactant, and the remaining ingredients are water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com