Waterproof composite coated fabric and production technology thereof

A composite coating and production process technology, applied in the field of textile fabrics, can solve the problems of lack of water resistance, heat sealing stability, tear strength, abrasion resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

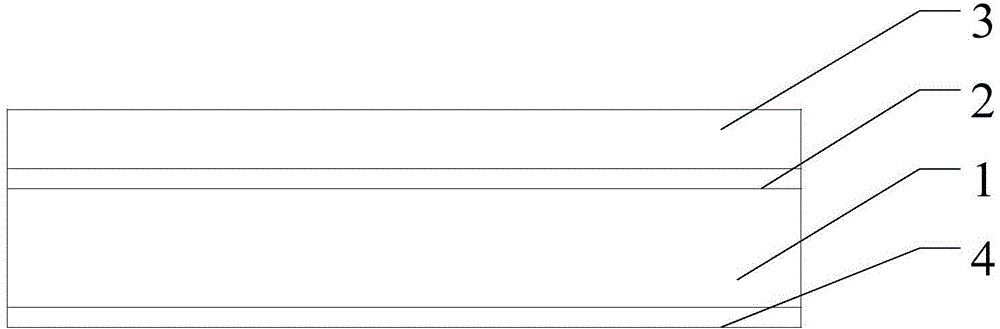

[0063] Take 1680D nylon gray cloth with a thickness of 0.4 mm, dry it waterproofly and shape it with a setting machine to form a nylon cloth layer. The parameter conditions of the setting machine are: drying tunnel temperature: 140°C; drying tunnel length: 20m; set speed: 6.5m / min. The components in the glue coating are taken in parts by weight, mixed and stirred evenly, wherein, raw glue: 100 parts; solvent: 20 parts; bridging agent: 8 parts.

[0064] One side of the nylon cloth layer is calendered and then scraped once, and then calendered and scraped twice to form a second glued layer with a thickness of 0.2mm. After the other side of the nylon cloth is calendered, the glue is scraped twice to form the first glue layer with a thickness of 0.1mm. Wherein, the parameters of the calender are set as follows: cylinder temperature: 90-125°C; pressure: 8-12T; vehicle speed: 20-25m / min; cloth unwinding mode: rolling; cloth receiving mode: rolling. The single-coating squeegee mach...

Embodiment 2

[0067] Take 1680D nylon gray cloth with a thickness of 0.4 mm, dry it waterproofly and shape it with a setting machine to form a nylon cloth layer. The parameter conditions of the setting machine are: drying tunnel temperature: 150°C; drying tunnel length: 25m; set speed: 7.0m / min. The components in the glue coating are taken in parts by weight, mixed and stirred evenly, wherein, raw glue: 150 parts; solvent: 30 parts; bridging agent: 10 parts.

[0068] One side of the nylon cloth layer is calendered and then scraped once, and then calendered and scraped twice to form a second glued layer with a thickness of 0.2mm. After the other side of the nylon cloth is calendered, the glue is scraped twice to form the first glue layer with a thickness of 0.1mm. Wherein, the parameters of the calender are set as follows: cylinder temperature: 90-125°C; pressure: 8-12T; vehicle speed: 20-25m / min; cloth unwinding mode: rolling; cloth receiving mode: rolling. The single-coating squeegee mac...

Embodiment 3

[0071] Take 1680D nylon gray cloth with a thickness of 0.4 mm, dry it waterproofly and shape it with a setting machine to form a nylon cloth layer. The parameter conditions of the setting machine are: drying tunnel temperature: 150°C; drying tunnel length: 15m; set speed: 6.0m / min. The components in the glue coating are taken in parts by weight, mixed and stirred evenly, wherein, raw glue: 50 parts; solvent: 10 parts; bridging agent: 5 parts.

[0072]One side of the nylon cloth layer is calendered and then scraped once, and then calendered and scraped twice to form a second glued layer with a thickness of 0.2mm. After the other side of the nylon cloth is calendered, the glue is scraped twice to form the first glue layer with a thickness of 0.1mm. Wherein, the parameters of the calender are set as follows: cylinder temperature: 90-125°C; pressure: 8-12T; vehicle speed: 20-25m / min; cloth unwinding mode: rolling; cloth receiving mode: rolling. The single-coating squeegee machin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com