Dyeing and finishing process of coffee yarn pure spinning fabric

A coffee yarn and fabric technology, applied in dyeing, textile and papermaking, fiber treatment, etc., can solve problems such as level dyeing and poor color fastness, and achieve improved dyeing rate, soft hand feeling, and good color fastness to rubbing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The coffee yarn pure spinning fabric used in this embodiment is 26-40S yarn made by 100% coffee yarn vortex spinning or compact siro spinning spinning process, and the width of weaving the above yarn as raw material is 150-170cm , coffee yarn pure spun knitted fabric with a weight of 120-200gsm.

[0042] The dyeing and finishing process of coffee yarn pure spinning fabric in this embodiment includes the following steps: pretreatment dyeing one-bath process—soaping process—softening process—moisture absorption and perspiration finishing process, wherein:

[0043] 1. Pre-treatment dyeing one-bath process:

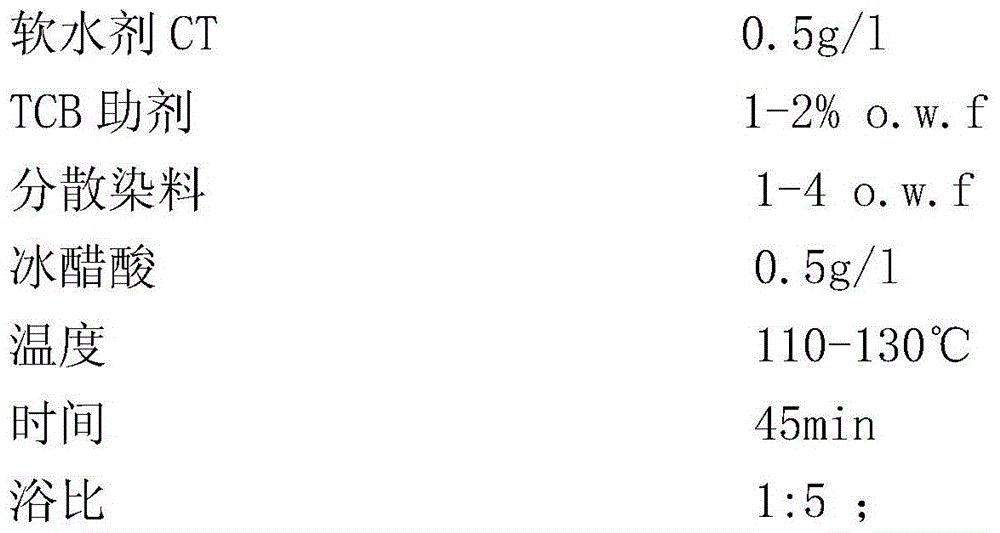

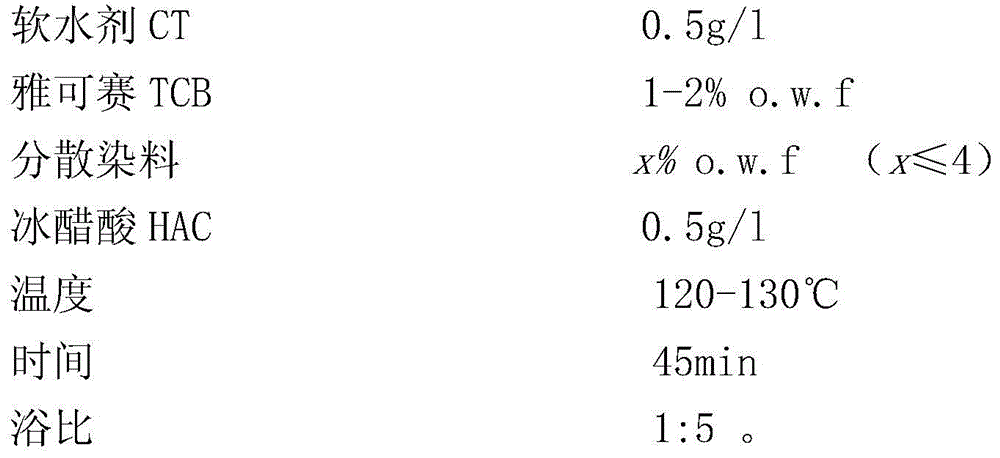

[0044] The pretreatment dyeing one-bath process formula is as follows:

[0045]

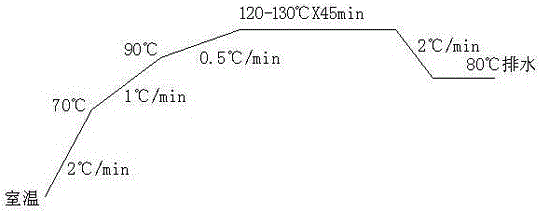

[0046] The pre-treatment dyeing one-bath process steps are as follows: prepare water, water softener CT, Acesel TCB, disperse dyes, and glacial acetic acid to prepare a pre-treatment dye solution according to the above formula, adjust the bath ratio to 1:5, and heat up to 120-130°C A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com