Monoazo compound as well as preparation method and application thereof

A compound and monoazo technology, applied in the field of monoazo compounds and their preparation, can solve the problems of poor washing fastness of dyes, difficulty in obtaining dark colors, and adding dyes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

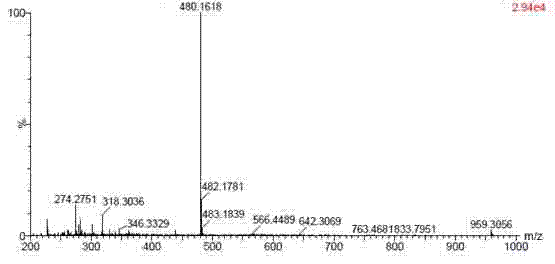

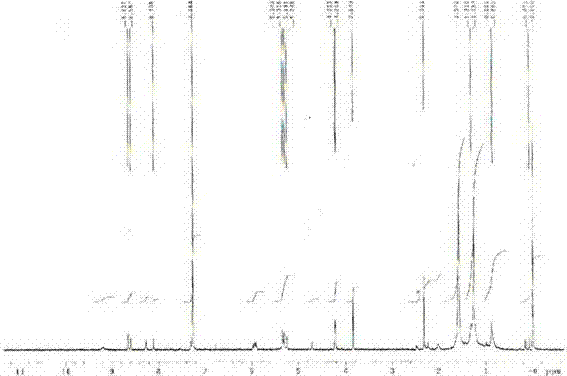

Image

Examples

Embodiment 1

[0072] (1) Add 130ml of water, 23.5g of 2-amino-4-acetamidoanisole, 21.3g of chloropropene, 0.3g of hydroquinone and 5.2g of magnesium oxide into the autoclave, seal the equipment after adding, and start magnetic stirring , uniformly heated to 95°C, maintained for 18 hours, and the pressure was 0.25MPa. After the end point, the temperature was lowered to about 75°C, adjusted to pH = 8, and then slowly cooled to 25°C, filtered, and the mother liquor was recovered. The filter cake was washed with water and dried to obtain 29.4 g of compound IIa represented by the structural formula (IIa).

[0073] (IIa)

[0074] (2) Put 19.2g of 98% sulfuric acid and 35g of 40% nitrosylsulfuric acid into a 100ml three-neck flask, stir to cool down, and slowly add 27g of 2,4-dinitro-6-bromoaniline at 25°C for about 2 hours After the addition is complete and the temperature is maintained for 4 hours, the end point is checked. After the end point is reached, the obtained diazonium salt so...

Embodiment 2

[0082] (1) Add 140ml of water, 19.7g of m-acetamidoaniline, 23.7g of chloropropene, 0.3g of hydroquinone and 5.5g of magnesium oxide into the autoclave. After the addition, close the equipment, start magnetic stirring, and evenly heat up to 85°C , keep for 15 hours, the pressure is 0.5MPa, after the end point, cool down to about 75°C, adjust the pH=6.5, then slowly cool down to 20°C, filter, and recover the mother liquor water. After the filter cake was washed with water and dried, 26.9g of compound IIb of the structural formula (IIb) was obtained,

[0083] (IIb).

[0084] (2) Put 17.1g of 50% sulfuric acid and 33g of 40% nitrosylsulfuric acid into a 100ml three-neck flask, stir to cool down, and slowly add 25g of 2,4-dinitro-6-bromoaniline at 30°C for about 2 hours After the addition is complete and the temperature is maintained for 5 hours, the end point is checked. After the end point is reached, the diazonium salt liquid sulfamic acid is obtained and left to stan...

Embodiment 3

[0091] (1) Add 120ml of water, 19.5g of 2-amino-4-acetamidoanisole, 9.2g of chloropropene, 0.2g of hydroquinone and 2.5g of magnesium oxide into the autoclave, seal the equipment after adding, and start the magnetic force Stir, evenly raise the temperature to 80°C, keep it for 15 hours, the pressure is 0.25MPa, after the end point, adjust the pH=9, then slowly cool down to below 30°C, filter, and recover the mother liquor water. The filter cake was washed with water and dried to obtain 22 g of 2-(N-allyl)amino-4-acetamidoanisole.

[0092] Add 7.8g of acrylocyanide, 22g of 2-(N-allyl)amino-4-acetamidoanisole, 3.8g of magnesium hydroxide, 0.2g of hydroquinone, and 0.7g of sodium bromide into the autoclave, and start Stir, evenly raise the temperature to 100°C and keep it for 10h, then slowly cool down to 15°C, filter, wash the filter cake with water, and dry to obtain 25g of compound IIc with the structural formula (IIc),

[0093] (IIc).

[0094] (2) Put 18g of 98% su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com