Method for manufacturing halogen-free, washing-resistant and flame retardant polyamide hook and loop fastener

A manufacturing method and Velcro technology, applied in textiles and papermaking, fiber processing, fiber types, etc., can solve the problem of visibility escapers unable to identify the escape route, limit the use of flame-retardant Velcro, not washable, not applicable, etc. problem, achieve the effect of increasing washing fastness, avoiding toxic gas and high visibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

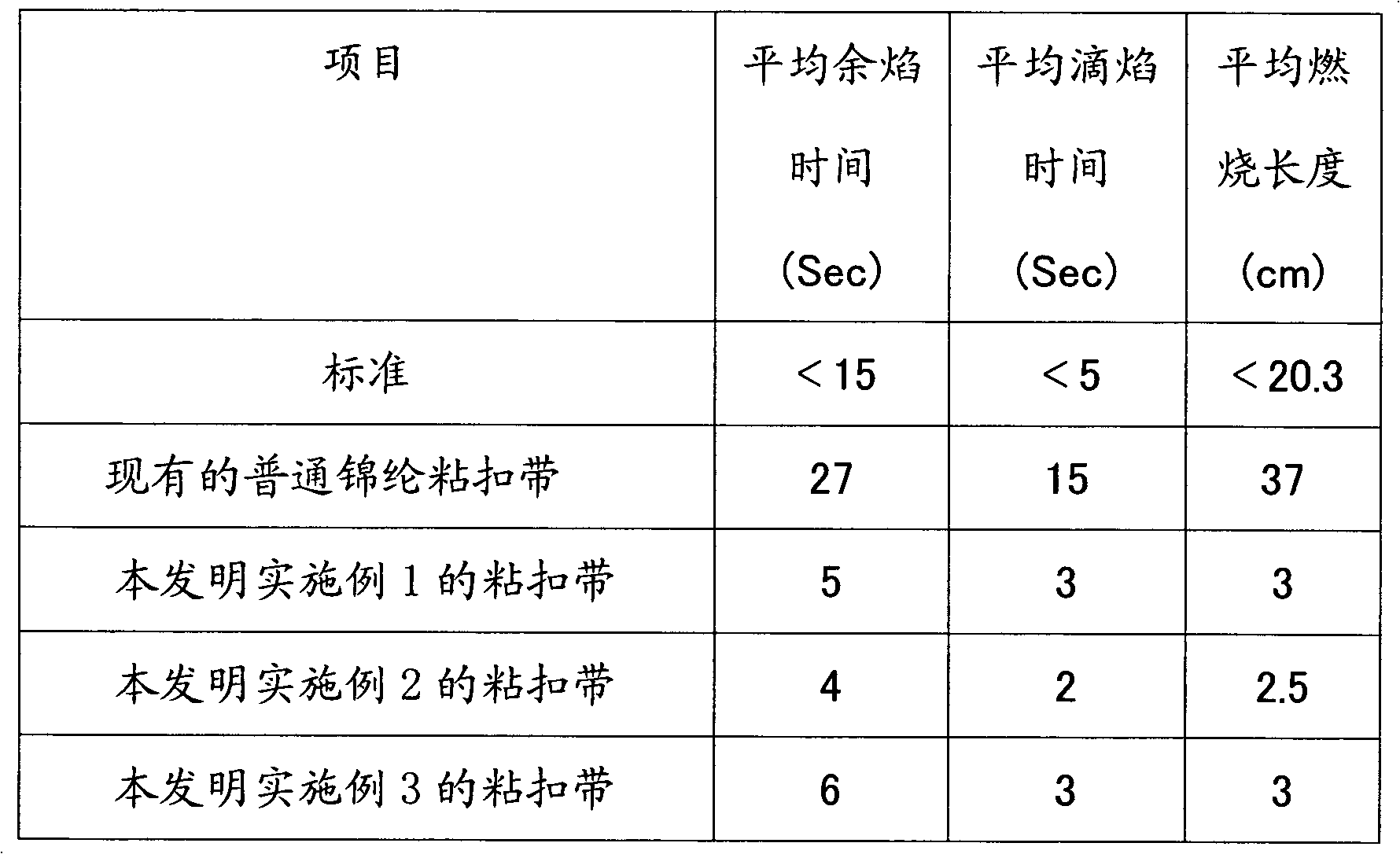

Embodiment 1

[0015] Embodiment 1: carry out as follows:

[0016] 1. To prepare the flame retardant finishing working solution, first mix phosphate ester, titanate and acrylic acid at a weight ratio of 1:0.13:0.83 at a temperature of 40°C, and then put them in a container containing 1000kg of warm water at a temperature of 60°C Add 135kg of phosphoric acid ester, titanate and acrylic acid mixed solution and 14kg of isopropanol respectively, and stir for 20 minutes to prepare a flame retardant finishing working solution.

[0017] 2. Immerse the nylon Velcro tape in the flame-retardant finishing working solution at 60°C for 2 hours. During dipping, the nylon Velcro tape is constantly stirred in the flame-retardant finishing working solution to ensure that the flame-retardant finishing working solution does not precipitate and fully Adsorbed on the nylon hook and loop, for every 100kg of nylon hook and loop processed, the amount of flame retardant finishing working fluid is 960kg.

[0018] 3....

Embodiment 2

[0023] Embodiment 2: carry out as follows:

[0024] 1. To prepare the flame retardant finishing working solution, first mix phosphate ester, titanate and acrylic acid at a weight ratio of 1:0.15:0.85 at a temperature of 45°C, and then put them in a container containing 1000kg of warm water at a temperature of 65°C Add 150kg of phosphoric acid ester, titanate and acrylic acid mixed solution and 15kg of isopropanol respectively, and stir for 25min to prepare flame retardant finishing working solution.

[0025] 2. Dip the nylon Velcro in the flame retardant finishing working solution at 65°C for 2.5 hours. Fully adsorbed to the nylon hook and loop, for every 100kg of nylon hook and loop processed, the amount of flame retardant finishing working fluid is 980kg.

[0026] 3. Dehydrate the nylon Velcro after impregnated with the flame retardant finishing solution for 4 minutes.

[0027] 4. Preparation of flame retardant glue, the composition weight ratio of flame retardant glue is ...

Embodiment 3

[0031] Embodiment 3: carry out as follows:

[0032] 1. To prepare the flame retardant finishing working solution, first mix phosphate ester, titanate and acrylic acid at a weight ratio of 1:0.18:0.89 at a temperature of 50°C, and then put them in a container containing 1000kg of warm water at a temperature of 70°C Add 165kg of phosphoric acid ester, titanate and acrylic acid mixed solution and 17kg of isopropanol respectively, and stir for 30min to prepare flame retardant finishing working solution.

[0033] 2. Immerse the nylon Velcro tape in the flame retardant finishing working solution at 70°C for 3 hours. During dipping, the nylon Velcro is constantly stirred in the flame retardant finishing working solution to ensure that the flame retardant finishing working solution does not precipitate and fully Adsorbed on the nylon hook and loop, for every 100kg of nylon hook and loop processed, the amount of flame retardant finishing working fluid is 1100kg.

[0034] 3. Dehydrate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com