Fluoride-free water-repellent textile fabric finishing method based on ultraviolet light curing reaction

A curing reaction, fluorine-free water-repellent technology, applied in fiber treatment, plant fibers, textiles and papermaking, etc., can solve the problems of high price of fluorine-containing mercaptans, poor fastness of finishing agents, not resistant to washing, etc., to achieve water repellency The effect is obvious, the operation is simple, and the effect of washing fastness is high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

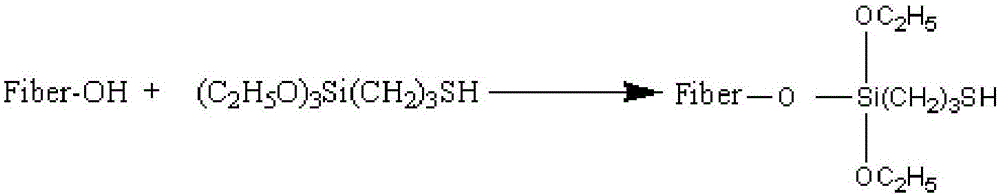

[0042] Use 3-mercaptopropyltriethoxysilane to modify the cotton fabric, and react with vinyl POSS and mercaptosilane to make the cotton have good water repellency. The specific steps are:

[0043] (1) Pre-processing stage:

[0044] ①Prepare 15g / L of sodium hydroxide and 7g / L of Pingping O solution (solvent is water), and wash the cotton fabric for 20min at 70°C;

[0045] ②Prepare 5wt% ethyl acetate solution of 3-mercaptopropyltriethoxysilane, put the roughened cotton fabric into the above solution, seal the mouth of the beaker with a film, place it in a constant temperature magnetic stirring water bath, and vibrate at 25°C 2 hours of processing;

[0046] ③Take out the cotton fabric, wash it thoroughly in distilled water, and dry it under vacuum at 60°C;

[0047] (2) Finishing stage:

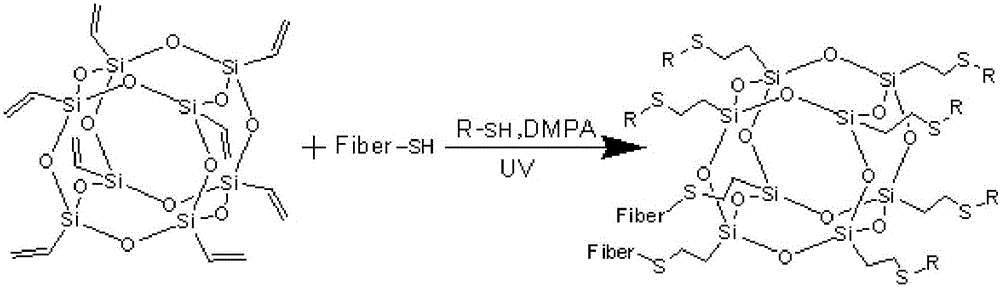

[0048] ①Prepare dichloromethane solutions of vinyl POSS and 3-mercaptopropyltriethoxysilane with a mass concentration of 1wt%, fully ultrasonically oscillate, and then add 0.1wt% of 2,2-dimeth...

Embodiment 2

[0052] Use 3-mercaptopropyltriethoxysilane to modify the cotton fabric, and react with vinyl POSS and alkyl mercaptan to make the cotton have good water repellency. The specific steps are:

[0053] (1) Pre-processing stage:

[0054] ①Prepare 15g / L of sodium hydroxide and 7g / L of Pyrene O solution (solvent is water), roughen the cotton fabric for 20min at 70°C;

[0055] ②Prepare 5wt% ethyl acetate solution of 3-mercaptopropyltriethoxysilane, put the roughened cotton fabric into the above solution, seal the mouth of the beaker with a film, place it in a constant temperature magnetic stirring water bath, and vibrate at 25°C 2 hours of processing;

[0056] ③Take out the cotton fabric, wash it thoroughly in distilled water, and dry it under vacuum at 60°C;

[0057] (2) Finishing stage:

[0058] ①Prepare dichloromethane solutions of vinyl POSS and dodecanethiol with a mass concentration of 1wt%, fully ultrasonically oscillate, and then add 0.1wt% 2,2-dimethoxy-2-phenylacetophenon...

Embodiment 3

[0062] Use 3-mercaptopropyltriethoxysilane to modify polyester-cotton fabric (65 / 35), and react with vinyl POSS and alkyl mercaptan to make polyester-cotton have good water repellency. The specific steps for:

[0063] (1) Pre-processing stage:

[0064] ①Prepare 15g / L sodium hydroxide and 7g / L Pyrex O solution, roughen the polyester-cotton fabric for 20min at 70°C;

[0065] ②Prepare 5wt% ethyl acetate solution of 3-mercaptopropyltriethoxysilane, put the roughened polyester-cotton fabric into the above solution, seal the mouth of the beaker with a film, and place it in a constant temperature magnetic stirring water bath at 25°C Shock treatment for 2 hours;

[0066] ③Take out the polyester-cotton fabric, wash it thoroughly in distilled water, and dry it under vacuum at 60°C;

[0067] (2) Finishing stage:

[0068] ① Prepare a dichloromethane solution of vinyl POSS and dodecanethiol with a mass concentration of 1wt%, fully ultrasonically oscillate, and then add 0.1wt% of 2,2-di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com