High-fastness turquoise blue disperse dye composition

A composition, blue dye technology, applied in the direction of organic dyes, dyeing methods, textiles and papermaking, etc., can solve the problems of low color strength and high price

Active Publication Date: 2014-04-23

ZHEJIANG LONGSHENG GROUP

View PDF4 Cites 24 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

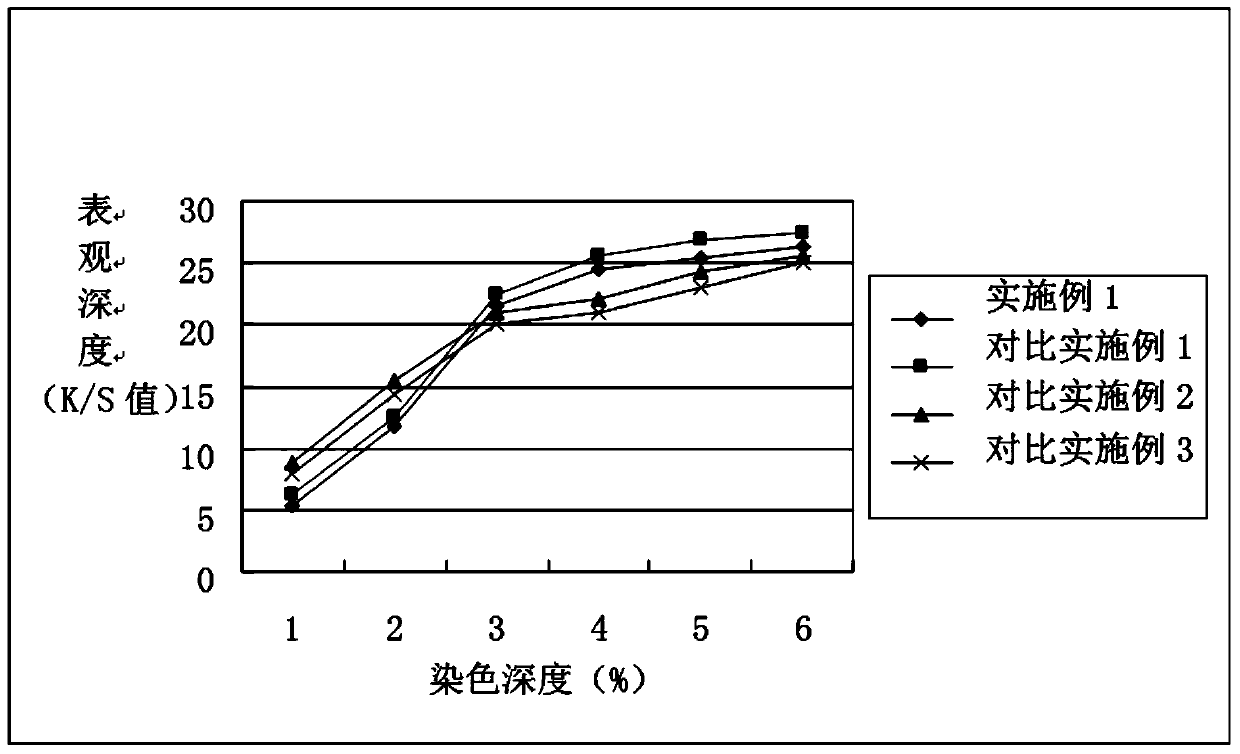

Polyester-spandex fabrics can also be dyed with conventional disperse dyes, such as C.I. Disperse Blue 60, which is widely used because of its bright color and high light fastness, but the dye has low color strength and high price, and its washing fastness and sublimation fastness, etc. The indicators are difficult to meet the requirements of middle and high-end sportswear fabric enterprises. Considering the limitations and development costs of single-color dyes in dyeing dark colors, industry technicians are increasingly trying to improve the dyeing of dyes through compounding and synergistic technologies. performance

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0027] According to the components and contents shown in Table 1, the original dye was mixed with auxiliary agents and water, ground and dispersed with a sand mill, and then spray-dried to obtain a high-fastness disperse turquoise blue dye.

[0028] Table 1: Dye Composition and Content

[0029]

[0030]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

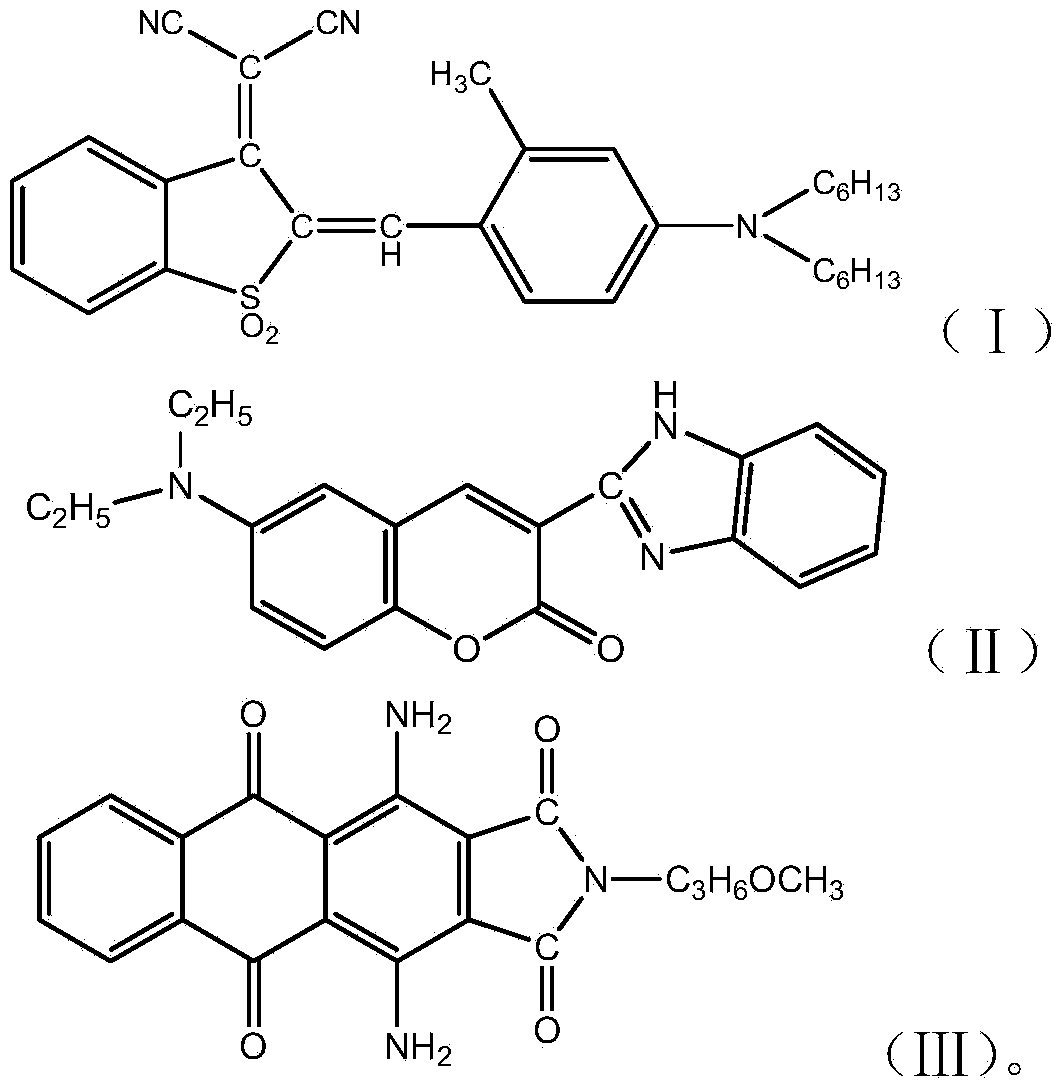

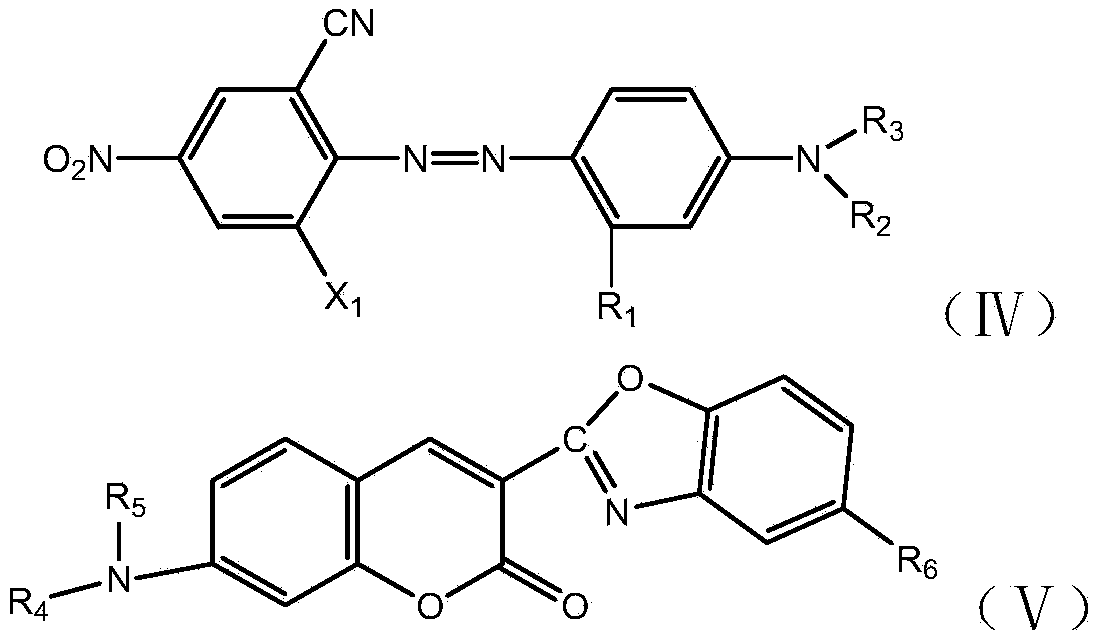

The invention provides an environment-friendly and economical high-fastness turquoise blue disperse dye composition with bright colored light, good leveling property, good elevating power and excellent washing fastness and sublimation fastness. The high-fastness turquoise blue disperse dye composition mainly comprises the following components in parts by weight: 50-90 parts of a component A shown by a formula (I), 0.1-10 parts of a component B shown by a formula (II) and 0.1-45 parts of a component C shown by a formula (III). After being commercialized, the turquoise blue disperse dye composition provided by the invention can be ground to be in a liquid state by a sand mill or a grinder, and can be in the shape of powder or particle after being subjected to spray drying, so that the turquoise blue disperse dye composition is suitable for dyeing of polyester and a blended fabric thereof, and particularly suitable for dyeing of a spandex blended fabric, and has the characteristics of good elevating power, small contamination to spandex, excellent washing fastness, excellent color fastness to sublimation and the like.

Description

(1) Technical field [0001] The invention relates to a disperse dye composition, in particular to a high-fastness disperse turquoise blue dye composition suitable for dyeing polyester fibers and their blended fabrics. (2) Background technology [0002] With the accelerated development of the times and the continuous improvement of people's living standards, different types of new textile fabrics have emerged. Swimwear and related casual clothing. Although polyester and ammonia fabrics can also be dyed with conventional disperse dyes, such as C.I. disperse blue 60, which is widely used because of its bright color and high light fastness, but the dye has low color strength, high price, washing fastness, sublimation fastness, etc. The indicators are difficult to meet the requirements of mid-to-high-end sportswear fabric enterprises. Considering the limitations and development costs of monochromatic dyes when dyeing dark colors, industry technicians are increasingly trying to im...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09B67/38D06P1/16D06P3/54D06P3/85

Inventor 欧其高怀庆汪仁良吕建君

Owner ZHEJIANG LONGSHENG GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com