Patents

Literature

105results about How to "Good color fixation rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Digital-printing active ink suitable for wide-width micro-piezoelectric printer

InactiveCN102585590AImprove printing stabilityImprove washing fastnessInksDyeing processElectricityPh buffering

The invention relates to a digital-printing active ink suitable for a wide-width micro-piezoelectric printer. The digital-printing active ink is characterized in that an ink formula system contains the following ingredients by weight percent: 5-15wt%of active dye, 5-40% of humectant, 1-10wt% of viscosity regulator, 0.1-1wt% of bactericide, 0-1wt% of pH buffering agent, 0-5% of surfactant, 0-2% of dispersing agent, 0-10% of cosolvent and the balance of deionized water. The digital-printing active ink disclosed by the invention has the characteristics that the performance parameter can favorably adapt to the wide-width micro-piezoelectric printer, and has good printing stability on the type of printer; the digital-printing active ink has good reaction activity and excellent fixation performance on fabric such as cotton, hemp, hair and silk, and has good washing fastness, good perspiration fastness, good friction fastness and good light fastness on the fabric; the digital-printing active ink is wide in color range and excellent in color expressive force; and through a strict high / low temperature ageing experiment, the digital-printing active ink is good in storage stability.

Owner:北京联创佳艺影像新材料技术有限公司

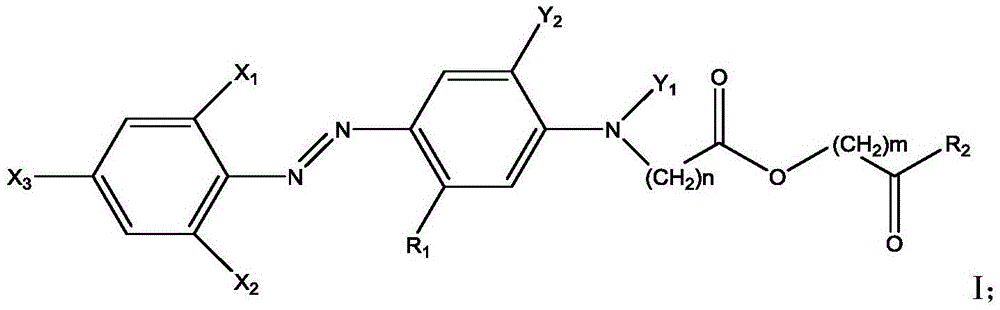

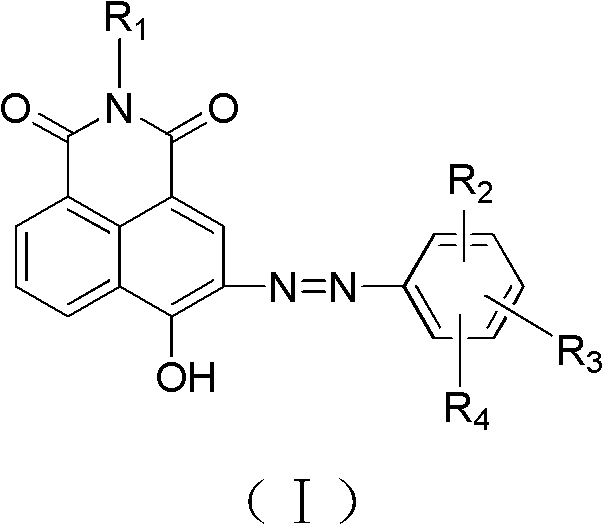

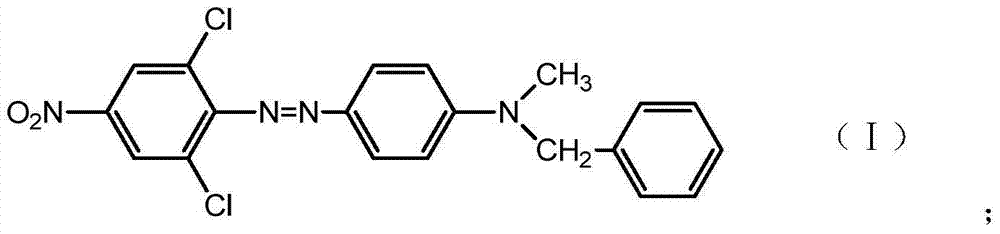

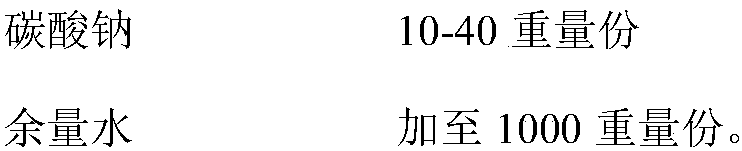

Monoazo compound as well as preparation method and application thereof

ActiveCN102603572AImprove washing fastnessGood fastness to sublimationAzo dye preparationPreparation by cyanide reactionColour fastnessDisperse dye

The invention relates to the technical field of disperse dyes and provides a monoazo compound as well as a preparation method and application thereof for the purposes of solving the problems that dyeing is carried out on fabrics such as terylene and superfine fiber so as to obtain very deep color and excellent washing resistance fastness and sublimation resistance fastness. The monoazo compound has a general formula (I). When the monoazo compound is dyed on fabrics such as terylene and superfine fiber, the obtained fabrics have very deep color, excellent washing resistance fastness and sublimation resistance fastness, friction resistance color fastness and light fastness and good color fixation rate in dip dyeing. The monoazo compound provided by the invention is also suitable for compounding of mixed tones with other disperse dyes.

Owner:HANGZHOU JIHUA JIANGDONG CHEMICAL CO LTD

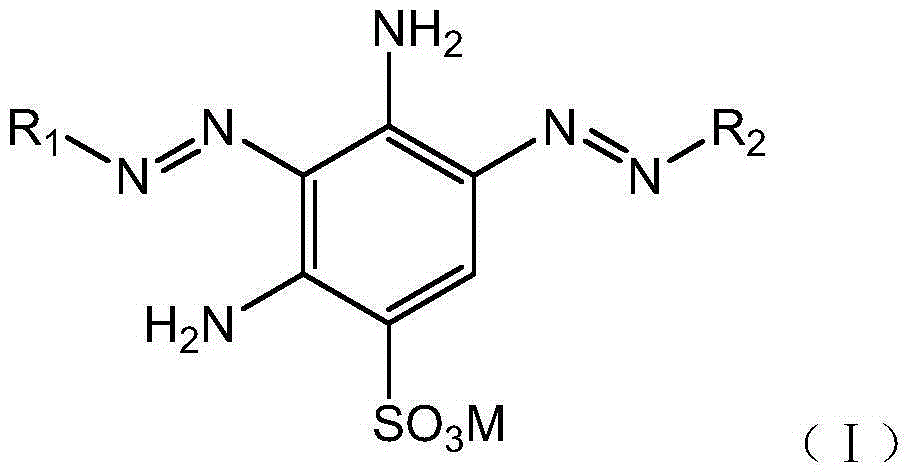

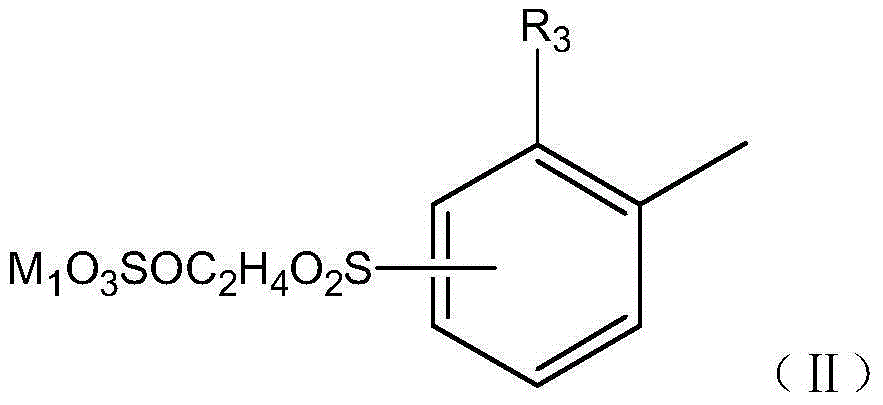

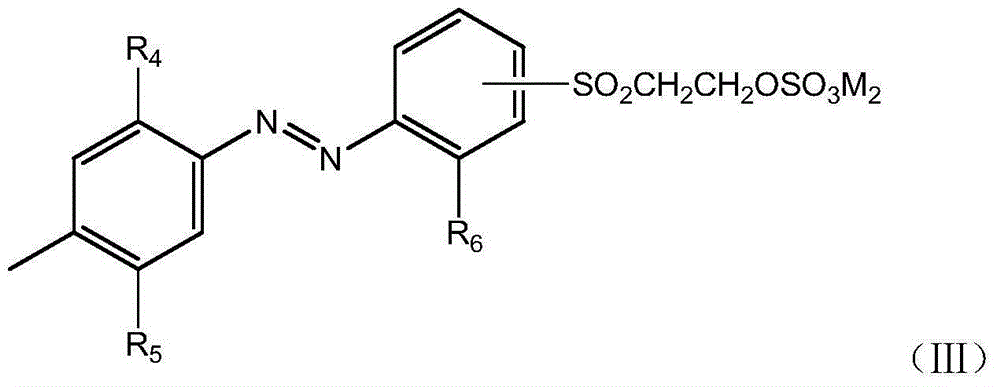

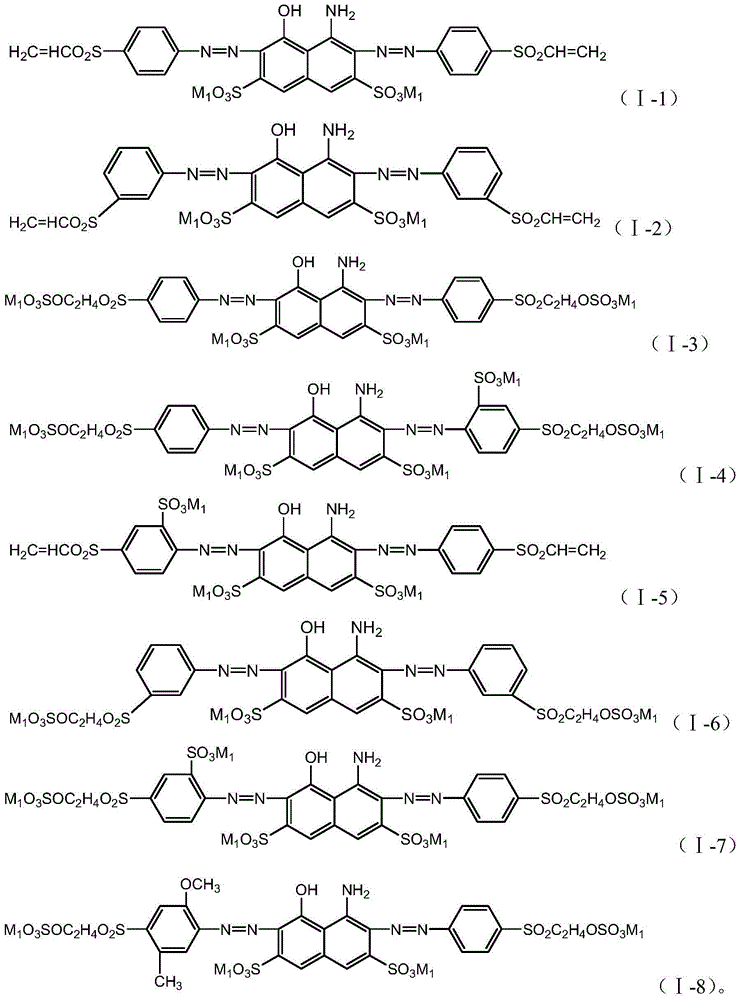

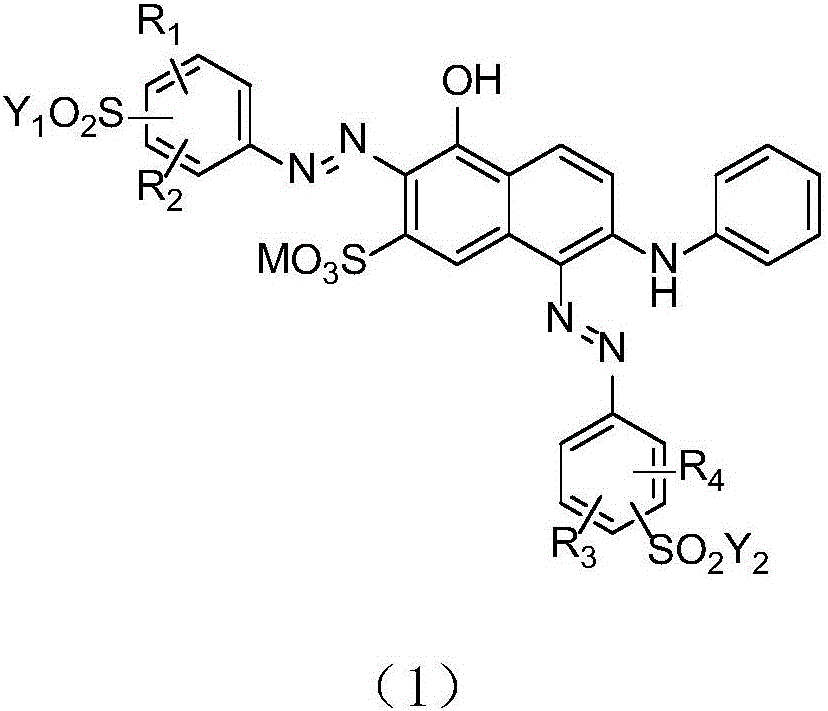

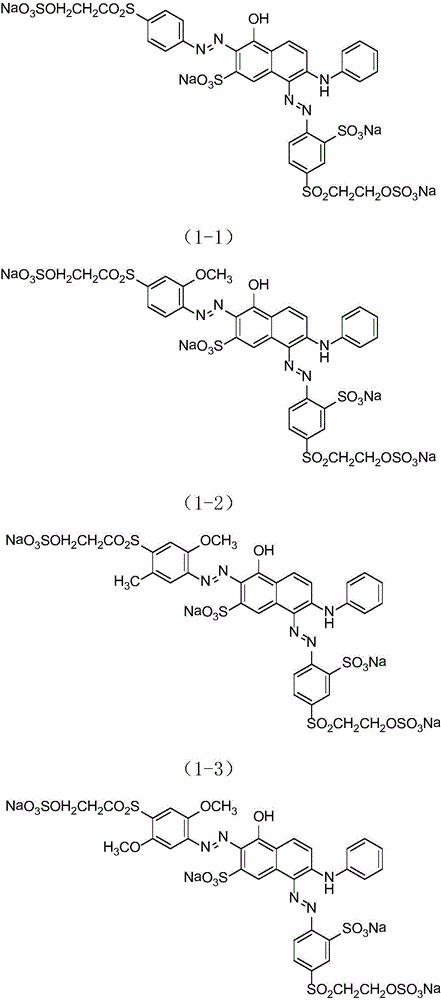

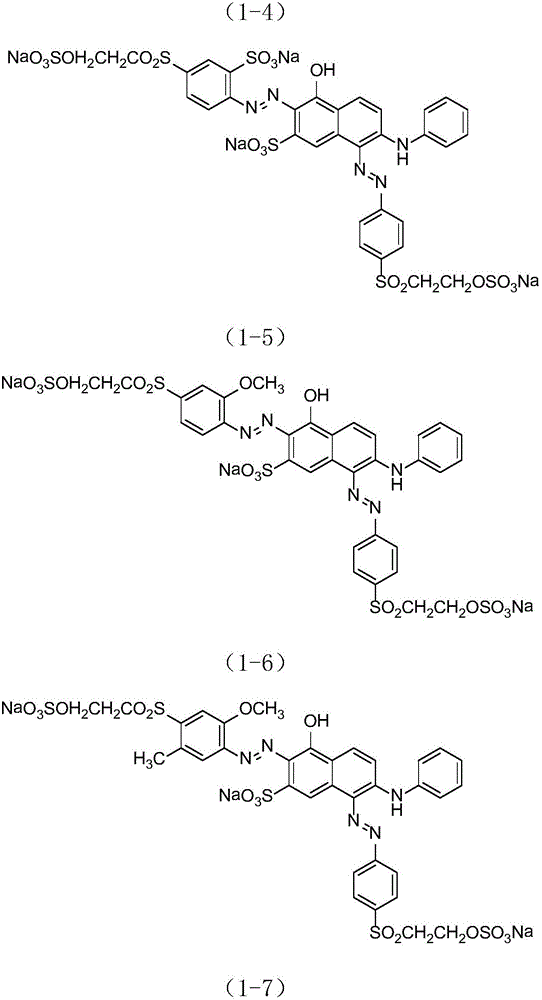

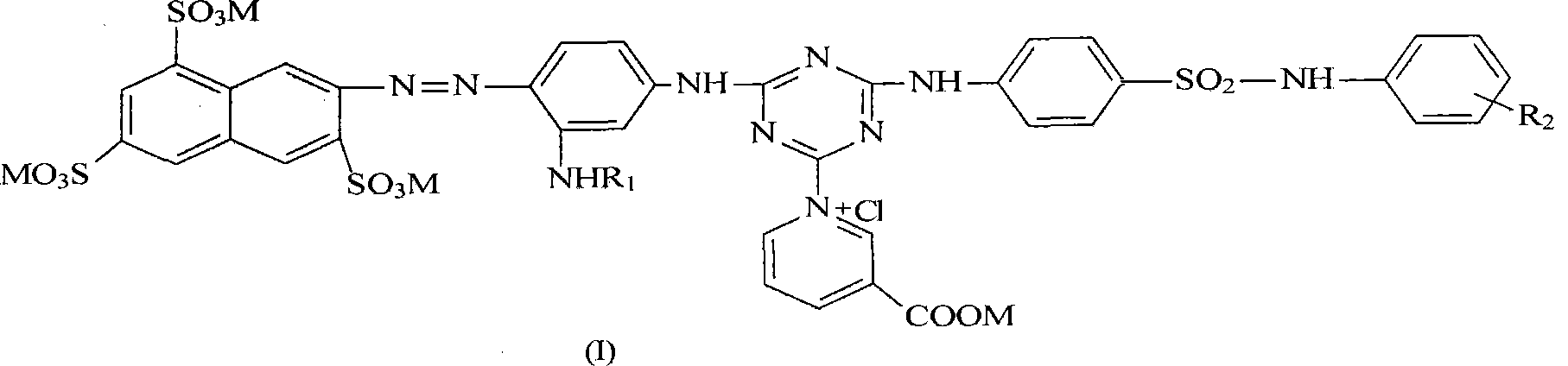

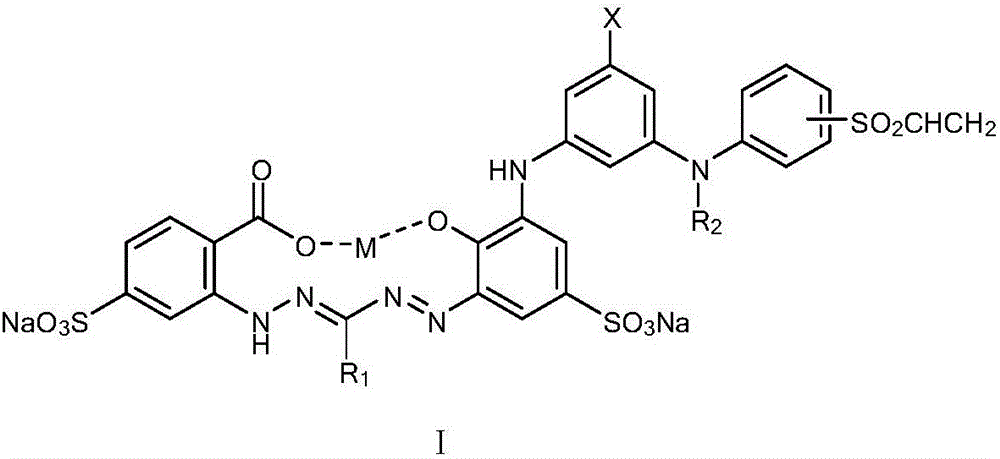

Brown polyazo reactive dye compound, and preparation method and application thereof

ActiveCN105176139ANovel structureImprove performanceReactive dyesDyeing processCombustionCellulose fiber

The invention discloses a brown polyazo reactive dye compound, and a preparation method and an application thereof. The structure of the brown reactive dye compound is represented by general formula (I), one of R1 and R2 in the formula (I) is selected from groups represented by general formula (II), the other one of the R1 and R2 is selected from groups represented by general formula (III), and R3 in the formula (II) is H, -OCH3 or -SO3M; -SO2OCH2CH2OSO3M is positioned in the para-position or the meta-position of an azo group; and in the formula (III), R4 is -NHCONH2 or -NHCOCH3, R5 is H or -OCH3, R6 is H, -OCH3 or -SO3M, and M1 and M2 respectively and independently are H or alkali metals. The dye compound is suitable for printing and dyeing cellulose fibers, and has the advantages of excellent dye uptake, high color fixing rate, excellent launderability, excellent friction resistance, excellent color fastness, and good combustion stability with the fibers.

Owner:ZHEJIANG LONGSHENG GROUP +1

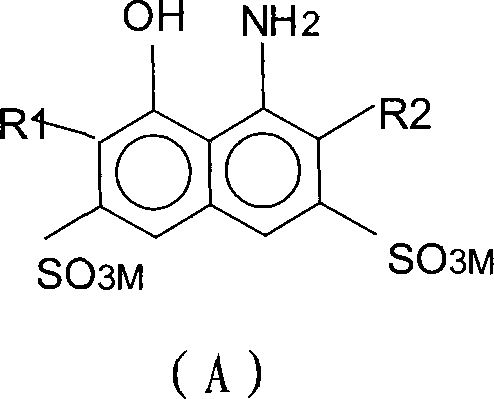

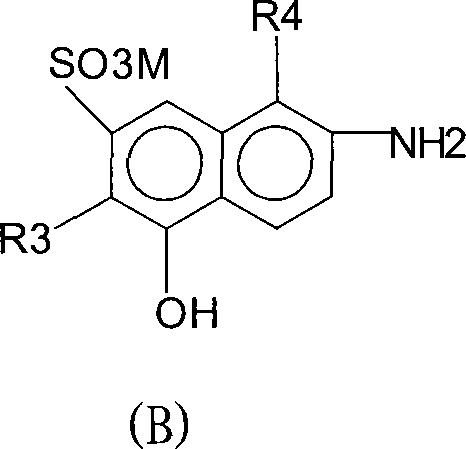

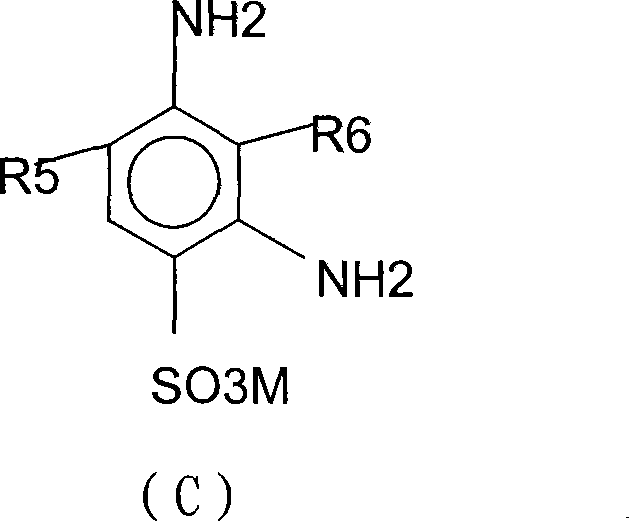

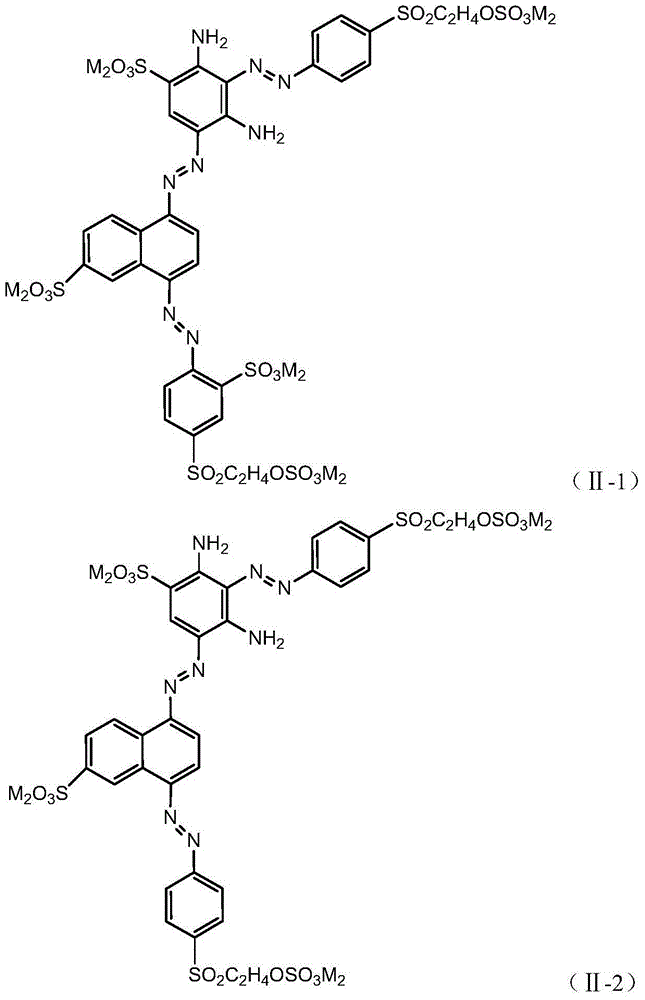

Reactive dye composition and preparing process and application thereof

InactiveCN101143972AHigh color fixing rateGood synchronization of dyeingOrganic dyesDyeing processCelluloseOil water

The invention discloses an active dye composition, which includes compound as showed in formula (A), formula (B), formula (C) and formula (D) and additive. 4 components of the active dye composition of the invention active dye composition are medium temperature dye, wherein the oil-water ratio, dye curve, affinity to cellulose, degree of dyeing, color fixing rate, sensitivity to salt and base, effect on bath ratio and sensitivity to temperature are very close. The composition has good dyeing synchronism and level dyeing property, and much higher color fixing rate, thereby being applicable for dip dyeing, continuous dyeing, cold dome, and printing and embossing of cellulose or protein fiber.

Owner:ZHEJIANG RUIHUA CHEM

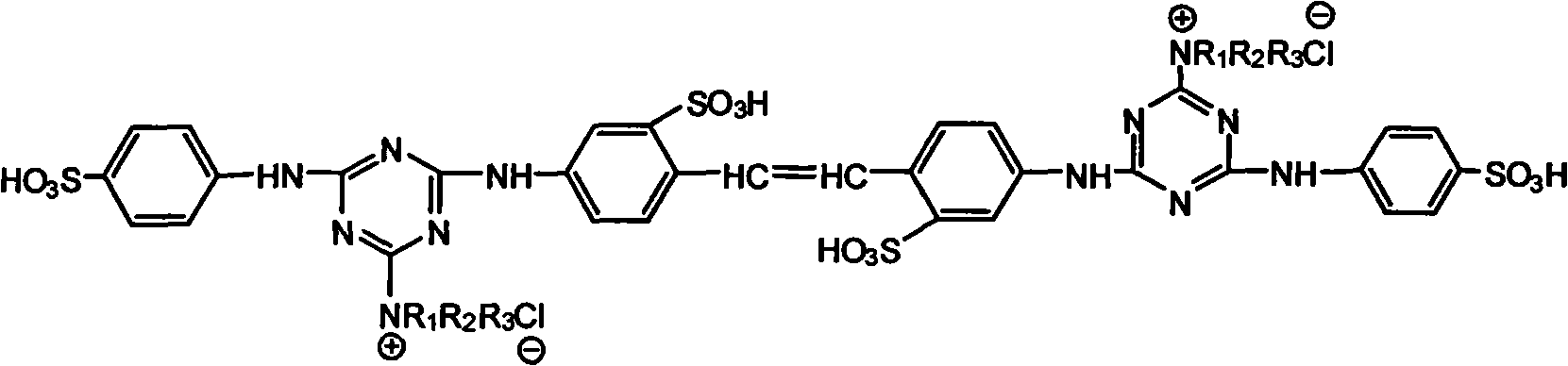

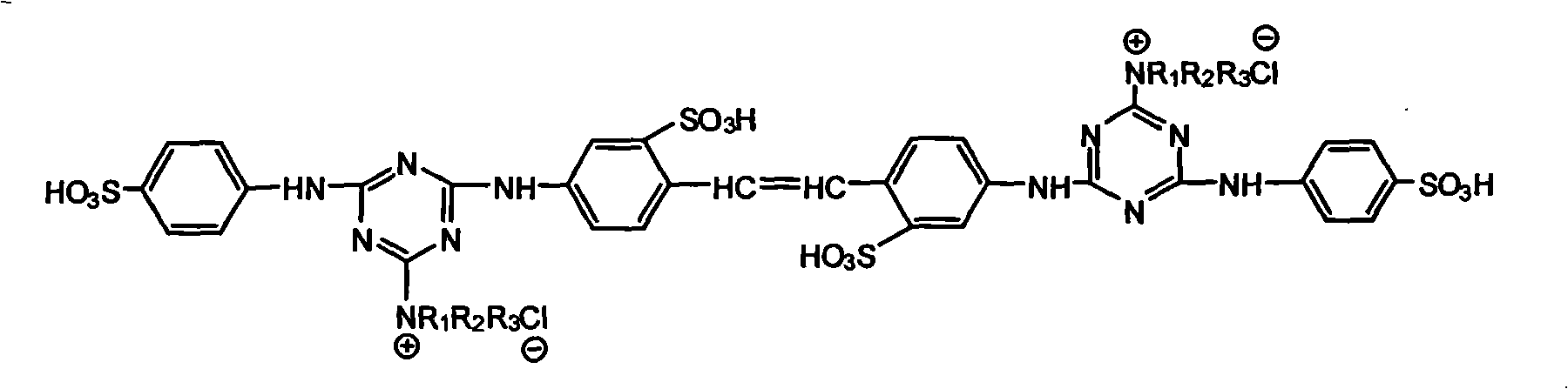

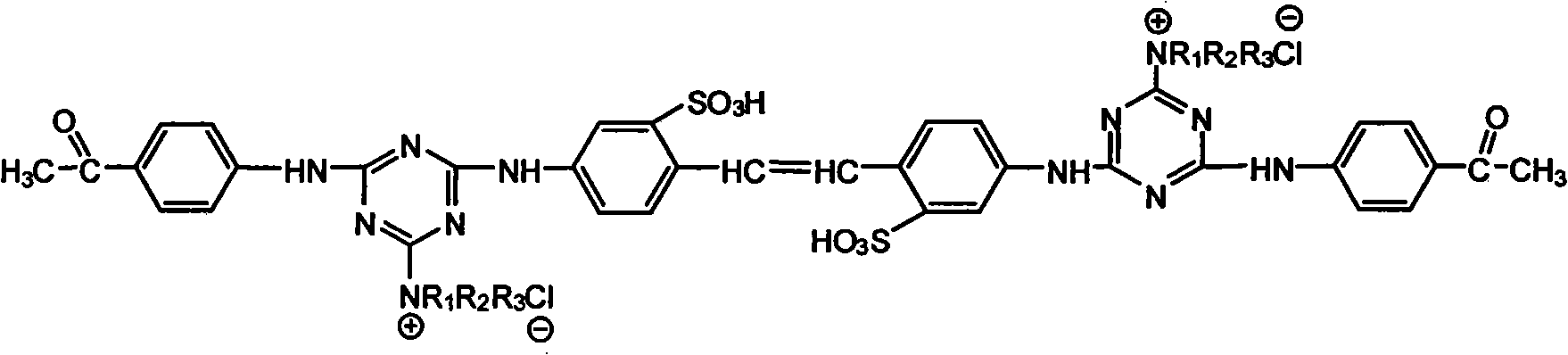

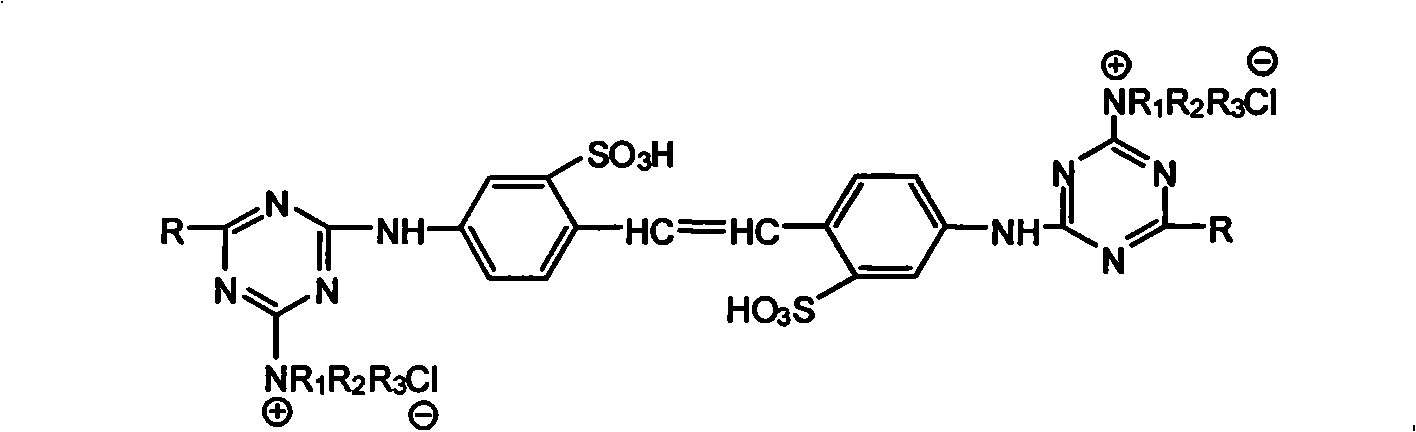

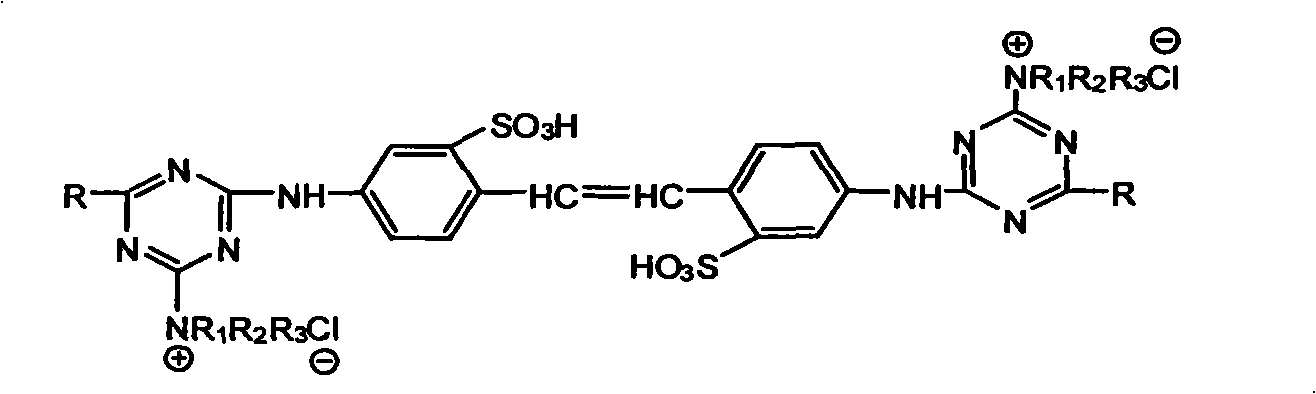

Amphiprotic triazine-DSD acid fluorescent whitener of tetra-sulfonic acid, synthesizing method thereof and applications

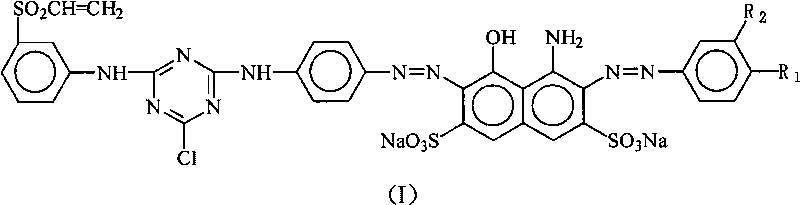

InactiveCN101307033AGood dyeing rateGood color fixation rateOrganic chemistryDetergent dyesSulfanilic acidQuaternary ammonium cation

The invention relates to a tetrasulfonic acid series of amphoteric triazine-DSD acidic fluorescent whitening agents, as well as synthesis and an application of the same. The series of fluorescent whitening agents are mainly applied to papermaking paint printing ink and textile. The synthesis adopts the following steps that: a. cyanuric chloride reacts with aminobenzene sulfonic acid at a temperature between 0 and 5 DEG C for 2.5 h, with pH value controlled to be between 1.8 and 2.1, so as to synthesize one-step condensation product; b. the one-step condensation product reacts with 4, 4'-diaminodiphenylethylene-2, 2'-disulfonic acid at a temperature between 40 and 45 DEG C for 2.5 h, with pH value controlled to be between 3.5 and 4.5, so as to synthesize two-step condensation product; the two-step condensation product reacts with a series of tertiary amine compounds at a temperature between 78 and 85 DEG C for 2.5 h, with pH value controlled to be between 7.5 and 8.5, so as to synthesize a series of amphoteric triazine-DSD acidic fluorescent whitening agents containing quaternary ammonium salt groups. Application results show that: the fluorescent whitening agents can be used under neutral / alkaline conditions, and has higher dye uptake rate and better whitening effect under acidic conditions.

Owner:SHANDONG UNIV

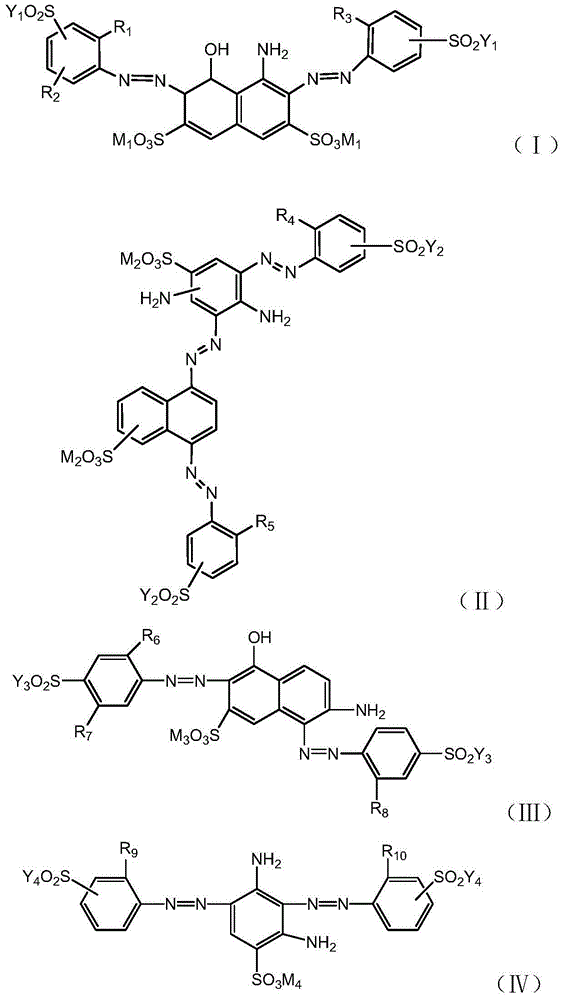

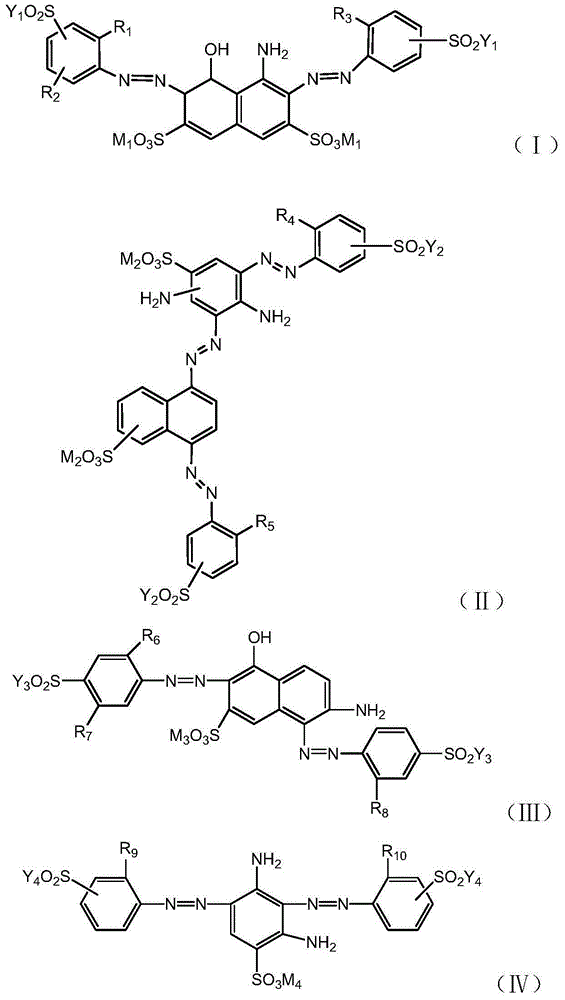

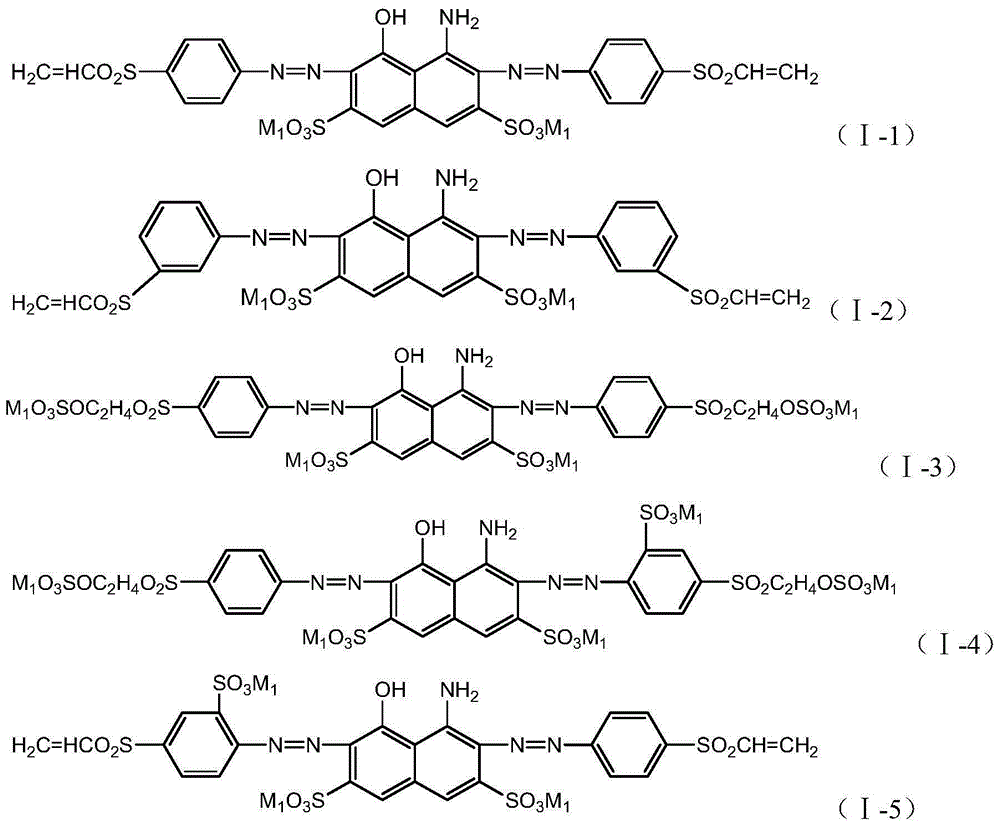

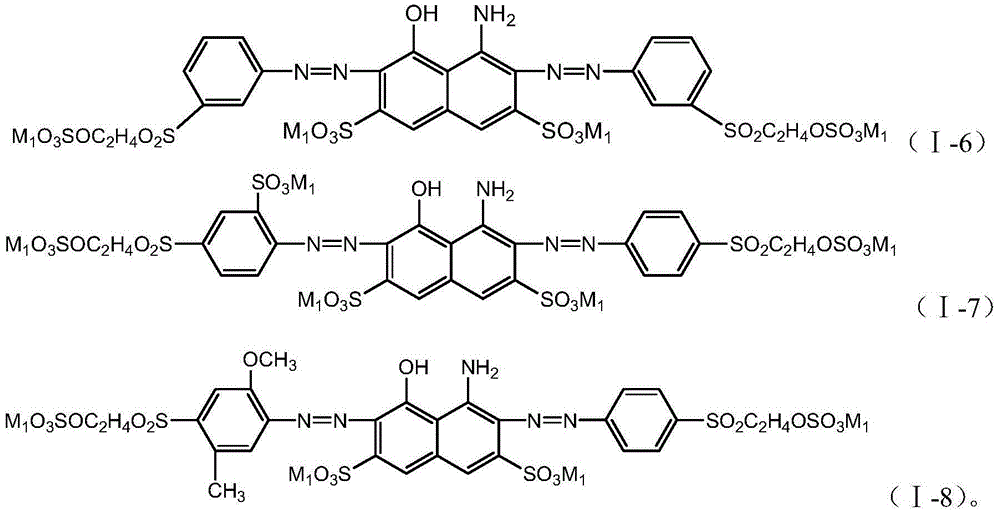

Active dye composition in dark blue to black and dye product

The invention relates to active dye composition in dark blue to black and a dye product. The dye composition comprises, in parts by weight, 45-95 parts of a component A, 5-55 parts of a component B and 0-40 parts of a component C, wherein the component A is selected from at least one compound represented by the formula (I), the component B is selected from at least one compound represented by the formula (II), and the component C is selected from at least one compound represented by the formula (III) and / or the formula (IV). The active dye product in dark blue to black comprises the dye composition. The dye product is good in deep dyeing property, excellent in improvement power, high in dye up-take, high in color fixation, good in compatibility and excellent in color fastness; during dyeing, the dye is small in use amount, easy to wash, clear in residual liquid, stable in salt and alkali resistance, excellent in metamerism, stable in dyeing property and applicable to different technologies of dip dyeing, pad dyeing, printing and the like.

Owner:SHANGHAI KEHUA DYESTUFF IND +1

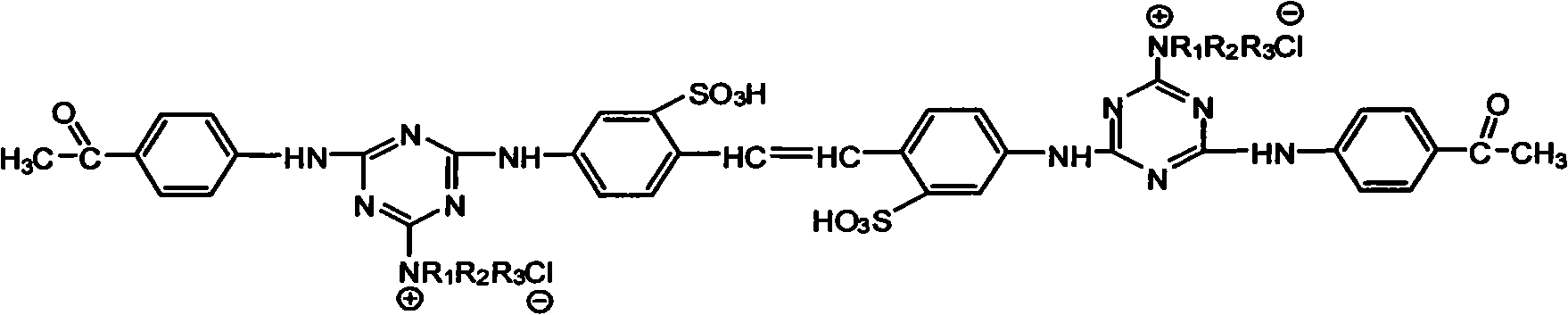

Fluorescent whitening agent containing p-aminoacetophenone group quaternary ammonium salt, synthesis and use thereof

InactiveCN101298438AGood dyeing rateGood color fixation rateOrganic chemistryDetergent dyesWhitening AgentsTriazine

The invention relates to a series of whitening agents containing p-aminoacetophenone radical hyamine fluorescence as well as synthesis and applications thereof; the series of whitening agent are mainly applied to paper making, dope, printing ink and weaving. The invention adopts the following synthetic steps of: a, using cyanuric chloride to react with p-aminoacetophenone for 2.5h under the temperature of 0 to 5 DEG C, controlling the pH between 1.8 to 2.1 and synthesizing a primary condensation product; b, using the primary condensation product to react with 4, 4'-Diaminostilbene-2, 2'-disulfonic acid for 2.0h under the temperature of 40 to 50 DEG C, controlling the pH between 3.8 to 4.2 and synthesizing a secondary condensation product; c, using the secondary condensation product to react with a series of tertiary amine compounds for 2.5h under the temperature of 80 to 85 DEG C, controlling the pH between 7.8 to 8.2 and synthesizing a series of p-aminoacetophenone radical hyamine triazine-DSD acid fluorescence whitening agents. The application result shows that; the whitening agents not only can be used under neutral conditions and alkaline conditions, but also has higher dying rate under acidic conditions and better whitening effect.

Owner:SHANDONG UNIV

High-fastness disperse dye composition as well as preparation method and application thereof

InactiveCN105602283AGood color fixation rateGood level dyeingOrganic dyesDyeing processDisperse dyePerspiration

The invention relates to high-fastness disperse dye composition as well as a preparation method and an application thereof. The high-fastness disperse dye composition comprises two compounds with two different structures in formula I, two compounds with two different structures in formula II, a compound shown in the formula III and a compound shown in the formula IV. The preparation method comprises steps as follows: the compounds shown in the formulas I, II, III and IV are mixed uniformly with an auxiliary, ground and subjected to spray drying, and the high-fastness disperse dye composition is obtained. The high-fastness disperse dye composition is applied to dyeing of hydrophobic fibers or fiber blended fabric. The high-fastness disperse dye composition has good fixation, leveling property, washing fastness, rub fastness, perspiration fastness, sublimation fastness and build-up property and also has very good light fastness, and the preparation method is simple in process, low in cost and has good application prospect.

Owner:俞杏英

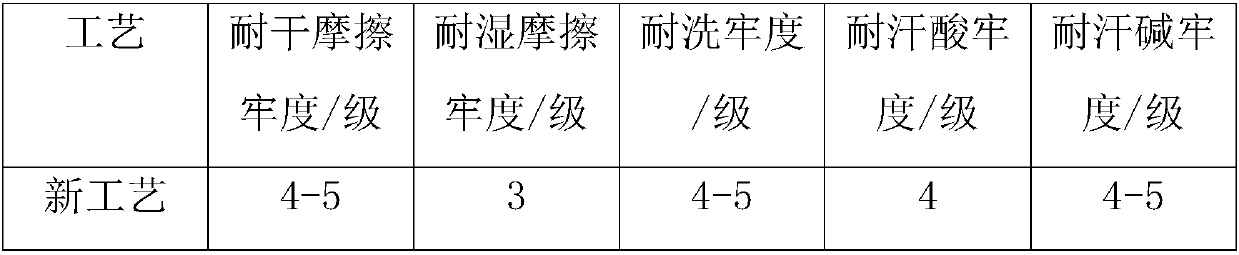

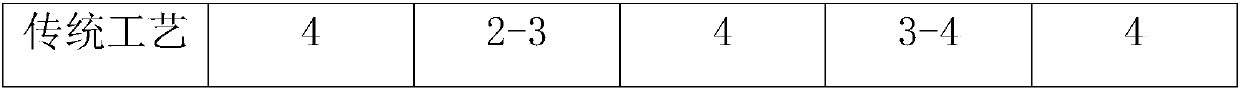

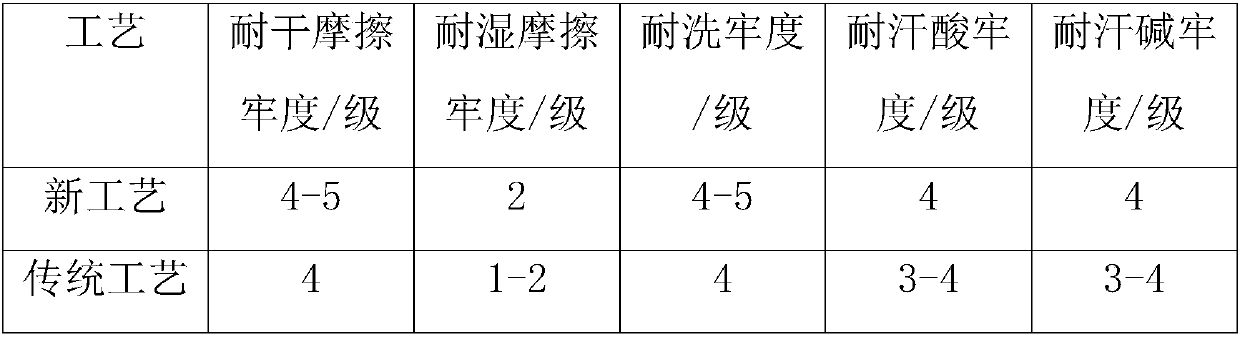

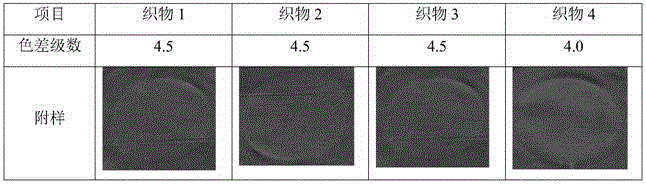

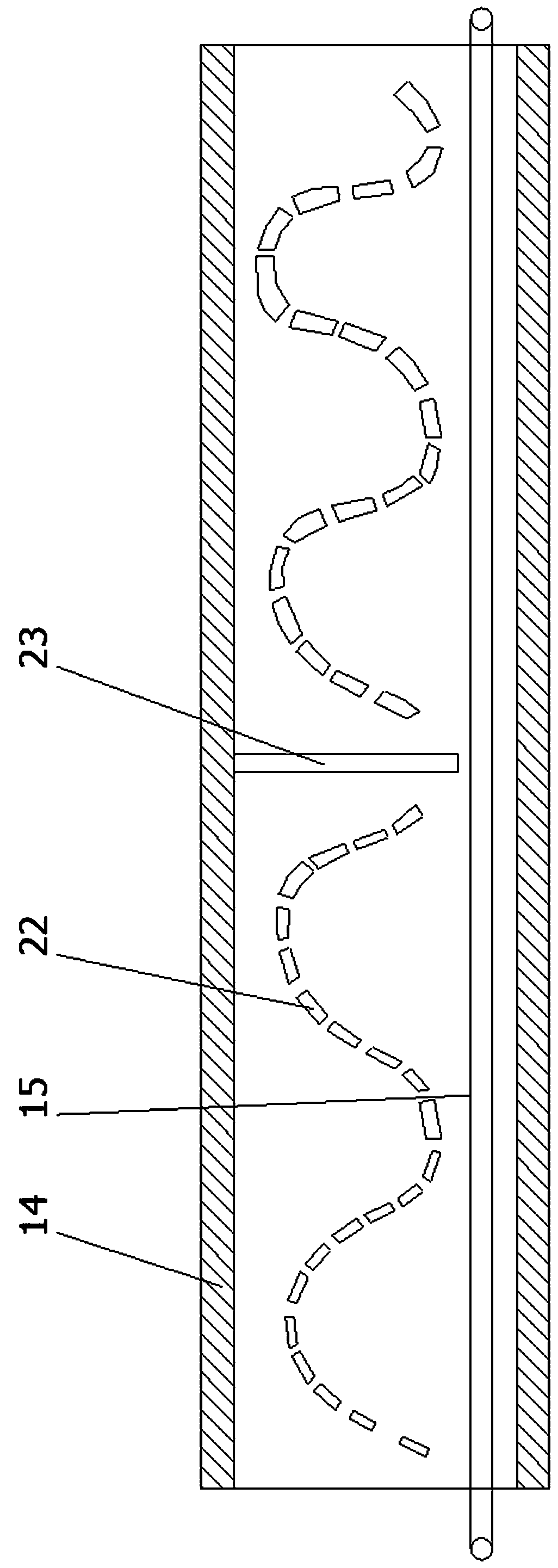

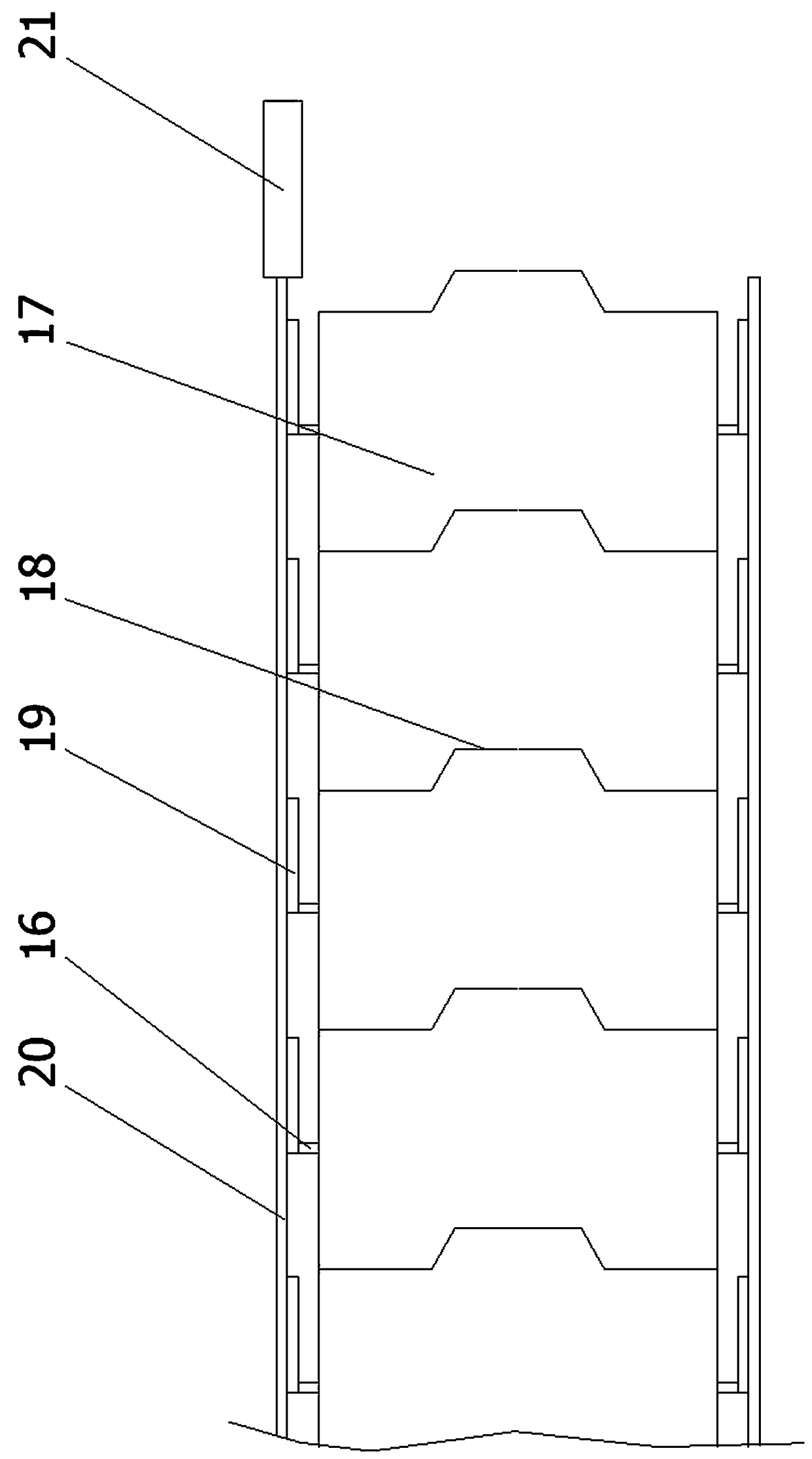

Process method for improving woven dark cloth wet rubbing fastness

ActiveCN107916518AImprove wet rubbing fastnessTightly bondedTextile storage in superimposed formLiquid/gas/vapor open-width material treatmentSurface finishProduct inspection

The invention discloses a process method, and particularly relates to a process method for improving woven dark cloth wet rubbing fastness. The process method includes the steps: (1) cloth distribution; singeing, cooling reaction and desizing; scouring and bleaching; mercerizing; pad dyeing or jig dyeing; wet rubbing fastness improver and auxiliary selection and preparation; wet rubbing fastness improver finishing; over-soft sizing; pre-shrinking; finished product inspection. According to the process method for improving the woven dark cloth wet rubbing fastness, production processes of all procedures are controlled, the capillary effect of a fabric is effectively improved, the surface finish degree of the fabric is improved, friction resistance is reduced, surface dyeing is decreased by strengthening soaping and washing after dyeing, wet rubbing fastness improvers of waterborne polyurethane complexes (Jiangxi Luxi County Xianghua Fine Chemical Co., Ltd., similarly hereinafter) are added after dyeing, under the assistant effects of assistant stabilizers 203 and cracking agents 109, the process method effectively solves the problem that oil floating points are generated in continuous production for 2000 meters or more when single wet rubbing fastness improvers are added in the past, the wet rubbing fastness of dark dyed cloth is improved by one level or more, corresponding washing fastness is improved, pH (potential of hydrogen) values meet requirements, continuous production and product quality are ensured, and a cloth surface has a certain color-deepening effect and softening effect, so that customer satisfaction is achieved.

Owner:佛山市顺德金纺集团有限公司

Efficient and rapid steaming printing technology adopting reactive dyes

An efficient and rapid steaming printing technology adopting reactive dyes comprises processes as follows: pretreatment of grey cloth, blending of print paste, paste scraping and printing on a printer, efficient and rapid steaming, water washing, soap washing and drying.

Owner:HUBEI YABI HOME TEXTILES

Reactive silk printing method

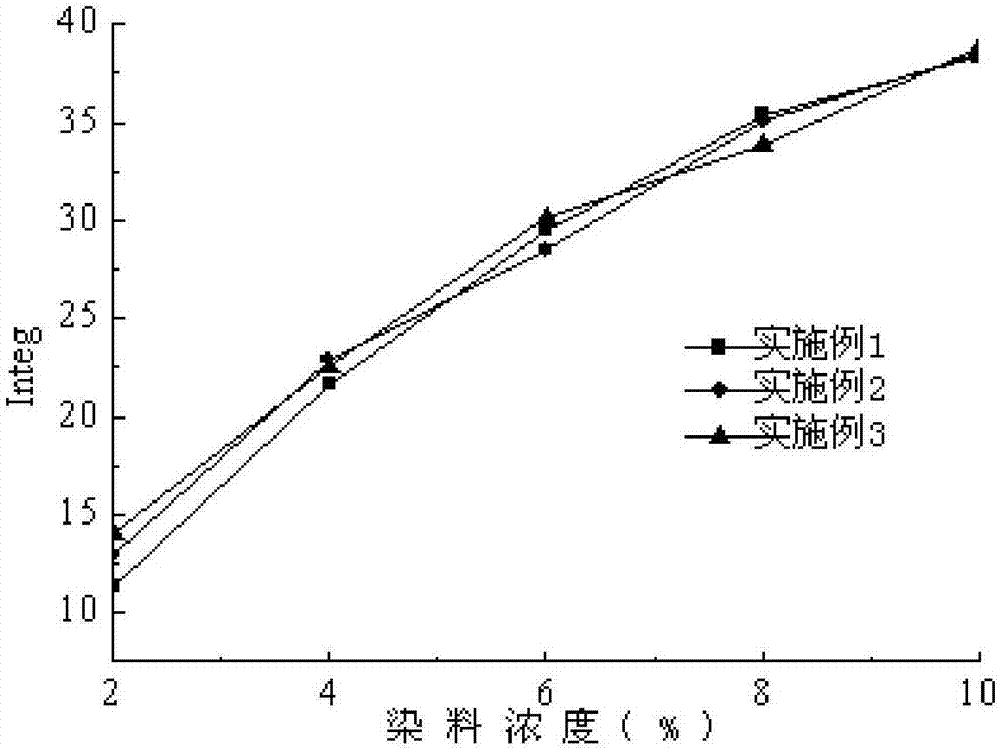

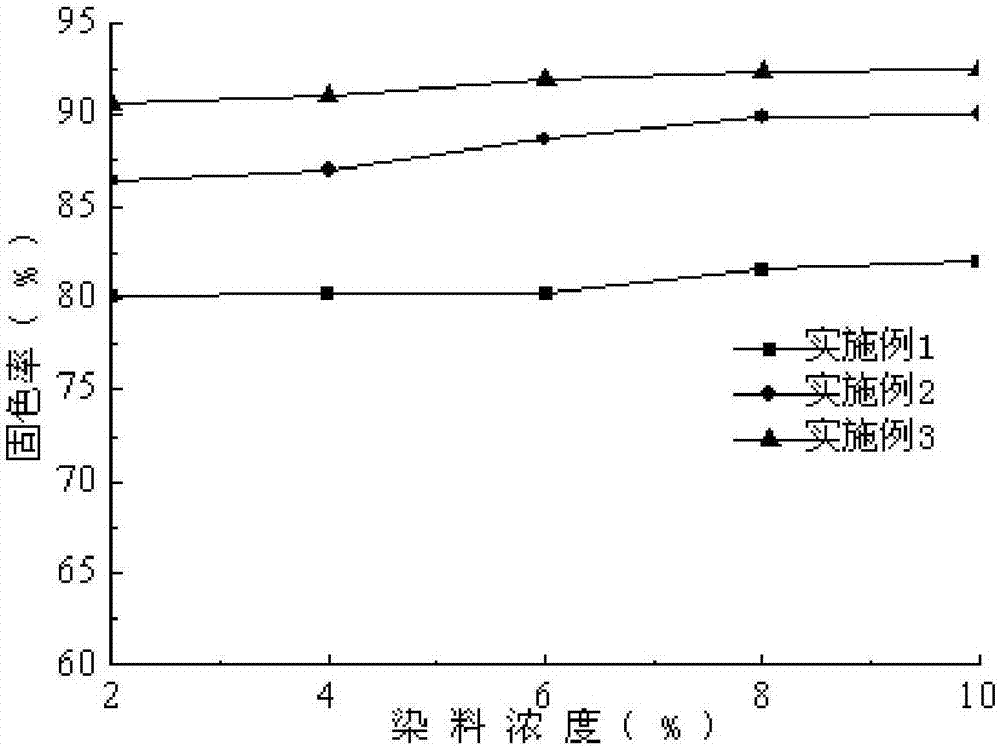

InactiveCN106087479AProcess environmental protectionGood K/S valueDyeing processTemperature controlPulp and paper industry

The invention discloses a reactive silk printing method, which comprises the following steps: (1) pretreatment; (2) treatment with a maintenance solution: preparing the maintenance solution from silk proteins, trehalose, glycine and aloe vera juice, and performing impregnation pretreatment on a pre-treated silk fabric for 60 to 80min at temperature controlled to be 30 DEG C; (3) sizing: performing single-sided sizing on the silk fabric subjected to maintenance treatment on a sizing machine; (4) drying: performing low-temperature drying at drying temperature of 60 DEG C by adopting infrared drying equipment; (5) document making; (6) spray printing; (7) steaming drying: performing reaction for color fixation for 30 to 50min under the condition of 100 to 110 DEG C saturated steam; (8) washing: performing washing with cold water; (9) tenter drying.

Owner:德清县新鑫达丝绸炼染有限公司

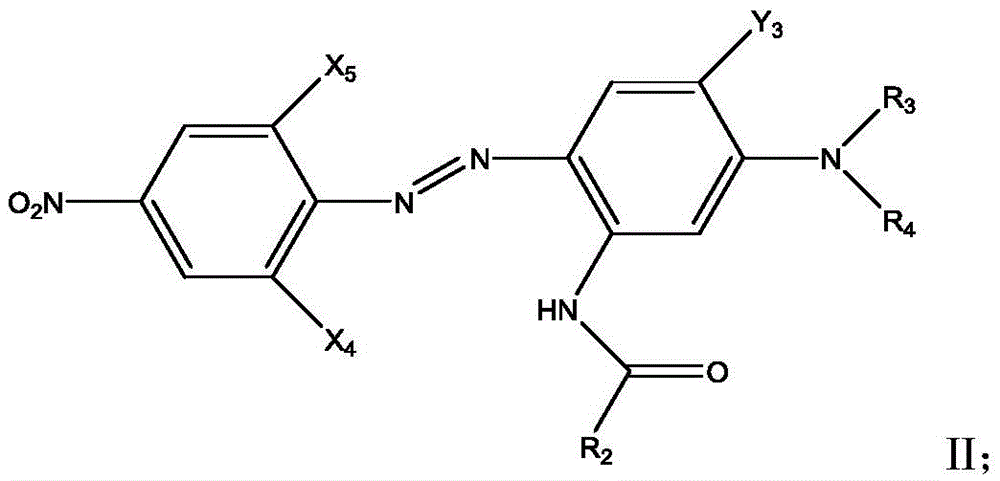

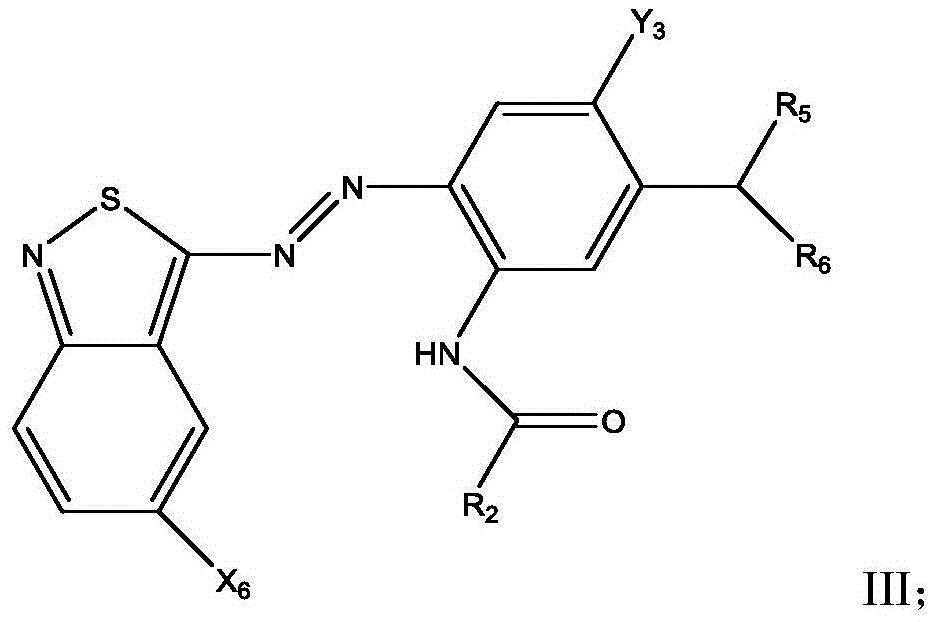

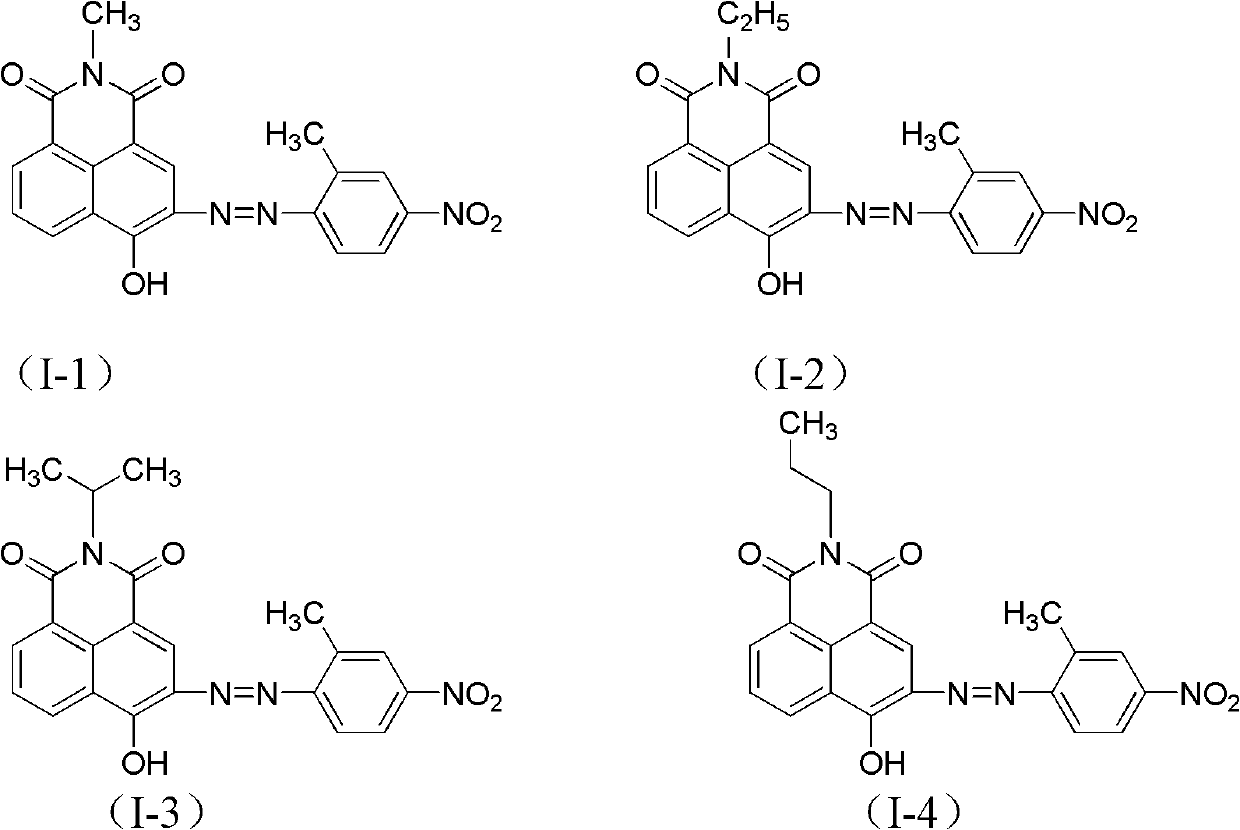

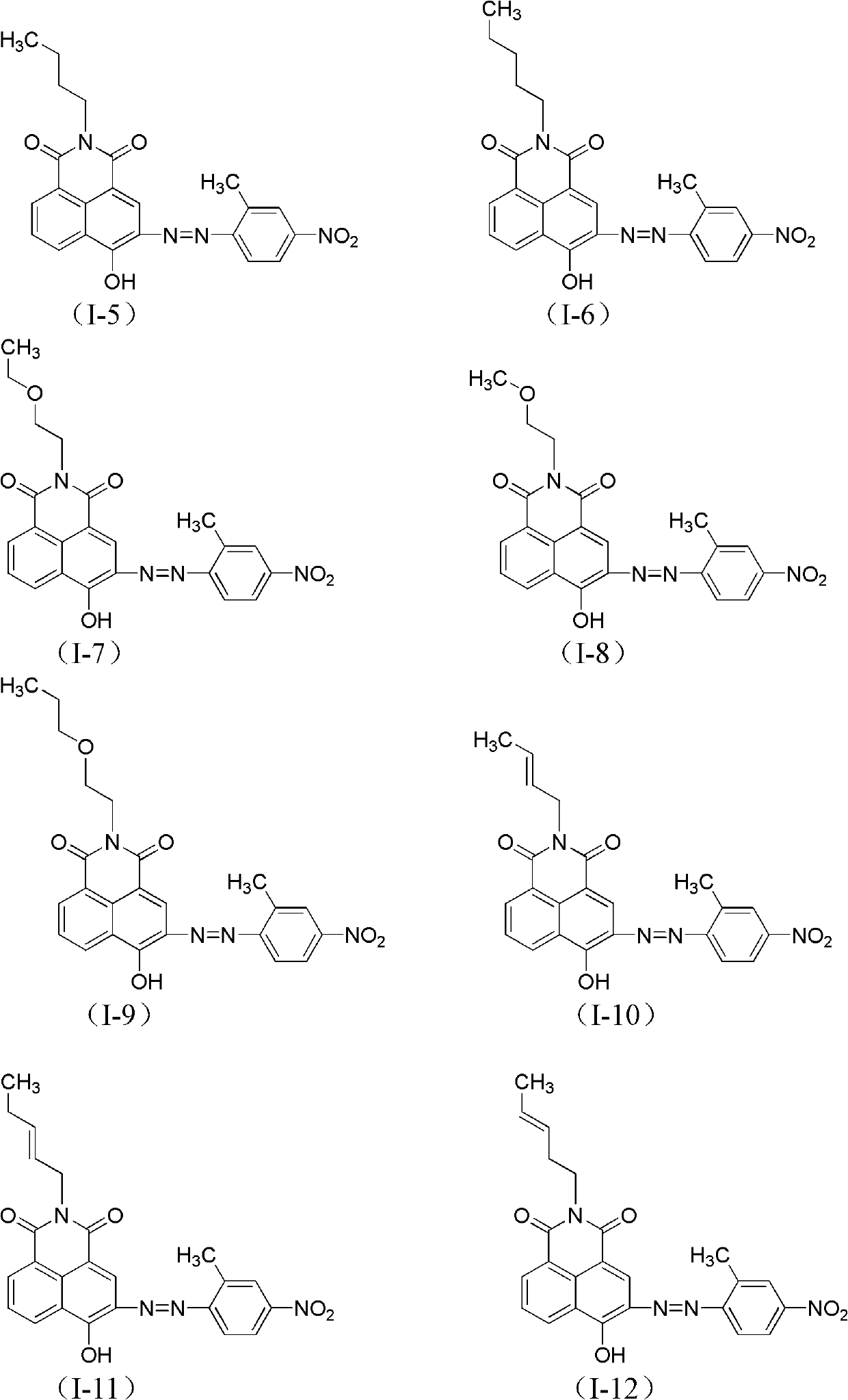

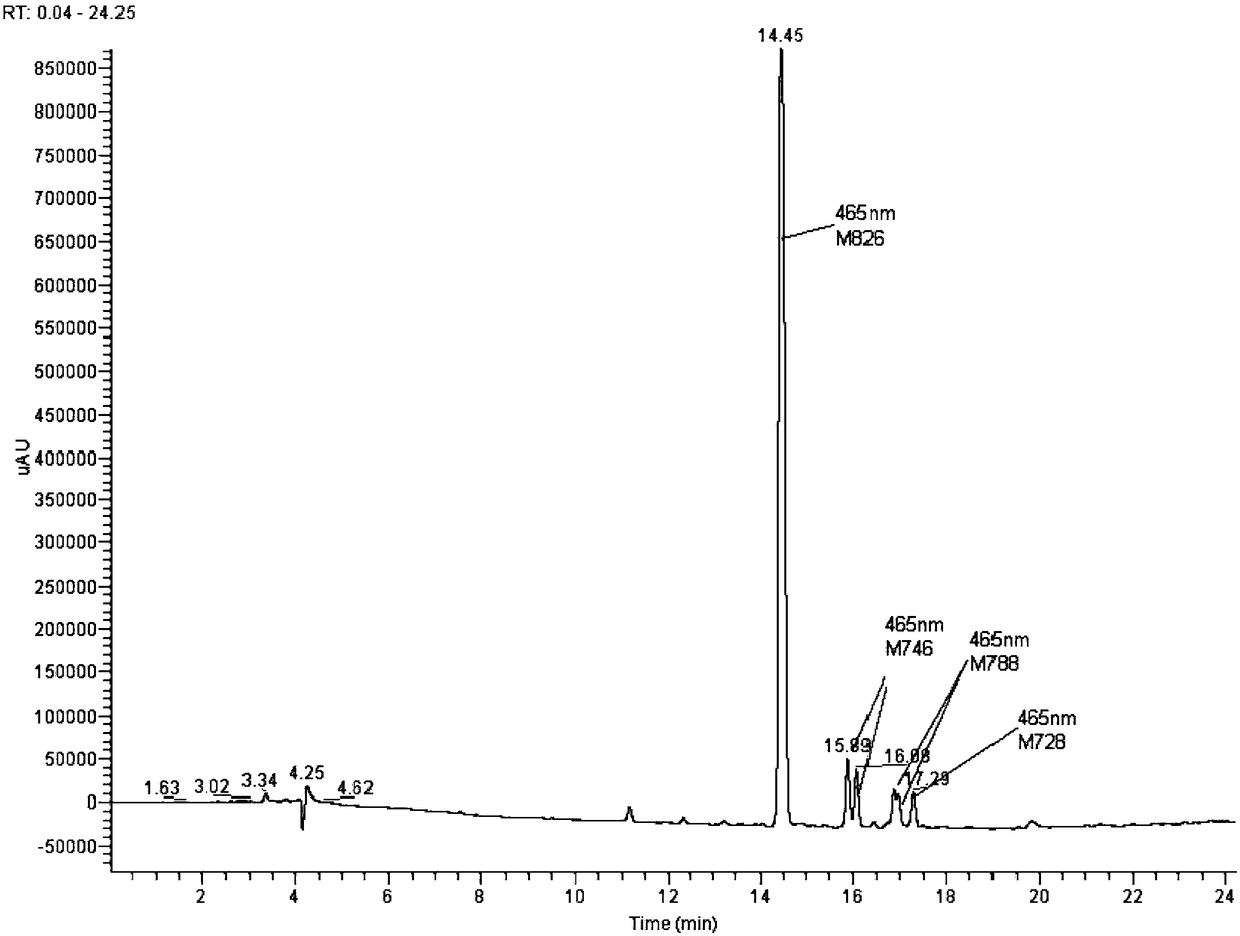

Azonaphthalene dicarboximide compound and composition, preparation and application thereof

InactiveCN102351792AGood light fastnessImprove washing fastnessMonoazo dyesOrganic chemistryAlkaneHydrogen

The invention discloses an azonaphthalene dicarboximide compound shown as a formula (I). In the formula (1), R1 is C1-C5 aliphatic hydrocarbon, aromatic hydrocarbon, substituted aromatic hydrocarbon or C3-C5 oxygen-containing aliphatic hydrocarbon; the substituted group of the substituted aromatic hydrocarbon is p-methoxy; R2, R3 and R4 are independently hydrogen, C1-C2 alkane, C1-C2 alcoxyl hydrocarbon, halogen or nitryl; the composition of the azonaphthalene dicarboximide compound consists of the following raw materials in part by mass: 20 to 60 parts of azonaphthalene dicarboximide compound, and 40 to 80 parts of auxiliary agent; and the auxiliary agent is an anionic surfactant. The azonaphthalene dicarboximide compound has the properties of excellent color fastness to sunlight, washing fastness and the like; and the composition has good dyeing property, color fixation and good lifting power.

Owner:HANGZHOU FLARIANT SPECIALTY

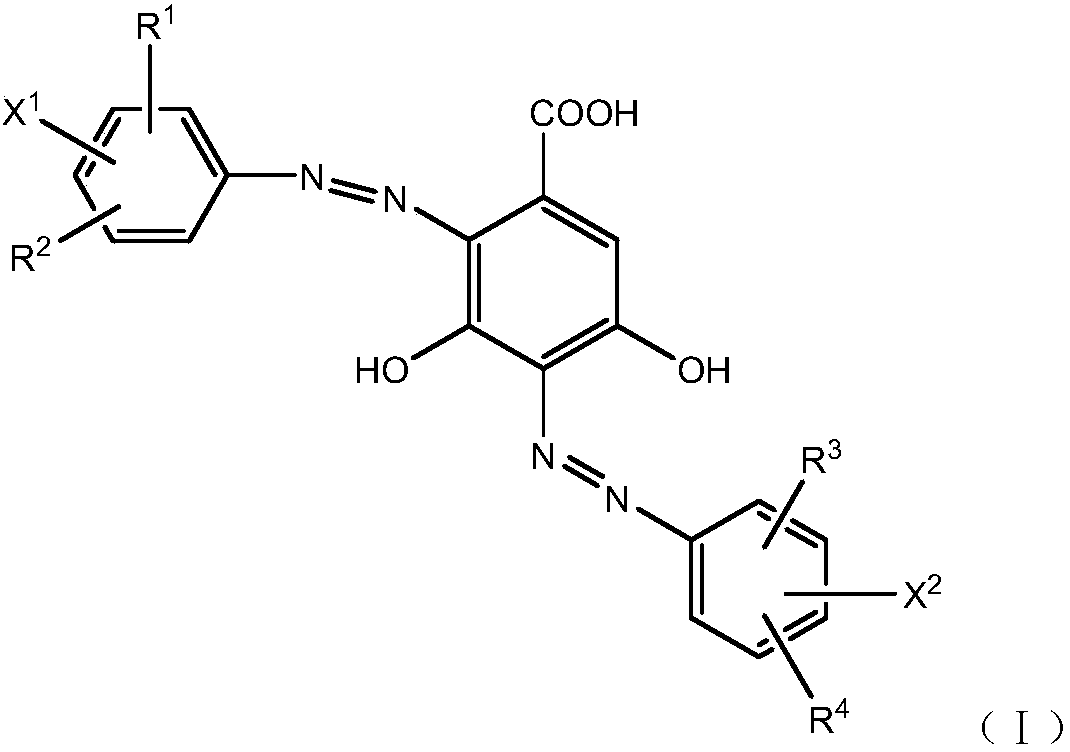

Orange reactive dye compound as well as preparation method and application thereof

ActiveCN108530944ANovel structureGood level dyeingReactive dyesDyeing processCellulose fiberPhotochemistry

The invention discloses an orange reactive dye compound as well as a preparation method and the application thereof. The structure of the orange reactive dye compound is as shown in the following formula (I), wherein R1, R2, R3 and R4 are independently H, C1 to C4 linear chain or branched alkyl, C1 to C4 alkoxy or sulfo group; X1 and X2 are independently H, C1 to C4 linear chain or branched alkyl,-SO2Y1, -NHCO(CH2)1 to 3 SO2Y2 or -CONH(CH2)1 to 3 SO2Y3, and at least one of X1 and X2 is a fibrous active group, namely -SO2Y1, -NHCO(CH2)1-3 SO2Y2 or -CONH(CH2)1 to 3 SO2Y3; Y1 to Y3 are independently -CH=CH2, -C2H4OSO3H or -CH2CH2Cl. The invention provides an orange reactive dye product which contains the orange reactive dye compound. The orange reactive dye compound and the orange reactive dye product are applicable to printing and dyeing of a cellulosic fiber, a polyarmide fiber and a fabric thereof, and have the advantages of high leveling property, high lifting force, high fixation rate, clear dyeing residual liquid, excellent washability and color fastness and high stability in fiber combination.

Owner:ZHEJIANG KEYONG CHEM CO LTD +1

Synthesis method for acid red R3G adapted for virgin pulp spray

InactiveCN101125964AHigh yieldReduce consumptionReactive dyesDyeing processSynthesis methodsDissolution

The invention relates to a synthesis method of protoplasm spray drying acid red R3G, comprising the steps of dissolution of 2-amino-5-naphthol-7-sulfonic acid, one-step condensation, diazoniation, coupling and finally two-step condensation. The 2-amino-5-naphthol-7-sulfonic acid is dissolved before the one-step condensation through that the 2-amino-5-naphthol-7-sulfonic acid is added to water and stirred evenly; then pH of the solution is adjusted to 7 through sodium hydroxide solution of 30 percent and the temperature rises to 60-70 DEG C; after the full dissolution, the solution is provided with a bush, the temperature is decreased to 25-15 DEG C and the solution is stirred for two hours under the temperature; then precipitated 2-amino-5-naphthol-7-sulfonic acid is filtered and filtering cake is pressed and dried for purpose in one-step condensation; the finished process is after the completion of dye synthesis, the strength of the 2-amino-5-naphthol-7-sulfonic acid is adjusted to the strength of finished product through glauber salt and spay dried under the temperature of outlet ranging from 90-110 DEG C and the finished produce can be packed directly at last. Compared with the products of the prior art, the acid red R3G of the invention improves 10 percent of yield, and eliminates waste water with salt generated from salt precipitation technique, which not only saves raw materials but also shortens production time, improves product economic benefit, eliminate discharge of waste water and facilitates environmental protection.

Owner:TIANJIN DEK CHEM

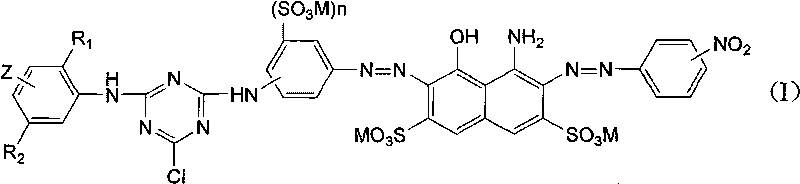

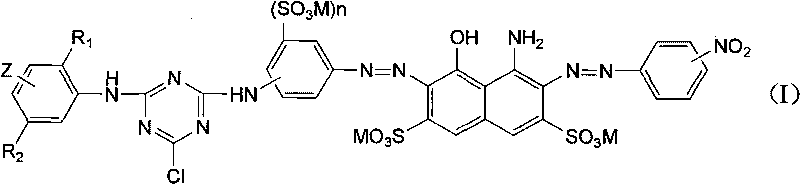

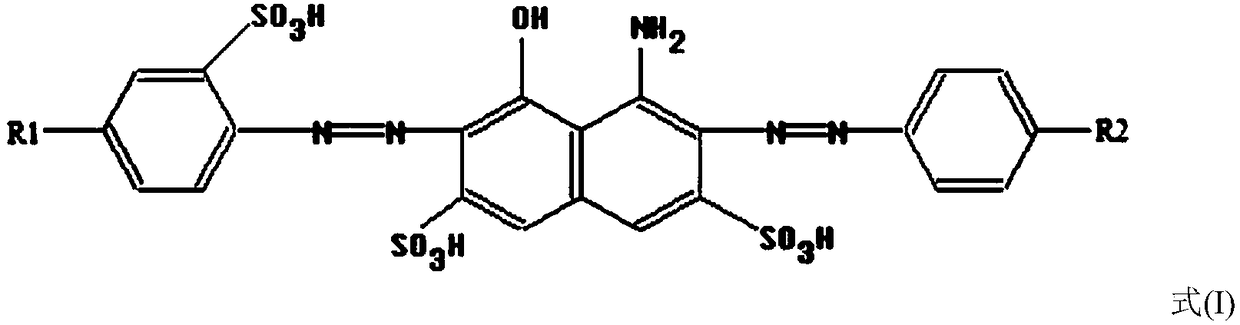

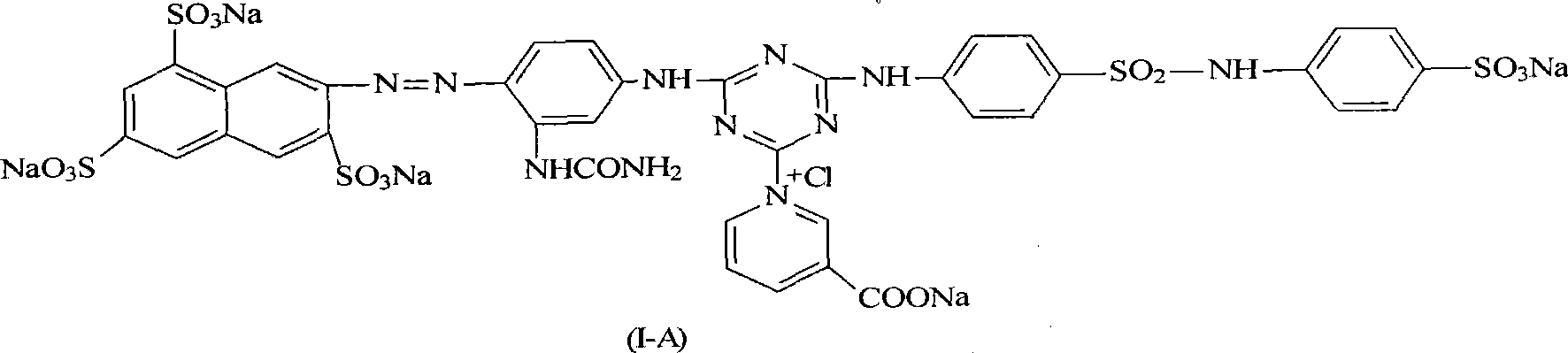

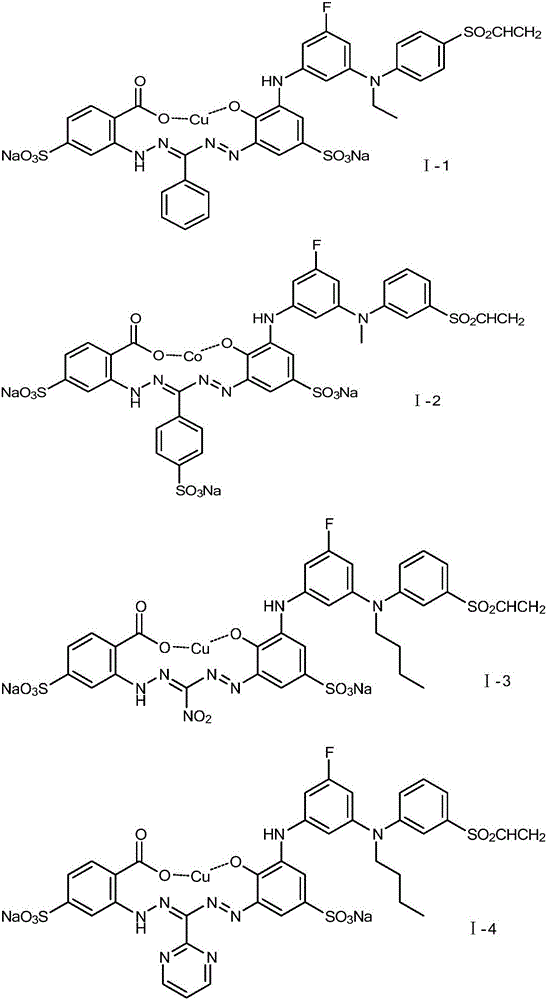

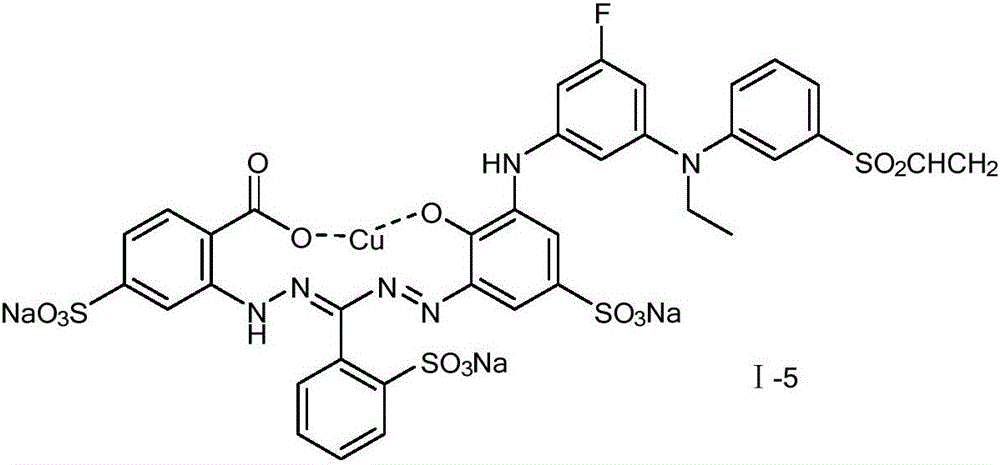

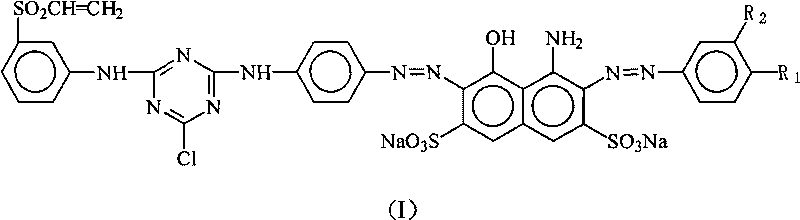

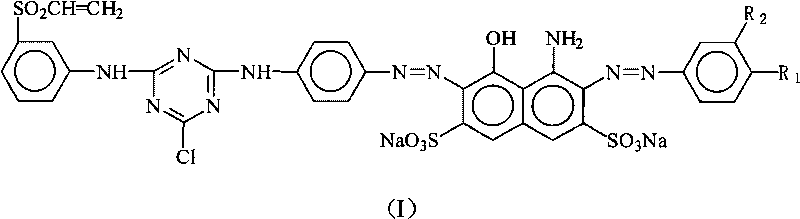

Reactive navy blue dye suitable for dyeing nylon and preparation method thereof

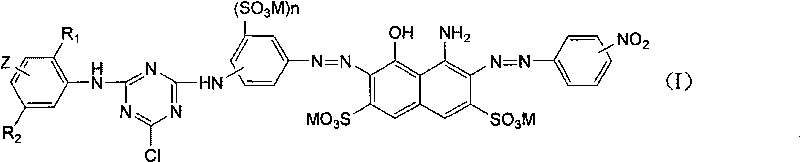

ActiveCN101735658AImprove sharpnessGood color fixation rateReactive dyesDyeing processAlkali metalPhotochemistry

The invention relates to a reactive navy blue dye suitable for dyeing nylon and a preparation method thereof. The dye has the following structural formula (I), wherein R1 is H, alkyl group, alkoxy group or SO3M; R2 is H, alkyl group, alkoxy group or SO3M; and Z is SO2CHCH2; M is H or alkali metal; and n is 0 or 1.

Owner:TIANJIN DEK CHEM

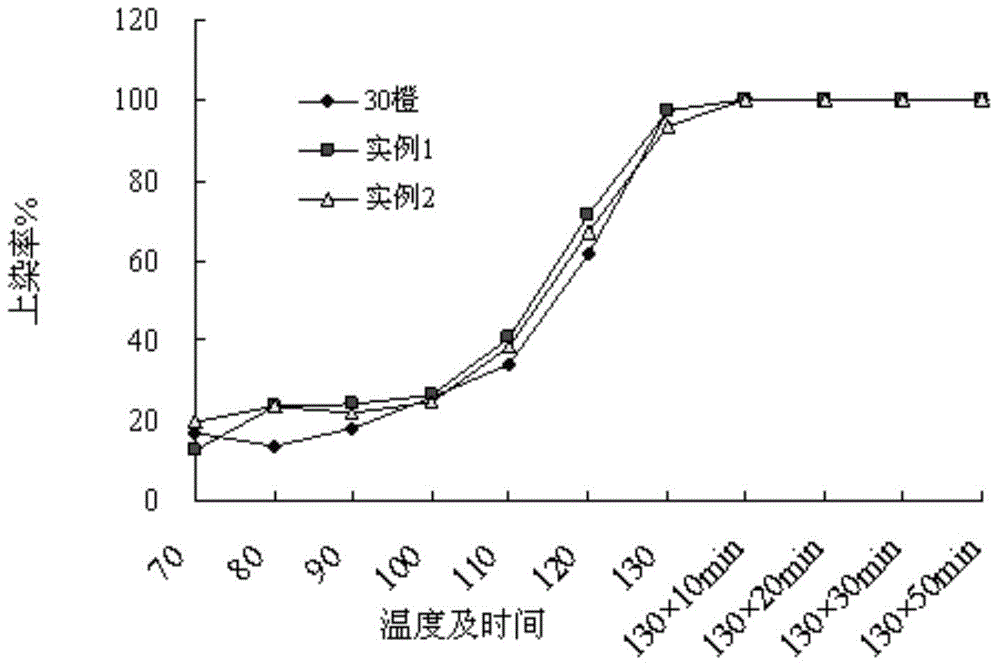

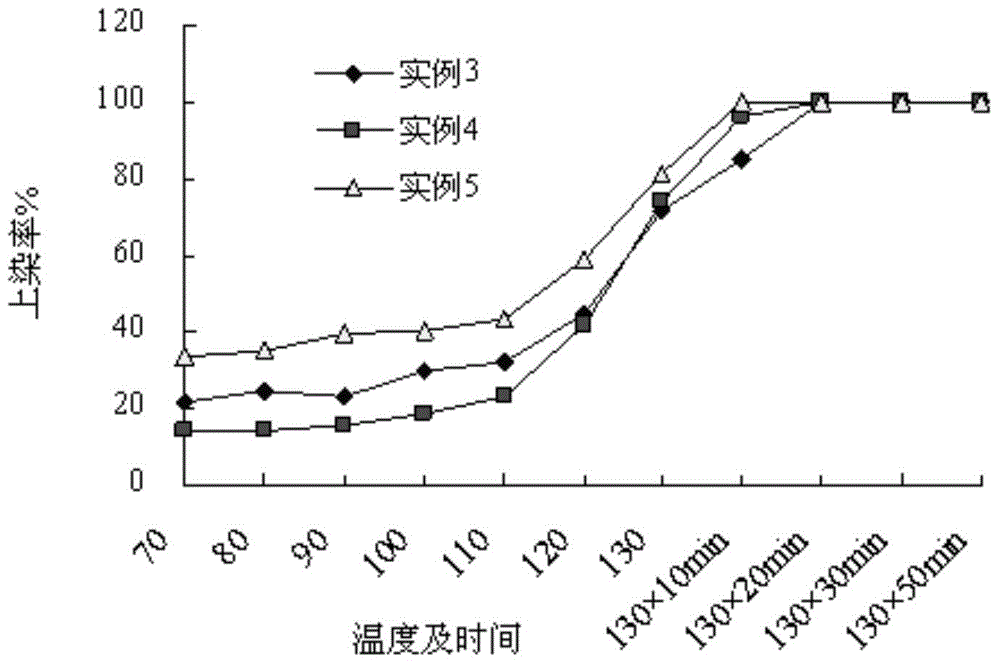

Environment-friendly alkaline-resistant high-washing-dispersity orange dye composition and application thereof

ActiveCN104151865AStructural environmental protectionGood alkali resistanceOrganic dyesDyeing processDispersityStructural formula

The invention relates to an environment-friendly alkaline-resistant high-washing-dispersity orange dye composition and an application thereof. The dye composition comprises dyes and auxiliaries, wherein the dyes include a dye A and a dye B; the structural formula of the dye A is as shown in the specification, while the structural formula of the dye B is as shown in the specification; the environment-friendly alkaline-resistant high-washing-dispersity orange dye composition is applied to textile dyeing. The environment-friendly alkaline-resistant high-washing-dispersity orange dye composition is good in all build-up, fixation rate, levelling property, compatibility and alkali resistance, and especially quite excellent in washing fastness. Specially, the dye composition is similar to the existing C.I. disperse orange 30 dye in chromatic light intensity and dyeing property, overcomes the defects of no resistance to alkali and non-environmental friendliness of the existing dye, and thus can be used for substituting for the existing C.I. disperse orange 30 dye.

Owner:ZHEJIANG WANFENG CHEM

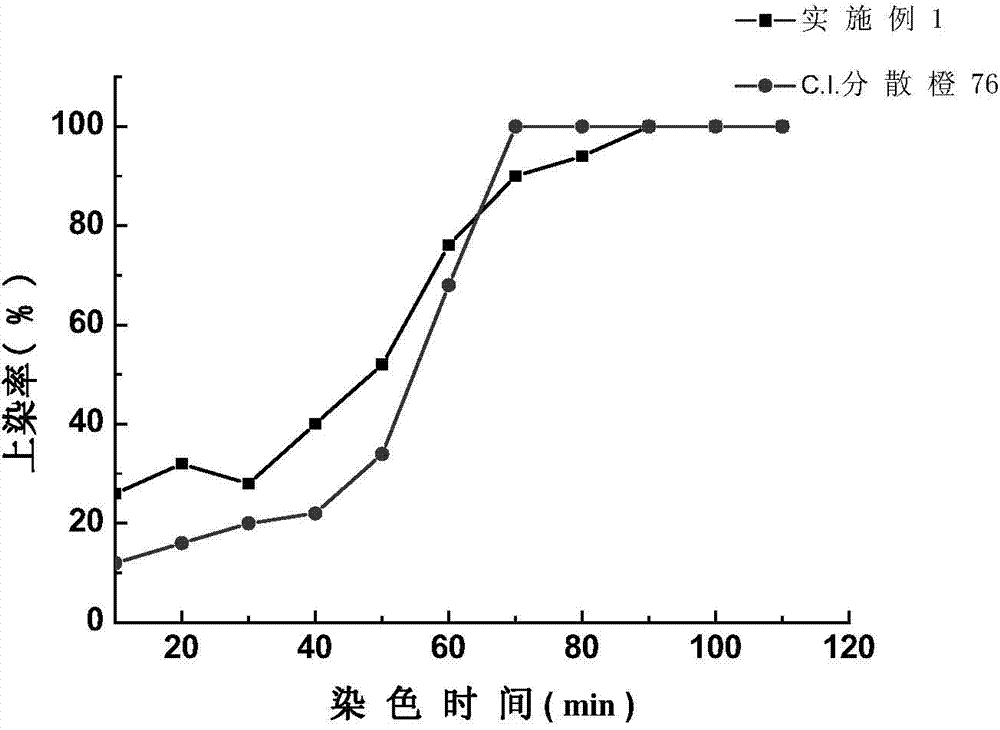

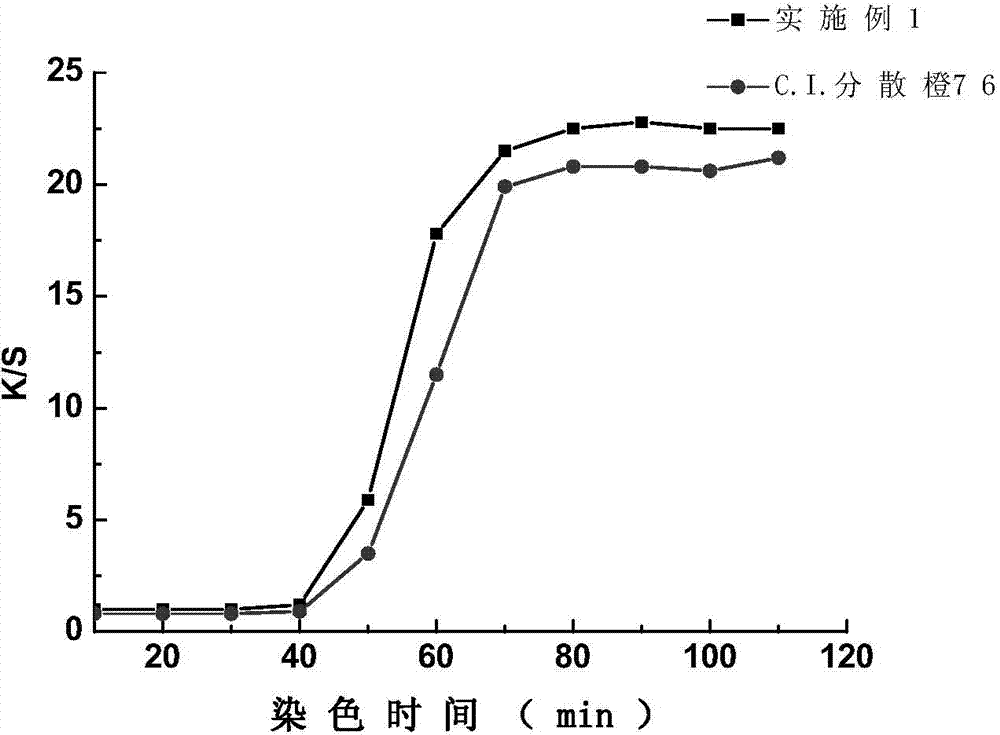

Environment-friendly type high-efficiency washing disperse orange dye composition and application thereof

ActiveCN104119695AStructural environmental protectionGood alkali resistanceOrganic dyesDyeing processColor intensityStructural formula

The invention relates to an environment-friendly type high-efficiency washing disperse orange dye composition and an application thereof. The dye composition comprises dyes and auxiliaries, wherein the dyes consist of a dye A, a dye B and a dye C; a structural formula of the dye A is as shown in the specification; the structural formula of the dye B is as shown in the specification; the structural formula of the dye C is as shown in the specification. The environment-friendly type high-efficiency washing disperse orange dye composition disclosed by the invention is applied to fabric dyeing. The dye disclosed by the invention is good in lifting power, fixation rate, leveling property, compatibility and alkali resistance, and especially extremely excellent in washing fastness. Especially, compared with the existing C.I. disperse orange 76 dye, the dye composition disclosed by the invention has similar color intensity and dyeing performance, overcomes the defect that the existing dye is not environment-friendly, and can be used for substituting the existing C.I. disperse orange 76 dye.

Owner:ZHEJIANG WANFENG CHEM

Amino-chloro-benzene-containing quaternary ammonium salt type fluorescent whitener, synthesizing method thereof and applications

InactiveCN101307031AWhiteness stabilityIncrease the scope of applicationOrganic chemistryDetergent dyesPhenyl groupCyanuric chloride

The invention relates to a series of fluorescent whitening agents containing amino chlorophenyl group quaternary ammonium salt, as well as synthesis and an application of the same. The series of fluorescent whitening agents is mainly applied to papermaking paint printing ink and textile. The synthesis adopts the following steps that: a. cyanuric chloride reacts with amino-chloro-benzene at a temperature between 0 and 5 DEG C for 2.5 h, with pH value controlled to be between 1.8 and 2.1, so as to synthesize one-step condensation product; b. the one-step condensation product reacts with 4, 4'-diaminodiphenylethylene-2, 2'-disulfonic acid at a temperature between 40 and 45 DEG C for 2.5 h, with pH value controlled to be between 3.5 and 4.5, so as to synthesize two-step condensation product; c. the two-step condensation product reacts with a series of tertiary amine compounds at a temperature between 78 and 85 DEG C for 3.0 h, with pH value controlled to be between 7.8 and 8.5, so as to synthesize a series of triazine-DSD acidic fluorescent whitening agents containing amino chlorophenyl group quaternary ammonium salt. Application results show that: the fluorescent whitening agents can be used under neutral / alkaline conditions, and has higher dye uptake rate and better whitening effect under acidic conditions.

Owner:SHANDONG UNIV

Preparation of CI 222# reactive blue

The invention provides a method for improving preparation of CI 222# reactive blue. The method changes one-step condensation reaction conditions and acid coupling conditions, so that product transformation ratio is improved by 8%, product quality reaches requirements for qualified products, thus avoiding generating process effluent; specifically, in the method of the invention, phase transfer catalyst is added to shorten ice grinding time in the one-step condensation, therefore, reaction efficiency is greatly improved; pH value of diazo salt is adjusted to 2.0-3.5 before the acid coupling, and after the alkali coupling, dye is blended to be qualified for virgin stock spray drying.

Owner:TIANJIN DEK CHEM

Chinese herbal medicine hair dye based on pineapple extract

InactiveCN109846778AGood dyeing performanceFavorable for adsorption or bindingCosmetic preparationsHair cosmeticsHerbChinese herbs

The invention discloses a Chinese herbal medicine hair dye based on pineapple extract. The hair dye consists of the following components by weight: 20-35g of fleece-flower roots, 5-10g of pineapple extract, 18-28g of dried rehmannia roots, 25-30g of yerbadetajo herb and 15-18g of vegetable dyes. The pineapple extract is extracted by the following steps: weighing 1000g of pineapple flesh, cleaningand draining the pineapple flesh in clear water, cutting the pineapple flesh into small sections, placing the sections into an ultra-high speed mixer, and adding about 60mL of a pre-cooled 0.1 mol / L PBS buffer solution. According to the invention, the pineapple extract is added into traditional Chinese herbal medicine hair dyes, and the hair dye of the technical solution has high-performance dyeing auxiliary performance on hair with protein as a main component through the pineapple extract, so that the dyeing coloring rate and the color fastness of the plant dyes are improved, better dyeing performance is reflected, and the problems that existing plant hair dyes are not added with chemical substance, but have high dyeing temperature, poor color fastness and dyeing effect after dyeing are solved.

Owner:岳双辰

Dark red reactive dye and preparation method thereof

InactiveCN106634045AHigh liftHigh color fixing rateReactive dyesDyeing processHydrogenHeat stability

The invention discloses dark red reactive dye and a preparation method thereof. The dark red reactive dye is one material selected from general formulas of the formula (I) or is a mixture obtained through compounding two or more structures selected from the general formulas of the formula (I) according to any proportion. One material shown by the formula (I) is selected from any one of materials of the following structure general formulas or is a mixture of two or more materials of the structural general formulas, wherein R1, R2, R3 and R4 in the formula (I) respectively and independently represent -H, -CH3, -OCH3 or -SO3M; Y1 and Y2 respectively and independently represent -CH=CH2 or -C2H4OSO3M; M represents hydrogen or alkali metal. The dark red reactive dye has the advantages that the lifting performance is good; the friction firmness, the water washing firmness, the light fastness and the heat stability are high. The formula (I) is shown as the accompanying drawing.

Owner:ZHEJIANG YIDE CHEM

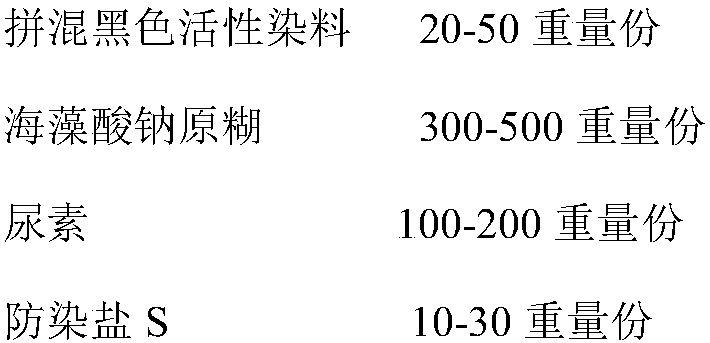

Artificial cotton active printing technology, and artificial cotton textile fabric

The invention discloses an artificial cotton active printing technology. The artificial cotton active printing technology comprises steps of pretreatment; printing; steaming; and water washing. 1000 parts of a color past adopted in the step of printing is composed of, by weight, 20 to 50 parts of a blended black active dye, 300 to 500 parts of a sodium alginate original paste, 100 to 200 parts ofurea, 10 to 30 parts of reserve salt S, 10 to 40 parts of sodium carbonate, and the balance water. The invention also discloses the artificial cotton textile fabric prepared through the artificial cotton active printing technology. According to the artificial cotton active printing technology, the blending synergistic principles of the blended black active dye are adopted, so that excellent substantivity, color fixing rate, colour fastness to wet rubbing, and colour fastness to perspiration are achieved, and the artificial cotton active printing technology is especially suitable for artificialcotton textile fabric.

Owner:SHAOXING YONGTONG PRINTING CO LTD

Reactive dye

The invention provides a yellow active dye. A quaternary ammonium salt dye is formed by dye matrix and nicotinic acid which is an active group of the dye, can dye in neutral or alkalescent medium, and is good in each fastness index after dyeing.

Owner:TIANJIN DEK CHEM

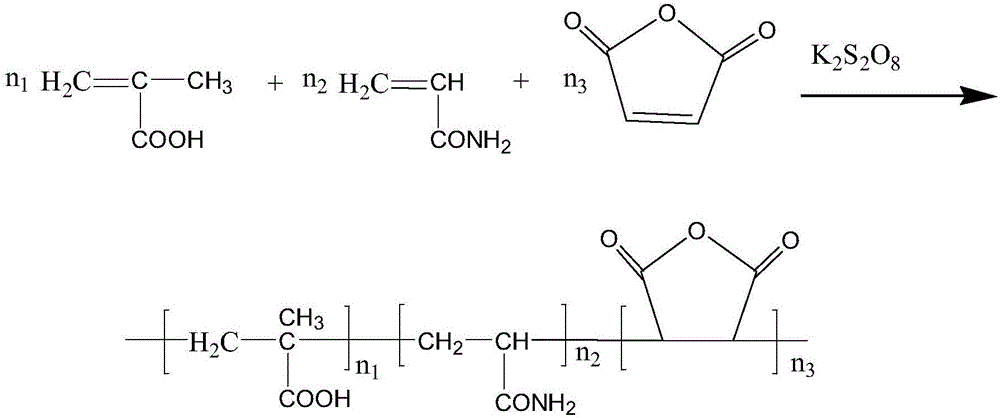

Environment-friendly migration inhibitor and preparation method thereof

InactiveCN106120396AOvercome swimming phenomenonEasy to gel adsorptionDyeing processPolyesterMigration inhibition

Owner:合肥市东方美捷分子材料技术有限公司

Reactive blue dye and preparation and application thereof

ActiveCN106590026ANovel structureGood color fixation rateReactive dyesDyeing processFiberResource consumption

The invention discloses a reactive blue dye and preparation and application thereof. The structure of the reactive blue dye is shown in a formula (I) defined in the description. The reactive blue dye is novel in structure and excellent in performance, has the good fixation rate and color fastness, can effectively lower resource consumption, has the good stability after dyeing is performed, is bright in color, can be widely applied to dip dyeing, pad dyeing, inkjet printing and other dyeing technologies of cotton fiber products such as polyeseter, fiber and artificial cotton, is low in production cost and can achieve large-scale application and popularization.

Owner:TAIXING JINYUN DYESTUFF

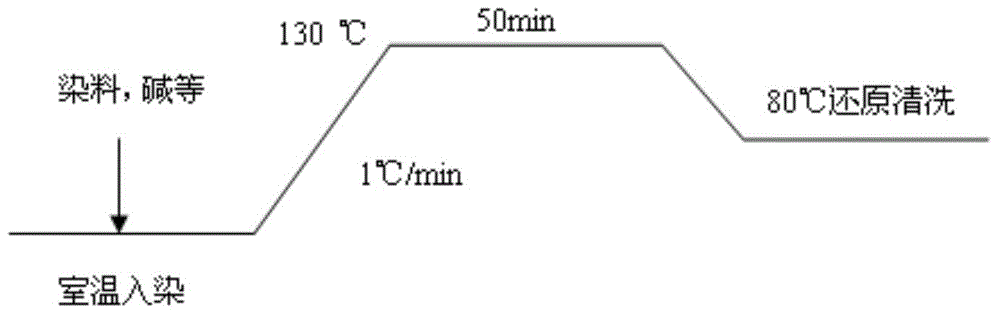

Dyeing method of cheese yarn subjected to low-temperature pretreatment

The invention belongs to the field of dyeing auxiliary agents, and particularly relates to a method of using cationic starch for cheese yarn reactive dye dyeing, in particular to a dyeing method of cheese yarn subjected to low-temperature pretreatment. The method aims at solving the technical problems to realize the effects of improving the dyeing rate of reactive dye dyeing, reducing the rely oninorganic salts in the dyeing process, improving the color fixing rate after the dyeing at the same time and improving the production efficiency. The method comprises the following steps of pretreatment: putting the cheese yarn into alkaline liquid, raising the temperature to 50 to 70 DEG C at the speed of 1 to 3 DEG C / min, and performing treatment for 20 to 30 min; dyeing: preparing a cationic starch solution according to a certain bath ratio, adding the cheese yarn subjected to pretreatment, and performing soaking at normal temperature for 10 to 20 min; then, adding dye for soaking; color fixation: after the dyeing is completed, adding an alkaline agent into dyeing liquid, then raising the temperature to 60 to 90 DEG C at the speed of 1 to 3 DEG C / min, and performing heat insulation for30 to 60 min; drying: taking out a fabric, and performing drying; and post treatment: sequentially performing soap washing and water washing on the dried fabric to remove the unreacted dye, and finally performing drying.

Owner:ZHEJIANG SAINTYEAR TEXTILE

Dark blue dye suitable for dyeing nylon

ActiveCN101709156AExcellent sharpnessUniform lifting forceReactive dyesDyeing processDiamineChemistry

The invention relates to a dark blue dye suitable for dyeing nylon. The dye has the following structural formula (I). A method for preparing the dye comprises the following steps: (a) obtaining diazonium liquid by adding m-(p-) nitrophenylamine to a hydrochloric acid solution and a sodium nitrite solution; (b) adding an H acid dropwise into the diazonium liquid obtained in the step (a) for reaction to produce acid coupling liquid; (c) dissolving meta-ester in water to produce a meta-ester solution; (d) adding the meta-ester solution produced in the step (c) into cyanuric chloride suspension for the reaction, and adding para-phenylene diamine after the reaction; (e) adding the hydrochloric acid solution into condensation reaction liquid produced in the step (d), and then adding sodium nitrite solution to form the diazonium liquid; (f) adding the diazonium liquid produced in the step (e) dropwise into the acid coupling liquid produced in the step (b) so as to form basic coupling liquid; and (g) converting beta-sulfate ethyl sulfone of the basic coupling liquid formed in the step (f) to vinyl sulphone radical under a basic condition so as to prepare the compound of the structural formula (I), wherein R1 represents H; R2 represents NO2 or H; and R1 represents NO2.

Owner:TIANJIN DEK CHEM

Active navy blue to black dye composition and product

The invention relates to active dye composition in dark blue to black and a dye product. The dye composition comprises, in parts by weight, 45-95 parts of a component A, 5-55 parts of a component B and 0-40 parts of a component C, wherein the component A is selected from at least one compound represented by the formula (I), the component B is selected from at least one compound represented by the formula (II), and the component C is selected from at least one compound represented by the formula (III) and / or the formula (IV). The active dye product in dark blue to black comprises the dye composition. The dye product is good in deep dyeing property, excellent in improvement power, high in dye up-take, high in color fixation, good in compatibility and excellent in color fastness; during dyeing, the dye is small in use amount, easy to wash, clear in residual liquid, stable in salt and alkali resistance, excellent in metamerism, stable in dyeing property and applicable to different technologies of dip dyeing, pad dyeing, printing and the like.

Owner:SHANGHAI KEHUA DYESTUFF IND +1

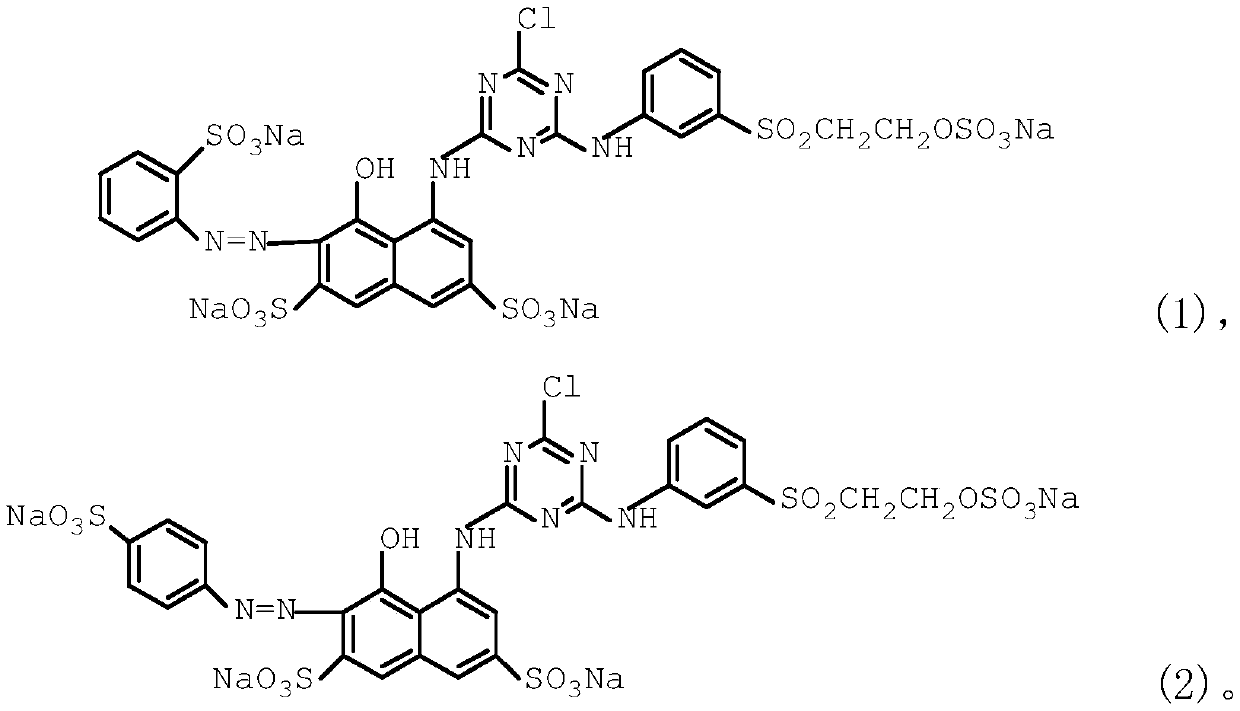

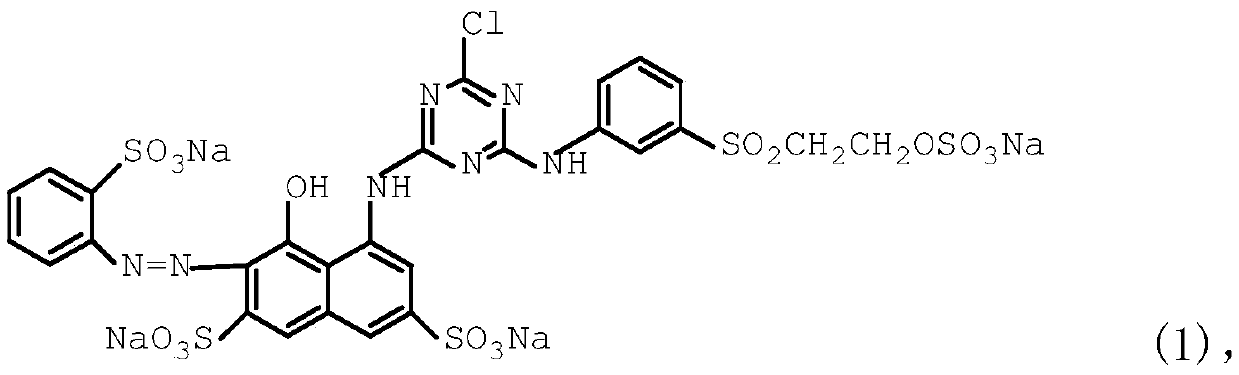

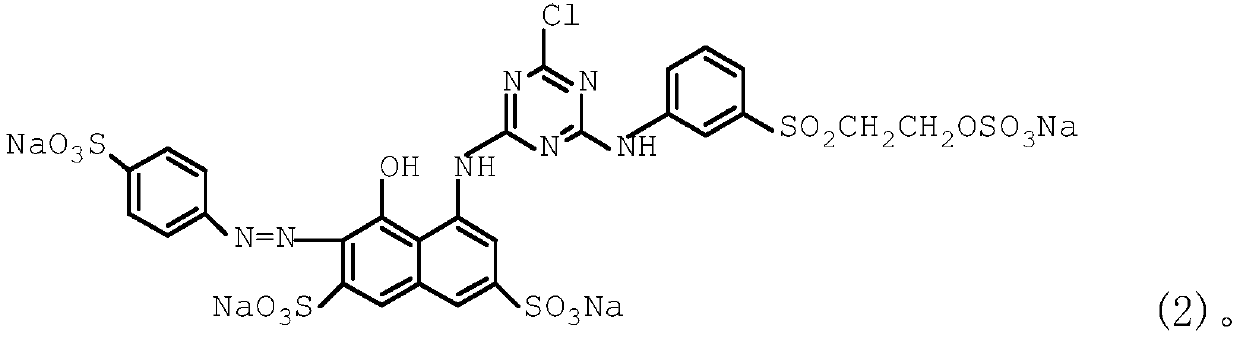

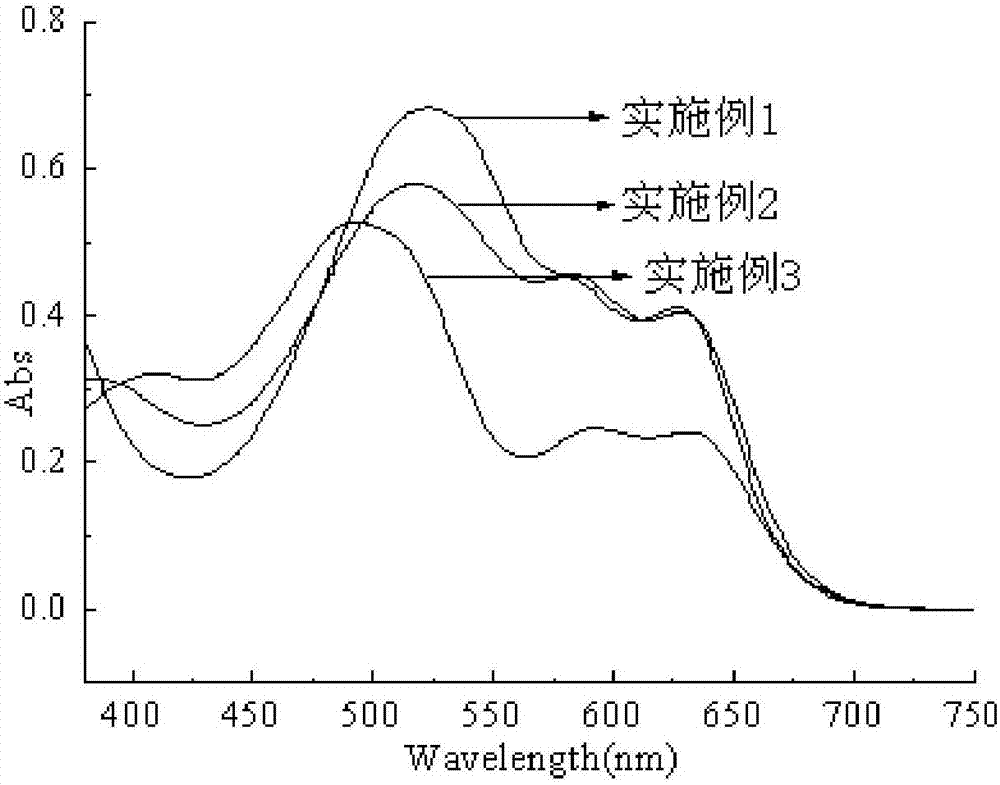

Composite bright red reactive dye and preparation method and application thereof

ActiveCN109796786AImprove solubilityHigh color fixing rateReactive dyesDyeing processEnvironmental resistanceSolubility

The invention provides a composite bright red reactive dye, which is prepared from the following components in parts by weight: 25-75 parts of compound of formula (1) and 25-75 parts of compound of formula (2), wherein the formula is shown in the description. The composite bright red reactive dye is prepared by mixing a compound of formula (1) and a compound of formula (2) which are isomers of each other, the solubility and the color fixing rate of the dye are improved by utilizing the compound synergistic principle, the problems of low solubility of a single compound of formula (1), low solidcontent of a semi-finished product and overhigh drying cost of the dye of the compound of formula (1) are overcome; meanwhile, the concentration of the dye is increased through concentration, the cleaning water in the dye drying process is reduced, and the production environment-friendly pressure of the product is reduced.

Owner:HUBEI HUALI DYESTUFF INDAL

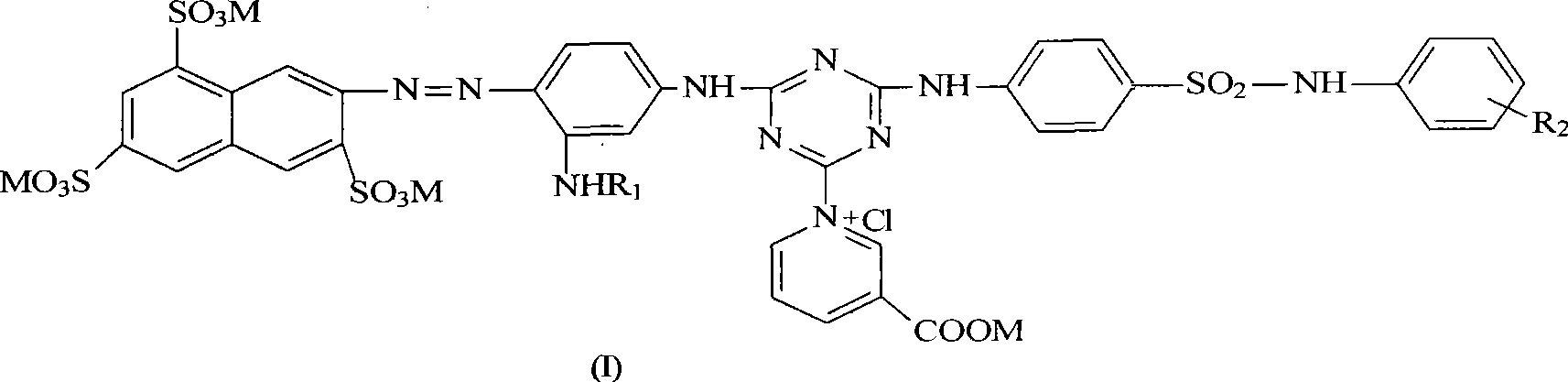

Red light black active dye of azo anthraquinone mixing light emitting system containing iso-bifunctional groups with high color fixation rate, and preparation method and application of red light black active dye

ActiveCN106883639AHigh molar extinction coefficientGood color fixation rateReactive dyesDyeing processFiberStructural formula

The invention relates to a red light black active dye of an azo anthraquinone mixing light emitting system containing iso-bifunctional groups with a high color fixation rate, and a preparation method and application of the red light black active dye. A structural formula of the red light black active dye is shown in the description, wherein R2 and R4 are respectively shown in the description; M is hydrogen or alkaline metal; n is 1, 2 or 3. The preparation method comprises the following steps of reacting cyanuric chloride and -amino-2-sulfonic acid-4-(3-amino-2,4,6-trimethyl-5-phenylamino sulfonate)anthraquinone sodium salt, so as to obtain condensing liquid I; adding a corresponding intermediate of R1 into the condensing liquid I, and reacting, so as to obtain condensing liquid II; cooling the condensing liquid II to the temperature below 5 DEG C, adding a diazonium salt of R2, and reacting, so as to obtain the red light black active dye of the azo anthraquinone mixing light emitting system containing the iso-bifunctional groups with the high color fixation rate. The red light black active dye has the advantages that the red light black active dye is suitable for printing cotton, manmade cotton, jute, regenerated fiber and textiles thereof, the color fixation rate of printing is high, the improvement is excellent, and the washing-resistant, light-resistant and friction-resistant color fixation rate is good.

Owner:DONGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com