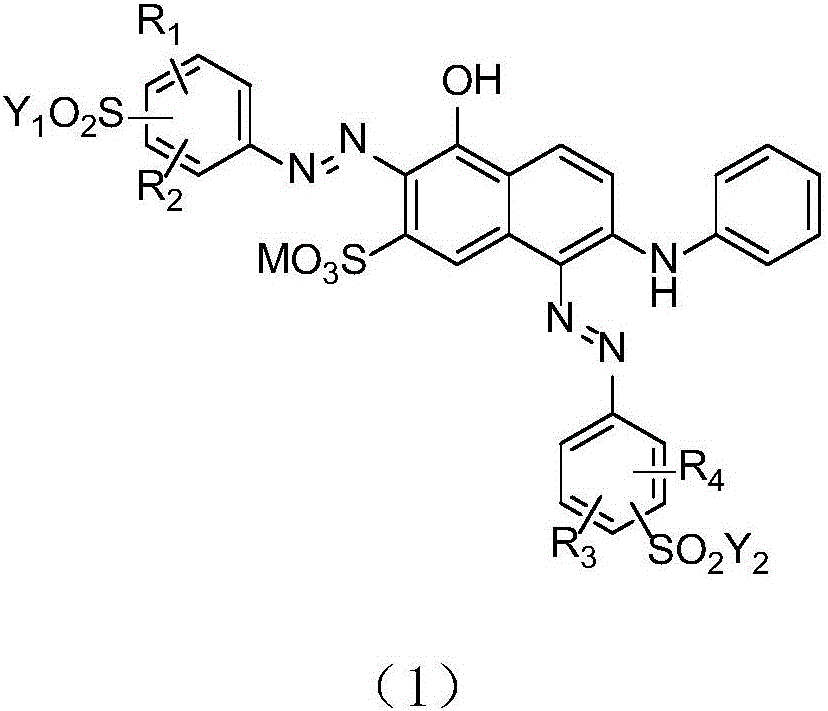

Dark red reactive dye and preparation method thereof

A technology of reactive dyes and crimson, applied in reactive dyes, dyeing methods, azo dyes, etc., can solve problems such as rubbing fastness, poor washing fastness, difficulty in improving color and dyeing depth, and difficult to meet, and achieve Improve rubbing fastness, excellent color synchronization, and improve lifting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

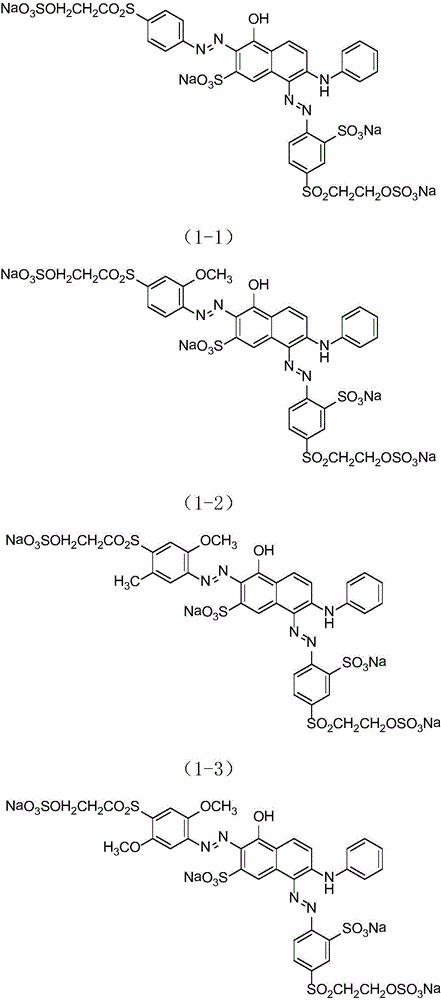

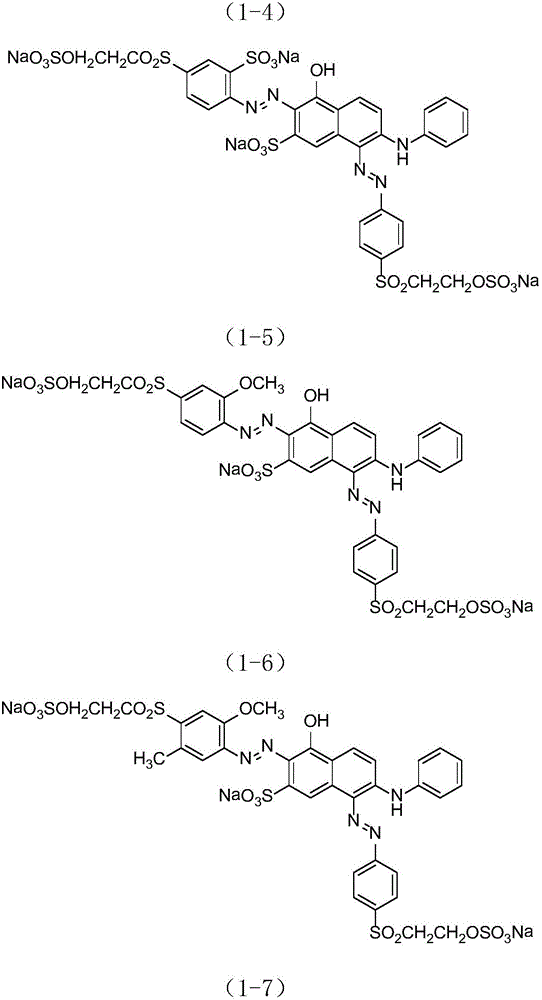

[0059] A kind of deep red reactive dye, is made up of the compound of simple formula (1-1) structure:

[0060]

[0061] (1-1) Its synthetic method step of the compound of structure is as follows:

[0062] 1. Condensation reaction: add 100g of bottom water to the beaker, control the temperature at 25-45°C, add 20g of sodium bisulfite and stir until completely dissolved, then add 25g of J acid, and adjust the pH to 5.0-6.0 with 10g of baking soda , slowly add 9g of aniline solution, after the addition is completed, the measured pH is 5.0-6.0, then the temperature is raised to 100-120°C, and the pH value is kept at a temperature, and the stirring reaction is continued for 20-30 hours. The condensation reaction formula is shown in formula (a):

[0063]

[0064] 2. Diazo reaction: Add 50g of sulfonated para-ester into 100g of water and 50g of crushed ice solution for beating for 1 hour. Then add 10g of hydrochloric acid (30%), and after stirring for 1 minute, add 23g of the...

Embodiment 2

[0073] A kind of deep red reactive dye, is made up of the compound of simple formula (1-2) structure:

[0074]

[0075] (1-2) Its synthetic method step of the compound of structure is as follows:

[0076] 1. Condensation reaction: add 100g of bottom water to the beaker, control the temperature at 25-45°C, add 20g of sodium bisulfite and stir until completely dissolved, then add 25g of J acid, and adjust the pH to 5.0-6.0 with 10g of baking soda , slowly add 9g of aniline solution, after the addition is completed, the measured pH is 5.0-6.0, then the temperature is raised to 100-120°C, and the pH value is kept at a temperature, and the stirring reaction is continued for 20-30 hours. The condensation reaction formula is shown in formula (a):

[0077]

[0078] 2. Diazo reaction: Add 50g of sulfonated para-ester into 100g of water and 50g of crushed ice solution for beating for 1 hour. Then add 10g of hydrochloric acid (30%), and after stirring for 1 minute, add 23g of the...

Embodiment 3

[0087] A kind of deep red reactive dye, is made up of the compound of simple formula (1-3) structure:

[0088]

[0089] (1-3) Its synthetic method step of the compound of structure is as follows:

[0090] 1. Condensation reaction: add 100g of bottom water to the beaker, control the temperature at 25-45°C, add 20g of sodium bisulfite and stir until completely dissolved, then add 25g of J acid, and adjust the pH to 5.0-6.0 with 10g of baking soda , slowly add 9g of aniline solution, after the addition is completed, the measured pH is 5.0-6.0, then the temperature is raised to 100-120°C, and the pH value is kept at a temperature, and the stirring reaction is continued for 20-30 hours. The condensation reaction formula is shown in formula (a):

[0091]

[0092] 2. Diazo reaction: Add 50g of sulfonated para-ester into 100g of water and 50g of crushed ice solution for beating for 1 hour. Then add 10g of hydrochloric acid (30%), and after stirring for 1 minute, add 23g of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com