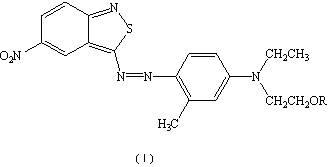

Bi-component monoazo disperse blue dye composition

A dye composition and disperse blue technology are applied in the field of dye chemistry to achieve the effects of low production cost, excellent comprehensive performance and high upgradeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Diazotization: Add 57 ml of 93% (wt) concentrated sulfuric acid to a 100 ml three-necked flask, start stirring, and add 99% (wt) of 3-amino-5-nitro-[2,1]-benzisothiazole 19.6 g, at this time the temperature was raised to 35~45°C, and kept stirring for 4 hours to completely dissolve the diazo component. Cool to 0°C in an ice-water bath, slowly add 34 g of 40% (wt) nitrosyl sulfuric acid dropwise, then control the reaction temperature at 10°C, stir and react for 4 hours to obtain a brown diazonium salt solution for later use.

[0029] Preparation and coupling of coupling components (a accounts for 1% molar percentage of the whole):

[0030] Add 300 ml of water to a 3000 ml beaker, add 10 ml of 93% (wt) concentrated sulfuric acid (the pH is about 1 at this time), 0.19 g (0.00105 moles) of component a coupling component, and 24.15 g of component b coupling component while stirring. gram (0.10395 mol), 0.3 gram of Pingpingjia O, 0.7 gram of sulfamic acid, fully stirred unti...

Embodiment 2

[0032] On the basis of Example 1, only change the proportioning ratio of the couple and components, that is, a accounts for 5% of the overall molar percentage, and the other process steps remain unchanged, finally obtaining 40.6 grams of former dyestuffs, an average molecular weight of 436, and a yield of 92 %; HPLC analysis dye molar ratio is a: b = 4.1: 95.9.

Embodiment 3

[0034] Diazotization: Add 57 ml of 98% (wt) concentrated sulfuric acid to a 100 ml three-neck flask, start stirring, add 99% (wt) 3-amino-5-nitro-[2,1]-benzisothiazole 19.6 g, at this time the temperature was raised to 35~45°C, and kept stirring for 4 hours to completely dissolve the diazo component. Cool to 0°C in an ice-water bath, slowly add 34 g of 40% (wt) nitrosyl sulfuric acid dropwise, then control the reaction temperature at 10°C, stir and react for 4 hours to obtain a brown diazonium salt solution for later use.

[0035] Preparation and coupling of coupling components (a accounts for 10% mole percent of the total):

[0036] Add 300 ml of water to a 3000 ml beaker, add 10 ml of 98% (wt) concentrated sulfuric acid under stirring (the pH is about 1 at this time), 1.88 g (0.0105 moles) of component a coupling component, and 21.96 g of component b coupling component gram (0.0945 mol), 0.3 gram of Pingpingjia O, 0.7 gram of sulfamic acid, fully stirred until each raw mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com