High pressure annular jet pump suitable for pumping pressure type supply system

A technology of supply system and annular jet, which is applied in aviation and aerospace fields, can solve the problems that centrifugal pumps cannot run at high speed, and achieve the effects of improving anti-cavitation performance, improving efficiency and head, and reducing momentum mixing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

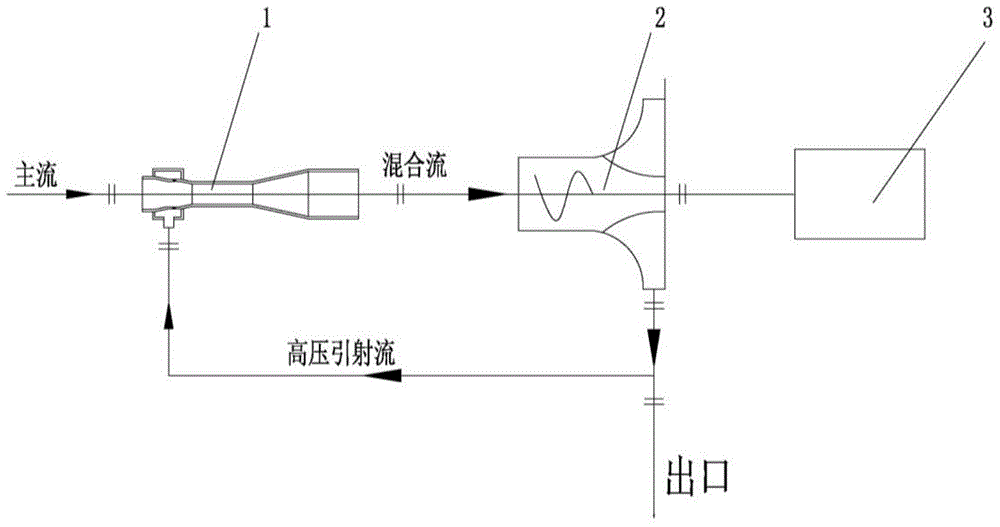

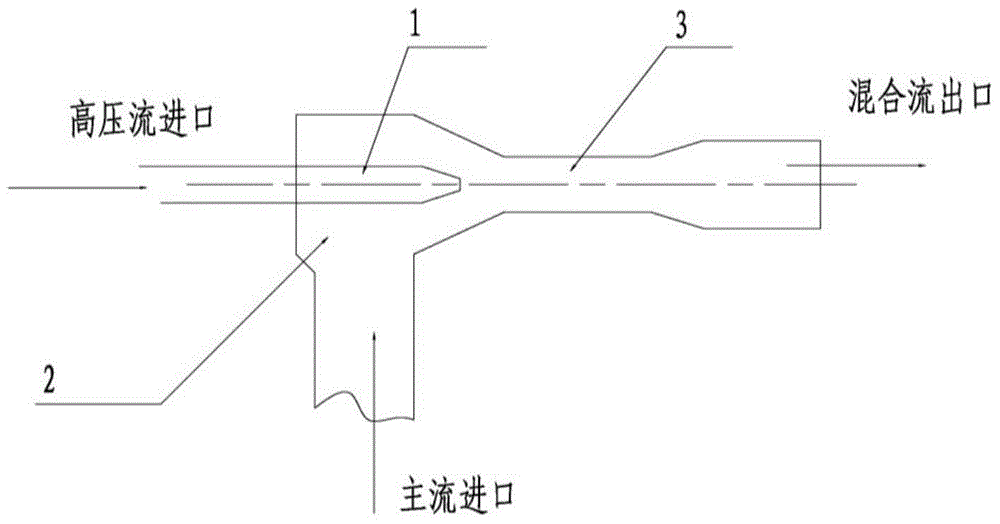

[0030] Such as figure 1 As shown, the pump pressure supply system consists of a high-pressure annular jet pump 1, a centrifugal pump 2, a driver 3, and a high-pressure drainage pipeline 4; the main flow inlet of the high-pressure jet pump 1 is connected to the upstream pipeline, and the high-pressure fluid is injected The pipeline 4 is connected with the pipeline behind the centrifugal pump 2, and the mixing outlet is connected with the inlet of the centrifugal pump 2. The high-pressure annular jet pump 1 uses a high pressure at the outlet of the centrifugal pump 2 to boost the low-pressure fluid from the upstream pipeline and increase the pressure at the inlet of the centrifugal pump 2, so that the centrifugal pump 2 can work at a very high speed and achieve a small Structural dimensions and weight.

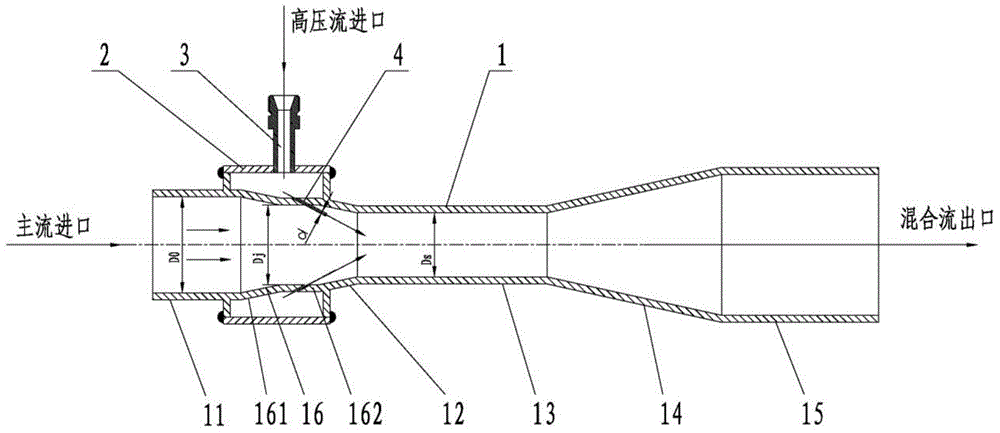

[0031] Such as image 3 As shown, the high-pressure annular jet pump 1 of the present invention includes an inlet section pipeline 11, a mixing section pipeline 12, a throat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com