Patents

Literature

62results about How to "Improve blending efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

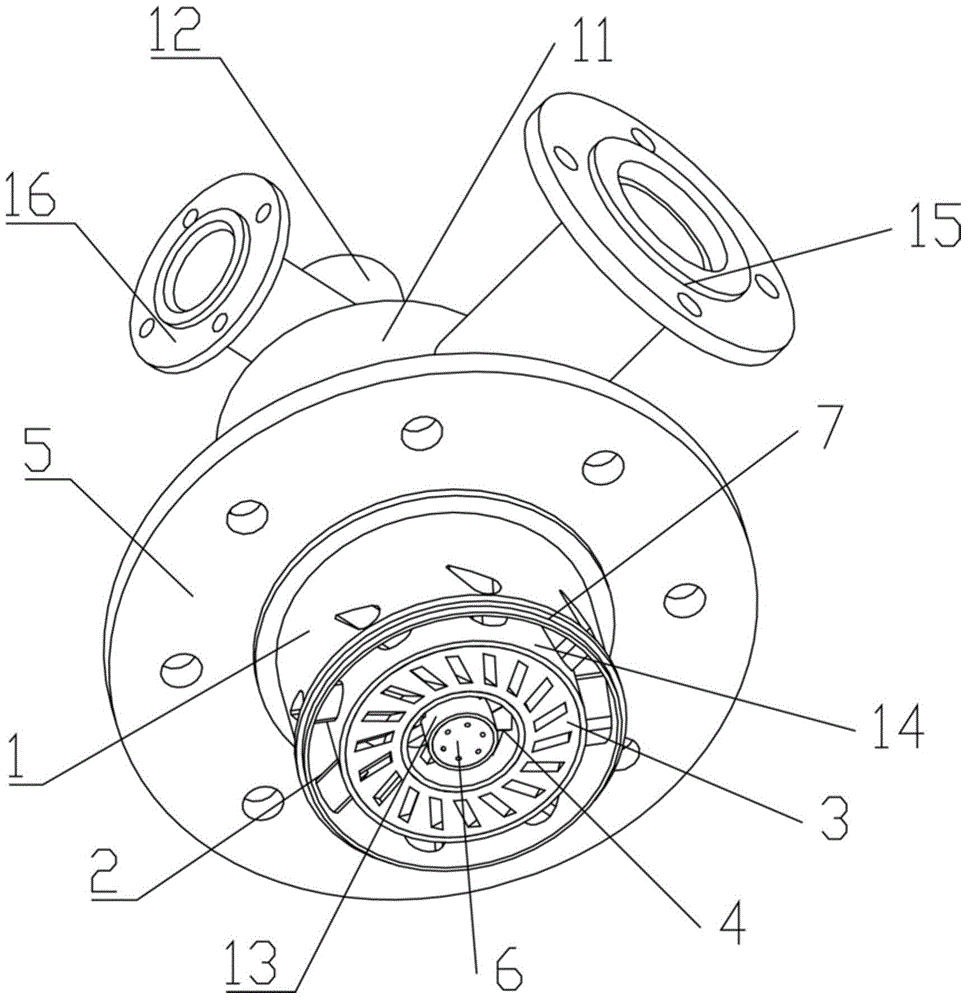

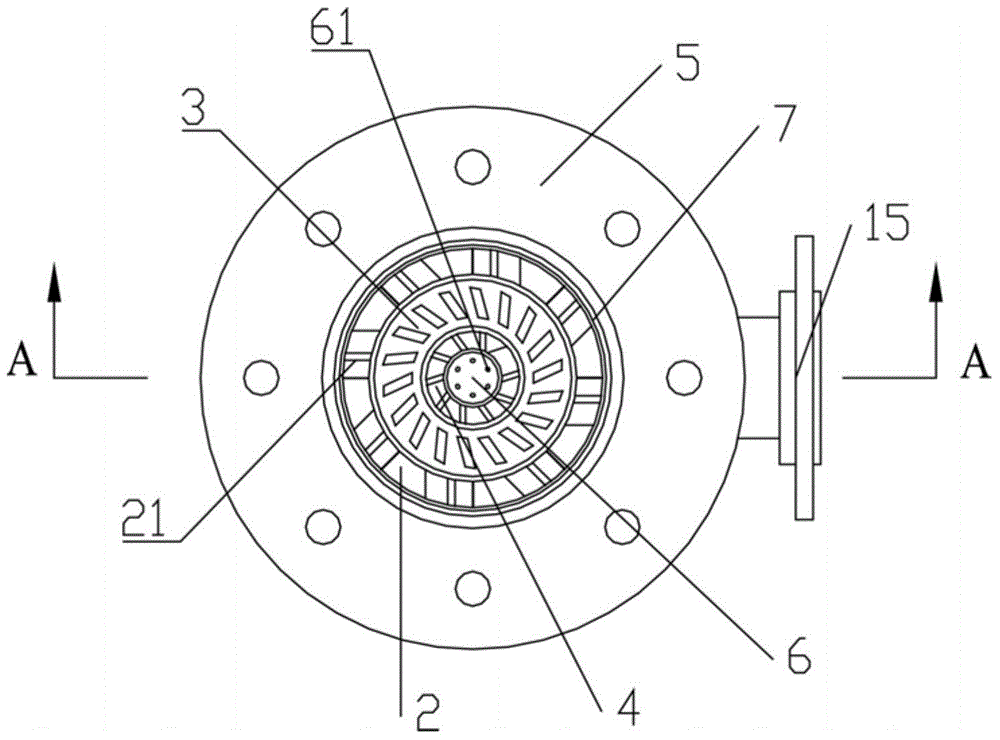

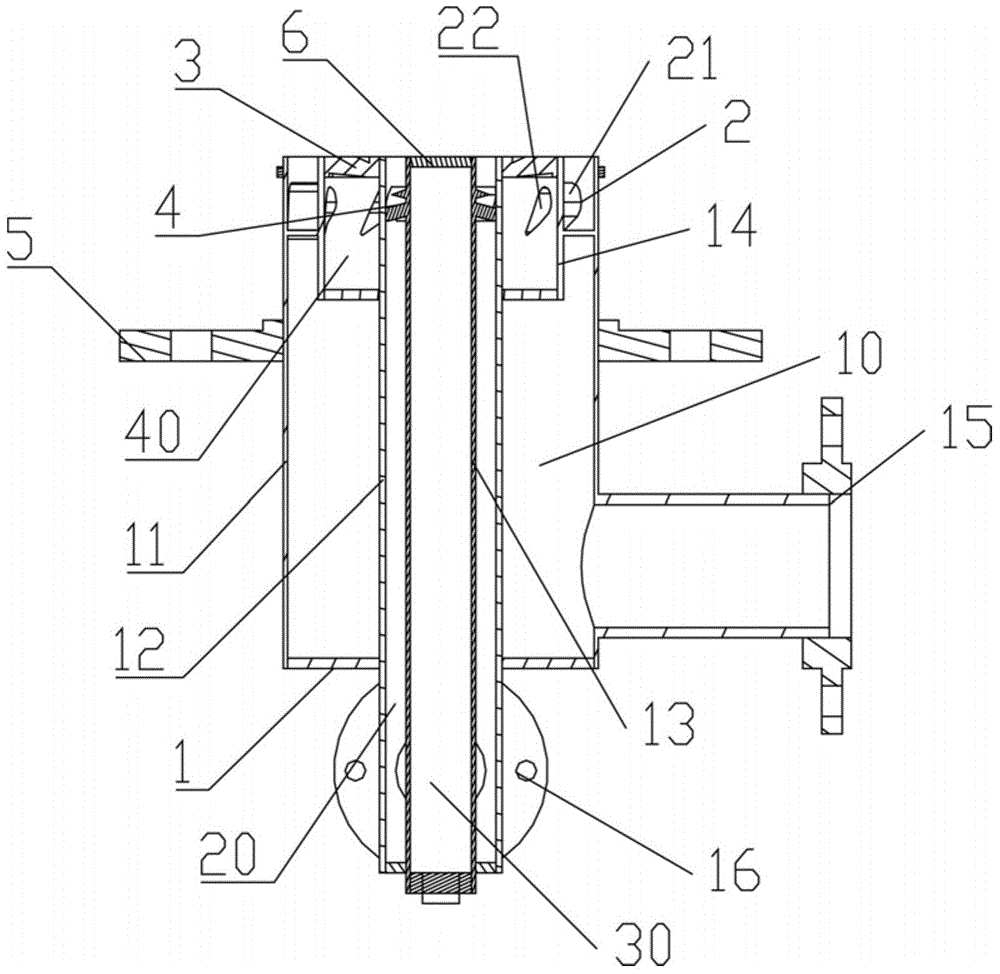

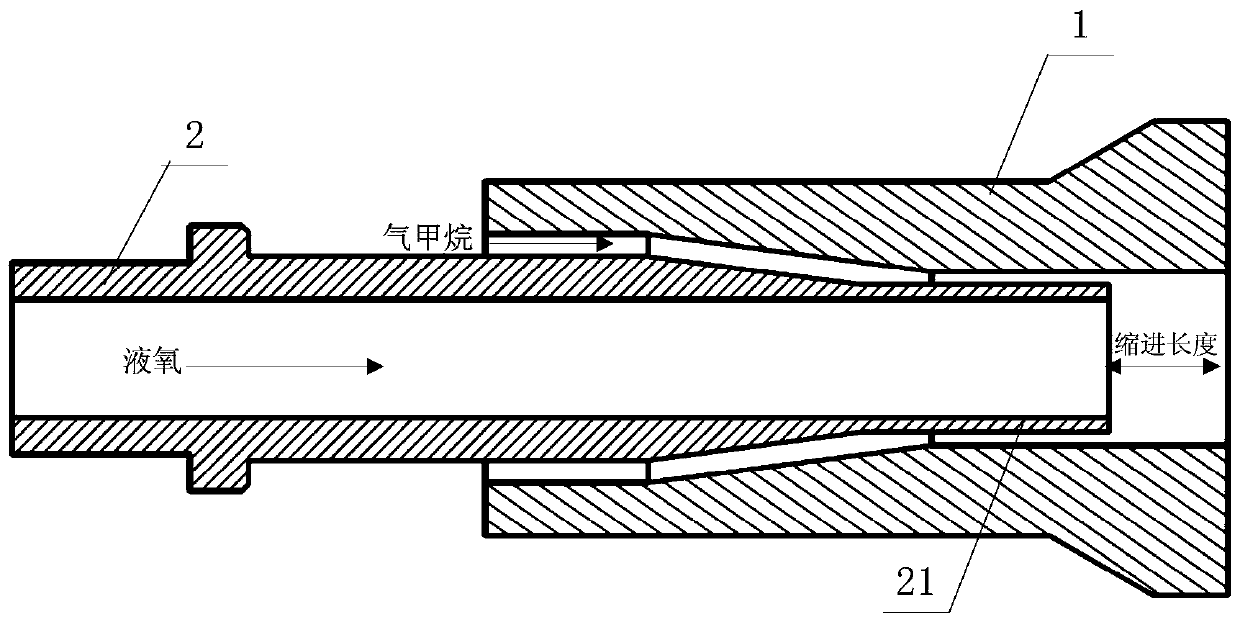

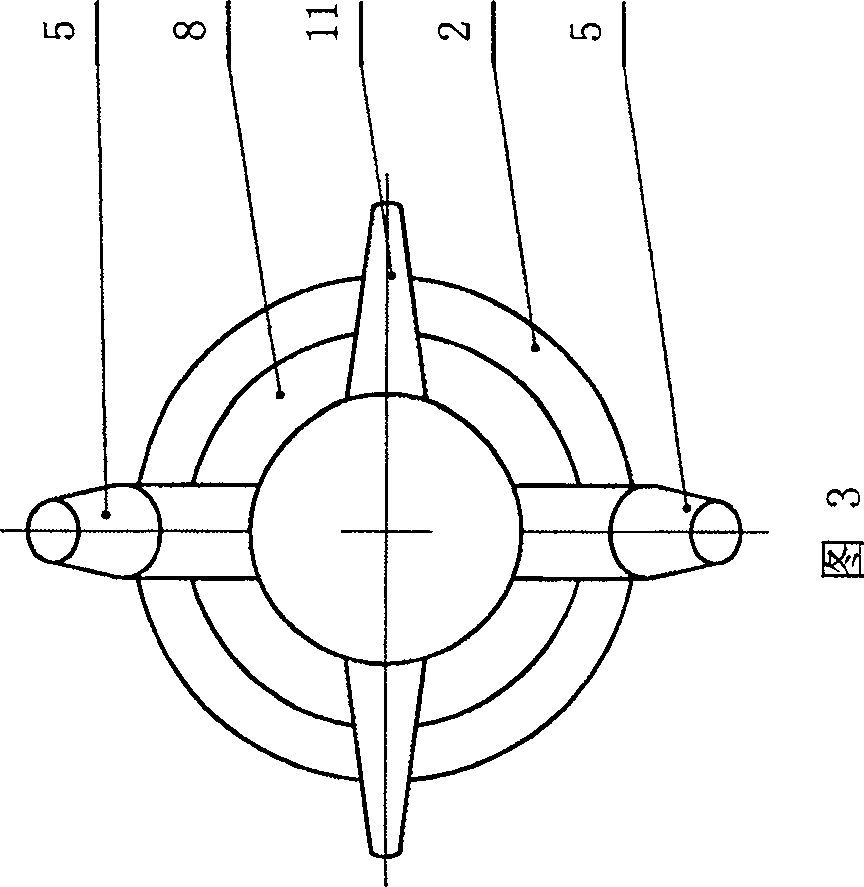

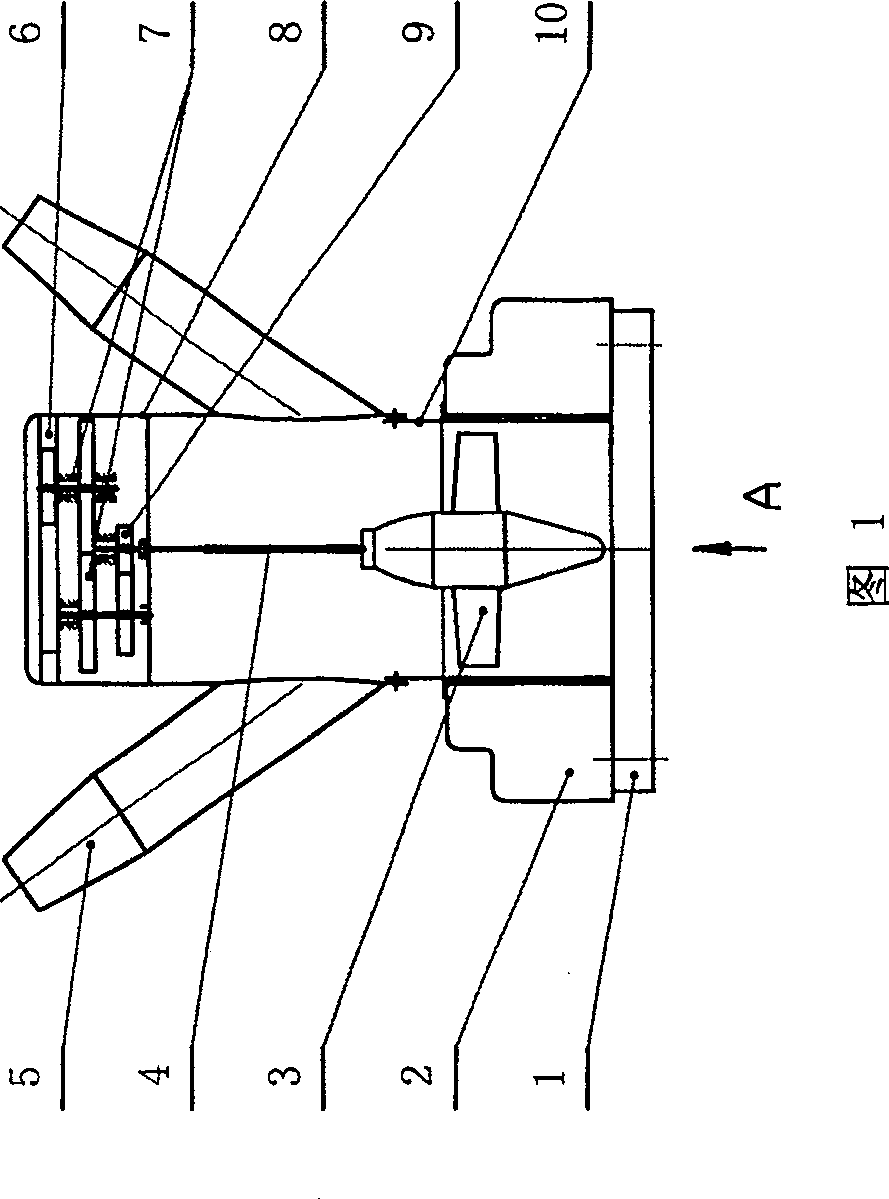

Pre-whirling type pintle injector applied to double-component liquid propellant rocket engine

ActiveCN108286478AImprove blending efficiencyImprove performanceRocket engine plantsSpray nozzleLiquid-propellant rocket

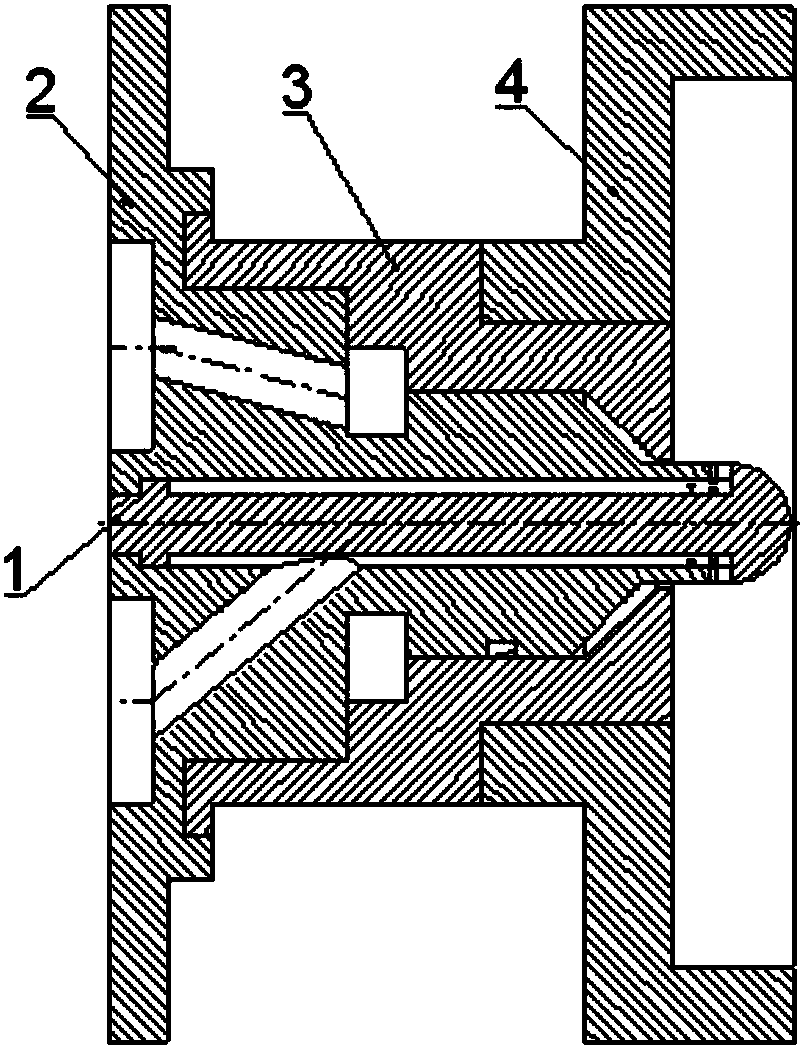

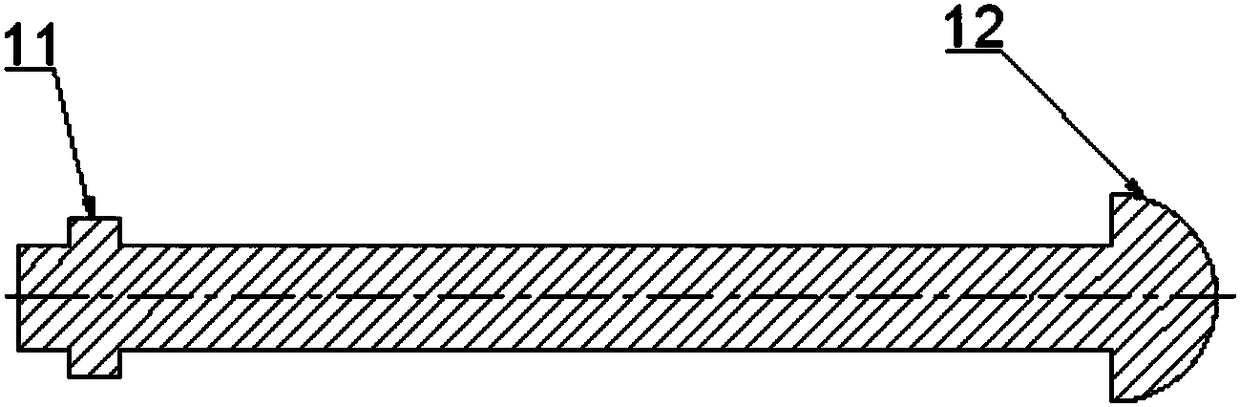

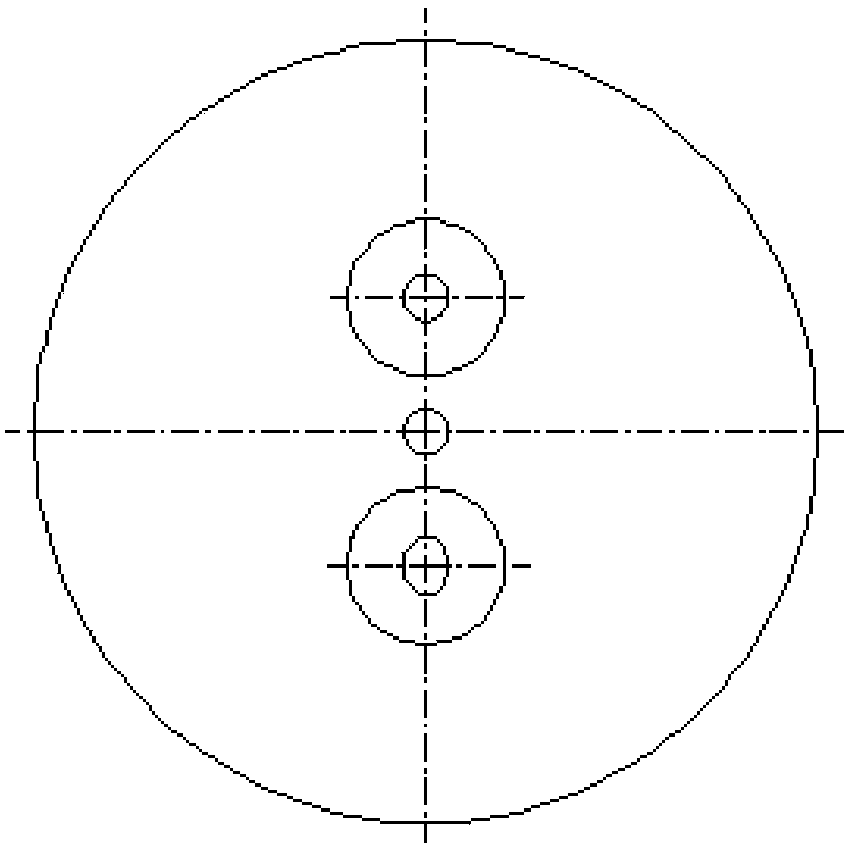

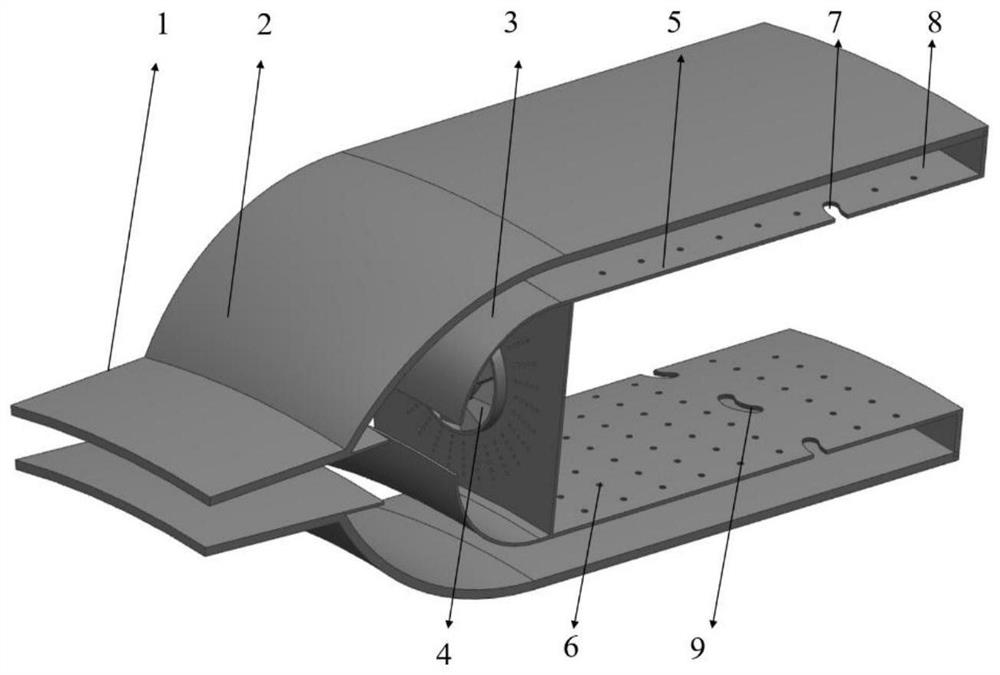

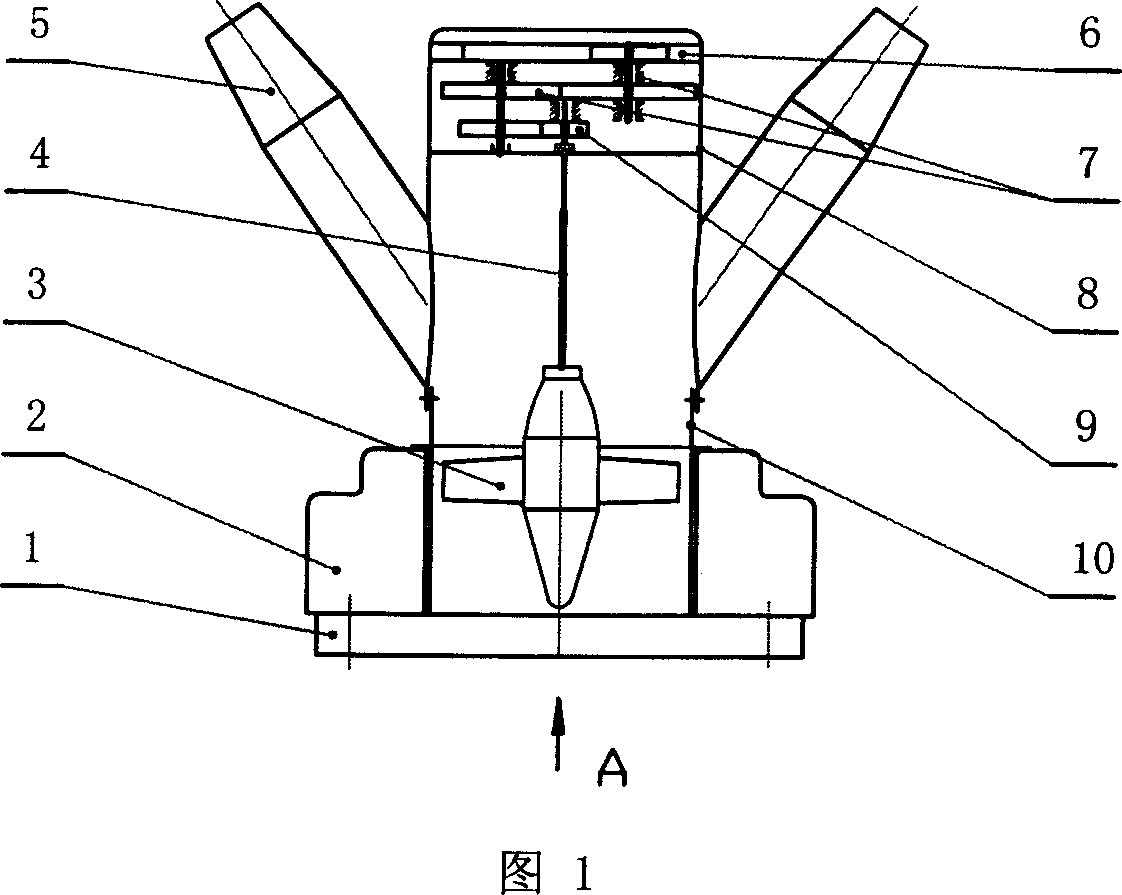

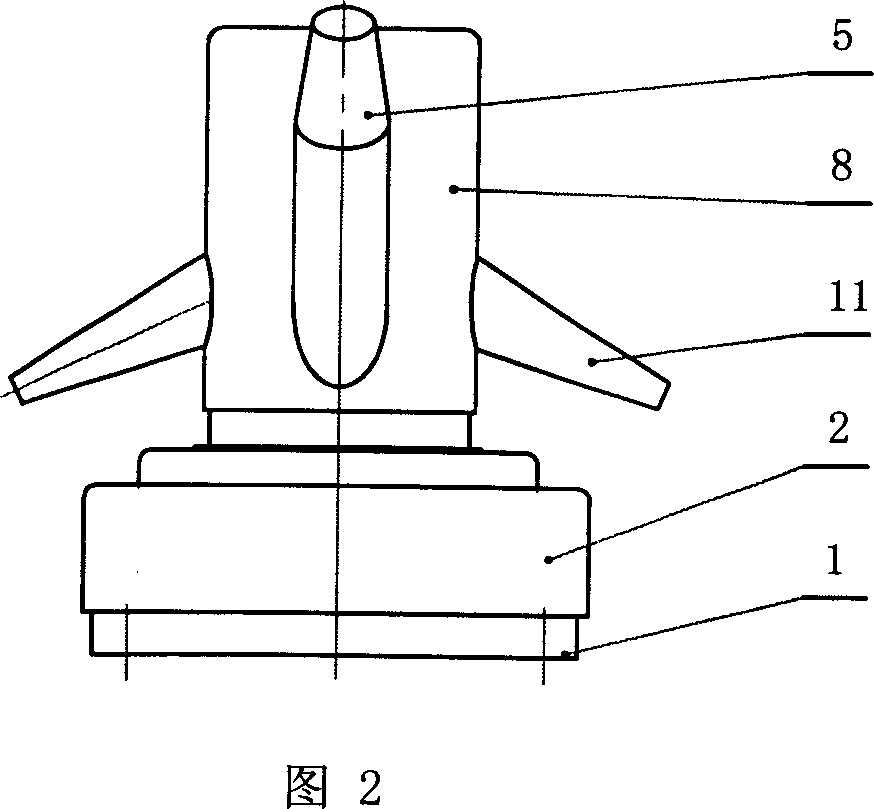

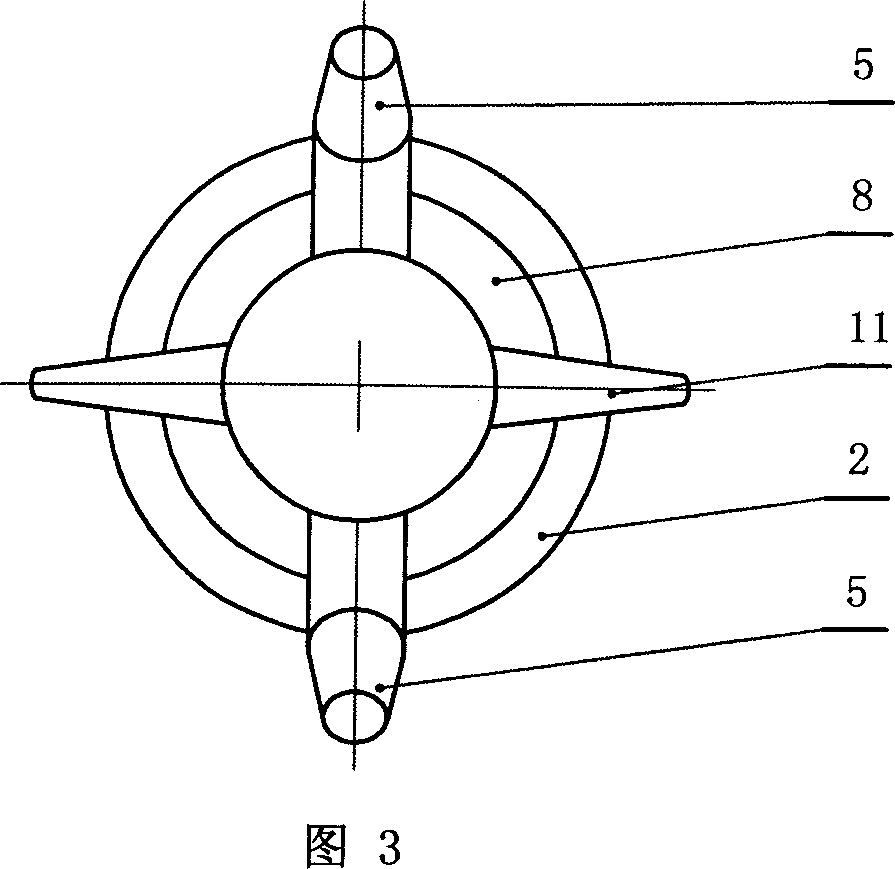

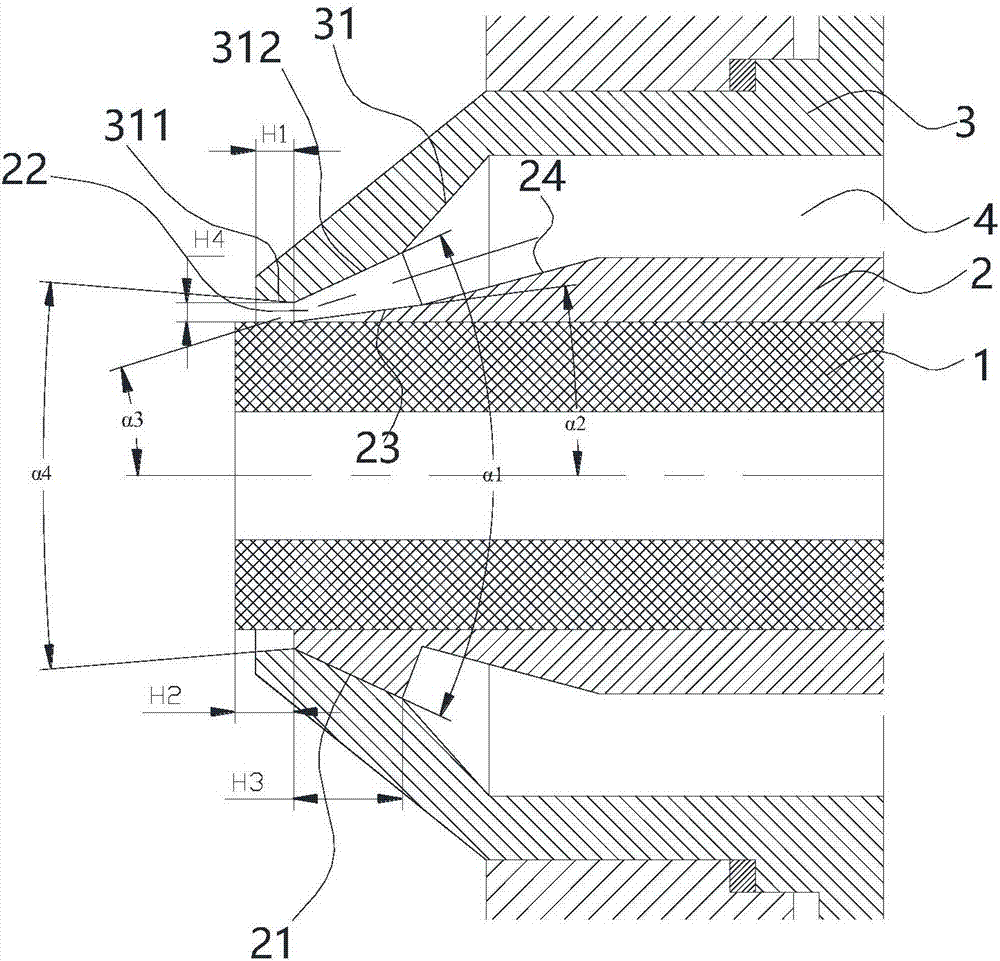

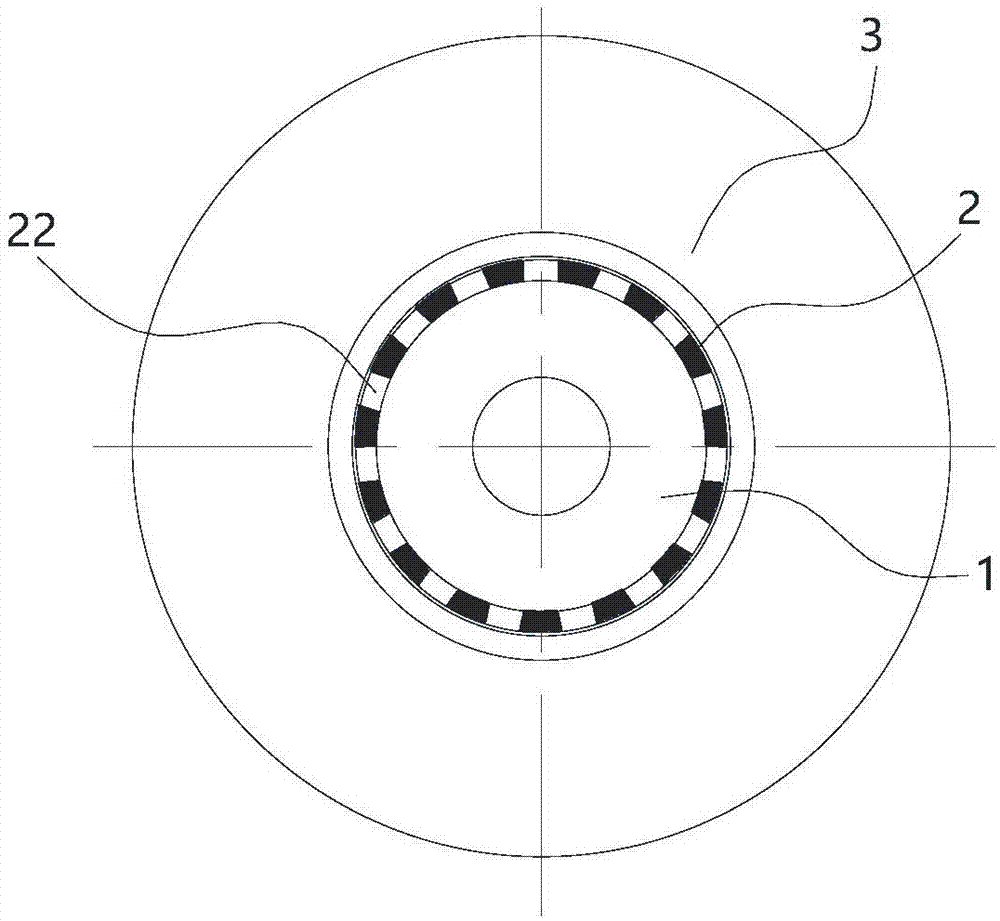

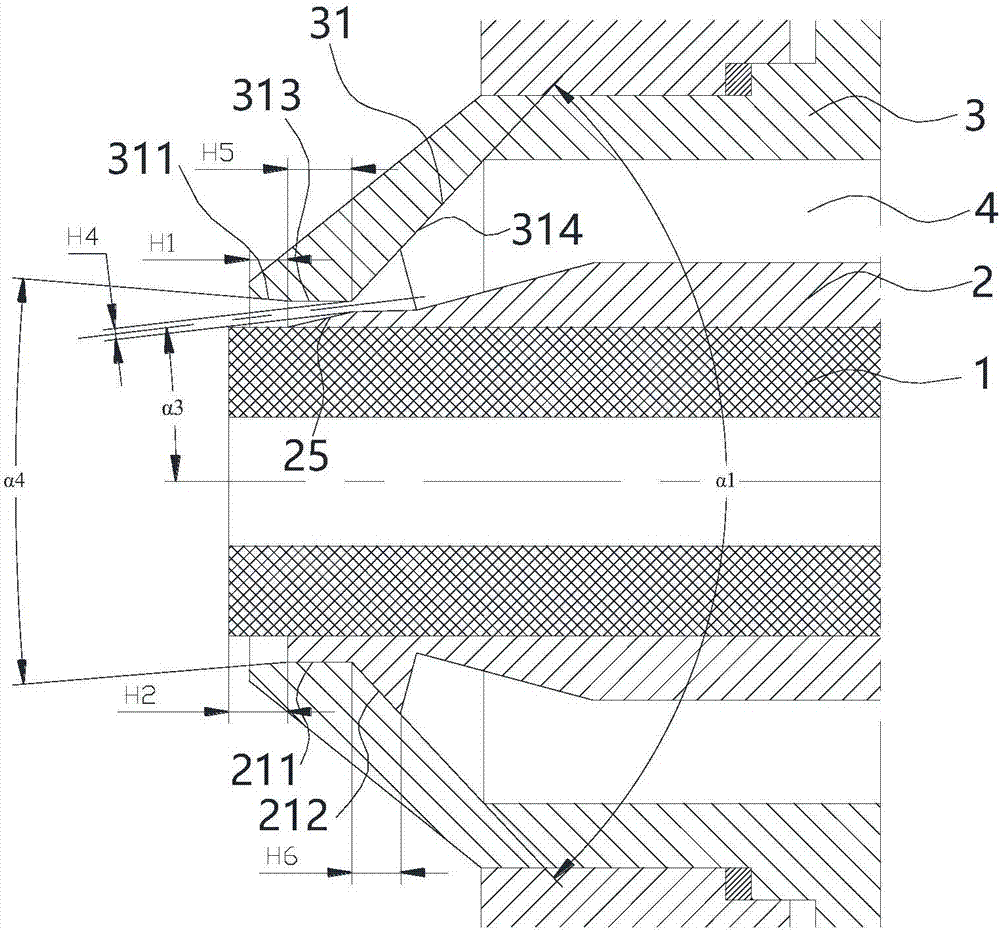

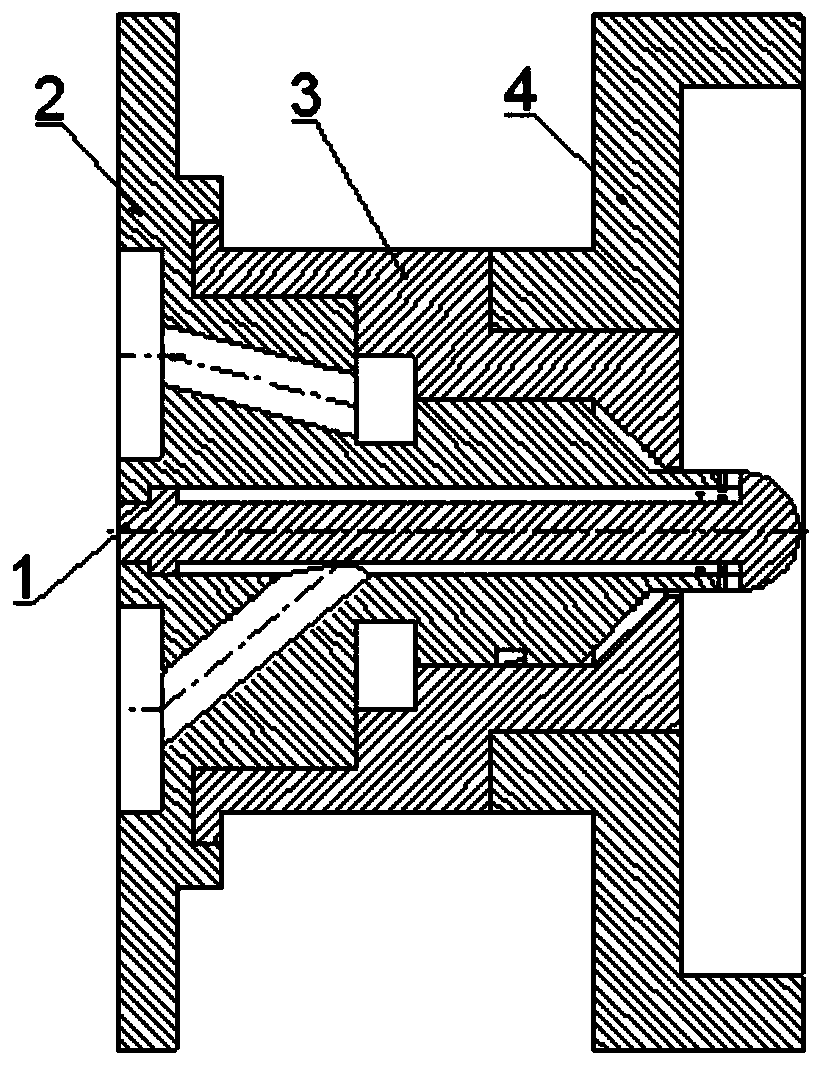

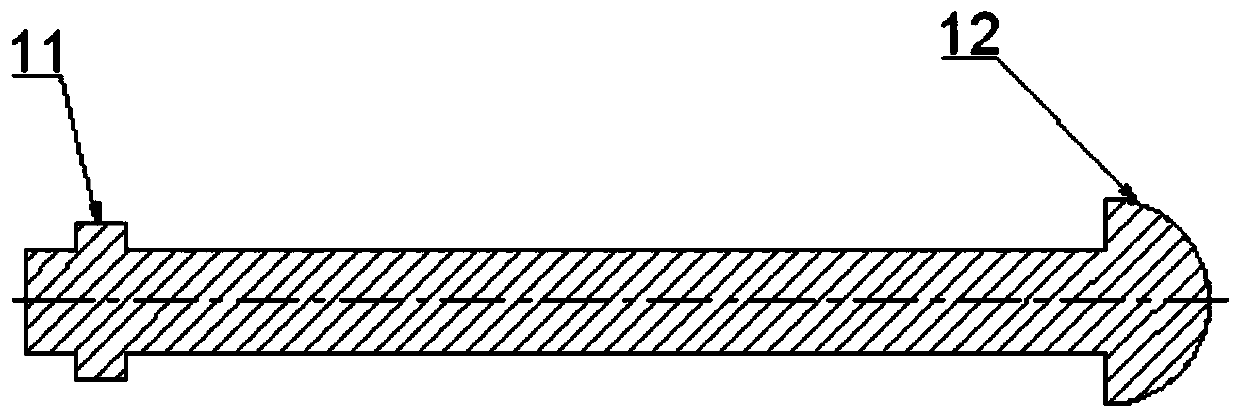

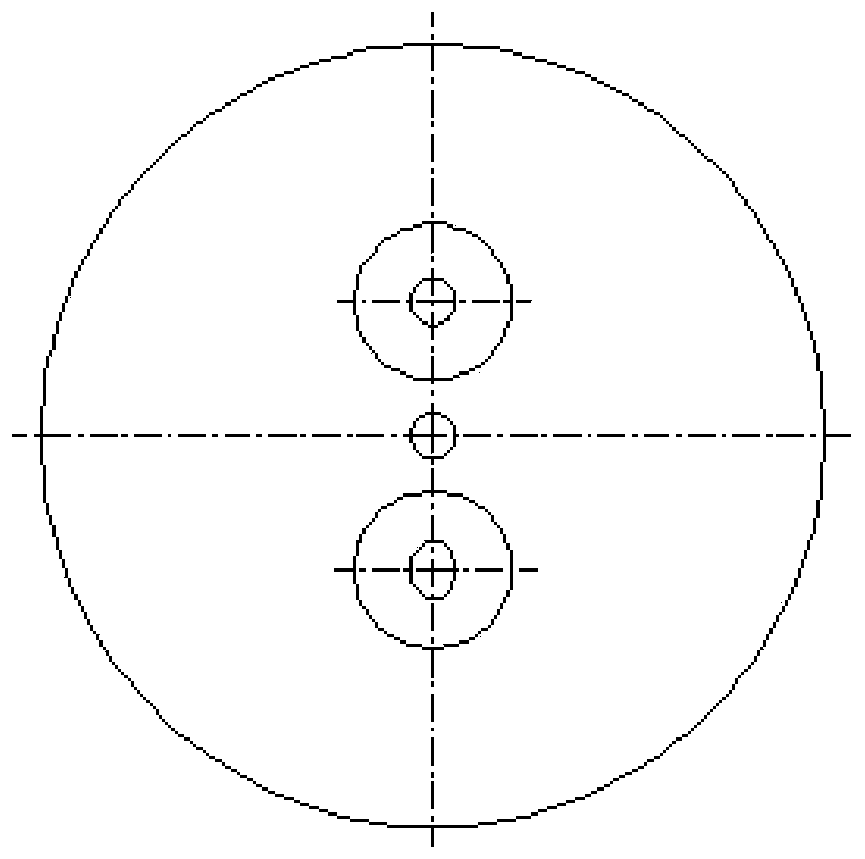

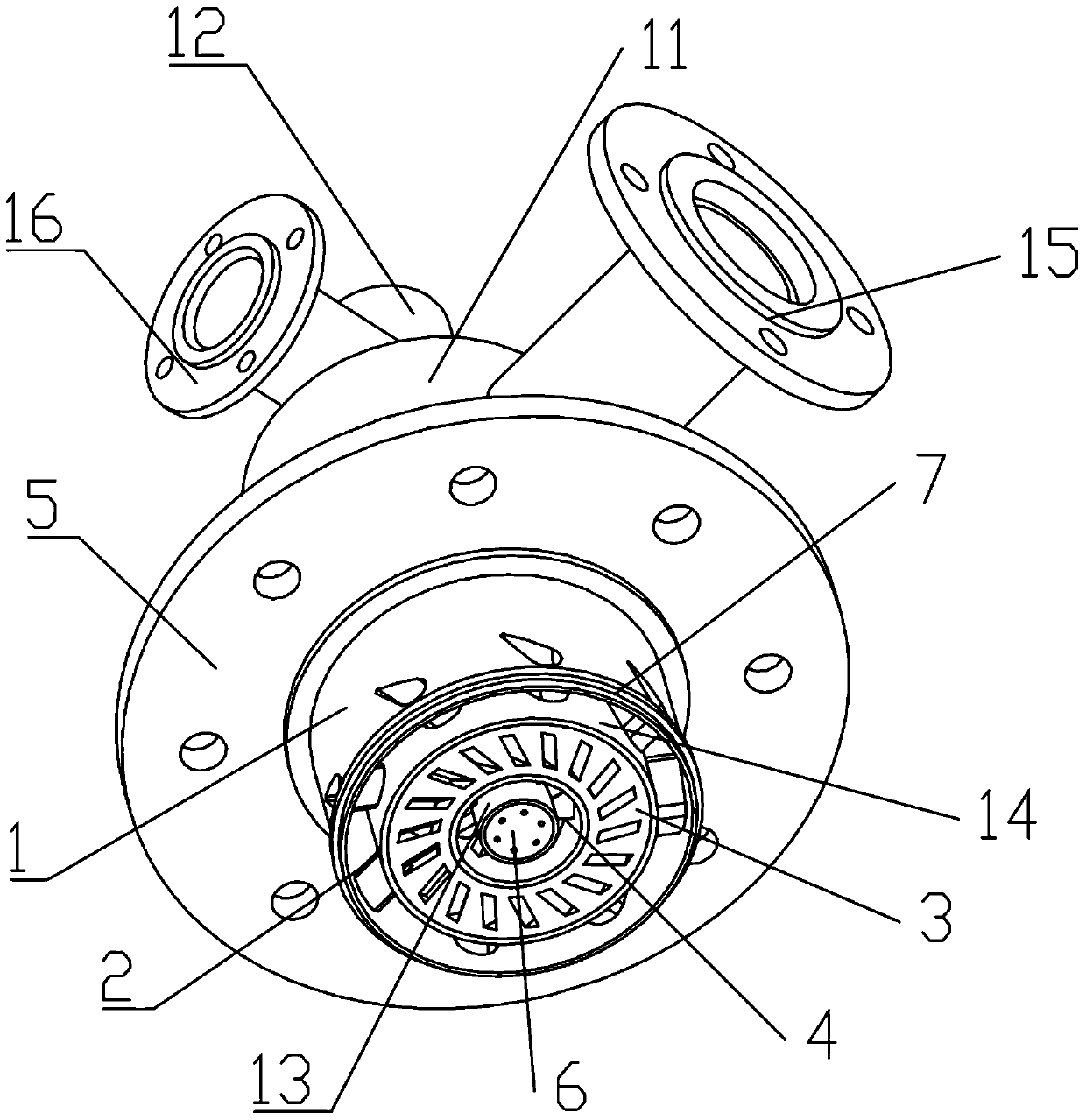

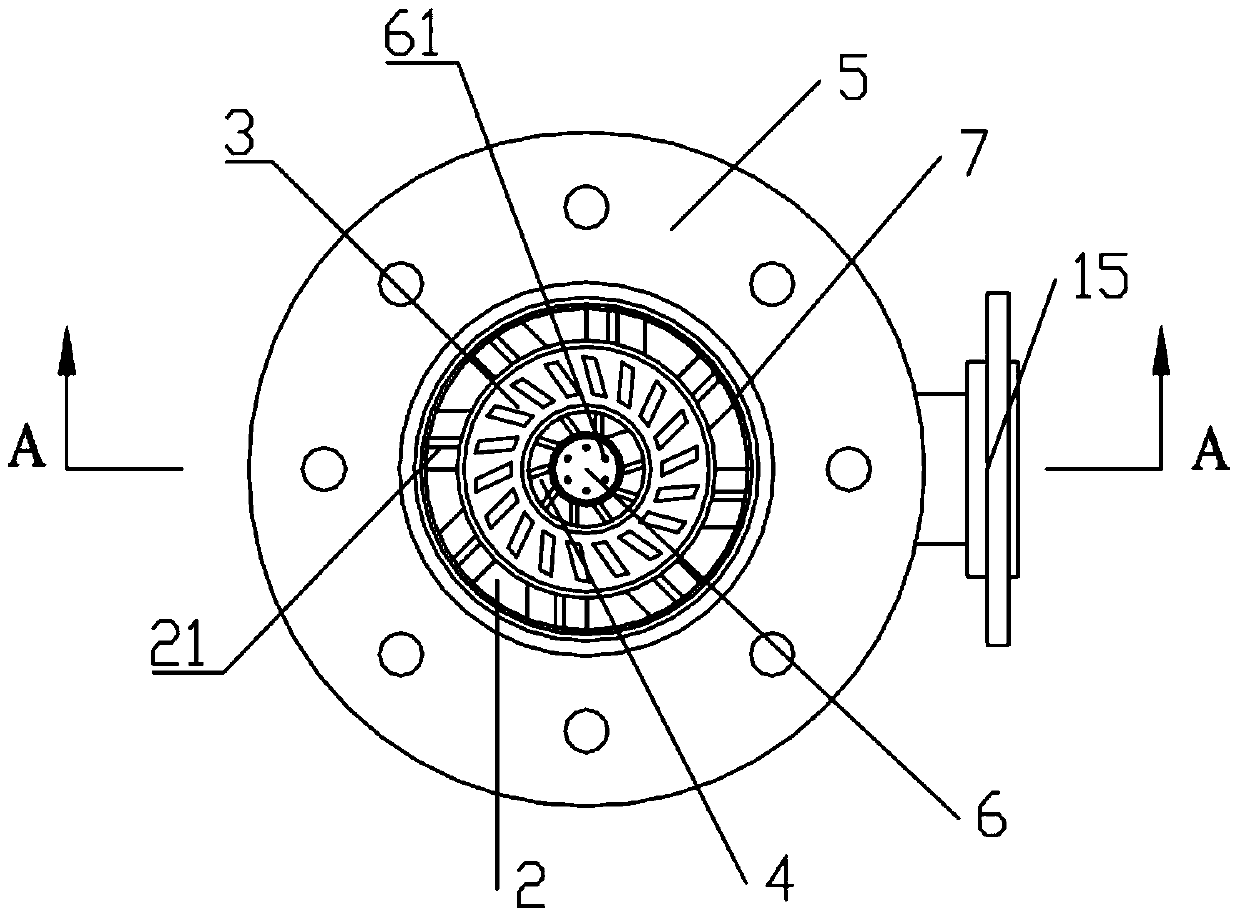

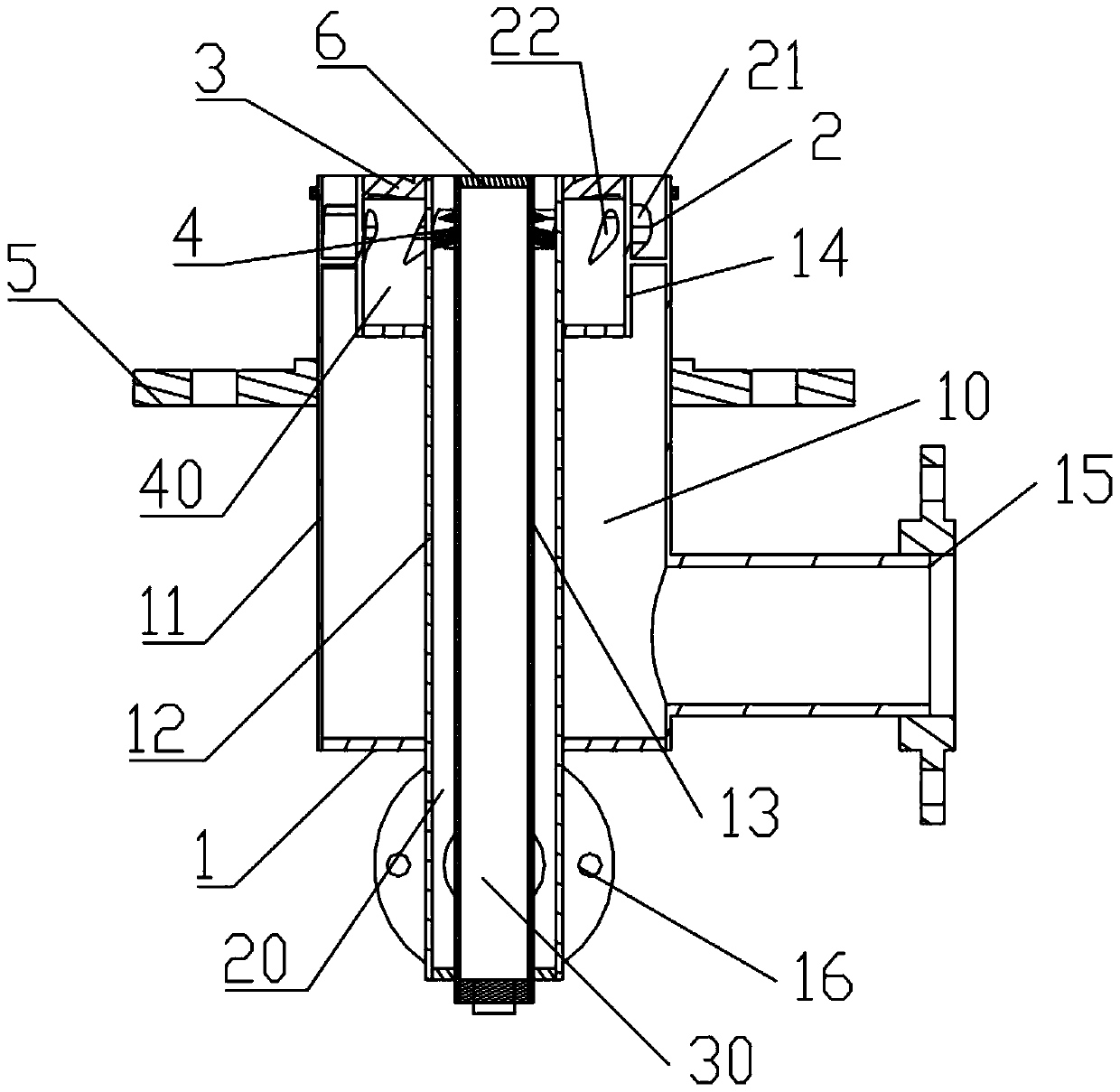

The invention discloses a pre-whirling type pintle injector applied to a double-component liquid propellant rocket engine. The pre-whirling type pintle injector applied to the double-component liquidpropellant rocket engine comprises a center rod, an inner nozzle, an outer nozzle and a connecting ring, all of which are rotation bodies. The inner nozzle coaxially sleeves the center rod, and a cavity for conveying fuel is formed by the inner nozzle and the center rod. The outer nozzle coaxially sleeves the outer nozzle, a cavity for conveying an oxidizing agent is formed by the outer nozzle andthe inner nozzle, and the connecting ring coaxially sleeves the outer nozzle. Pre-whirling treatment is conducted before oxidizing agent spraying-out, and the problem that a conventional pintle injector is not high in effective mixing efficiency is effectively solved; meanwhile, through the arrangement of two rows of fuel direct flow injection holes, cooling to a liquid film on the wall face of athrust chamber through propellant is effectively achieved; and the performance and the reliability of the double-component liquid propellant rocket engine can be obviously improved.

Owner:BEIJING INST OF CONTROL ENG

Double-combustion-chamber ramjet and hypersonic aerocraft

ActiveCN108708788AImprove thermal cycle efficiencyExcellent thrust performanceTurbine/propulsion fuel flow conduitsGas turbine plantsRamjetCombustion chamber

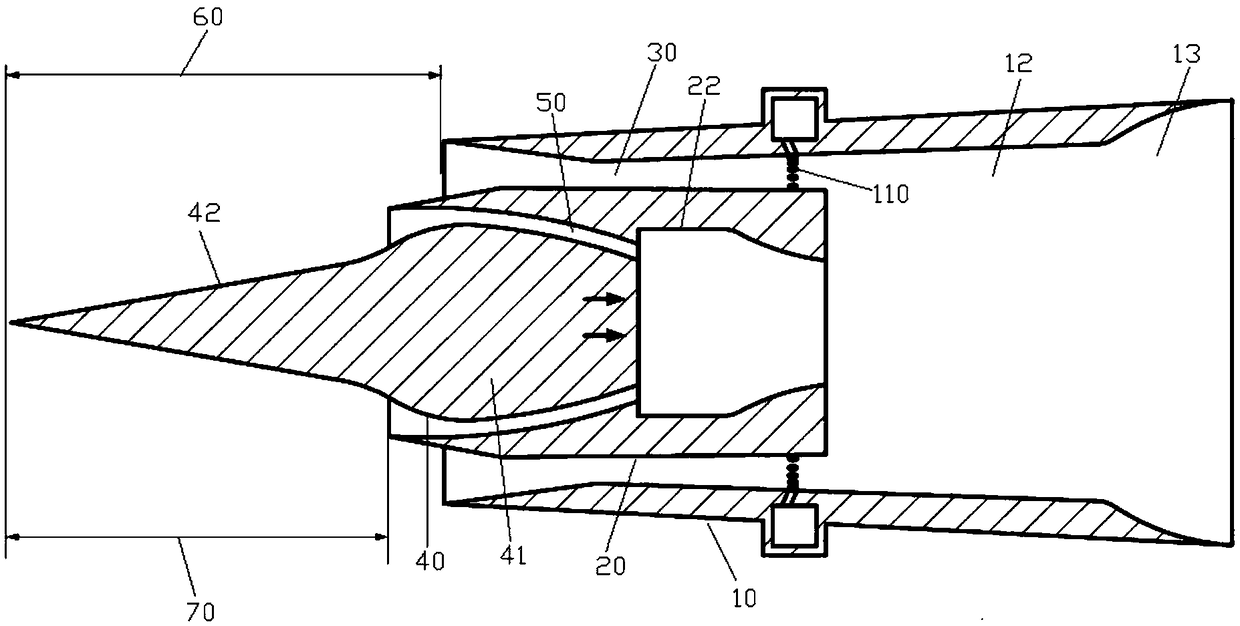

The invention discloses a double-combustion-chamber ramjet and a hypersonic aerocraft. The double-combustion-chamber ramjet comprises an outer shell; and the outer shell is a hollow cylinder with twocommunicating ends. The double-combustion-chamber ramjet further comprises a center shell; the center shell is arranged in a shaft hole of the outer shell, and is connected with the outer shell; a gapbetween the center shell and the outer shell forms an outer drainage channel; a cavity between the back end surface of the center shell and the inner wall of the outer shell forms a knocking chamber;and a tail spraying pipe communicates with the knocking chamber. The double-combustion-chamber ramjet further comprises a center cone; the back body of the center cone extends into the center shell,and is connected with the center shell; a gap between the center cone and the center shell forms a center drainage channel; a cavity between the back end surface of the center cone and the inner wallof the center shell forms a sub-combustion chamber; and the sub-combustion chamber is connected with a fuel source, and communicates with the knocking chamber. Multiple outer nozzles are formed in theouter wall of the outer shell; and the two ends of the outer nozzles communicate with the fuel source and the outer drainage channel. And / or multiple inner nozzles are formed in the outer wall of thecenter shell; and the two ends of the inner nozzles communicate with the fuel source and the outer drainage channel respectively.

Owner:NAT UNIV OF DEFENSE TECH

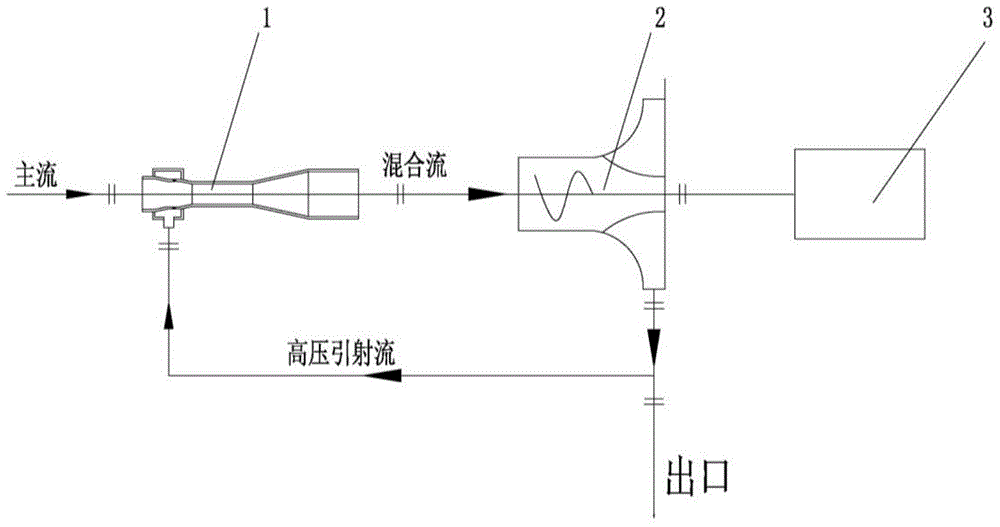

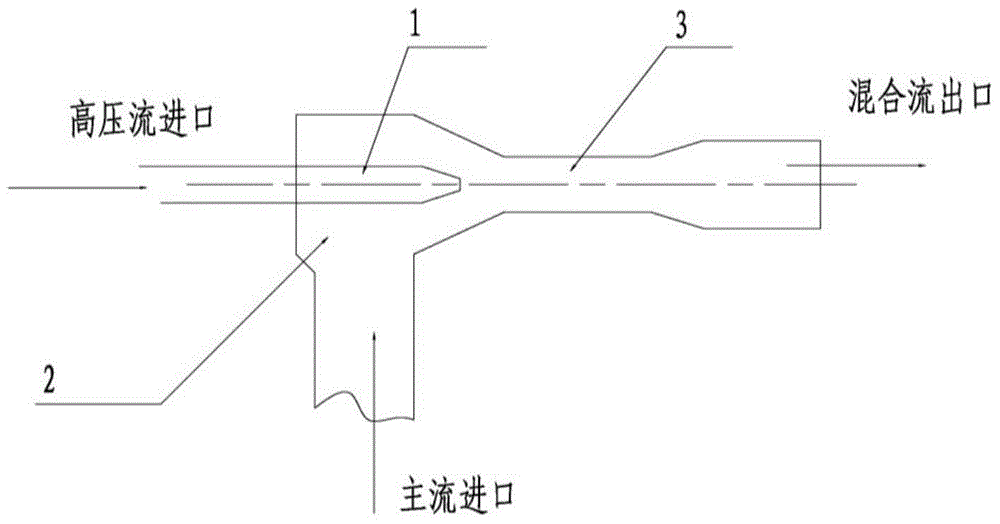

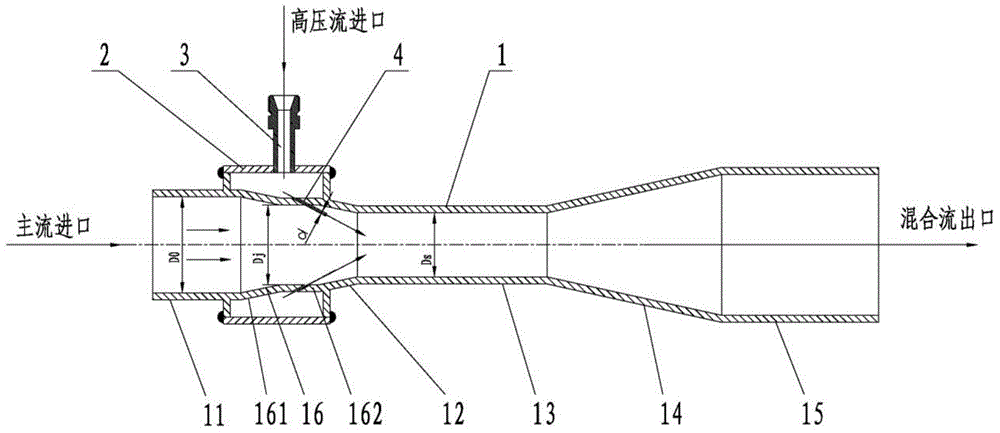

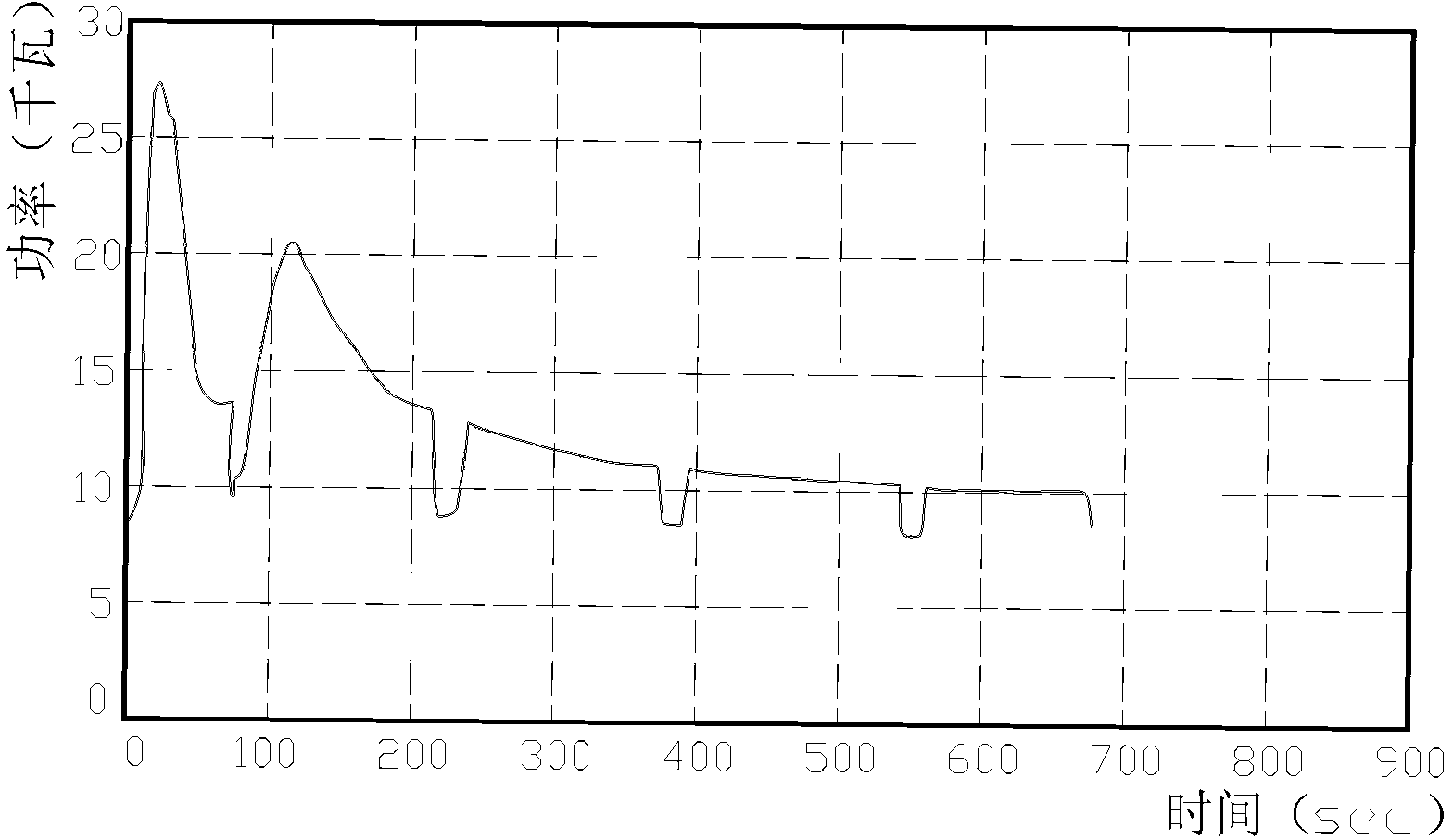

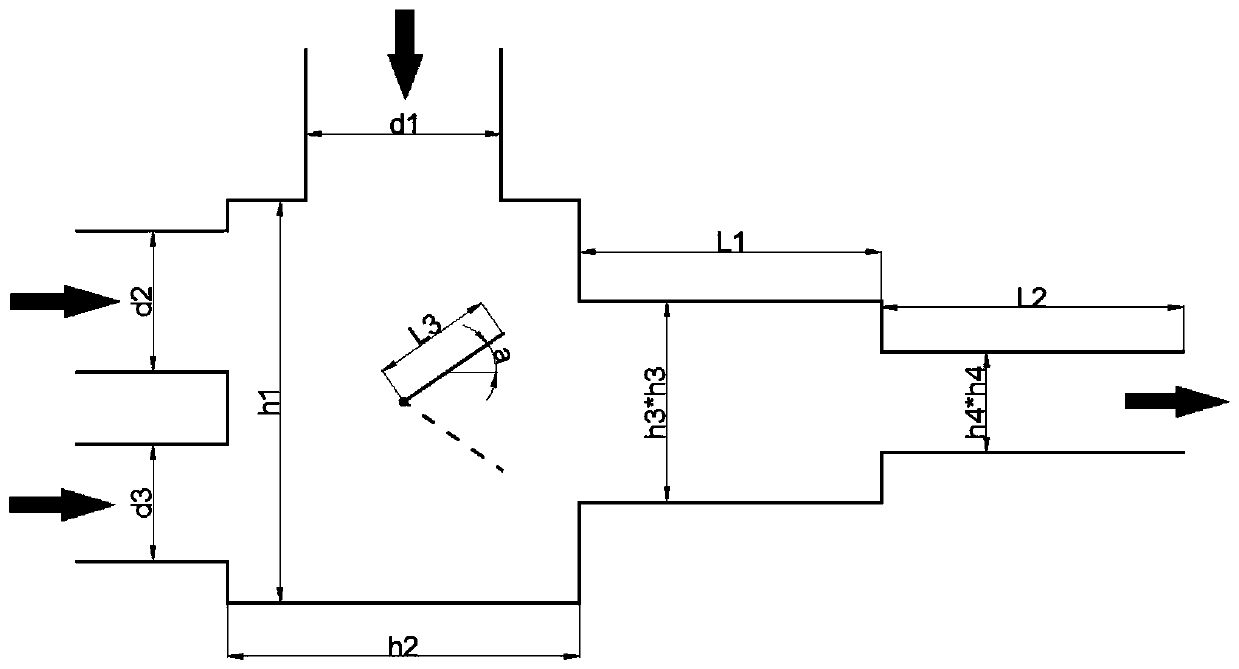

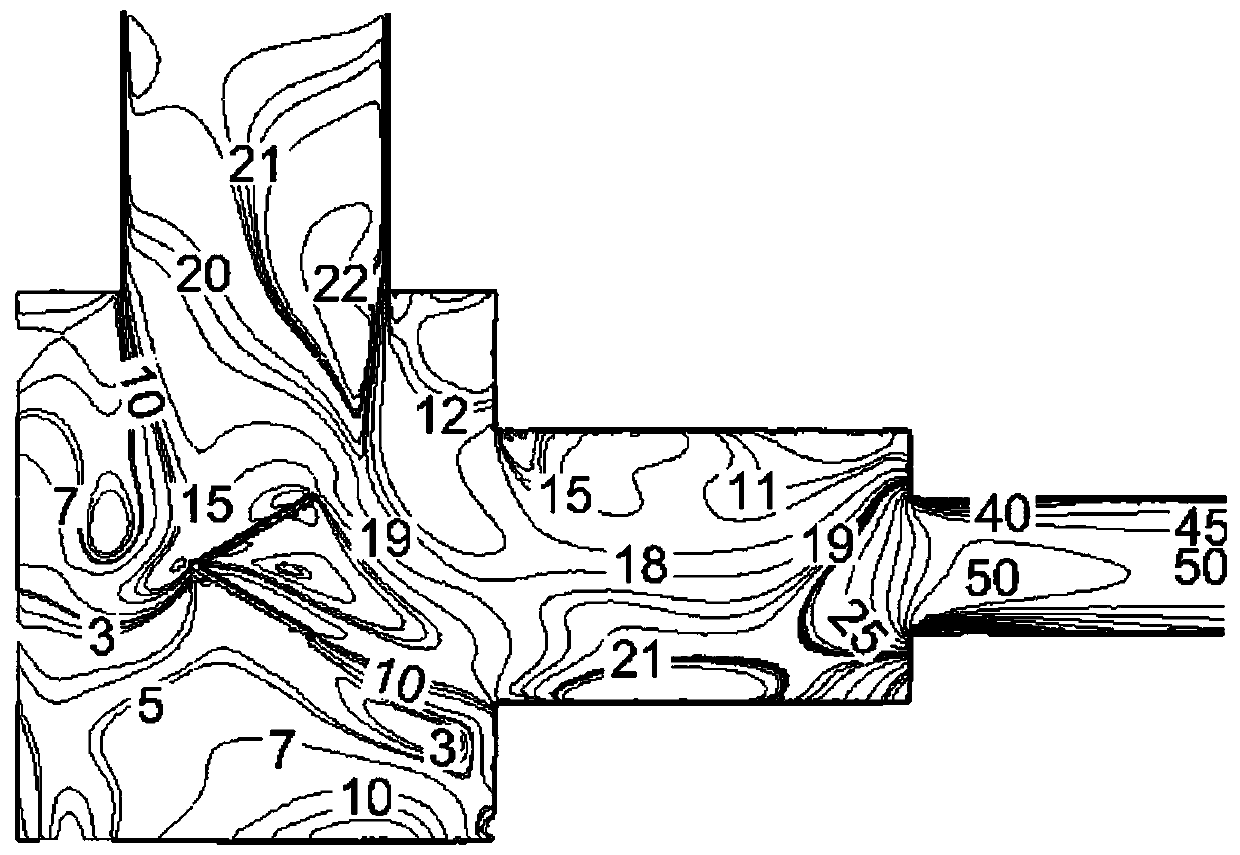

High pressure annular jet pump suitable for pumping pressure type supply system

The invention belongs to the technical field of aviation and space, and particularly relates to a high pressure annular jet pump suitable for a pumping pressure type supply system. The high pressure annular jet pump comprises an inlet section pipe, a mixing section pipe, a throat pipe, a diffusion section pipe and an outlet section pipe which are sequentially arranged in the flowing direction of main fluid. The high pressure annular jet pump is characterized by further comprising step section pipes which are sequentially arranged between the inlet section pipe and the mixing section pipe; each step section pipe comprises a convergence section pipe and a straight section pipe; each straight section pipe is provided with a spraying nozzle for providing high pressure fluid. The high pressure annular jet pump is compact in structure, light in weight, good in anti-cavitation performance and capable of meeting the requirement for normal work under the working conditions of high rotating speed and low inlet pressure.

Owner:NO 11 INST OF NO 6 ACADEMY OF CHINA AEROSPACE SCI & TECH

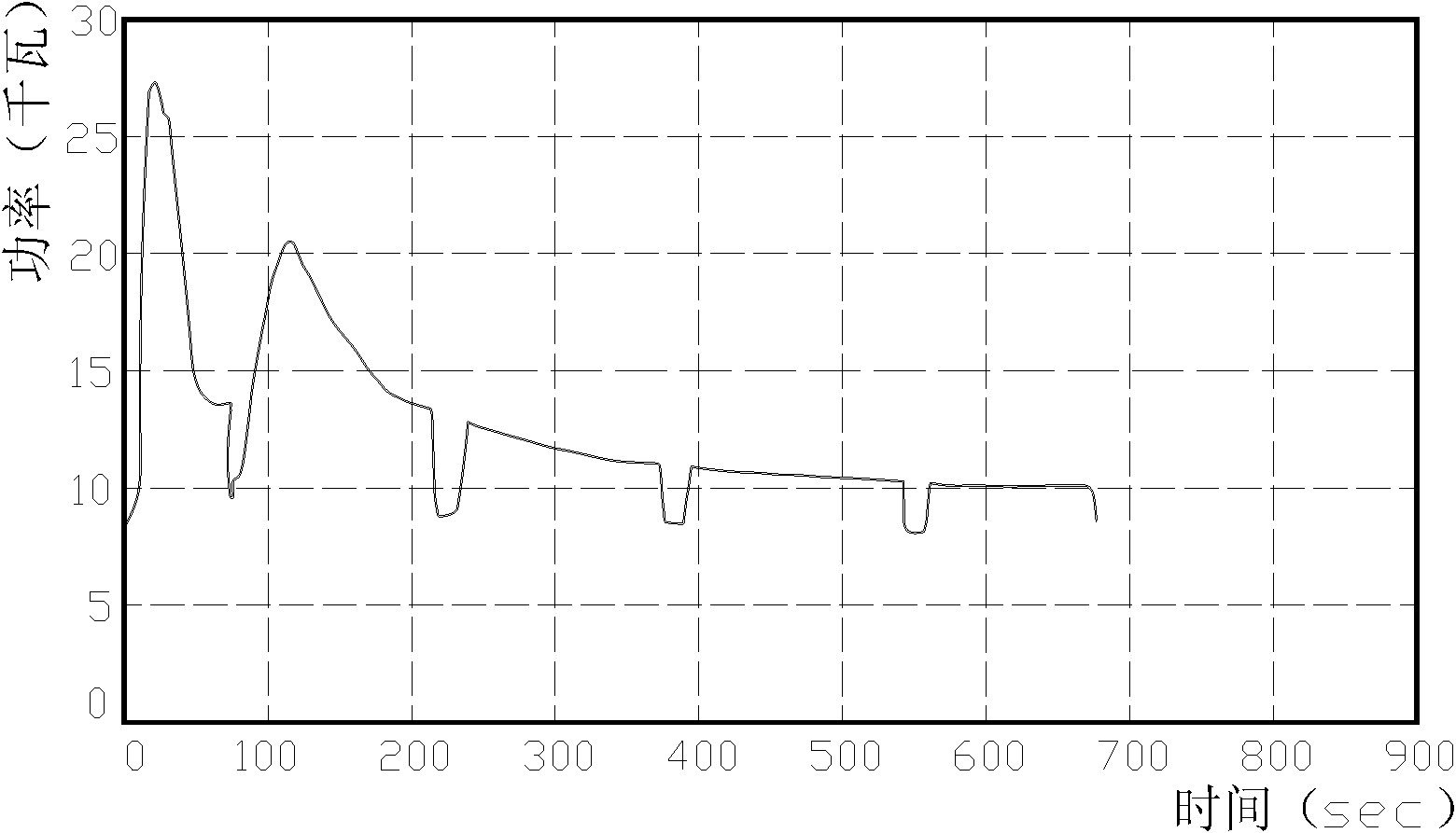

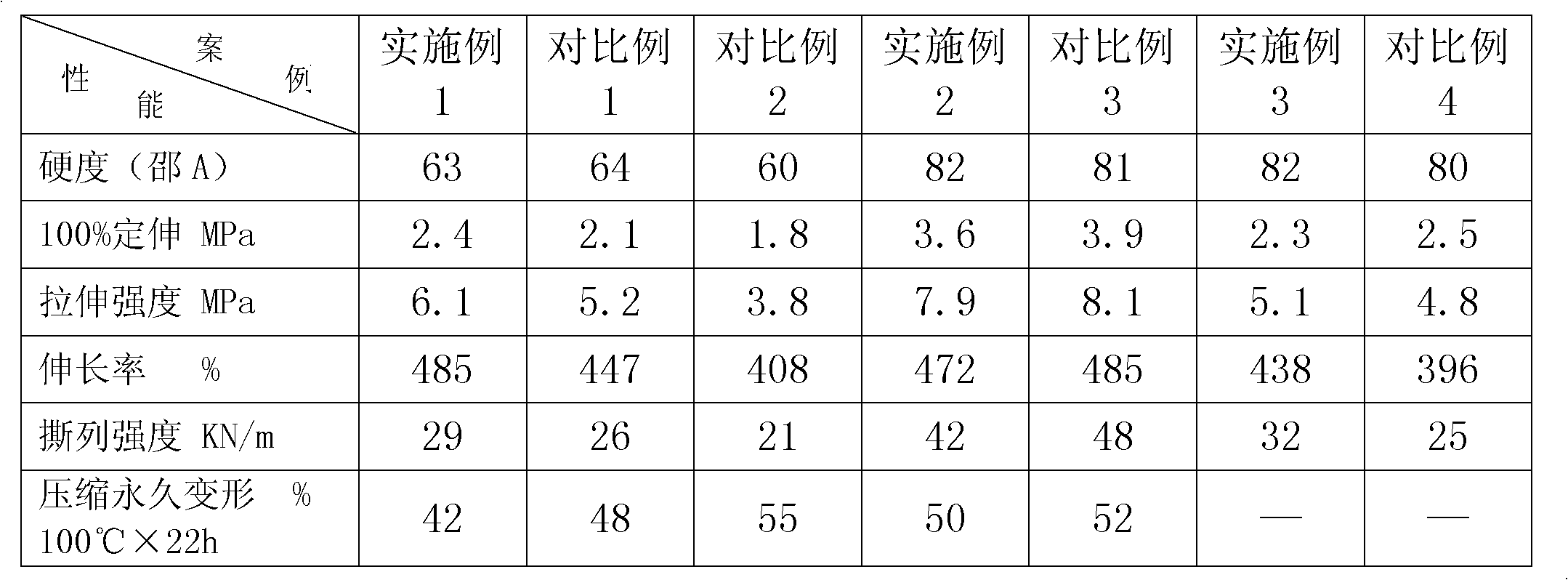

Method for preparing thermoplastic vulcanized rubber

The invention discloses a method for preparing thermoplastic vulcanized rubber and provides technology for preparing the thermoplastic vulcanized rubber by only using common rubber and plastic equipment. The common rubber and plastic equipment comprises a common rubber kneading machine and a heating temperature control system thereof, an open mill, a plastic crusher and a plastic extruder, wherein the temperature range of the heating temperature control system of the common rubber kneading machine is controlled to be between 100 and 220 DEG C; the blending process of the thermoplastic vulcanized rubber kneading machine comprises the following steps of: firstly pre-preparing rubber mixing glue; then blending the rubber mixing glue with the rubber kneading machine; and adding the mixture bysteps when the using amount of a softening agent or plastic is over 25 percent of the total capacity of mixing. The method creates a precedent of preparing the thermoplastic vulcanized rubber by using the common rubber and plastic equipment. The properties such as tensile strength, tear strength, dispersion, extrusion appearance and the like of the prepared thermoplastic vulcanized rubber are obvious better than those of the thermoplastic vulcanized rubber prepared by the prior art. Meanwhile, the method reduces equipment investment and production cost for TPV manufacturers.

Owner:GUANGZHOU SCUT BESTRY TECHNOLOGY CO LTD

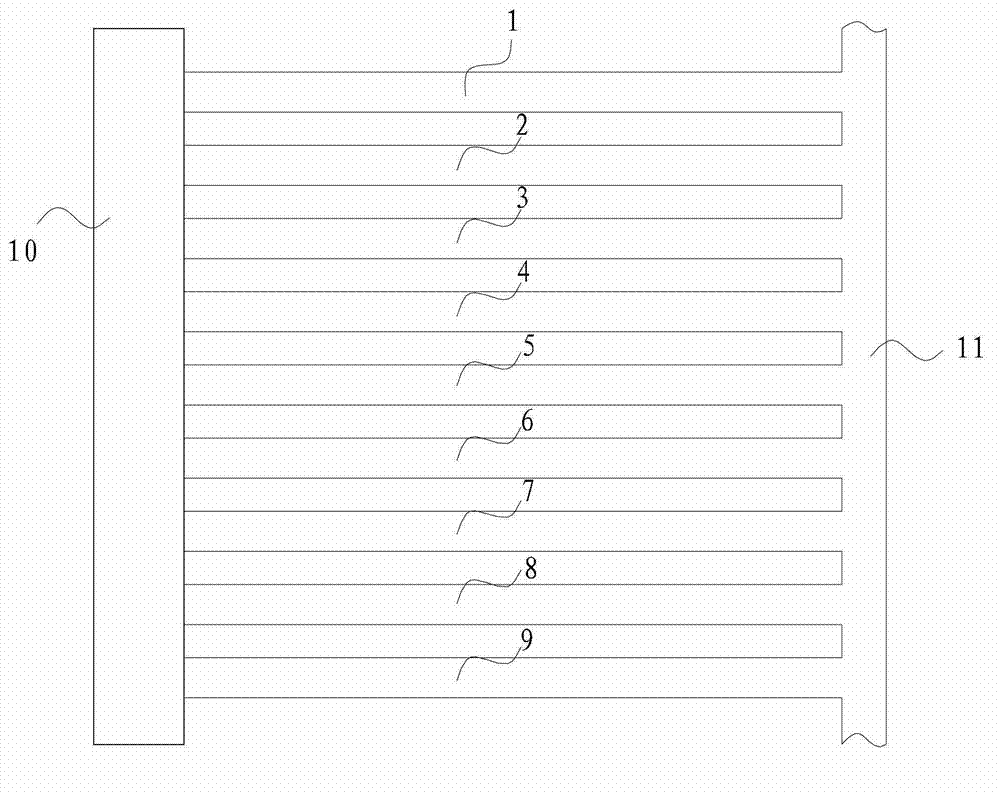

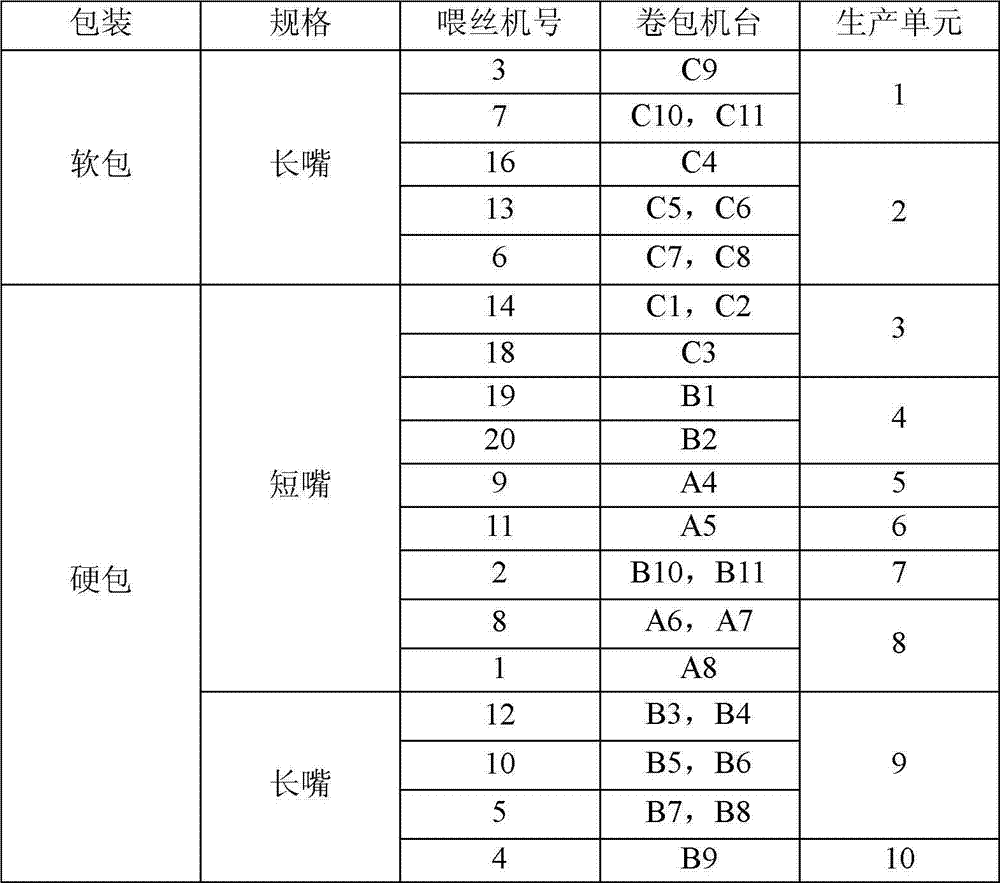

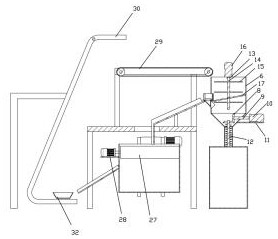

Finished product cigarette tobacco blending method in grouped processing mode and blending equipment

The invention discloses a finished product cigarette tobacco blending method in a grouped processing mode. The method comprises a step of selecting 9 passes respectively in different measurement ranges to carry out a blending procedure according to different usage amount of cigarette tobaccos, expanded cigarette tobaccos, cut stems, slice cigarette tobaccos and recycled cigarette tobaccos. The invention also discloses blending equipment for implementing the finished product cigarette tobacco blending method. According to the finished product cigarette tobacco blending method in the grouped processing mode, different types of cigarette tobaccos are distributed to different passes so as to meet grouped processing demands; in addition, the passes of the cut stems and the slice cigarette tobaccos are added, so that the interval of finished product cigarette tobacco blending proportion and the blending efficiency are improved.

Owner:CHINA TOBACCO ZHEJIANG IND

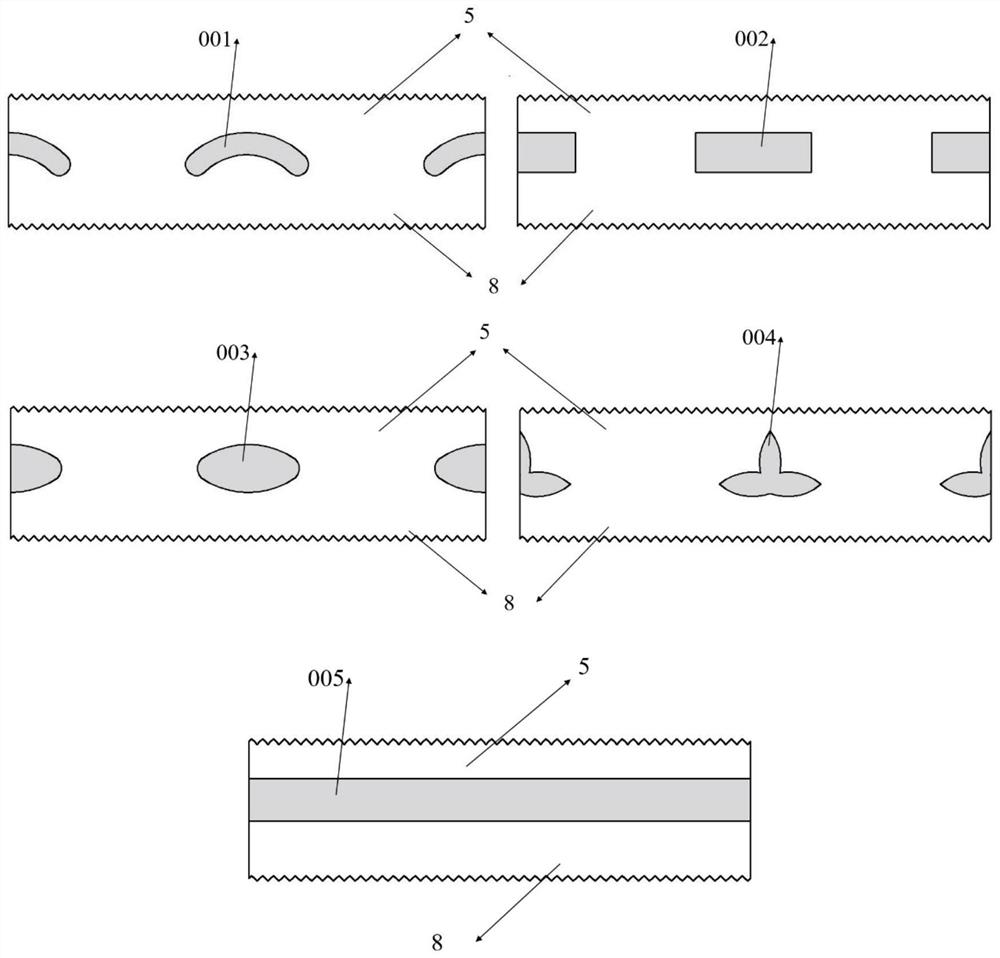

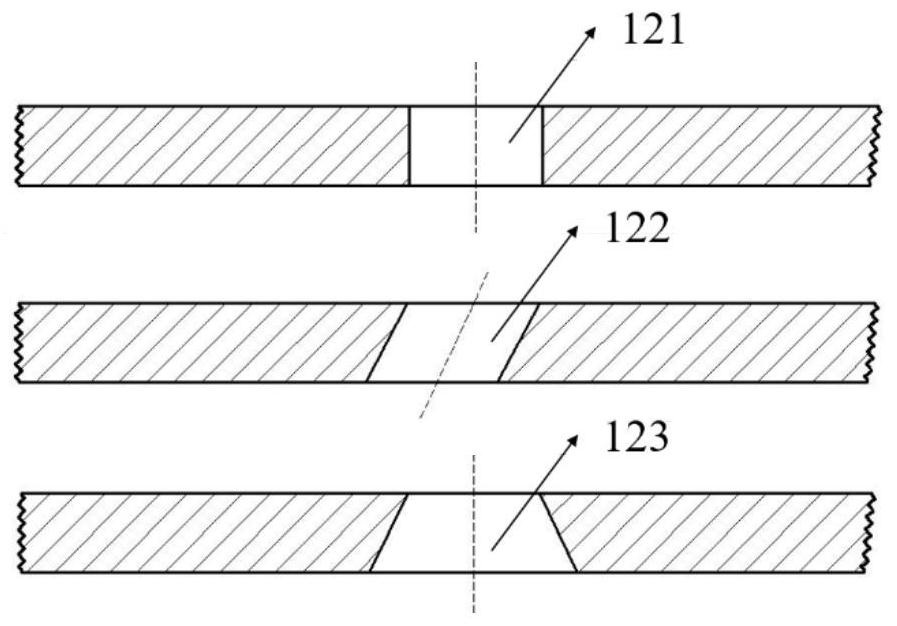

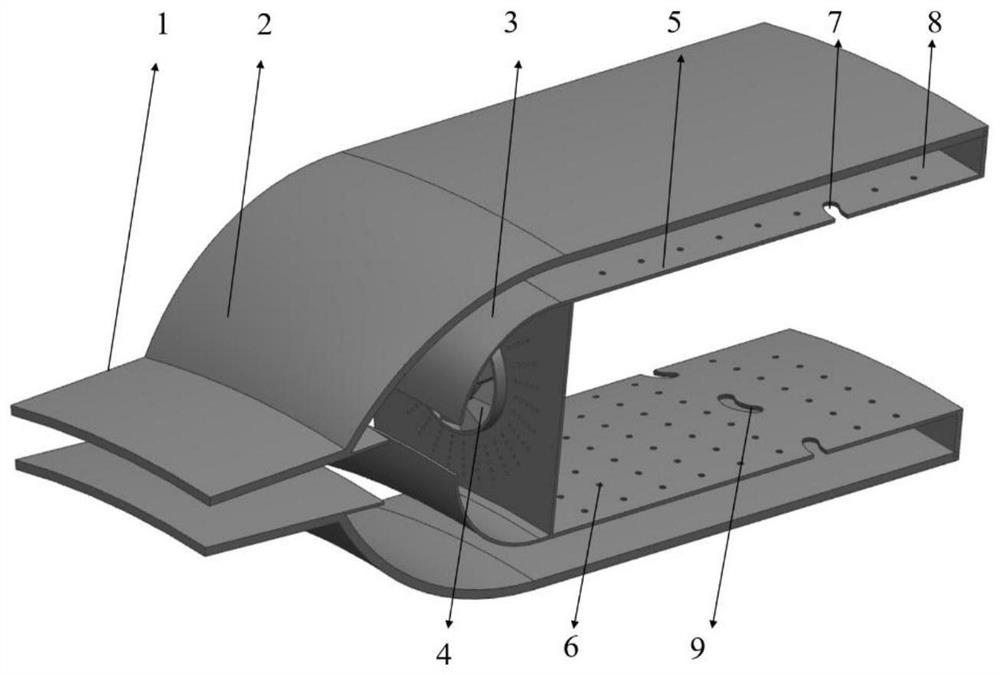

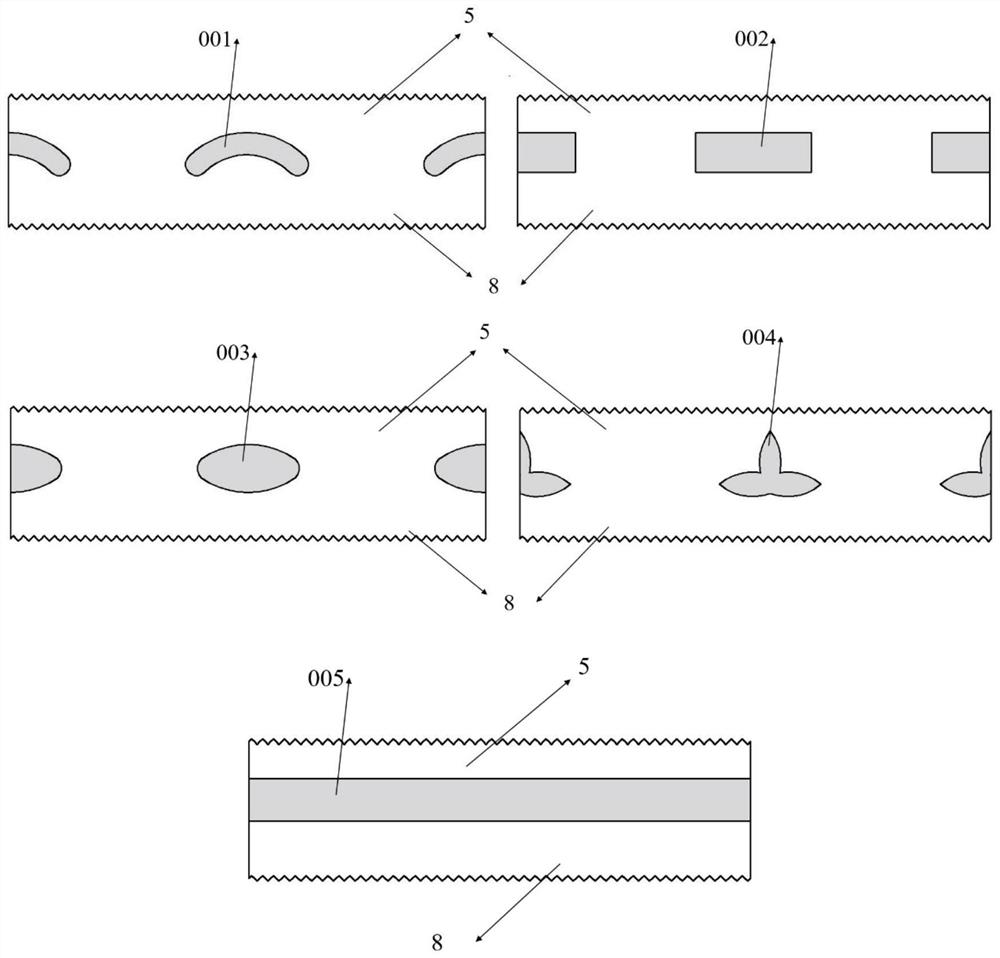

Specially-shaped mixing holes for adjusting outlet temperature distribution of combustion chamber

ActiveCN112146127AIncrease the divergence angleExpand space coverageContinuous combustion chamberCombustion chamberEngineering

The invention discloses specially-shaped mixing holes for adjusting outlet temperature distribution of a combustion chamber, and belongs to the field of combustion of gas turbines. The specially-shaped mixing holes are formed in the inner ring wall surface and the outer ring wall surface of a flame tube of the combustion chamber correspondingly; the specially-shaped mixing holes divide the wall surface of the flame tube into a flame tube front section and a flame tube back section; the specially-shaped mixing holes are evenly distributed in the circumferential direction of the wall surface ofthe flame tube to form mixing jet flows evenly distributed in the circumferential direction, the penetration depth of the mixing jet flows is increased, the contact area of mixing cold air and high-temperature main stream gas is increased, the mixing effect is improved, and the outlet temperature distribution quality of the combustion chamber is improved; the effect of adjusting outlet temperaturedistribution of the combustion chamber is achieved by changing the jet flow penetration depths, the jet flow circumferential expansion angles and the jet flow directions of the mixing holes; and outlet temperature distribution of the combustion chamber is adjusted, so that the temperature quality of an inlet of a turbine is improved, the service life of the turbine is prolonged, and the heat-proof design difficulty of the turbine is reduced.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

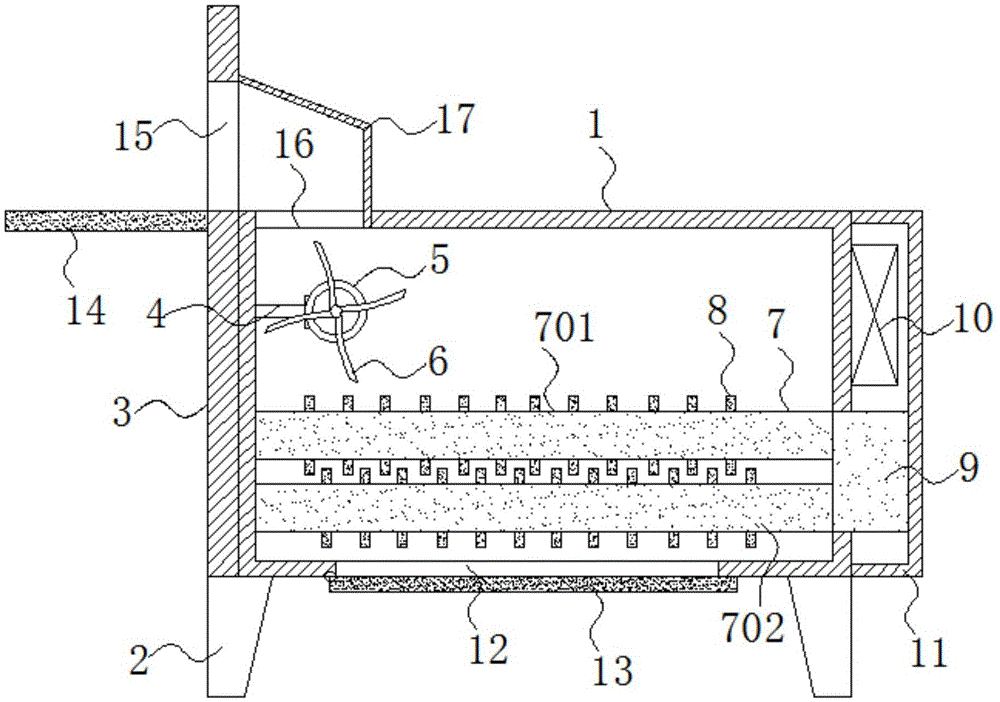

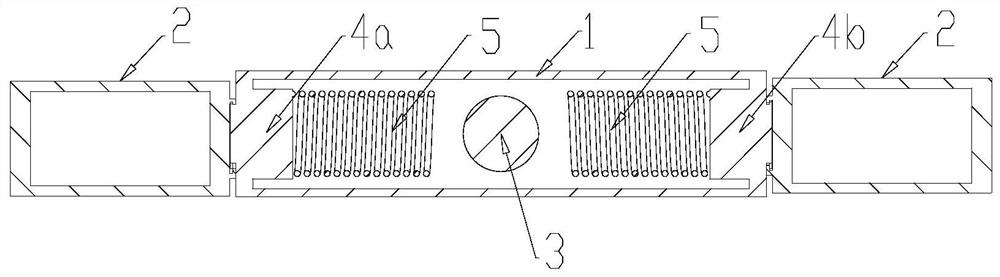

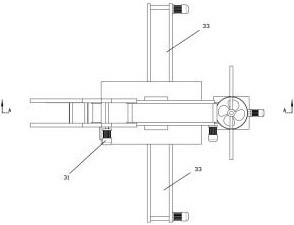

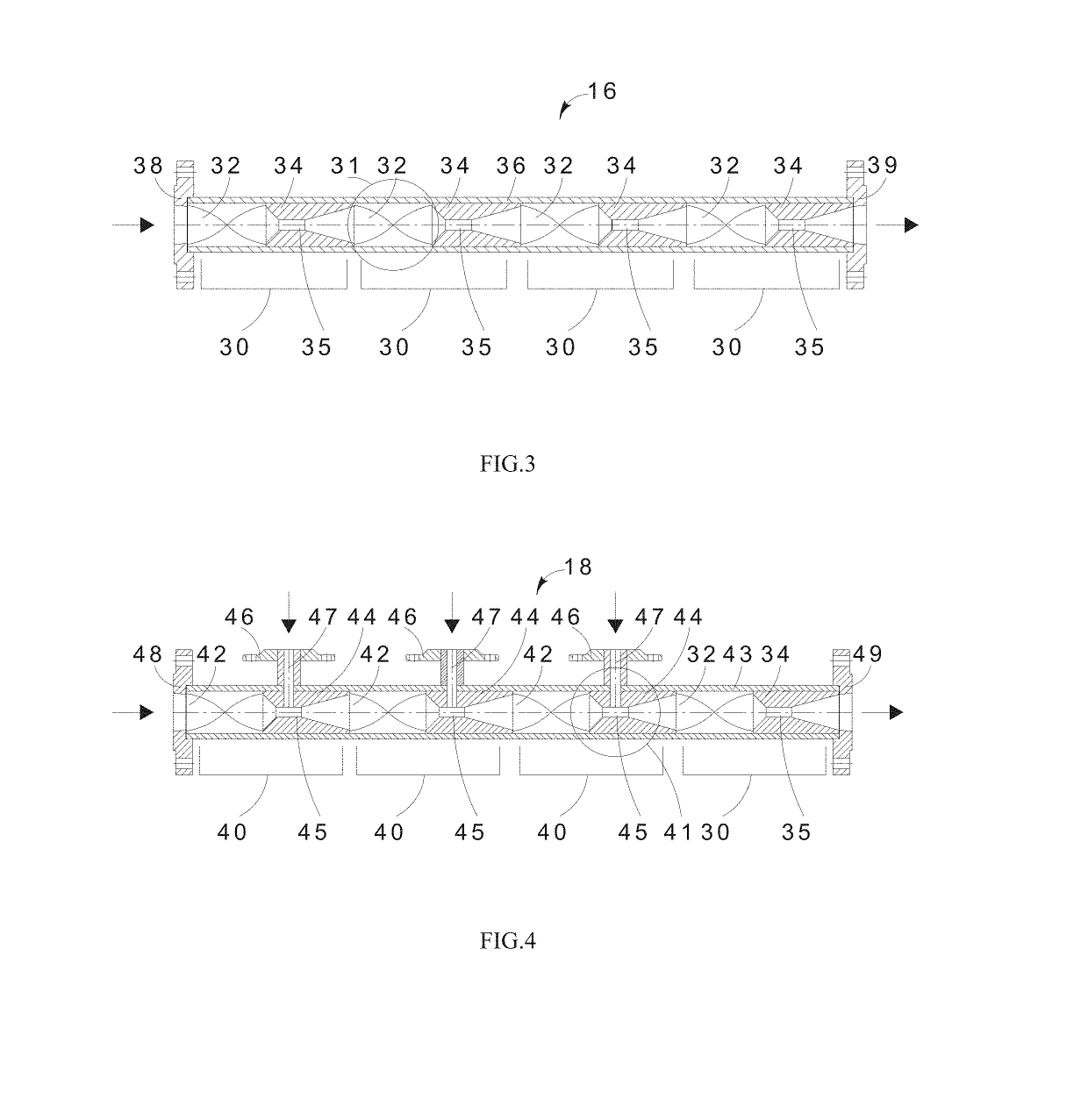

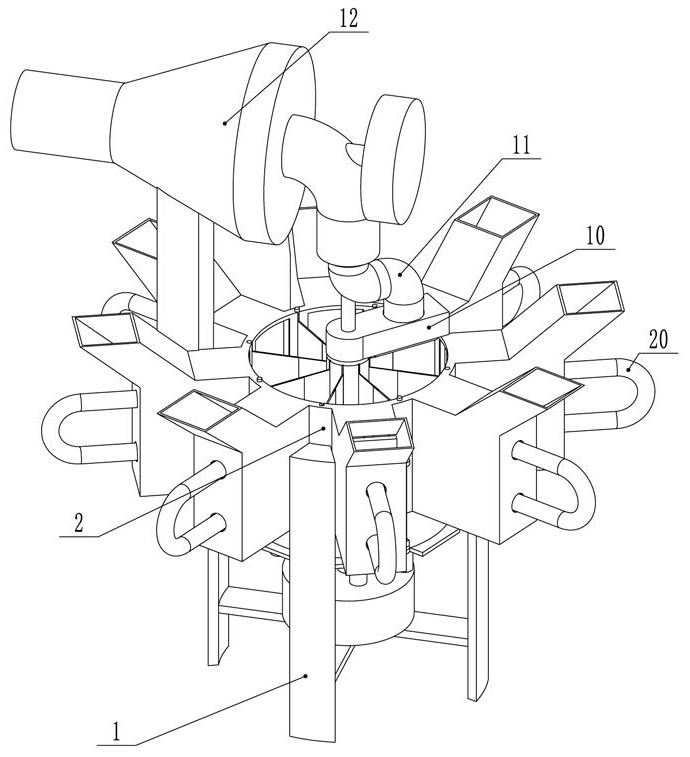

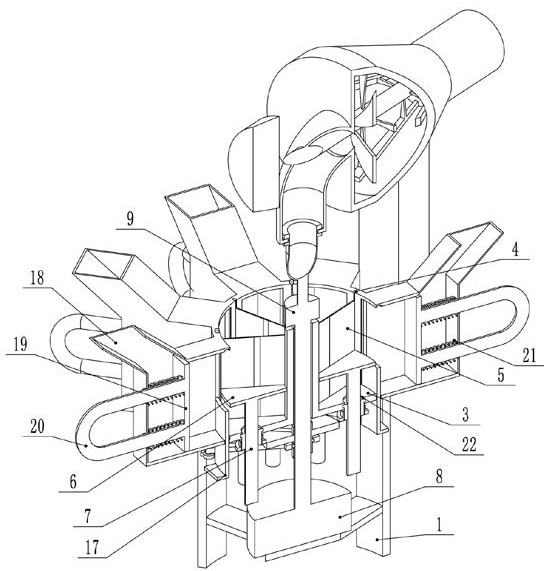

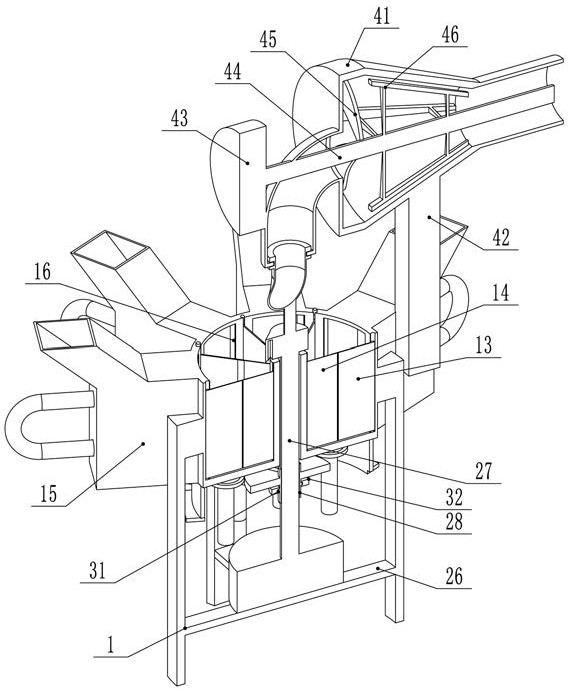

Blowing multi-cabin cotton mixing machine

PendingCN107177906AImprove blending efficiencyWell mixedFibre cleaning/opening by toothed membersFibre mixingEngineeringVALVE PORT

The invention discloses a blowing multi-cabin cotton mixing machine which comprises a cotton feeding channel, a cotton feeding roller, a cotton feeding fan, a first cotton mixing cabin, a second cotton mixing cabin, a swinging valve, an indicator and a cotton discharging channel, wherein the swinging valve is arranged on the lower part of the first cotton mixing cabin; the indicator is arranged above the swinging valve; the first cotton mixing cabin is communicated with the bottom of the second cotton mixing cabin; the first cotton mixing cabin comprises a first cotton feeding valve, a first cotton mixing screw arranged on the lower part of the first cotton feeding valve, two first rollers and a first beater arranged on the lower part of the first cotton mixing cabin; the second cotton mixing cabin comprises a second cotton feeding valve, a second cotton mixing screw arranged on the lower part of the second cotton feeding valve, two second rollers and a second beater arranged on the lower part of the second cotton mixing cabin; a first cotton mixing stab is arranged on the first cotton mixing screw; a second cotton mixing stab is arranged on the second cotton mixing screw. The blowing multi-cabin cotton mixing machine provided by the invention can uniformly mix the cotton products with different densities and the cotton mixing efficiency of the cotton mixing machine is high.

Owner:NINGXIA RUYI SCIENCE & TECHNOLOGY FASHION INDUSTRY CO LTD

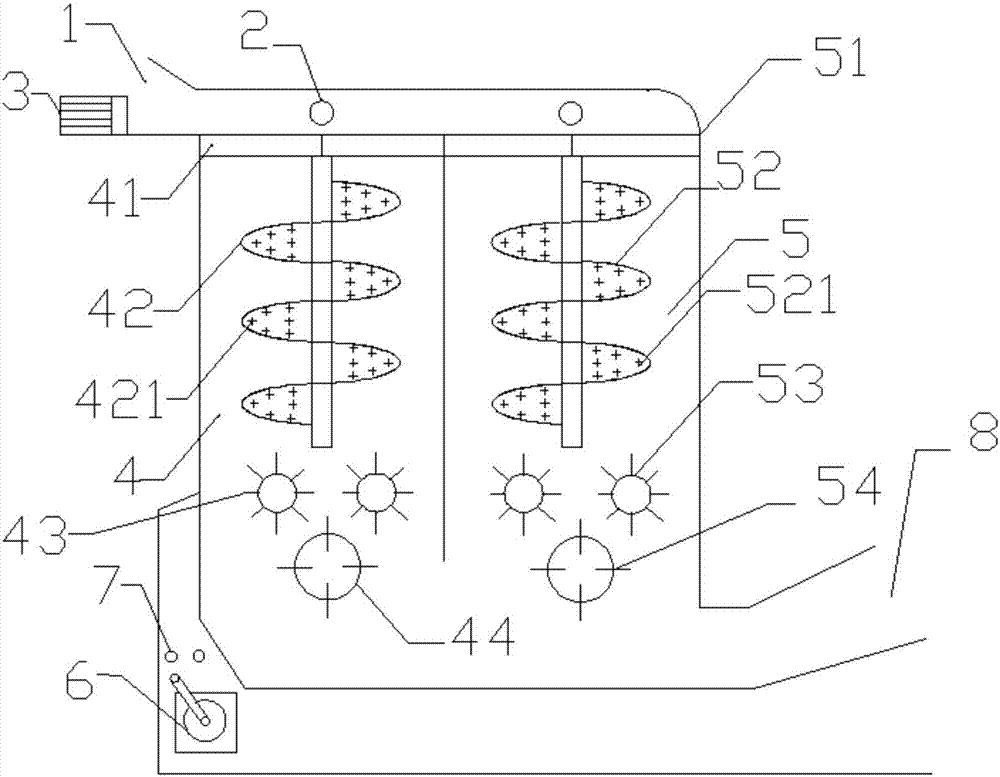

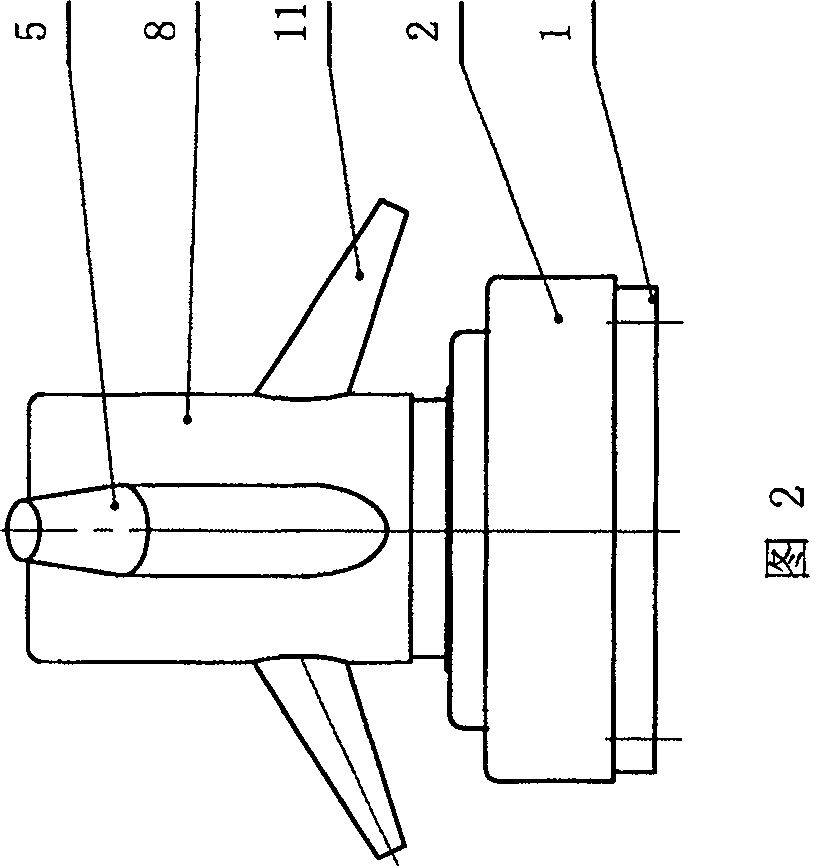

Dual-fuel nozzle structure of gas turbine

ActiveCN104154566AConvenience to workImprove blending efficiencyContinuous combustion chamberGas turbinesFuel gas

The invention relates to the technical field of gas turbines, and discloses a dual-fuel nozzle structure of a gas turbine. The dual-fuel nozzle structure of the gas turbine comprises a nozzle body, a medium-low heat value fuel gas whirlcone, a natural gas whirlcone and an end face whirlcone. The nozzle body comprises a slightly-blowing air barrel, a natural gas barrel, a nozzle air barrel and a medium-low heat value fuel gas barrel with the inner diameters being sequentially increased, and the barrels are isolated from one another. The end face whirlcone is arranged on the outlet end face of the nozzle air barrel. The natural gas whirlcone is arranged on the inner side wall of the natural gas barrel. The medium-low heat value fuel gas whirlcone is arranged on the inner side wall of the outlet end of the medium-low heat value fuel gas barrel, the medium-low heat value fuel gas whirlcone comprises a plurality of blades, and the blades are connected with the inner side wall of the medium-low heat value fuel gas barrel and the outer side wall of the nozzle air barrel. Each blade is provided with an air channel, and the air channels are communicated with the nozzle air barrel and an outside air flow channel of the medium-low heat value fuel gas barrel. An end face cover plate is arranged on the outlet end face of the slightly-blowing air barrel, and the end face cover plate is provided with a plurality of slightly-blowing air holes.

Owner:CHINA UNITED GAS TURBINE TECH CO LTD

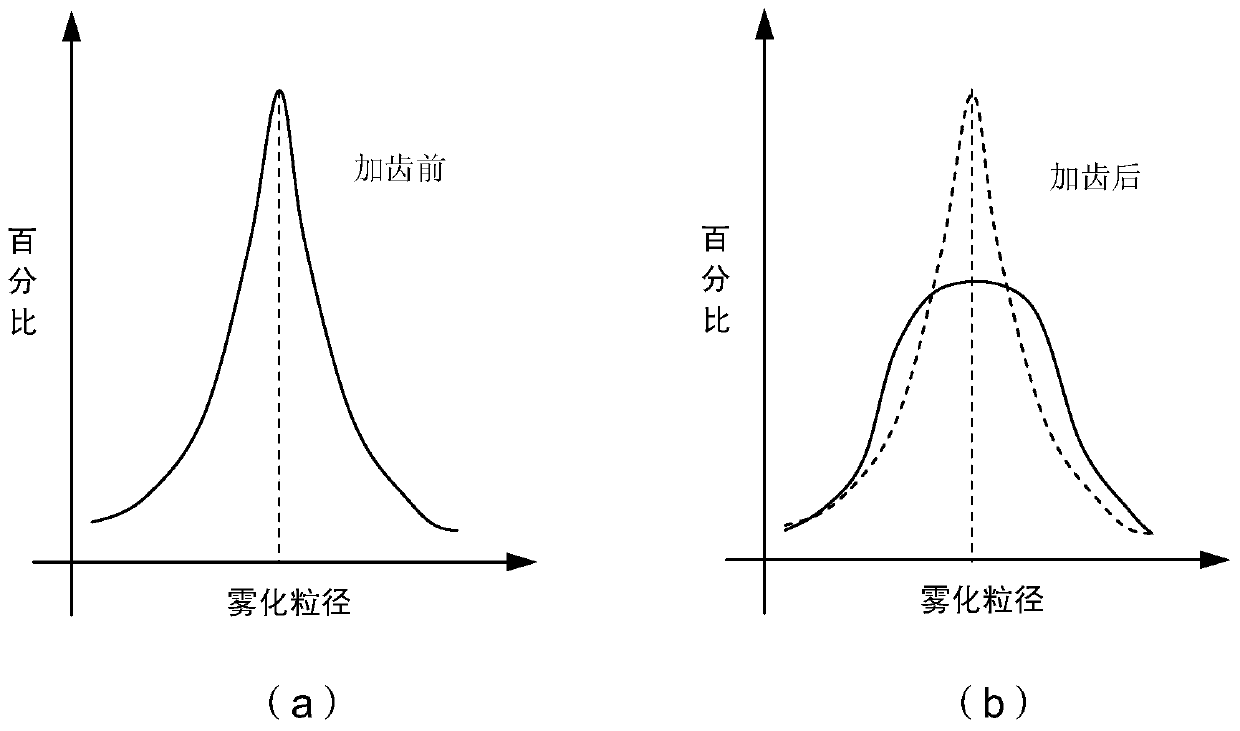

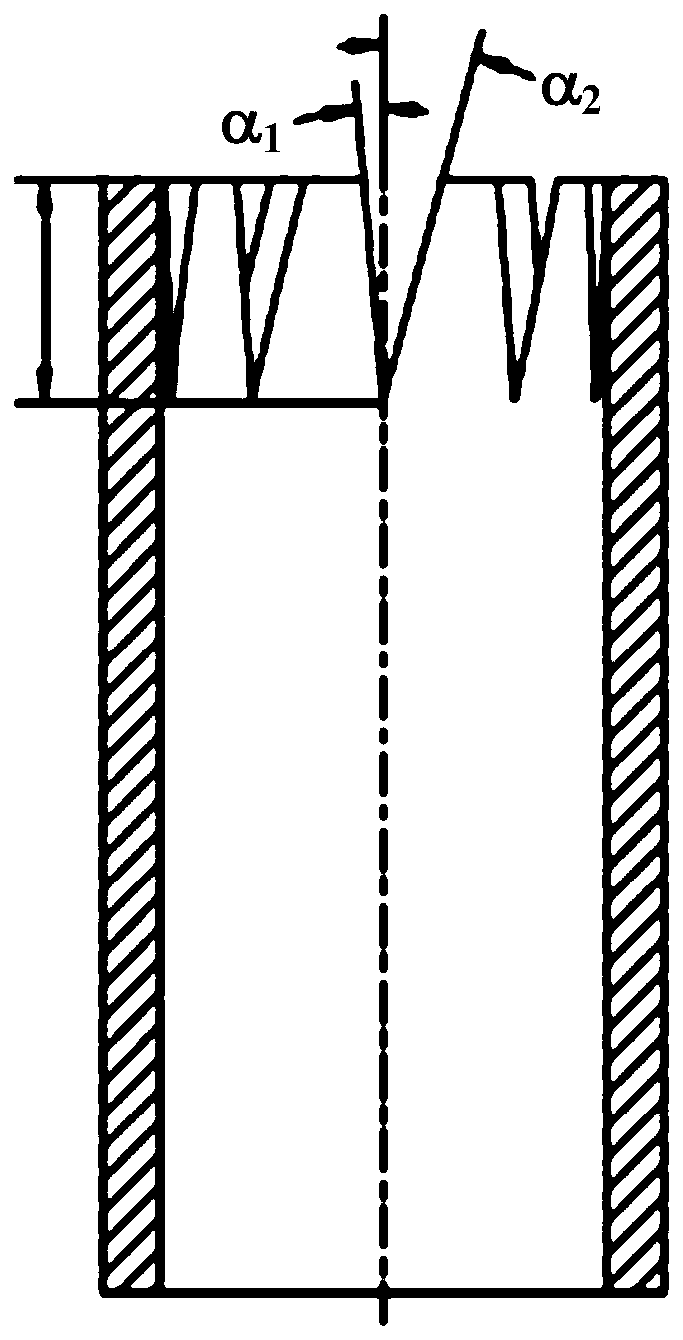

Gas-liquid coaxial shear type nozzle based on lip-mouth saw tooth design

The invention discloses a gas-liquid coaxial shear type nozzle based on lip-mouth saw tooth design. The gas-liquid coaxial shear type nozzle comprises an outer nozzle and an inner nozzle, the outer nozzle is arranged on the outer surface of the inner nozzle in a sleeving mode, the outer nozzle and the inner nozzle are coaxial, the lip mouth of the inner nozzle is located in the outer nozzle, a plurality of saw teeth are formed in the lip mouth of the inner nozzle in the circumferential direction of the inner nozzle, the inner nozzle is used for circulating the liquid, and the position betweenthe outer nozzle and the inner nozzle is used for circulating the gas. The gas-liquid coaxial shear type nozzle solves the contradiction between improving of the fuel atomization blending mixing efficiency and combustion stability of the gas / liquid coaxial shear nozzle and reducing of the risk of nozzle ablation.

Owner:XIAN AEROSPACE PROPULSION INST

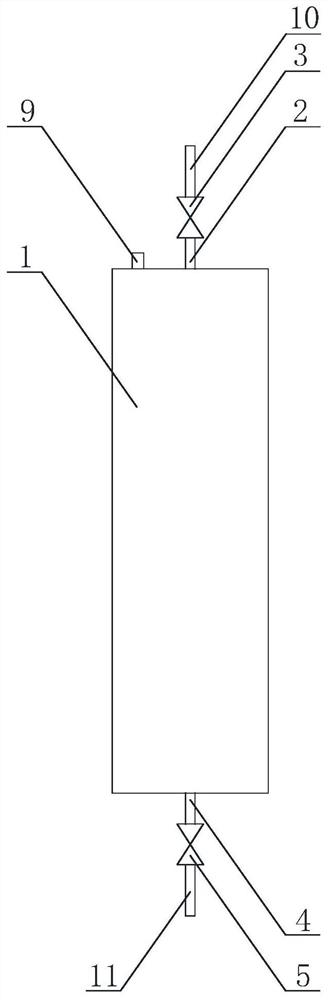

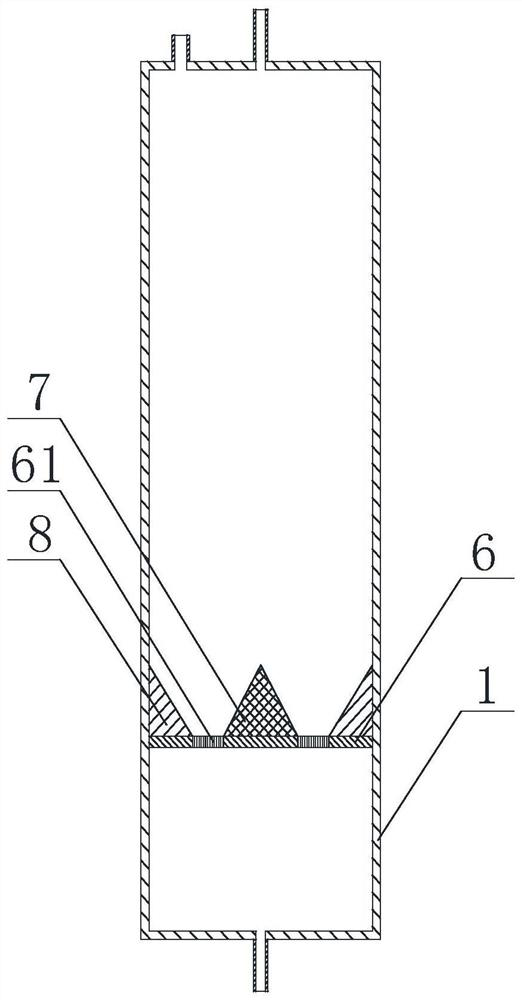

Uniform particle airflow generation device and method for flow field tracing

PendingCN113743034AImprove impact performanceAvoid sediment agglomerationDesign optimisation/simulationEngineeringCaking

The invention discloses a uniform particle airflow generation device and method for flow field tracing, and the device comprises a container, the top of the container is provided with a particle feed inlet and a gas outlet, the gas outlet is connected with an airflow guide pipe through a first valve, the bottom of the container is provided with a gas inlet, and the gas inlet is connected with a gas source guide pipe through a second valve. A first partition plate is arranged in the container, an annular body extending in the circumferential direction of the first partition plate and a cone located on the inner side of the annular body are arranged on the upper surface of the first partition plate, an accumulation area used for accumulating particles is formed between the cone and the annular body, the width of the accumulation area is gradually reduced from top to bottom, and a gas hole area is further arranged on the first partition plate. A plurality of first through holes is formed in the air hole area, and included angles exist between the axes of the first through holes and the axis of the container. The invention has the characteristics of no particle deposition and caking, uniform particle mixing and long particle airflow duration, and is suitable for gas flow fields and combustion flow fields with various speeds and temperatures.

Owner:中国空气动力研究与发展中心设备设计与测试技术研究所

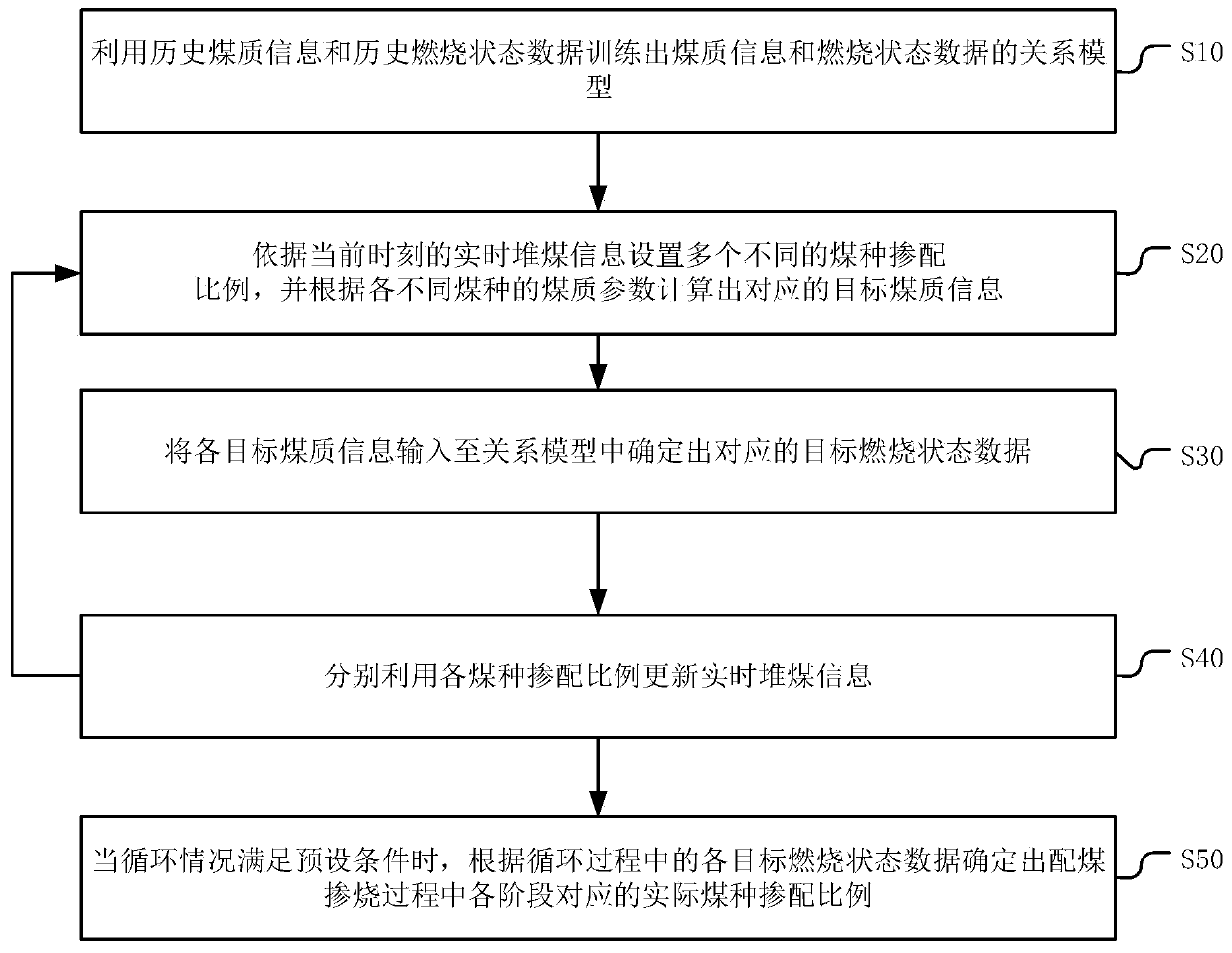

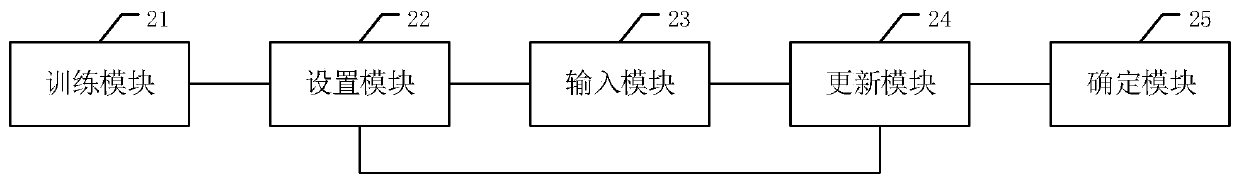

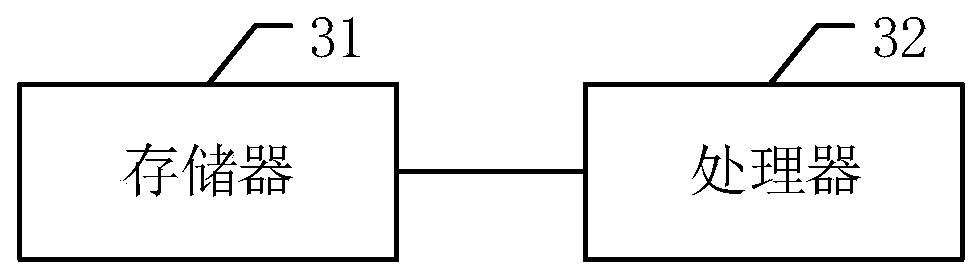

Coal blending combustion method, device and equipment and computer readable storage medium

ActiveCN111311023AImprove blending efficiencyAvoid coal blendingForecastingResourcesThermodynamicsProcess engineering

The invention discloses a coal blending combustion method, device and equipment and a medium. The method comprises the steps that a relation model of coal quality information and combustion state datais trained through historical coal quality information and historical combustion state data; setting a plurality of different coal blending proportions according to the real-time coal piling information at the current moment, and calculating corresponding target coal quality information according to the coal quality parameters of different coal types; inputting the target coal quality informationinto a relation model to determine corresponding target combustion state data; respectively updating the real-time coal piling information by utilizing the blending proportion of each coal type, andcontinuously setting the blending proportion of the coal types for cyclic calculation; and when the circulation condition meets a preset condition, determining an actual coal blending proportion corresponding to each stage in the coal blending combustion process according to each target combustion state data in the circulation process. According to the method, the coal blending combustion efficiency can be improved, and the operation cost is reduced.

Owner:华润电力技术研究院有限公司

Rotary oil-jetting mixer

The present invention relates to one kind of rotary oil-jetting mixer. The mixer has a pedestal, an inner rotary sleeve on the pedestal, a rotating drum fixed onto the inner sleeve, a reduction box with ring gear fastened to the top of the rotating drum and meshed to last outer gear and initial gear on the upper end of the spindle, an axial flow turbine in the lower end of the spindle, and upper nozzles and lower nozzles communicated to the inner cavity and on the outer wall of the rotating drum. The present invention drives the nozzles to rotate with the liquid flow to spray out oil and other material and to form eddy diffusion in high mixing efficiency and without dead zone.

Owner:江西省仁达实业有限责任公司

Tight coupling ring rectangular hole gas nozzle atomizer capable of improving atomization efficiency

The invention provides a tight coupling ring rectangular hole gas nozzle atomizer capable of improving the atomization efficiency which comprises a liquid guide pipe and a lower body arranged on the outer surface of the liquid guide pipe in a sleeved mode; the atomizer comprises an upper body which is a hollow tube body structure and is sleeved outside the lower body, and a closed gas parking space capable of stabilizing the gas pressure is formed between the upper body and the lower body; the inner surface of the upper body end port is a conical surface or a conical-shape surface which is inclined towards the tail end of the liquid guide pipe; the outer surface of the lower body end port is in sealing contact with the conical surface or the conical-shape surface of the upper body througha corresponding cone shape surface, between the contact of lower body and the upper body; and a plurality of rectangular gas nozzles communicating with the outside and the gas parking space are uniformly arranged along the circumference. The rectangular channel can be a two-dimensional contraction type or two-dimensional contraction-expand (laval) type gas nozzle. According to the atomizer, the efficiency for the kinetic energy of the high-speed airflow on the relatively static liquid and liquid drops is improved, and the liquid and the liquid drops are atomized into finer liquid drops.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

Raw cotton mixing device capable of effectively preventing raw cotton from being accumulated to add

InactiveCN105568436ASlow down mixing speed and mixing qualityImprove efficiencyFibre mixingPropellerEngineering

The invention discloses a raw cotton mixing device capable of effectively preventing raw cotton from being accumulated to add. The raw cotton mixing device comprises a mixing box body, support legs and a vertical plate, wherein the vertical plate is arranged at one side of the mixing box body; a feeding opening is formed in the top part of the mixing box body; a roller group is arranged in the mixing box body; a drive device is arranged at one end of the roller group; the roller group comprises a first roller and a second roller, which are arranged in parallel; rolling teeth are arranged on the first roller and the second roller; a support rod is arranged on the inner wall of one side of the mixing box body; a motor is arranged at one end of the support rod; a propeller is arranged at an output end of the motor; a discharge opening is formed in the bottom part of the mixing box body; one side of the discharge opening is hinged with a cover board; a power distribution box is arranged at one side of the drive device; the motor and the drive device are electrically connected to the power distribution box; and the raw cotton at the feeding opening is rotated into the mixing box body little by little by the propeller, so that the raw cotton is prevented from being accumulated to add to the mixing box body; and the mixing efficiency and quality are improved.

Owner:周盈裕

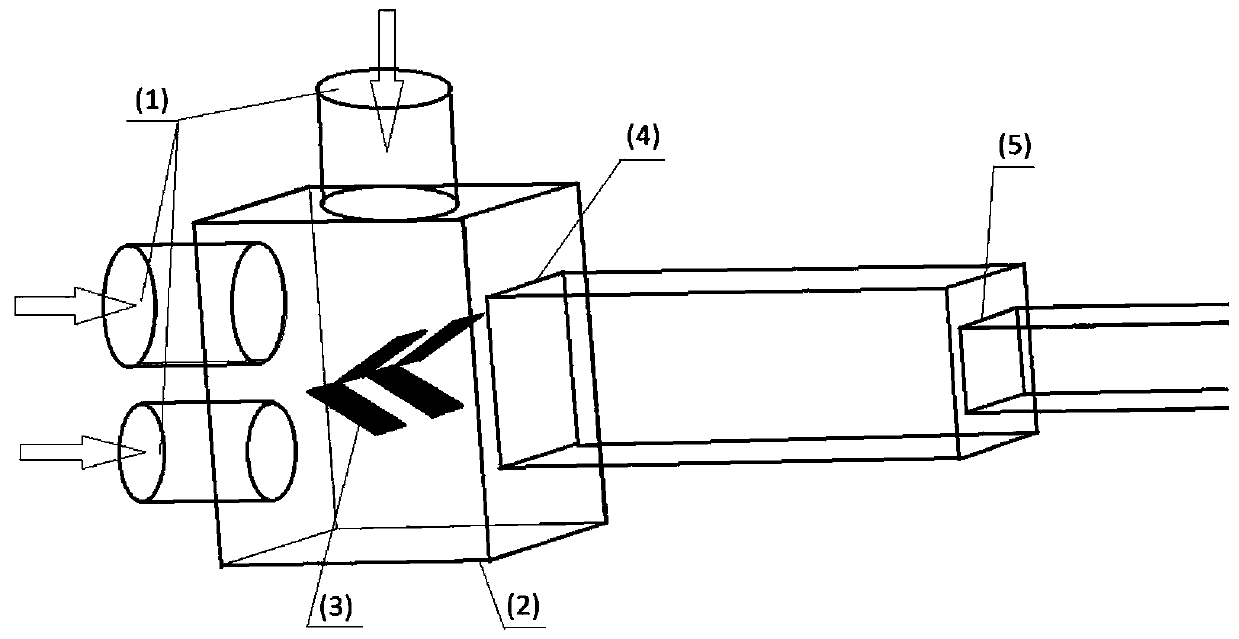

High-efficiency compact type mixer with asymmetric blade grid structure

PendingCN110559900AWell mixedReduce turbulenceFlow mixersTransportation and packagingShortest distanceEngineering

The invention discloses a high-efficiency compact type mixer with an asymmetric blade grid structure. The high-efficiency compact type mixer comprises a blending cavity and multi-channel and multi-direction inlets communicating with the blending cavity, wherein the asymmetric blade grid structure is distributed in the blending cavity, and an outlet of the blending cavity communicates with a first-stage sudden contraction section and a second-stage sudden contraction section in sequence. By sufficient utilization of multi-channel and multi-direction incoming flow conditions, two streams of blended gas are increased to be multiple streams, and the engineering application is wider; the asymmetric blade grid structure is added to the blending cavity, the turbulence intensity in the gas flow cavity is increased, and mass and heat transfer capacities among multiple streams of gas flow are improved; and the two stages of sudden contraction sections are used for performing rectification, scaleof turbulence is rapidly reduced in short distance, uniformly mixed fluid is obtained, follow-up work failure caused by too large scale of turbulence and non-uniform speed of the blended gas flow isavoided, and therefore, the use requirement of synchronous good mixing of multiple streams of gas flow in short distance and in compact space is met.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

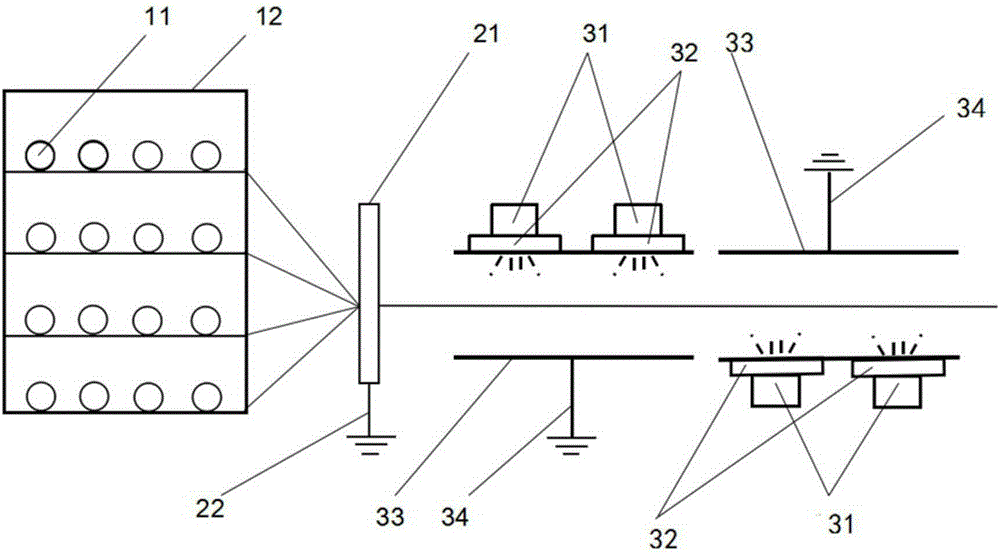

Device for fiber blending

ActiveCN106521722AGood effectImprove blending efficiencyFibre mixingFilament/thread formingFiberYarn

The application provides a device for fiber blending. The device comprises a yarn frame, a parallel yarn arrangement device and an electrostatic spinning system. The device is improved in that the fiber blending course is completed through an electrostatic spinning manner; and yarn blending of micron-grade reinforced fibers and nano-grade thermoplastic fibers can be achieved. In comparison with the prior art, the device for the fiber blending of the reinforced fibers and the thermoplastic nano fibers provided by the application has the advantages that the structure is simple; operations are easily; and the efficiency of the fiber blending of the thermoplastic nano fibers and the reinforced fibers is greatly increased.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +1

A Pre-swirl Pintle Injector Applied to Bicomponent Liquid Rocket Engine

ActiveCN108286478BImprove blending efficiencyImprove performanceRocket engine plantsOxidizing agentLiquid-propellant rocket

The invention discloses a pre-whirling type pintle injector applied to a double-component liquid propellant rocket engine. The pre-whirling type pintle injector applied to the double-component liquidpropellant rocket engine comprises a center rod, an inner nozzle, an outer nozzle and a connecting ring, all of which are rotation bodies. The inner nozzle coaxially sleeves the center rod, and a cavity for conveying fuel is formed by the inner nozzle and the center rod. The outer nozzle coaxially sleeves the outer nozzle, a cavity for conveying an oxidizing agent is formed by the outer nozzle andthe inner nozzle, and the connecting ring coaxially sleeves the outer nozzle. Pre-whirling treatment is conducted before oxidizing agent spraying-out, and the problem that a conventional pintle injector is not high in effective mixing efficiency is effectively solved; meanwhile, through the arrangement of two rows of fuel direct flow injection holes, cooling to a liquid film on the wall face of athrust chamber through propellant is effectively achieved; and the performance and the reliability of the double-component liquid propellant rocket engine can be obviously improved.

Owner:BEIJING INST OF CONTROL ENG

Rotary oil-jetting mixer

The present invention relates to one kind of rotary oil-jetting mixer. The mixer has a pedestal, an inner rotary sleeve on the pedestal, a rotating drum fixed onto the inner sleeve, a reduction box with ring gear fastened to the top of the rotating drum and meshed to last outer gear and initial gear on the upper end of the spindle, an axial flow turbine in the lower end of the spindle, and upper nozzles and lower nozzles communicated to the inner cavity and on the outer wall of the rotating drum. The present invention drives the nozzles to rotate with the liquid flow to spray out oil and other material and to form eddy diffusion in high mixing efficiency and without dead zone.

Owner:江西省仁达实业有限责任公司

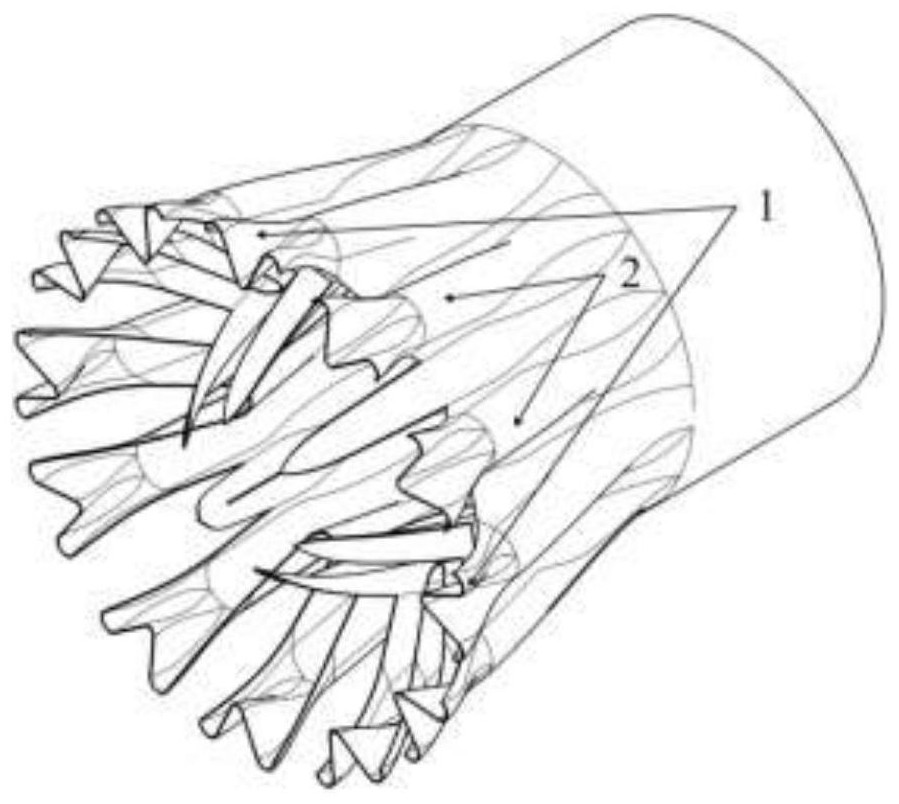

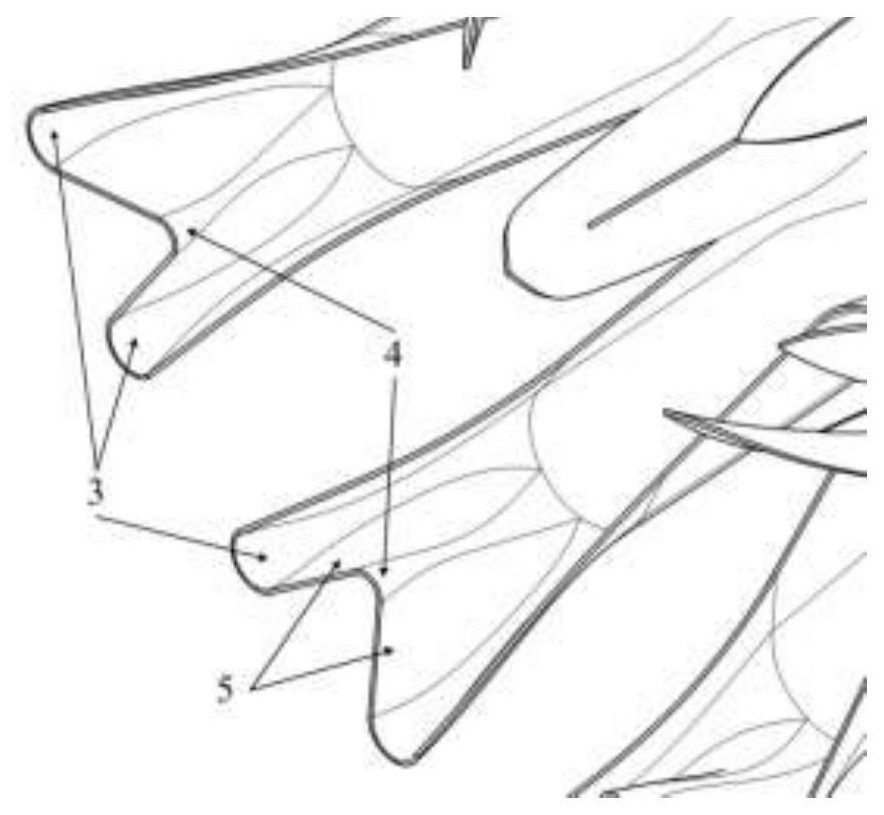

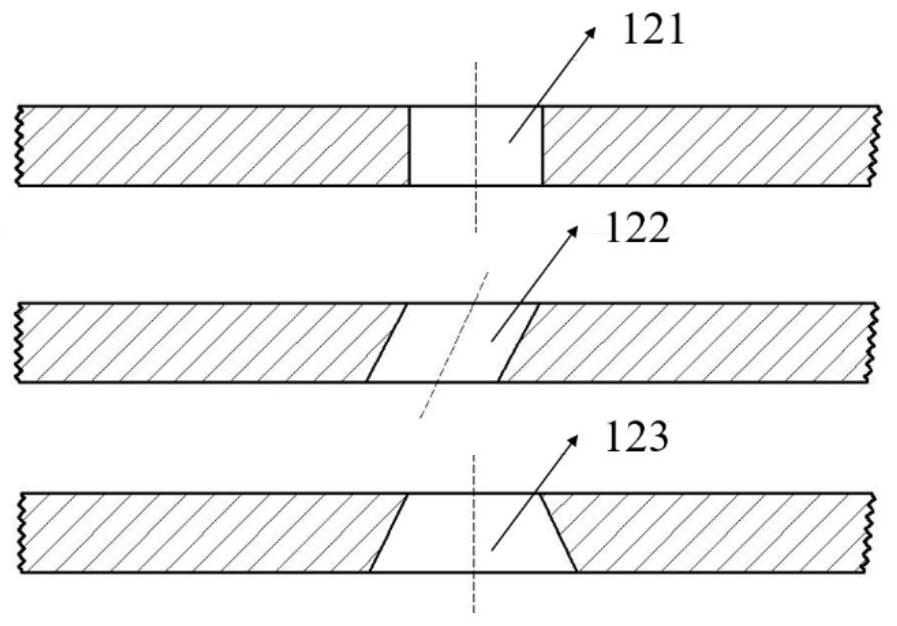

Lobe-shaped wave crest for inner beveled or fan-shaped treatment lobe spray pipe

InactiveCN113047979AImprove blending efficiencyMixing effect is smallJet propulsion plantsMechanical engineeringWave crest

The invention relates to a lobe-shaped crest for an inner beveled or fan-shaped treatment lobe spray pipe. The part, behind the cross section, of an outer lobe of the inner beveled or fan-shaped treatment spray pipe is cut off through the cross section perpendicular to the axis of the spray pipe, then lobe-shaped spoilers extend out of a new trailing edge formed through the cutting, and lobe-shaped wave crests are formed, and the lobe-shaped wave crests are composed of small wave crests on the two sides, small wave troughs in the middles and two small side walls connecting the small wave crests and the small wave troughs. The lobe-shaped wave crest has the advantages and beneficial effects that the lobe spray pipe with lobe-shaped crests is adopted, and the mixing efficiency is high under the conditions of injection air intake and stamping air intake.

Owner:NANCHANG HANGKONG UNIVERSITY

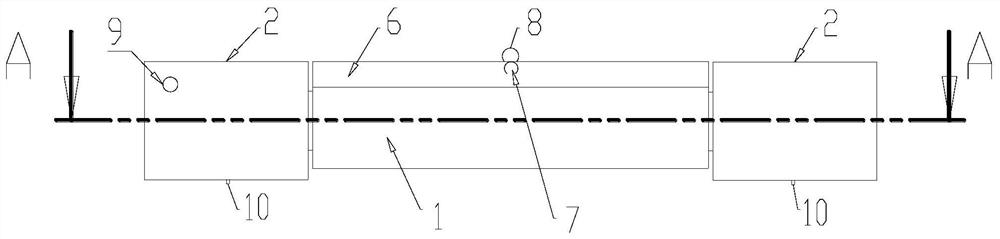

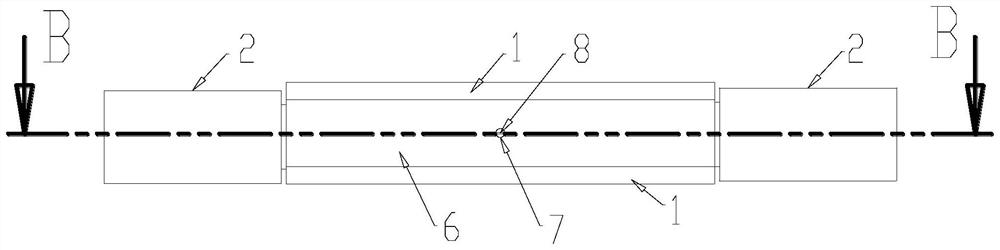

Vertical water body mixing device for improving water quality of eutrophication water temperature stratification reservoir

ActiveCN113332908AExpand the scope of actionImprove mobilityMixersWater/sewage treatmentEutrophicationEngineering

A vertical water body mixing device for improving water quality of a eutrophication water temperature stratification reservoir comprises a main body pipe and two balance water tanks connected to the two ends of the outer side of the main body pipe respectively, wherein a balance weight steel ball capable of moving left and right is arranged in the middle space in the main body pipe; a left electromagnet and a right electromagnet which are used for attracting the counterweight steel ball to move left and right are symmetrically arranged at the two ends in the main body pipe respectively; and the left electromagnet and the right electromagnet are connected through a cable to a control circuit which can enable the left electromagnet and the right electromagnet to generate attraction to the counterweight steel ball at different time. The device has the advantages of being simple in structure, small in size, easy to transport, small in energy loss, large in action range, high in maneuverability, high in mixing efficiency, economical, efficient, capable of solving the problem of reservoir eutrophication and the like, and through hydrodynamic disturbance, mechanical mixing is carried out near a thermocline of a layered water body to increase vertical hydrodynamic turbulent fluctuation, water body internal waves can be induced to be generated by repeatedly penetrating through the thermocline, and water body layering is further relieved.

Owner:TIANJIN UNIV

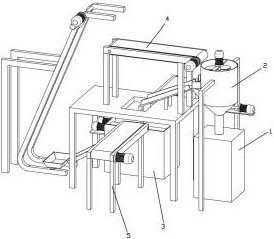

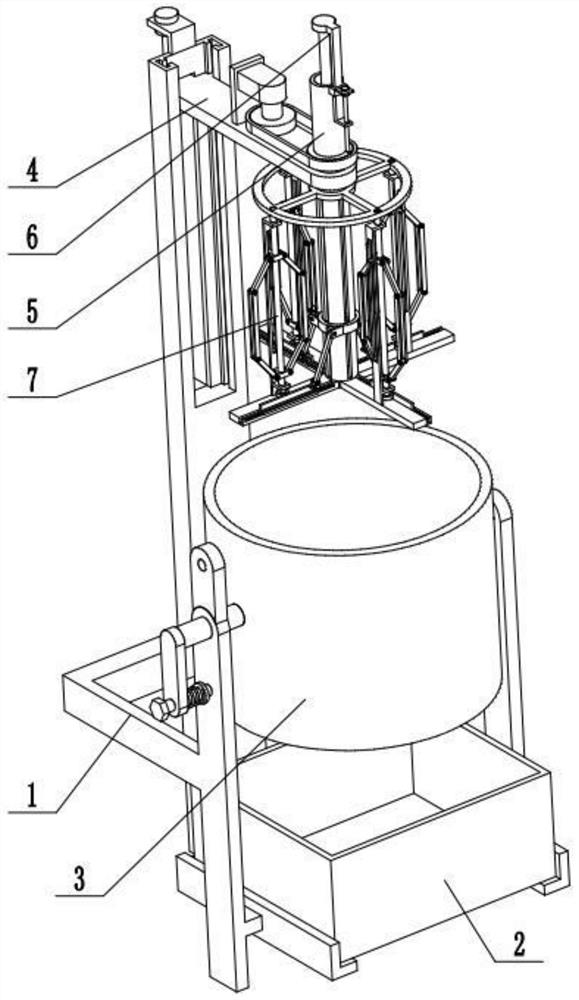

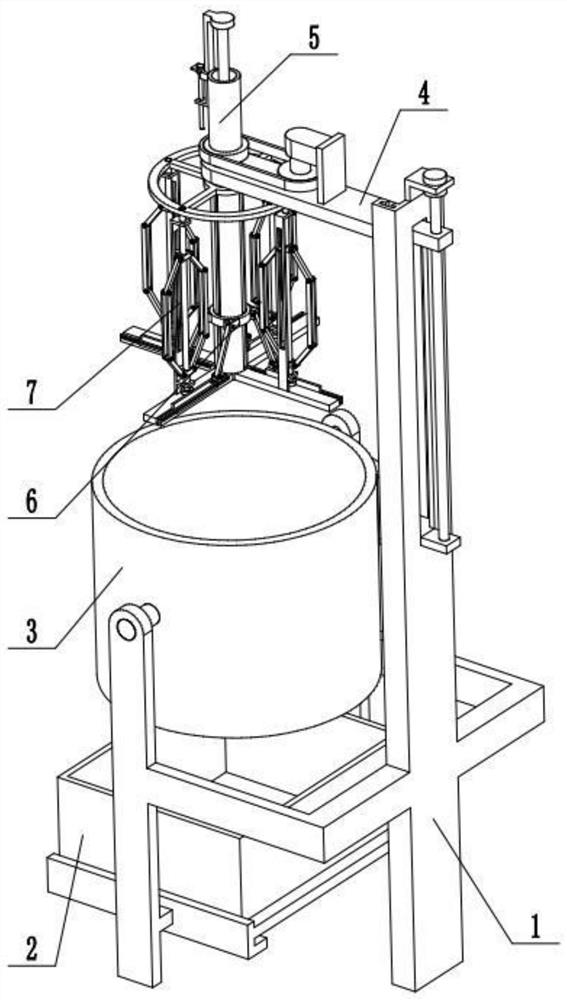

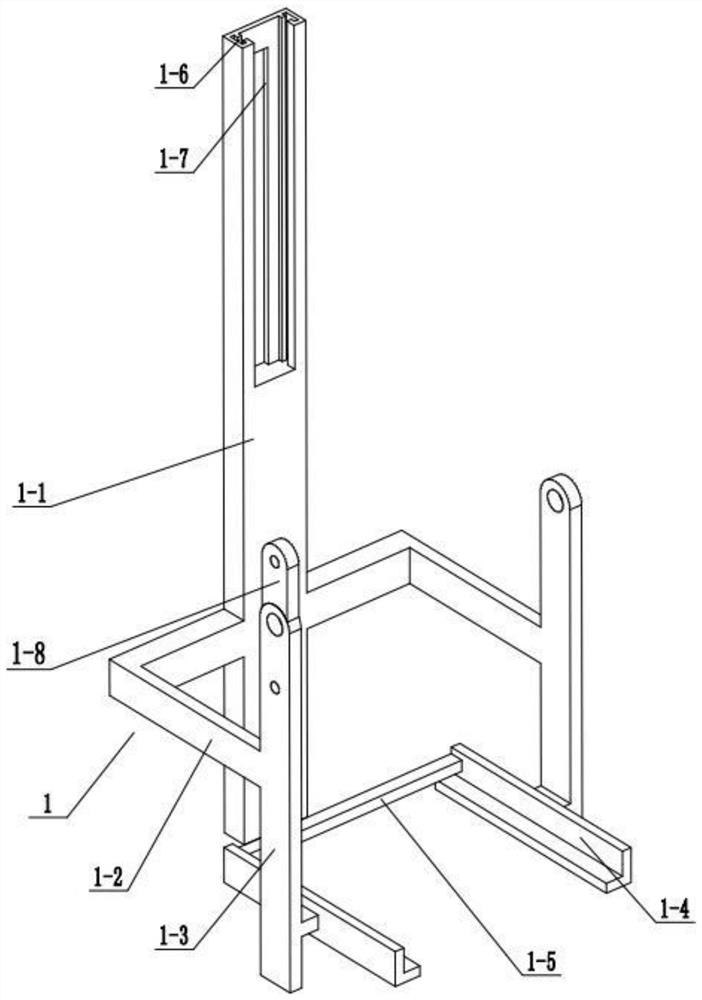

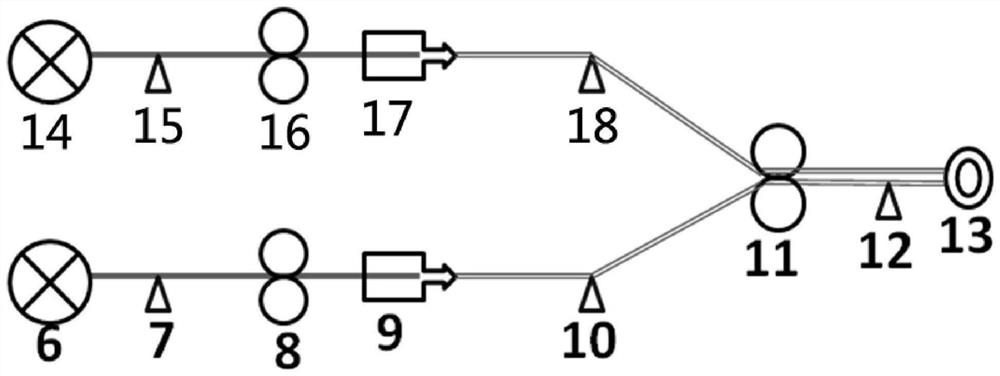

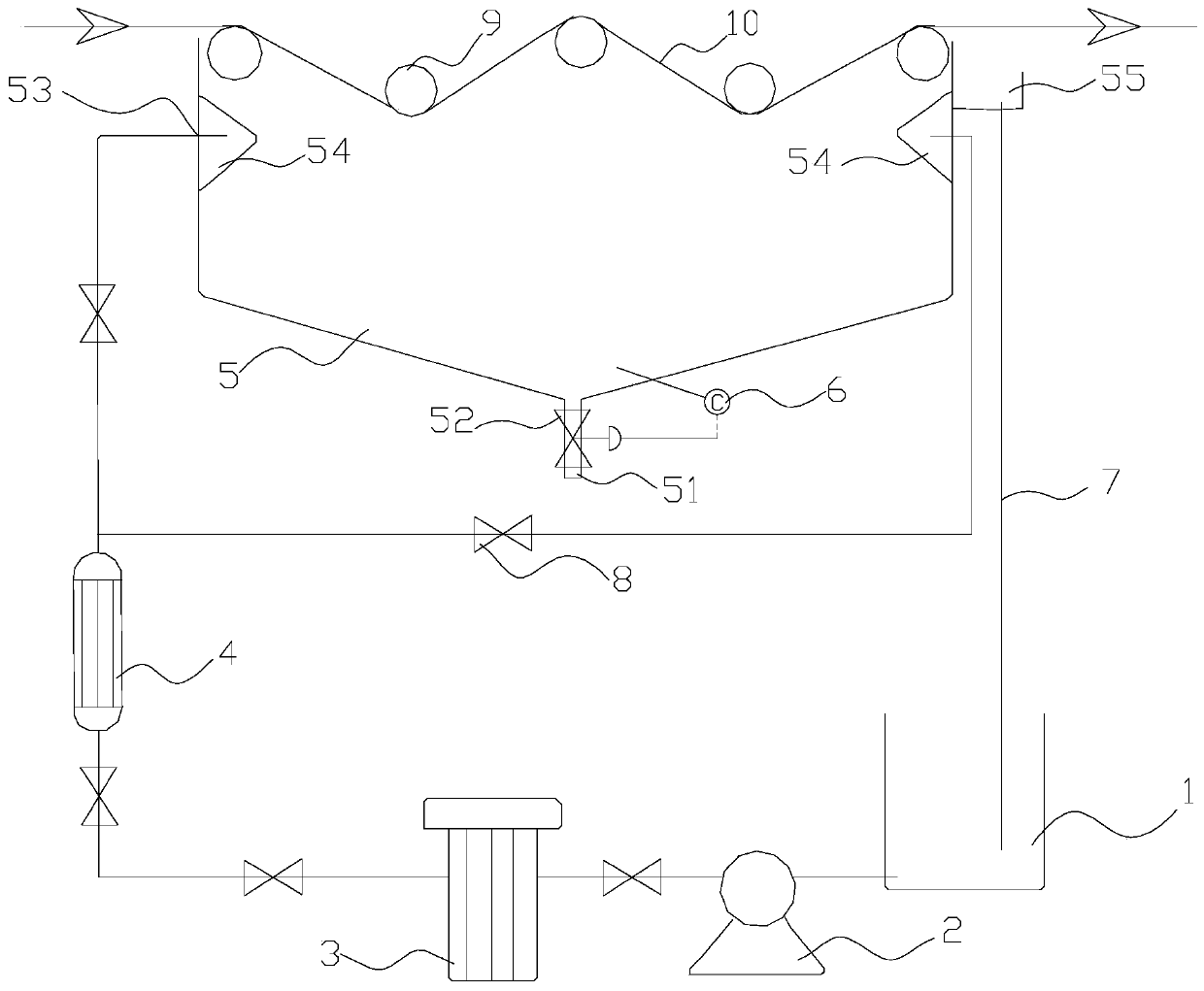

Oil sludge and coal co-combustion device and process

ActiveCN112524628AControl inflow speedParticle refinementSolid fuel pretreatmentWaste based fuelThermodynamicsCombustion

The invention discloses an oil sludge and coal co-combustion device and process, and belongs to the technical field of thermal power plant equipment. According to the oil sludge and coal co-combustiondevice and process, a combustion boiler, a stirring and mixing assembly, a smashing assembly, a lifting and conveying assembly and a co-combustion entering assemblies are included, and the bottom ofthe stirring and mixing assembly is connected to the combustion boiler. The upper end of the stirring and mixing assembly is connected with the lifting and conveying assembly, the side face of the stirring and mixing assembly is connected to the smashing assembly, and the co-combustion entering assemblies are arranged on the two sides of the smashing assembly and each comprises an oil sludge inletpiece and a coal inlet piece. According to the oil sludge and coal co-combustion device and process, uniform mixing of co-combustion can be guaranteed, meanwhile, a mixture is sorted, it is guaranteed that particles of the mixture are refined and enter the combustion boiler to be combusted, the combustion efficiency is improved, meanwhile, sorting is conducted twice through a vibration motor, fine particles are fully sorted, the situation that too many mixture particles enter a smashing box is avoided, and the co-combustion efficiency is improved.

Owner:XIAN TPRI THERMAL CONTROL TECH

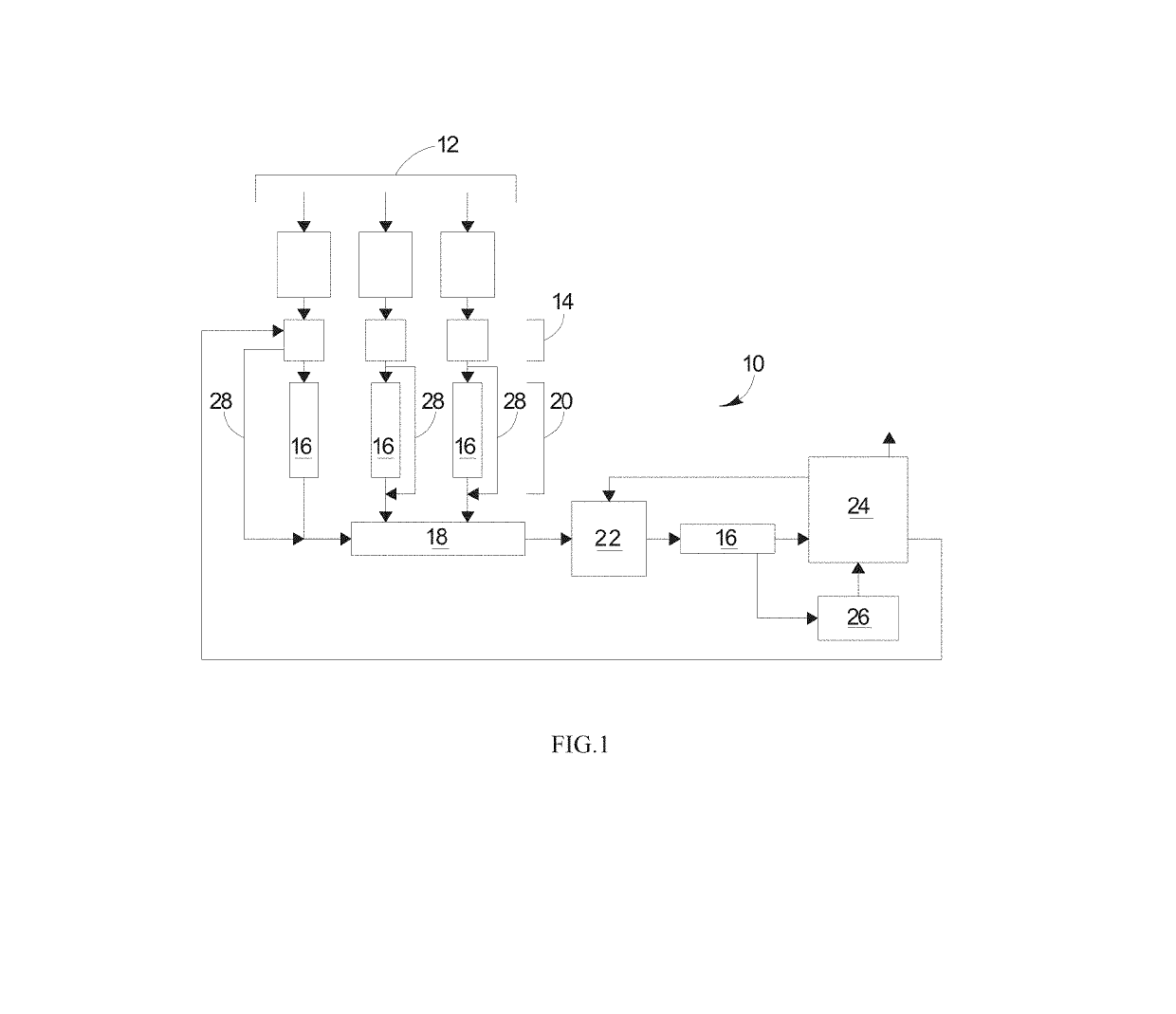

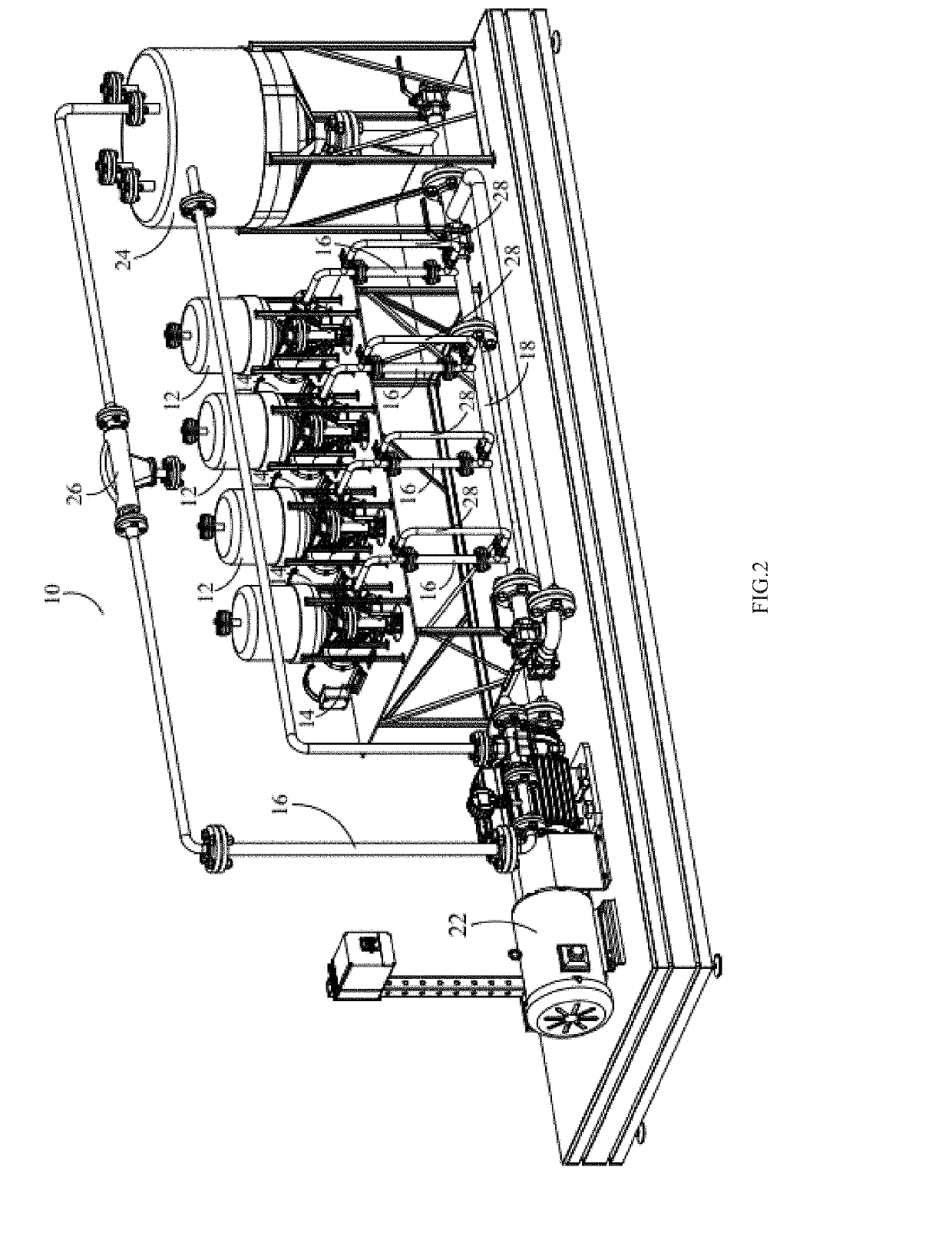

Method and device for producing of high quality alcoholic beverages

ActiveUS20190127671A1Increase organoleptic indexImprove blending efficiencyFood ingredient as colourAlcoholic beverage preparationHigh rateChemical composition

A method and device for producing high quality alcohol beverages, including liquor, cordial, tincture, whiskey, cognac, brandy, vodka, rum, gin, wine, cocktail, etc., is based on the action of hydrodynamic cavitation treatment of components of alcohol beverages. The fluid flow moves at a high rate through a multi-stage blending hydrodynamic device and multi-stage cavitation device to generate hydrodynamic cavitation features in the fluid flow. The cavitation features generate changes in the velocity, pressure, temperature, chemical composition and physical properties of the liquid. Hydrodynamic cavitation processing provides effective blending of components and homogenization of alcoholic beverage, improves its organoleptic qualities.

Owner:CAVITATION TECH

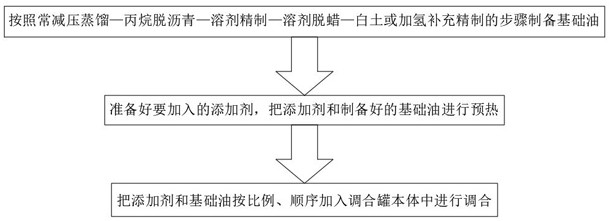

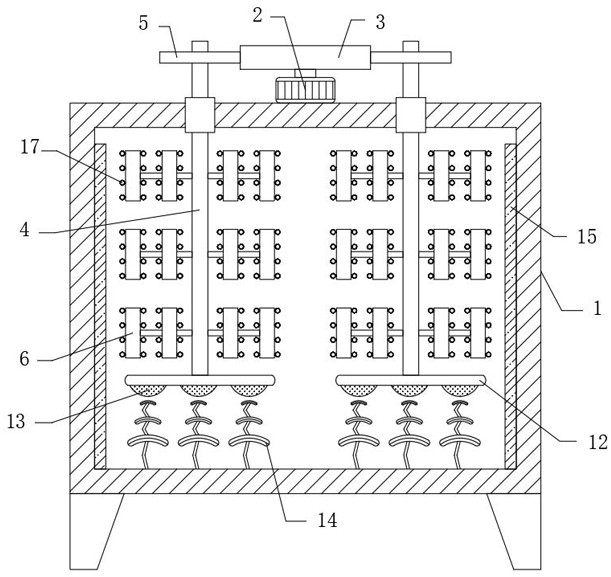

Preparation process of textile high-lubricating oil agent

InactiveCN112452181AGuaranteed stirringStir wellTransportation and packagingRotary stirring mixersProcess engineeringBase oil

The invention discloses a preparation process of a textile high lubricating oil agent, belongs to the field of lubricating oil, and relates to a preparation process of a textile high lubricating oil agent, the textile high lubricating oil agent comprises a blending tank body, and the preparation process comprises the following steps: S1, preparing base oil according to the steps of atmospheric andvacuum distillation, propane deasphalting, solvent refining, solvent dewaxing and carclazyte or hydrofinishing; S2, preparing an additive to be added, and preheating the additive and the prepared base oil; and S3, sequentially adding an additive and base oil into the blending tank body in proportion to be blended, producing an impact flow through an elastic agitation film to disturb fluid movingin the rotating direction of a stirring barrel, so that time is effectively shortened on the premise that sufficient mixing is guaranteed, energy consumption is reduced. While stirring, a magnetic lower pressure piece is made to pour up the oil at the bottom to ensure that there is no dead corner in the stirring. In addition, the blending tank body is composed of the two circles, so that convection diffusion of a main body can be formed, and the blending efficiency is further improved.

Owner:张春雨

A mixing device for rubber and plastic mixed polymer materials

Owner:广宁县汇和塑料有限公司

Process and device for preparing continuous combined filament yarn

ActiveCN114395834AStay apartEven blendTextile/flexible product manufactureYarnPolymer scienceFiber bundle

The invention belongs to the field of new material processing, and particularly provides a process and a device for preparing continuous combined filaments, which are mainly used for mixed filament processing of thermoplastic resin fibers and reinforced fibers, the processing process is realized by a combined device, and the device consists of a creel, a yarn releasing roller, an air injection diffusion device, a traction roller, a guider and a winding roller, wherein the air injection diffusion device consists of an observation plate, a yarn spreading plate, an air injection device, an air storage device and an air inlet device from top to bottom; by adopting the device and the corresponding process, the continuous combined filament yarn can be prepared, the effect of dispersing fiber bundles into monofilaments is greatly improved after the thermoplastic resin fibers and the reinforced fibers are spread respectively, micron-level mixing of the two continuous fibers can be conveniently and quickly realized, the fiber mixing efficiency of the thermoplastic resin fibers and the reinforced fibers is improved, and the production cost is reduced. And the interface distribution of the resin fiber and the reinforced fiber in the combined filament yarn is further optimized.

Owner:SHANDONG NON METALLIC MATERIAL RES INST

Special-shaped mixing holes for adjusting the temperature distribution at the outlet of the combustion chamber

ActiveCN112146127BImprove temperature distributionChange penetration depthContinuous combustion chamberCombustion chamberJet flow

The invention discloses a special-shaped mixing hole for adjusting the outlet temperature distribution of a combustion chamber, which belongs to the field of gas turbine combustion; the invention is provided with special-shaped mixing holes on the inner and outer ring walls of the combustion chamber flame tube respectively; the special-shaped mixing hole will The wall surface of the flame tube is divided into the front section of the flame tube and the rear section of the flame tube; the special-shaped mixing holes are evenly distributed along the circumferential direction of the wall surface of the flame tube to form a uniformly distributed mixing jet in the circumferential direction and increase the penetration depth of the mixing air flow. Increase the contact area between the blended cold air and the high-temperature mainstream gas, improve the blending effect, and improve the temperature distribution quality of the combustion chamber outlet; by changing the jet penetration depth of the blending hole, the jet circumferential expansion angle and the jet direction, the combustion chamber can be adjusted The effect of outlet temperature distribution; by adjusting the outlet temperature distribution of the combustion chamber, the quality of the turbine inlet temperature is improved, thereby increasing the service life of the turbine and reducing the design difficulty of turbine heat protection.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Gas Turbine Dual Fuel Nozzle Structure

ActiveCN104154566BConvenience to workImprove blending efficiencyContinuous combustion chamberGas turbinesFuel gas

The invention relates to the technical field of gas turbines, and discloses a dual-fuel nozzle structure of a gas turbine. The dual-fuel nozzle structure of the gas turbine comprises a nozzle body, a medium-low heat value fuel gas whirlcone, a natural gas whirlcone and an end face whirlcone. The nozzle body comprises a slightly-blowing air barrel, a natural gas barrel, a nozzle air barrel and a medium-low heat value fuel gas barrel with the inner diameters being sequentially increased, and the barrels are isolated from one another. The end face whirlcone is arranged on the outlet end face of the nozzle air barrel. The natural gas whirlcone is arranged on the inner side wall of the natural gas barrel. The medium-low heat value fuel gas whirlcone is arranged on the inner side wall of the outlet end of the medium-low heat value fuel gas barrel, the medium-low heat value fuel gas whirlcone comprises a plurality of blades, and the blades are connected with the inner side wall of the medium-low heat value fuel gas barrel and the outer side wall of the nozzle air barrel. Each blade is provided with an air channel, and the air channels are communicated with the nozzle air barrel and an outside air flow channel of the medium-low heat value fuel gas barrel. An end face cover plate is arranged on the outlet end face of the slightly-blowing air barrel, and the end face cover plate is provided with a plurality of slightly-blowing air holes.

Owner:CHINA UNITED GAS TURBINE TECH CO LTD

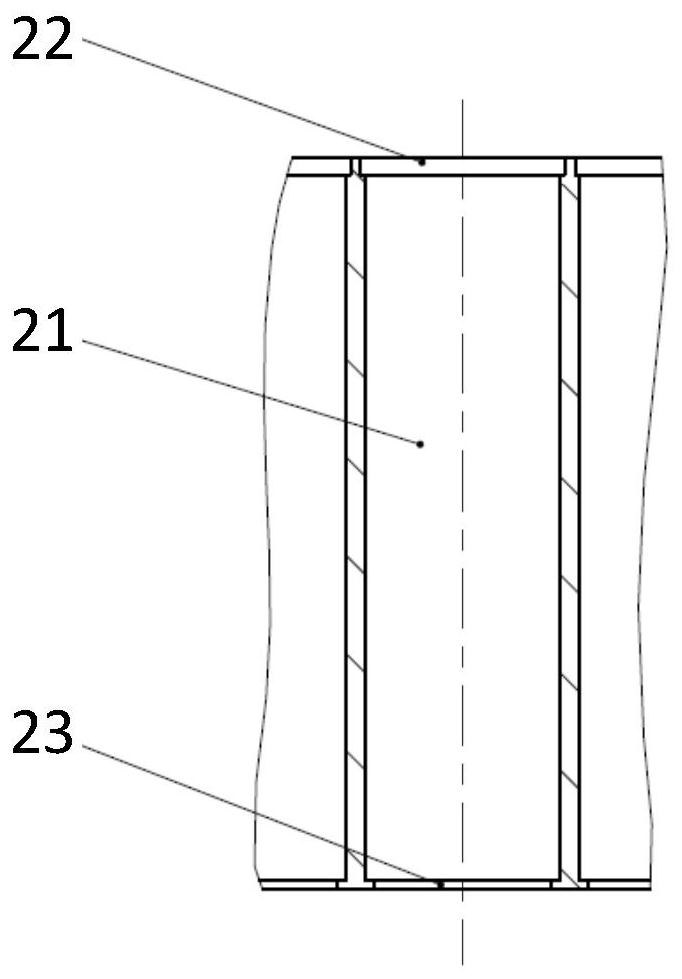

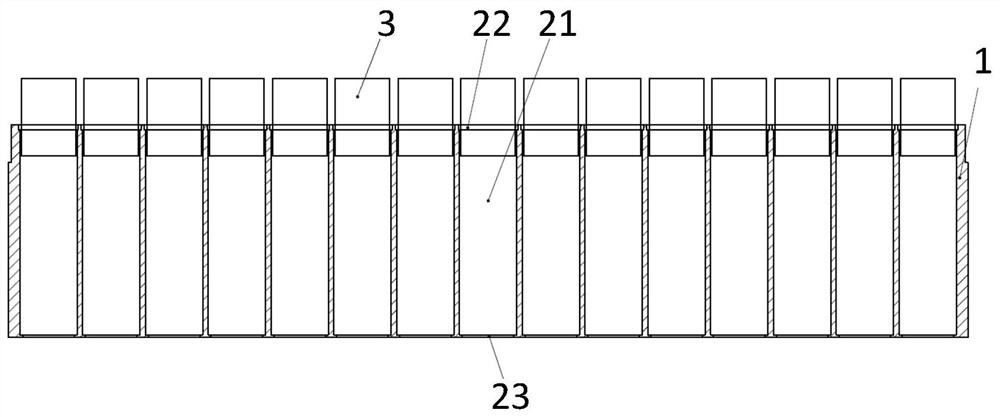

Oiling device and method for improving oil stability

ActiveCN106435785BIncrease the airtight partitionGuarantee continuous and stable operationFilament/thread formingFiberPneumatic valve

The invention discloses an oiling device and method for improving the stability of an oil agent, and belongs to the technical field of chemical fiber production. The oiling device comprises a circulating storage tank, an oil agent delivery pump, an external circulating filter, an external circulating heat exchanger and an oil tank; the circulating storage tank is connected with the oil inlet end of the oil agent delivery pump through a pipeline, the oil outlet end of the oil agent delivery pump is connected with the oil inlet end of the external circulating filter through a pipeline, the external circulating filter is connected with the oil inlet end of the external circulating heat exchanger through a pipeline, the oil outlet end of the external circulating heat exchanger is connected with the oil tank through a pipeline, and the oil tank is connected with the circulating storage tank through a pipeline, so that a circulating loop is formed; the bottom of the oil tank is provided with an emptying pipe with an emptying pneumatic valve. According to the oiling device, mixing uniformity of the oil agent in the oil tank can be improved, the possibility of oil dirt deposition in the oil tank is decreased, the stability of the oil agent is effectively improved, and oxidation destruction of air and humidity on the oil agent in the oil tank can be reduced.

Owner:ZHONGFU SHENYING CARBON FIBER

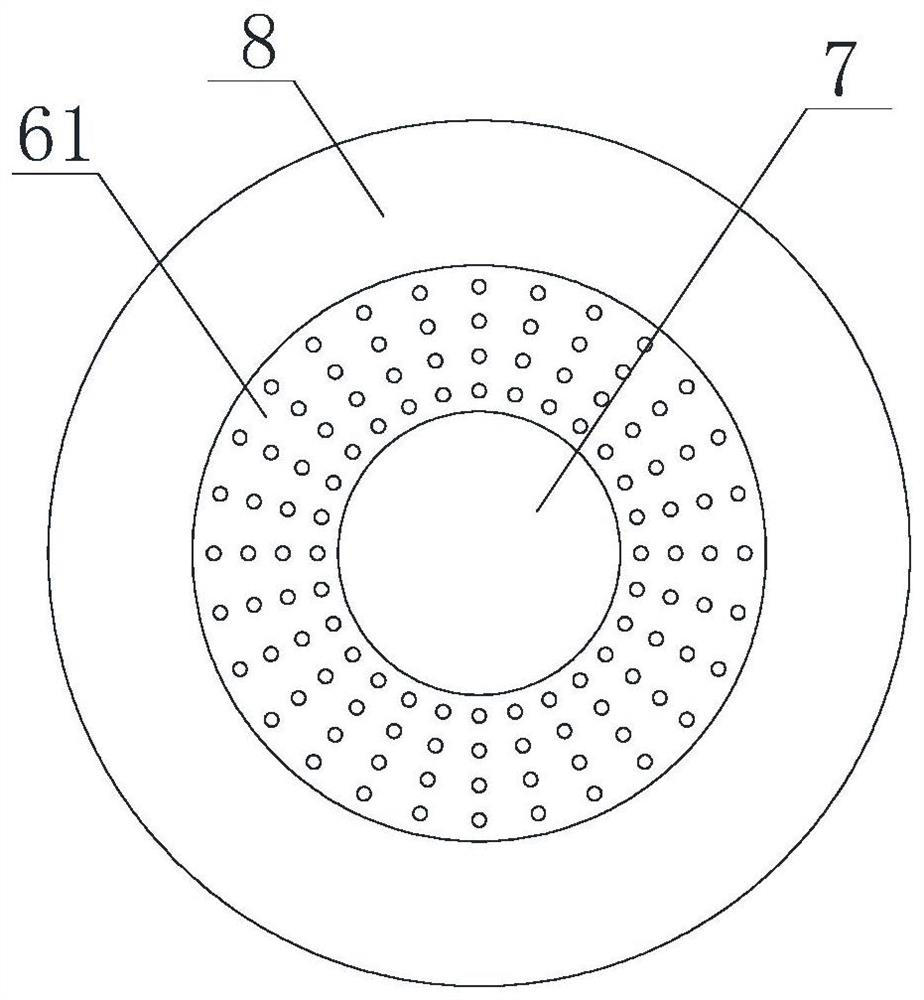

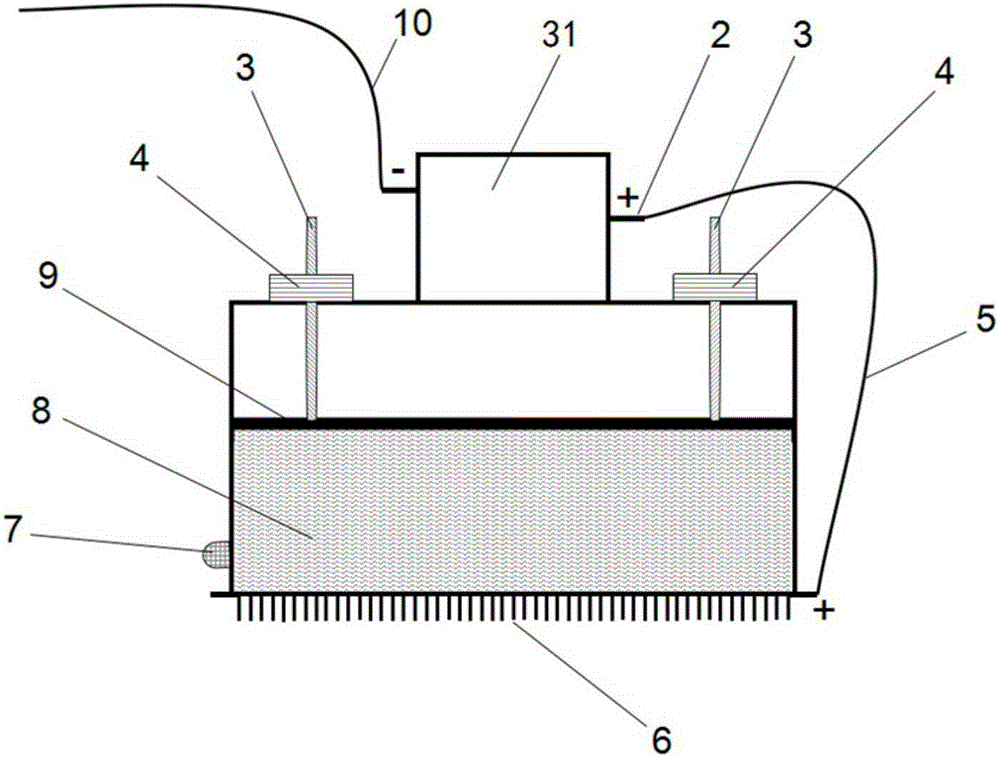

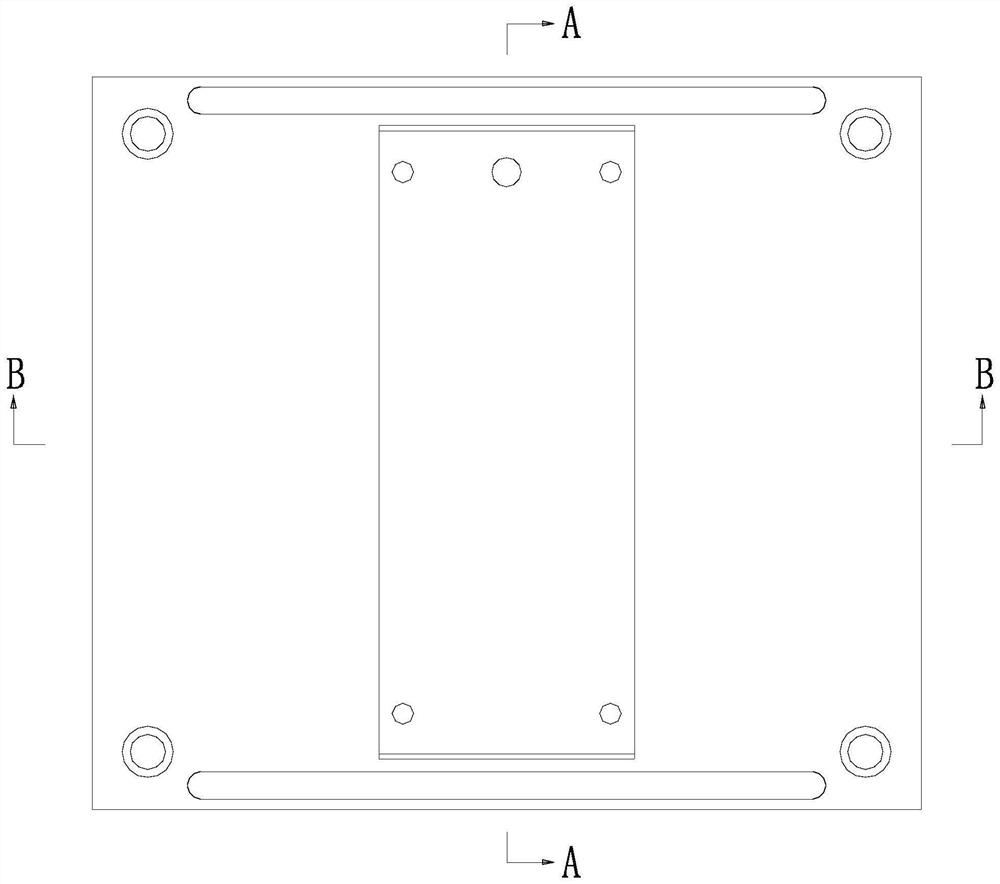

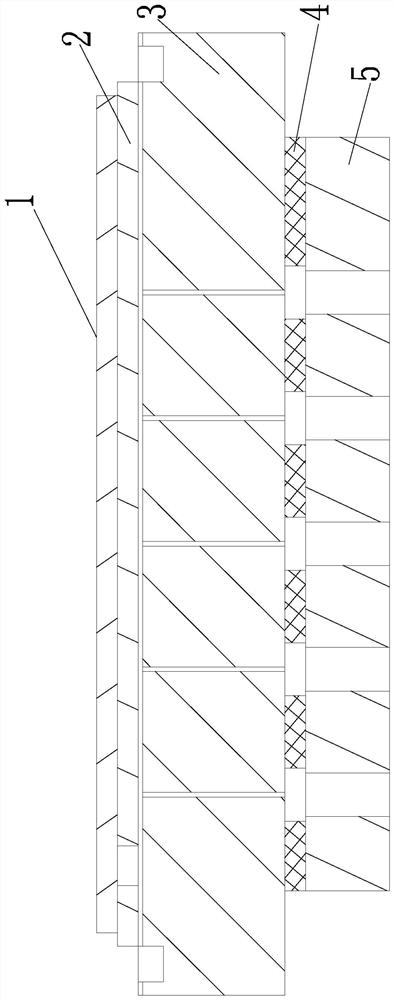

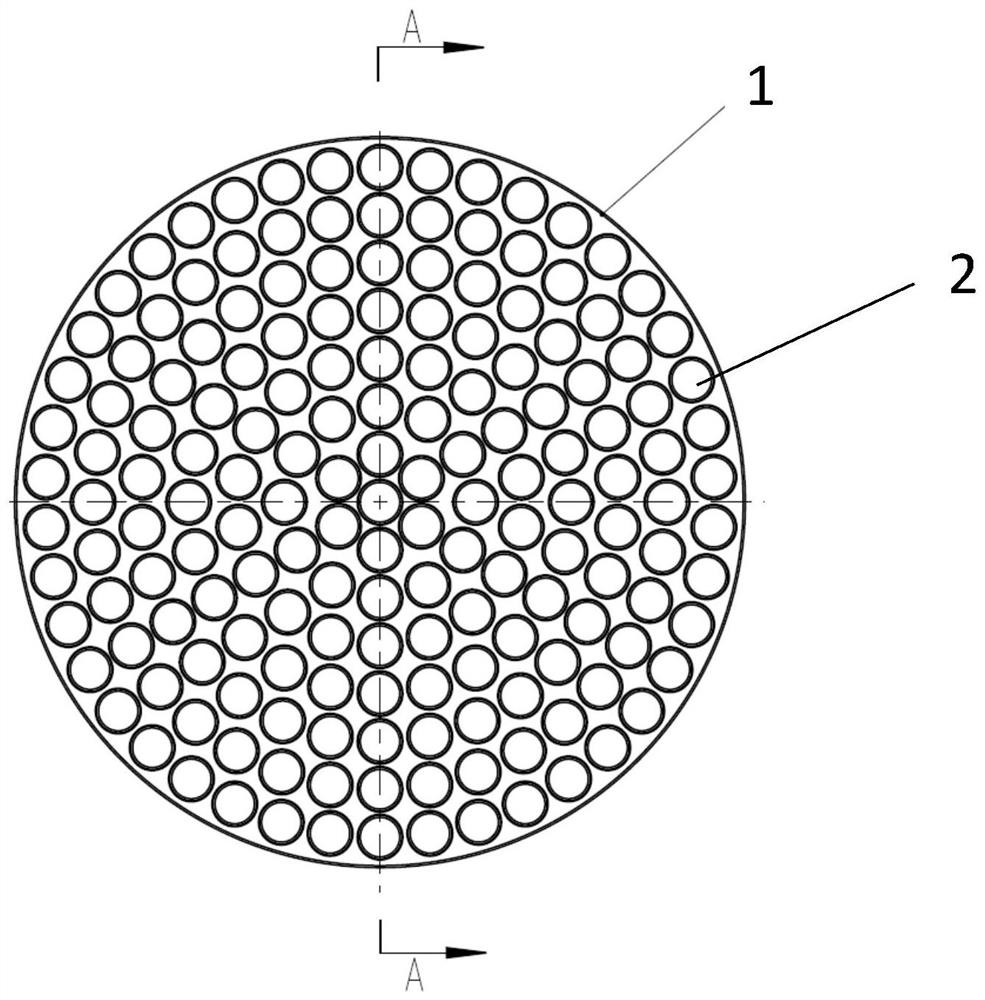

An Inner Bottom Structure for Improving Gas Temperature Uniformity of Gas Generator

ActiveCN112196700BImprove temperature uniformityImprove blending efficiencyRocket engine plantsGas generatorFuel gas

The invention relates to a gas generator, in particular to an inner bottom structure for improving the gas temperature uniformity of the gas generator, which is suitable for thermal components (such as the gas generator of an engine) that require high temperature uniformity of the outlet gas. The purpose of the present invention is to solve the technical problems that the existing gas generator has uneven gas temperature, poor reliability, and cannot meet the requirements of thermal components that have strict requirements on gas temperature uniformity, and provides a method for improving the gas temperature uniformity of the gas generator. Insole structure. The inner bottom plate of the structure is evenly provided with a plurality of axial through holes, and the outlet end of each axial through hole adopts a shrinkage structure. When the nozzle of the gas generator injector is installed on the axial through hole, the propellant enters the axial through hole through the nozzle, and the multiple axial through holes of the inner bottom plate provide combustion and mixing space, so that the propellant can be It is fully burned and mixed in the axial through hole, and then ejected after being further forced to be mixed at the outlet end with a smaller diameter.

Owner:XIAN AEROSPACE PROPULSION INST

A high-efficiency cotton blender

ActiveCN112877821BMeet the needs of cotton blendingShorten the timeFibre feedersProcess engineeringFan blade

The invention discloses a high-efficiency cotton blending machine, which includes a support, a storage tank is installed on the top of the support, storage tanks are evenly distributed inside the storage tank, and a Separator, the interior of the compartment is detachably installed with partitions, since the number of raw material bins and the number of storage tanks are in a one-to-one correspondence, so that each storage tank can be synchronized each time when feeding Feeding, thereby shortening the time required for feeding, and improving the production efficiency; when mixing, various materials enter the interior of the collecting rack one by one in small amounts, and enter and discharge under the rotation of the fan blade rack. The inside of the device is mixed by the stirring of the stirring frame, and then flows out, so that the collected raw materials can be directly mixed without buffering, thereby shortening the outflow of the mixed cotton, thereby improving the efficiency of the mixed cotton.

Owner:佛山市三水湘润包装材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com