Pre-whirling type pintle injector applied to double-component liquid propellant rocket engine

A liquid rocket and engine technology, which is applied in rocket engine devices, machines/engines, mechanical equipment, etc., can solve the problems of low effective mixing efficiency, achieve the effects of improving mixing efficiency, improving working life, and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the solution of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments:

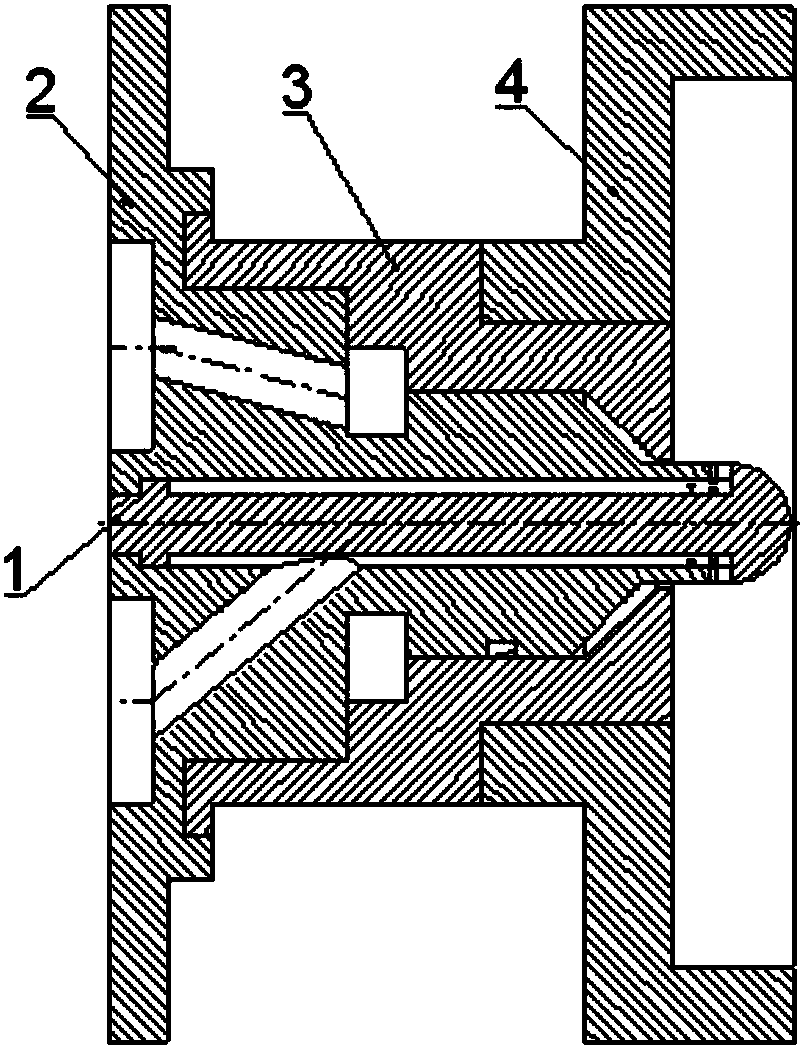

[0031] Such as figure 1 As shown, a pre-rotating pintle injector applied to a bicomponent liquid rocket engine includes a central rod 1, an inner nozzle 2, an outer nozzle 3 and a connecting ring 4; a central rod 1, an inner nozzle 2, an outer nozzle 3 and the connecting ring 4 are both rotary bodies; the inner nozzle 2 is coaxially set on the center rod 1, and forms a cavity for delivering fuel with the center rod 1, and the outer nozzle 3 is coaxially set on the inner nozzle 2, and A cavity for transporting oxidant is formed with the inner nozzle 2, and the connecting ring 4 is coaxially sleeved on the outer nozzle 3.

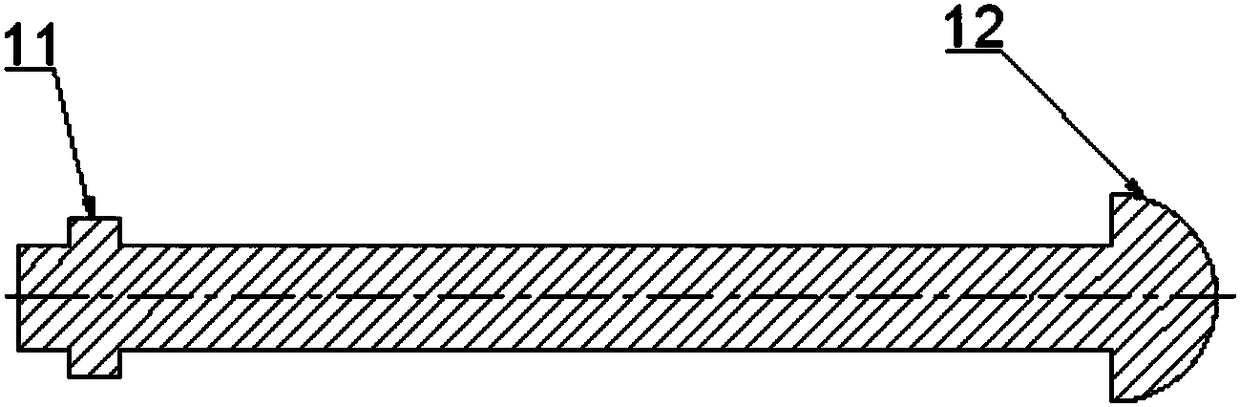

[0032] Such as figure 2 As shown, preferably, the central rod 1 is a solid cylinder, one end of the central rod 1 is provided with a cylindrical step 11 , and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com