An Inner Bottom Structure for Improving Gas Temperature Uniformity of Gas Generator

A gas generator and gas temperature technology, which is applied in the direction of machines/engines, jet propulsion devices, rocket engine devices, etc., can solve problems such as poor reliability, unsatisfactory thermal components, and uneven gas temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

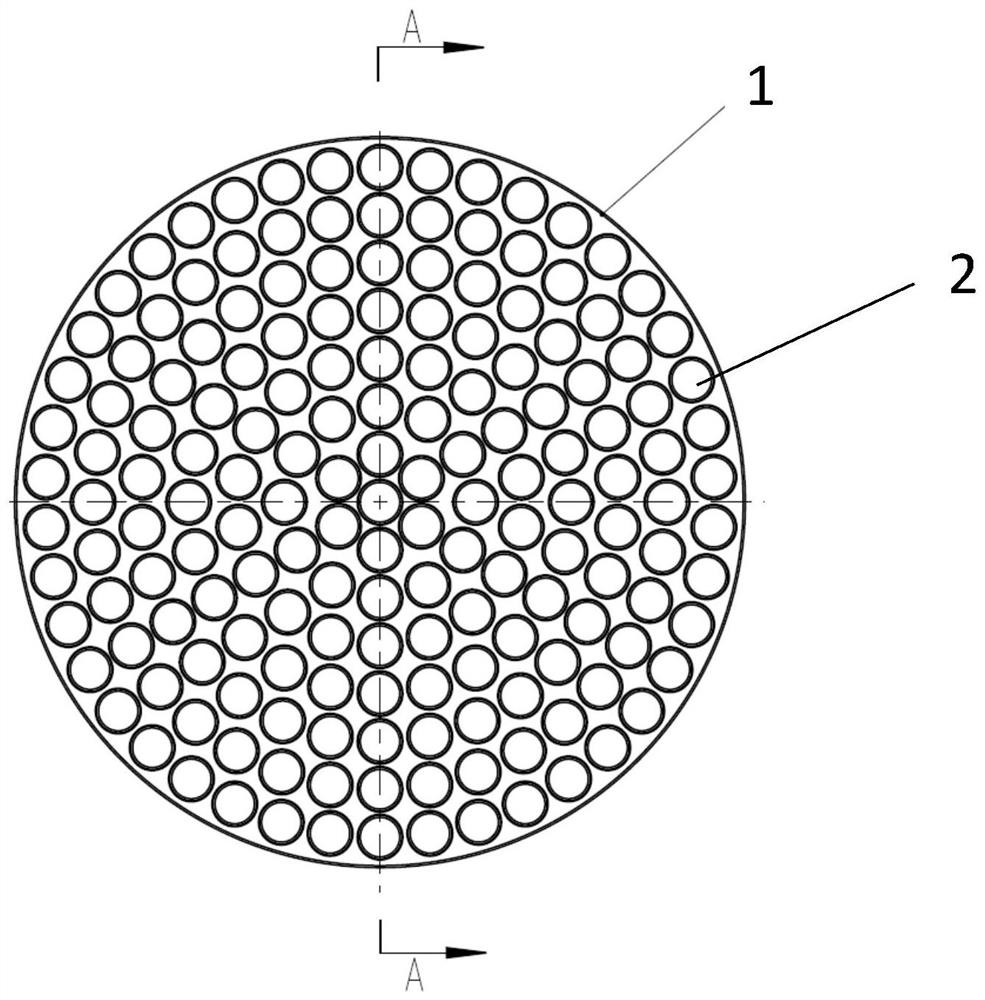

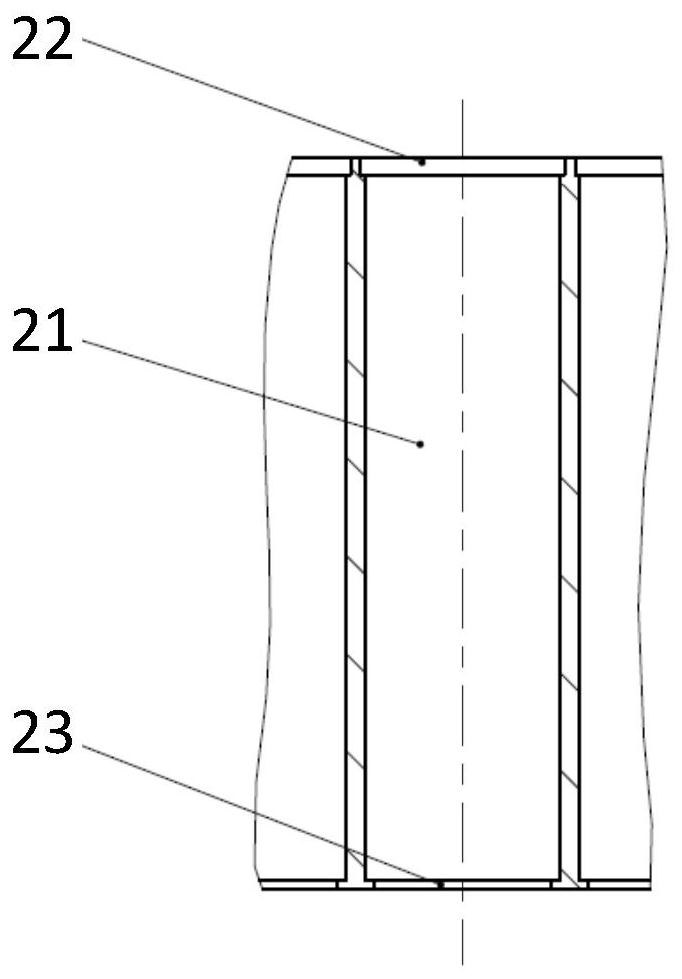

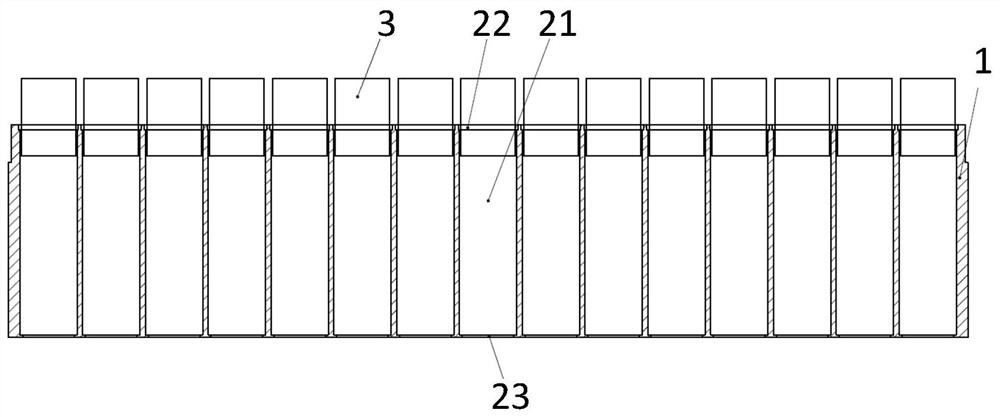

[0026] An inner bottom structure to improve the gas temperature uniformity of the gas generator, such as Figure 1 to Figure 3 As shown, the inner bottom plate 1 is included, and the inner bottom plate 1 is provided with a plurality of axial through holes 2 in a honeycomb manner. The axial through holes 2 include a hole body segment 21, and connecting ends 22 and The outlet end 23; the length of each axial through hole 2 is 2-5 times the diameter of the hole body section 21, and the length of the axial through hole is long enough to ensure sufficient mixing, so that the axial through holes can be used as a double group The channel for propellant combustion and mixing; the diameter of the connecting end 22 is greater than the diameter of the hole body section 21, and the diameter of the hole body section 21 matches the outer diameter of the gas generator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com