Patents

Literature

134 results about "Liquid-propellant rocket" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A liquid-propellant rocket or liquid rocket utilizes a rocket engine that uses liquid propellants. Liquids are desirable because their reasonably high density allows the volume of the propellant tanks to be relatively low, and it is possible to use lightweight centrifugal turbopumps to pump the propellant from the tanks into the combustion chamber, which means that the propellants can be kept under low pressure. This permits the use of low-mass propellant tanks, resulting in a high mass ratio for the rocket.

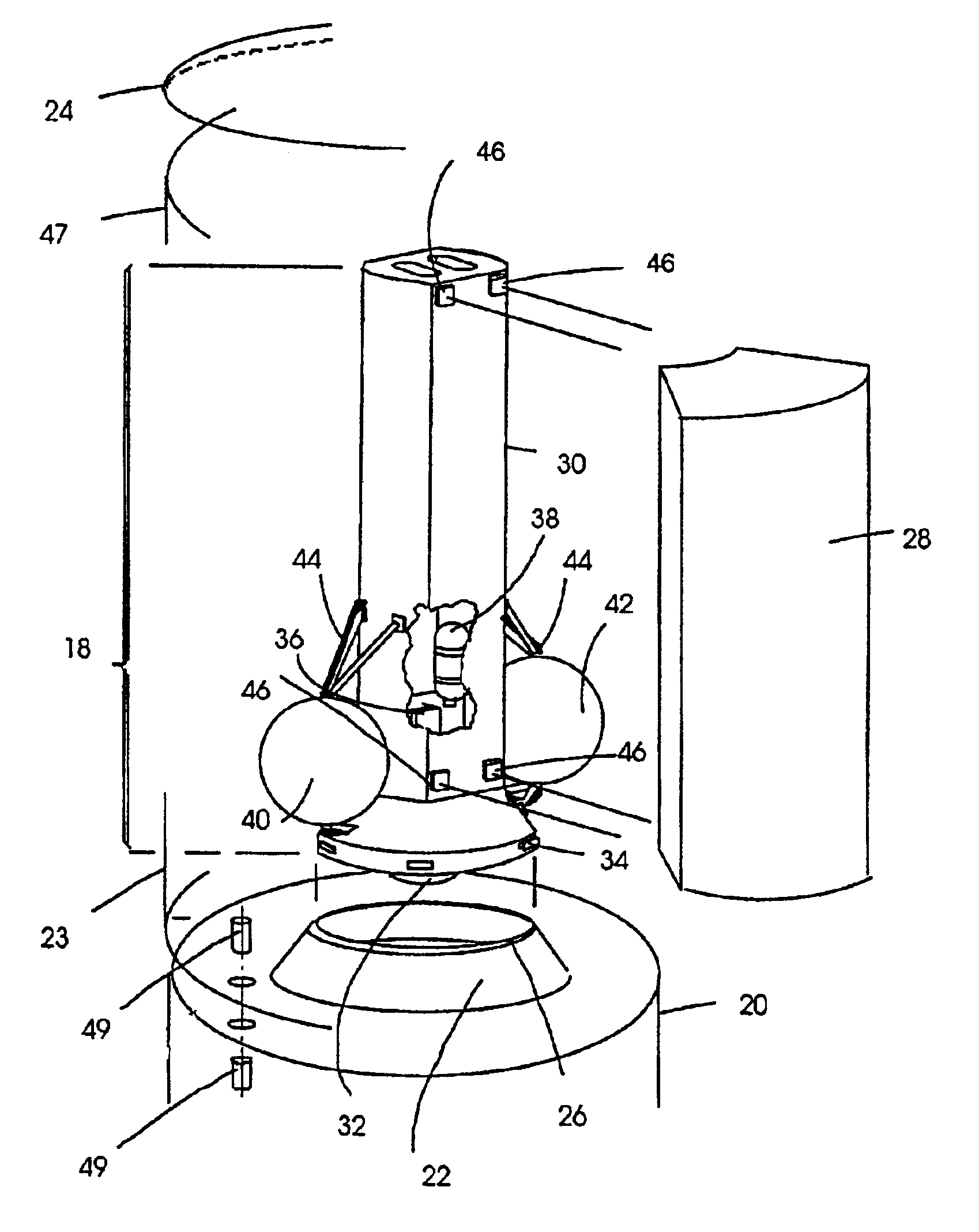

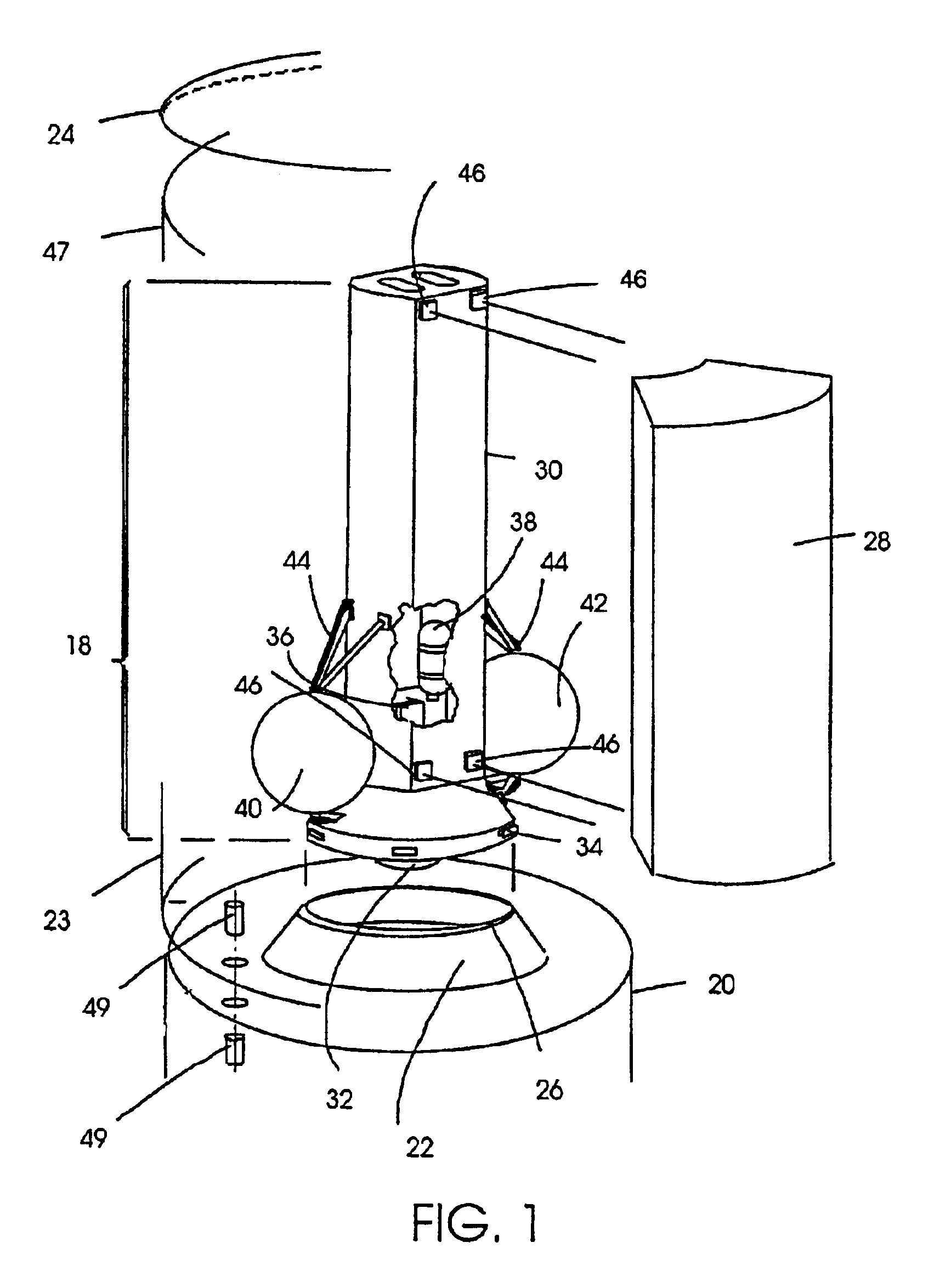

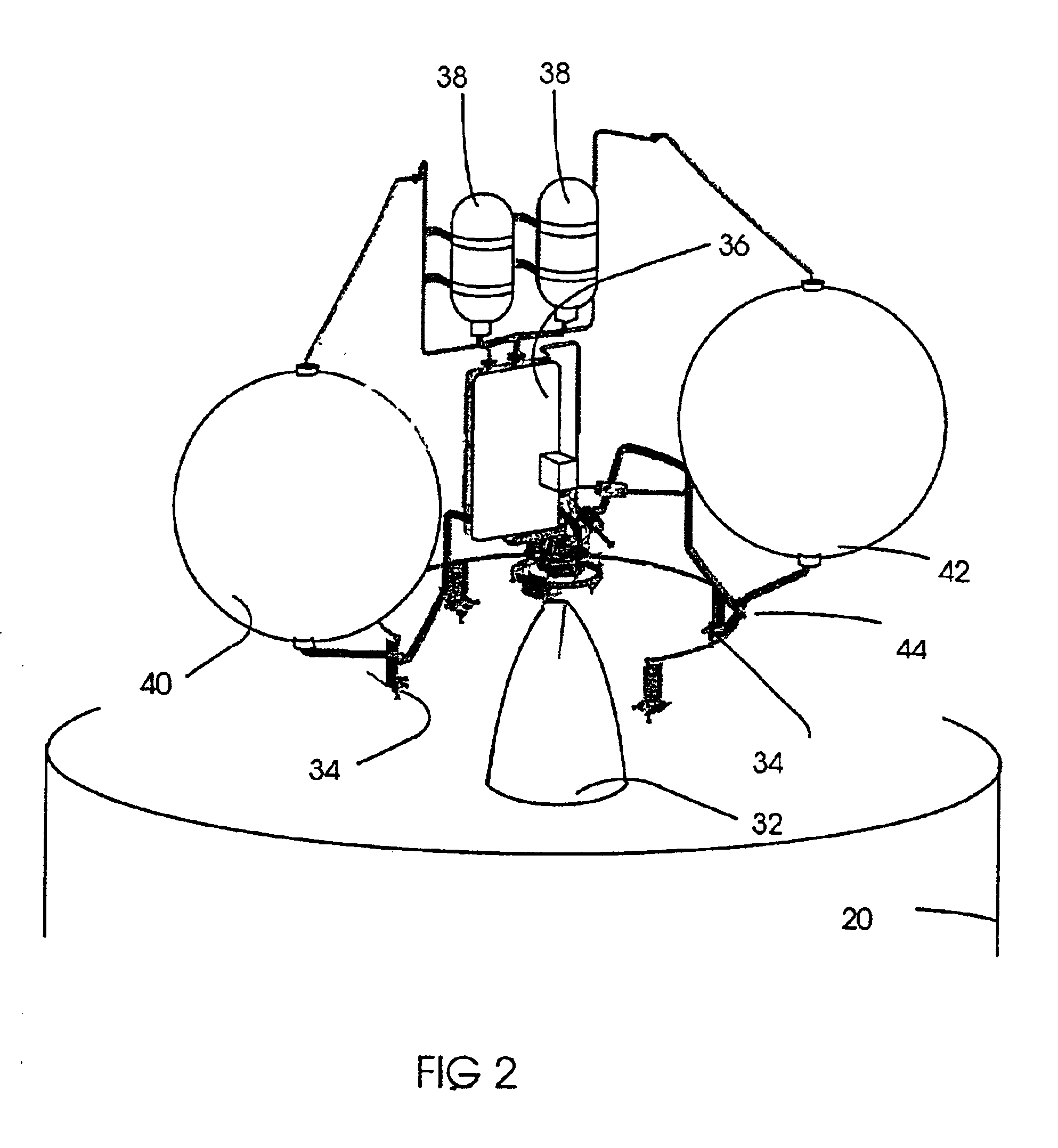

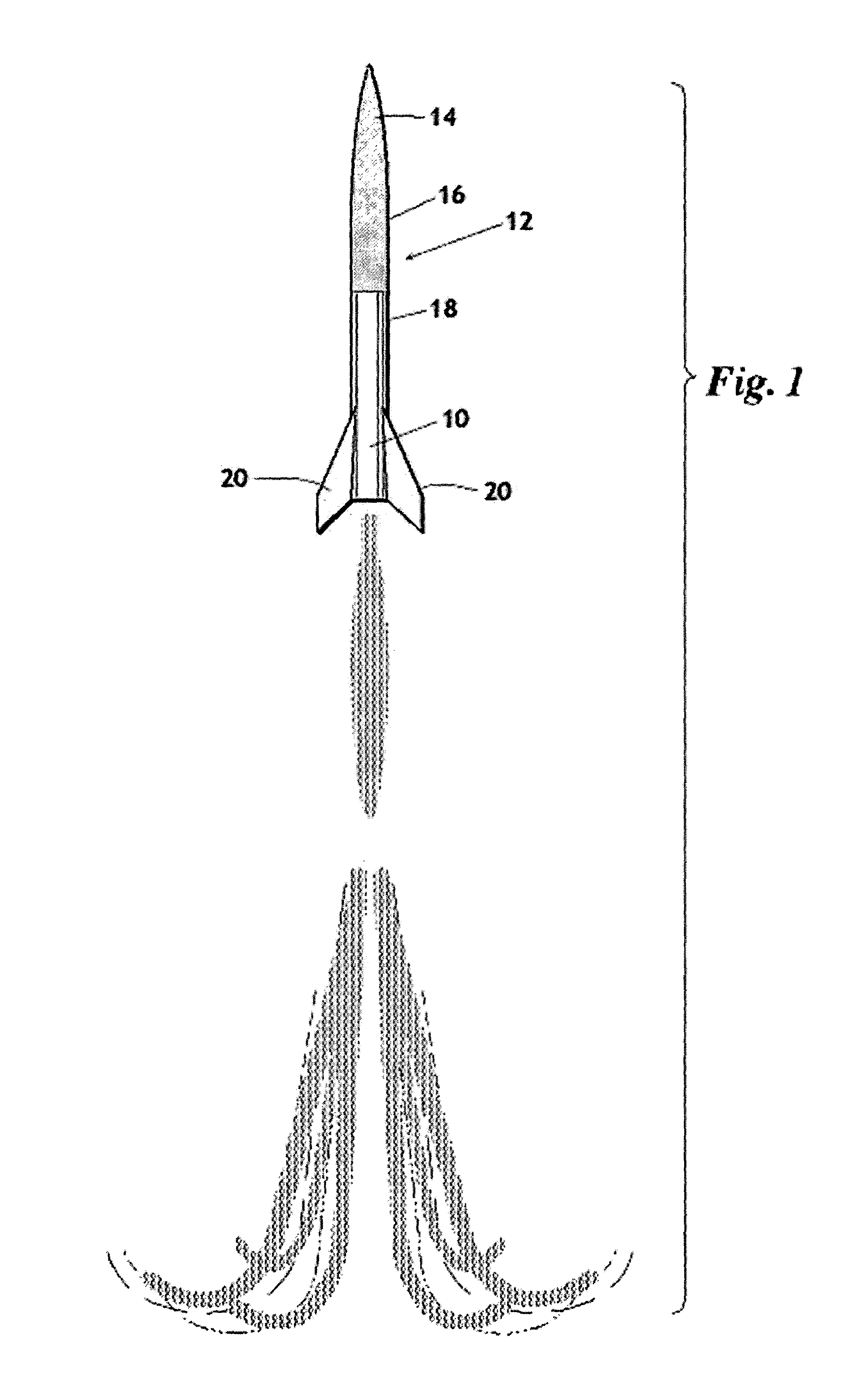

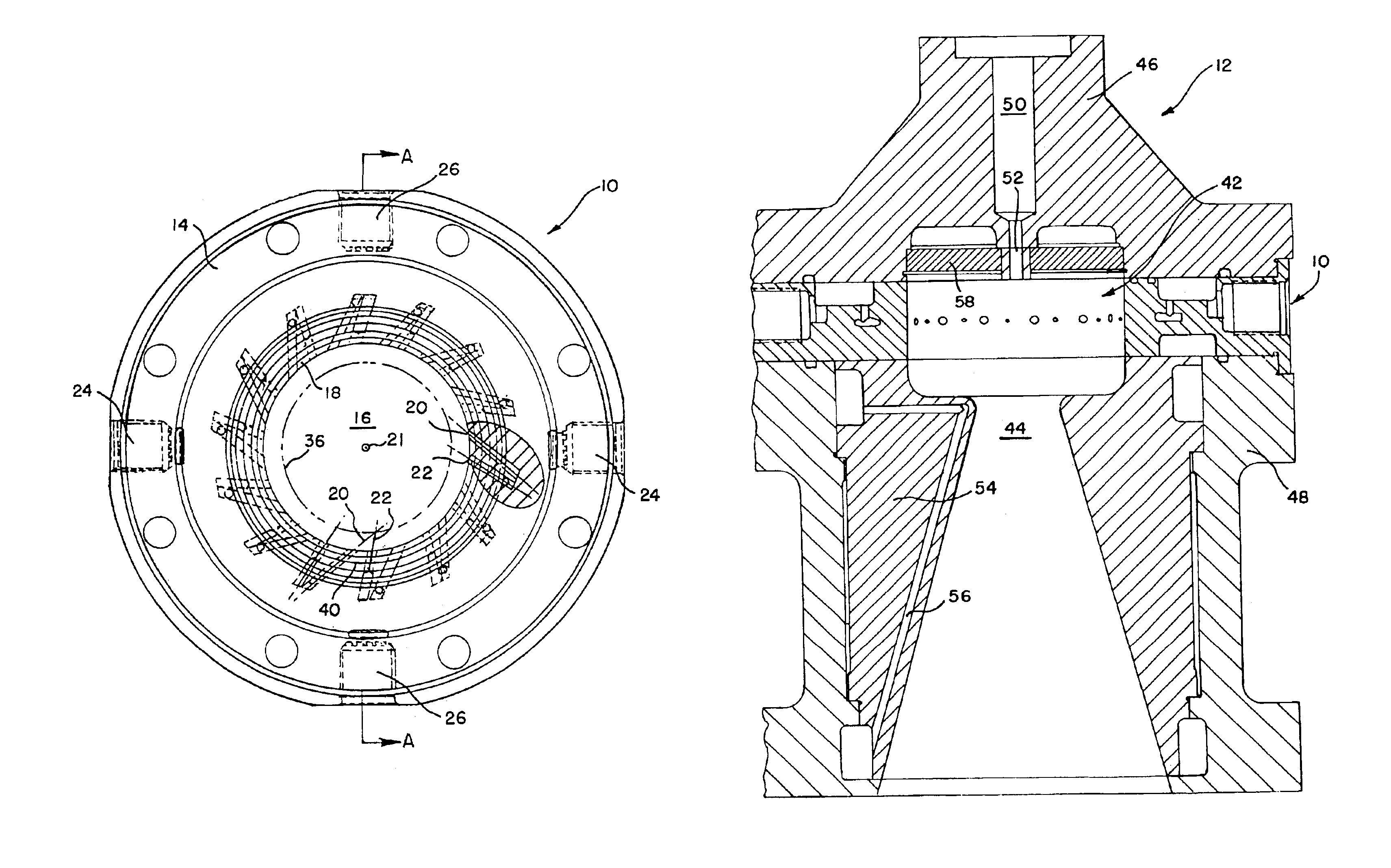

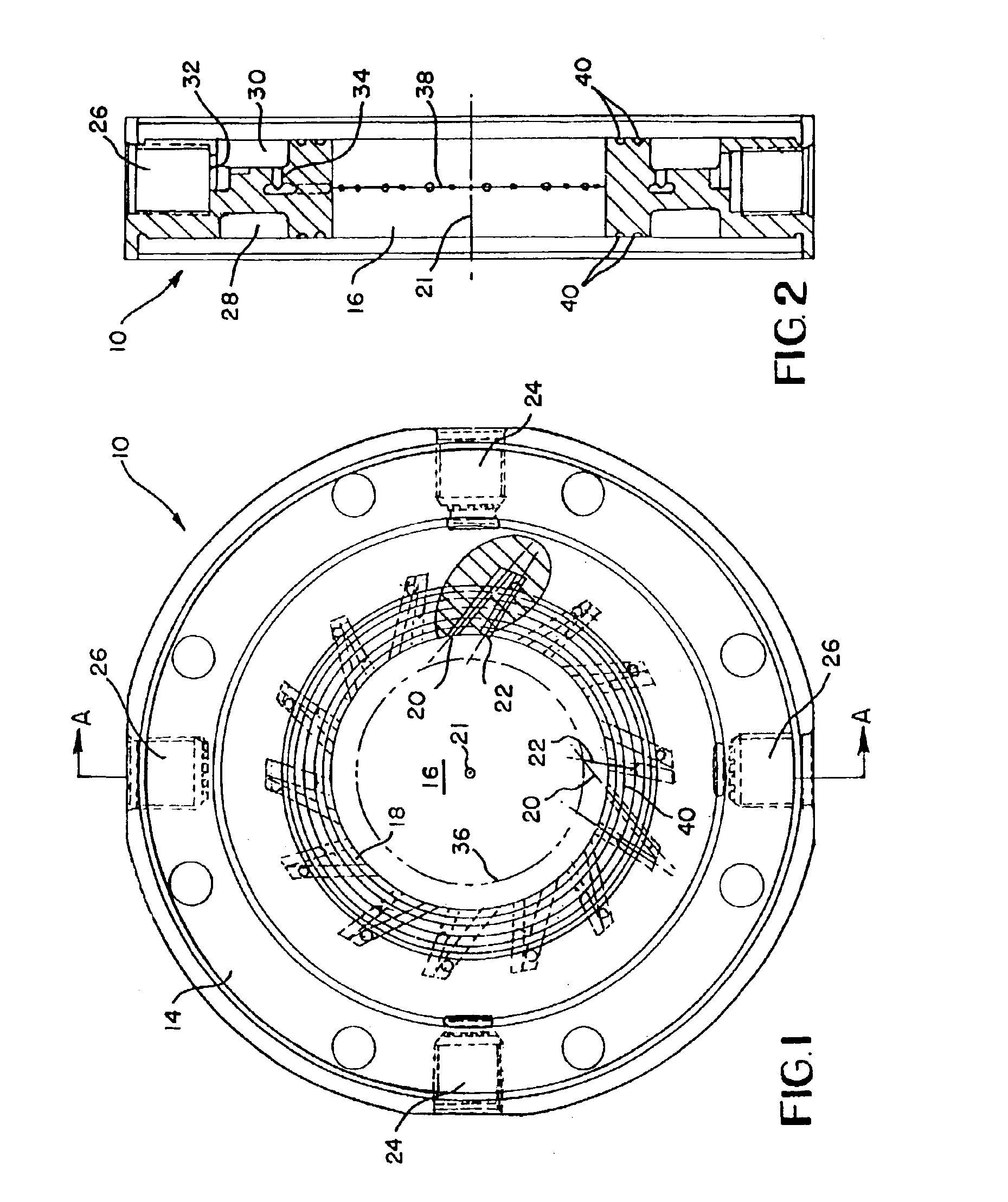

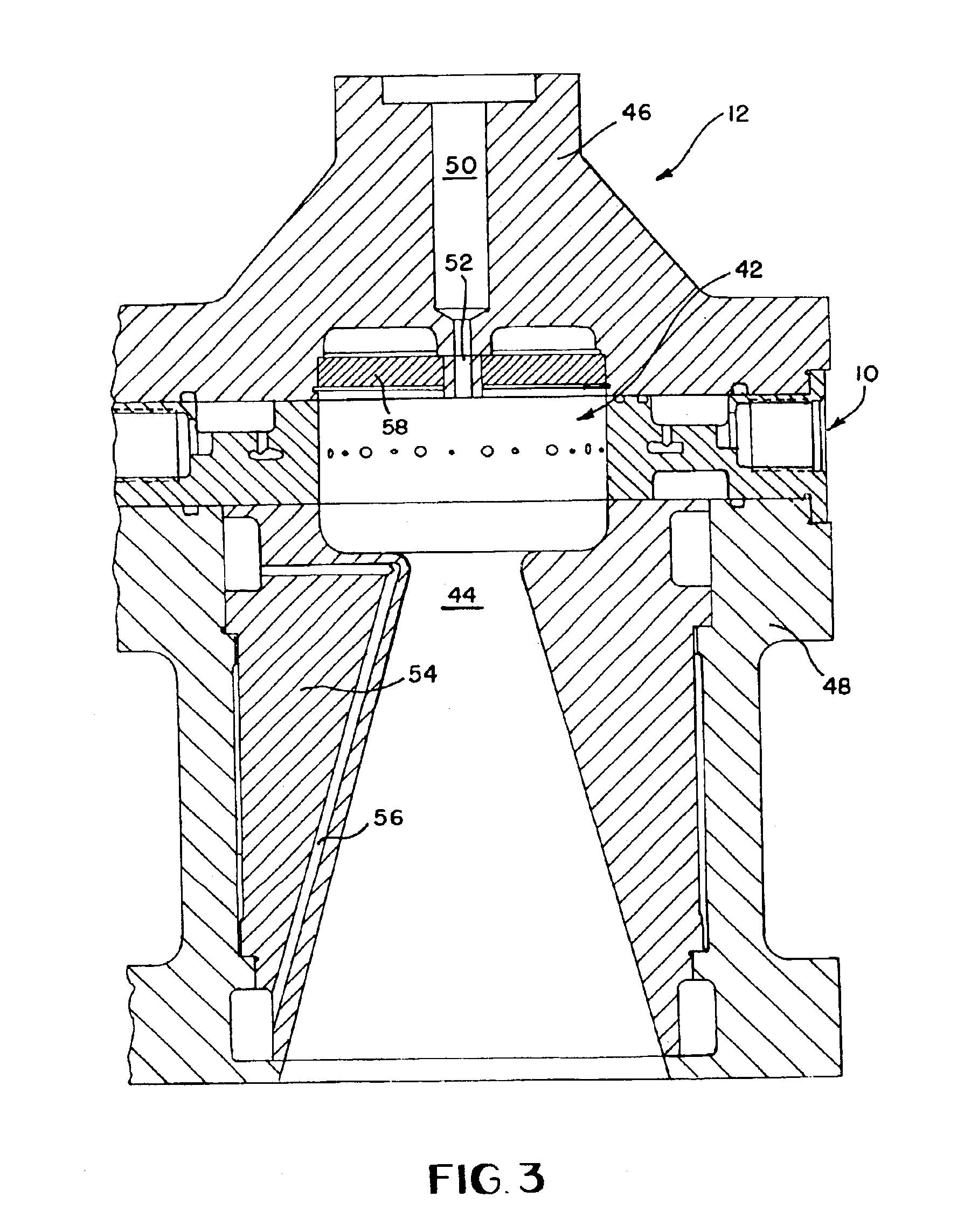

Active satellite dispenser for reusable launch vehicle

InactiveUS6789767B2Cost-effectiveDifferent from numberLaunch systemsArtificial satellitesAviationControl system

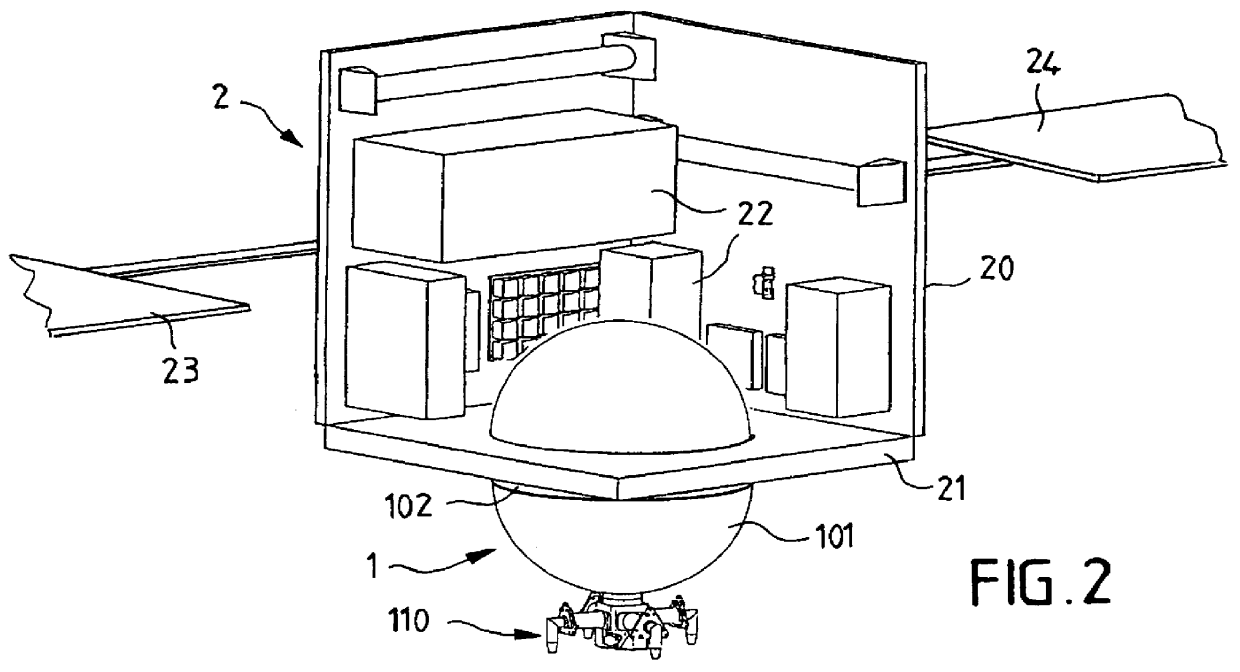

An active satellite dispenser is preferably attachable to a reusable launch vehicle for deployment of one or more satellites into one or more desired orbits. The active satellite dispenser includes a center mast that releasably receives the satellite(s), a liquid propellant rocket, and an orbital control system on an avionics pallet. In the preferred embodiment, a pressurized gas selectively pressurizes the propellant tanks (which may include fuel and oxidizer tanks), to provide propellant to the rocket. In operation, the launch vehicle releases the satellite dispenser in a first deployment orbit. The active dispenser rocket and orbital control system then transport the active dispenser and satellite(s) into the final deployment orbit. In the preferred embodiment the active dispenser can operate multiple times to place individual satellites in different orbits.

Owner:KISTLER SPACE SYST +1

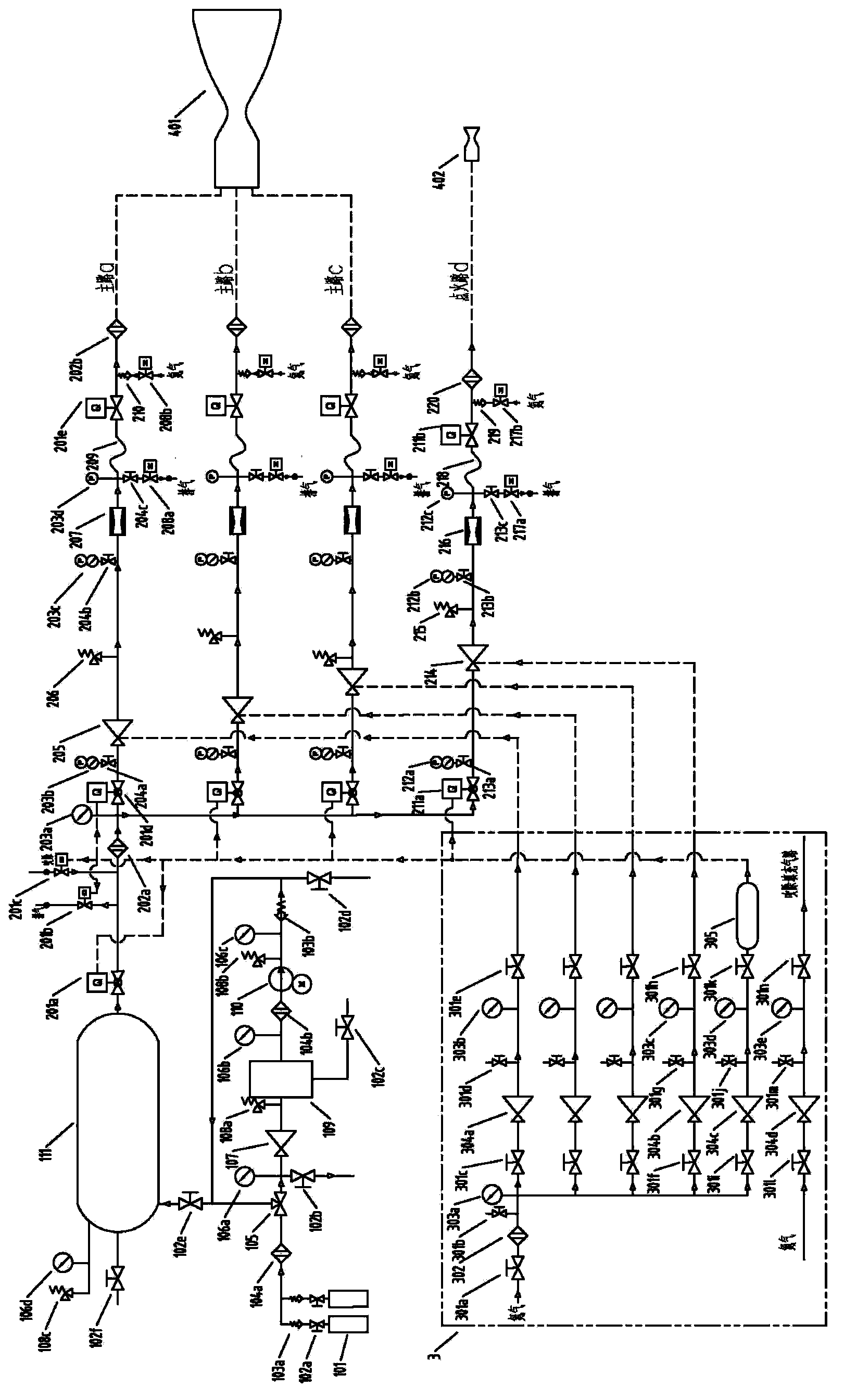

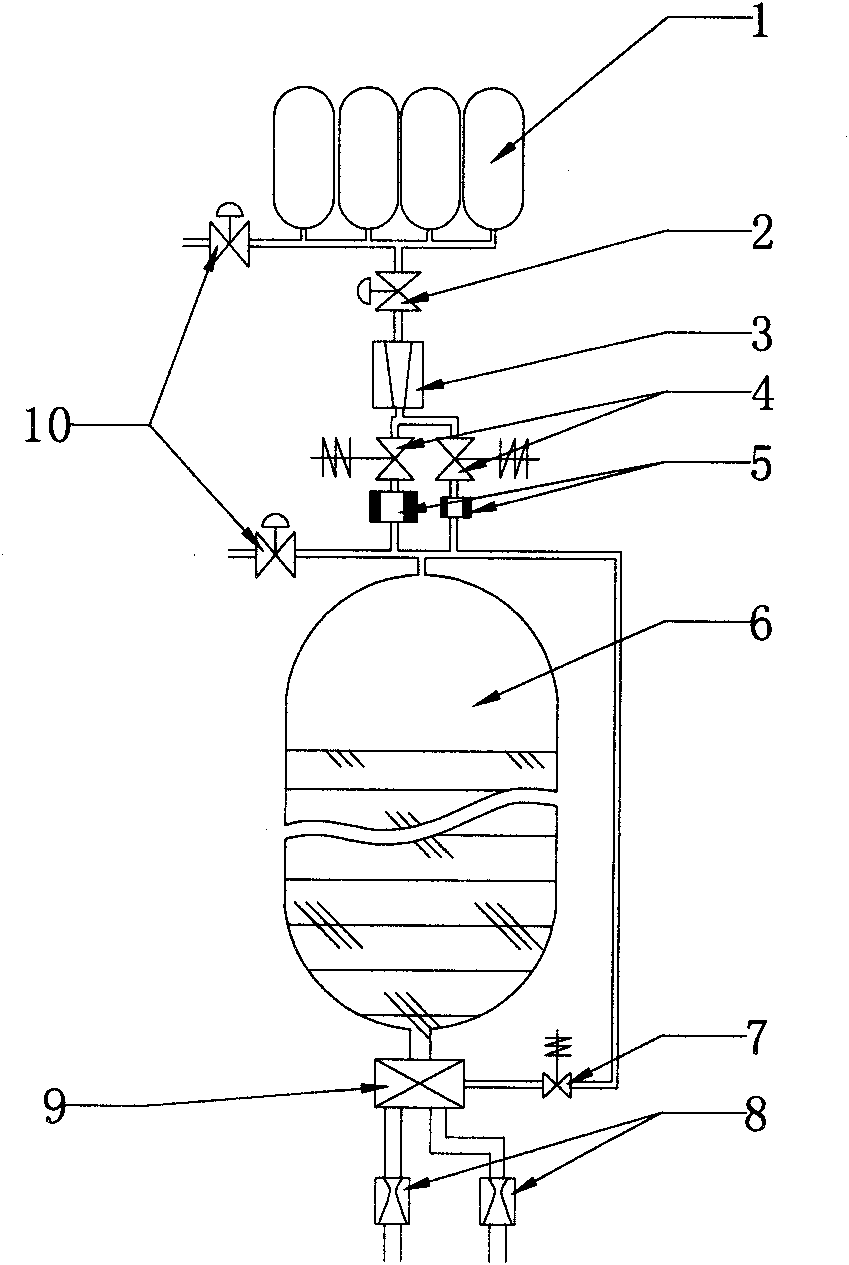

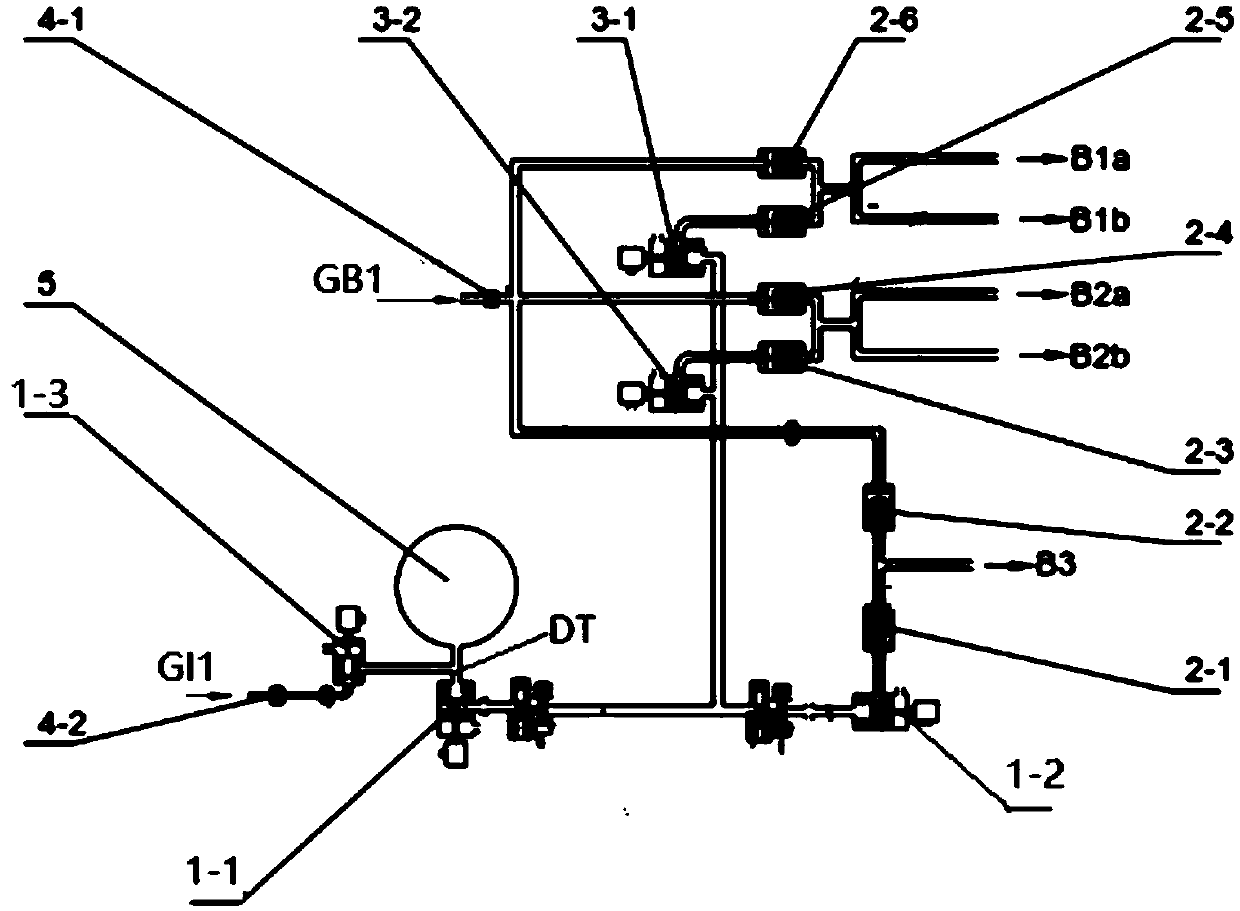

Fuel supplying system for liquid-propellant rocket engine test

ActiveCN103411775AMeet the needs of using other mediaTake advantage ofEngine testingGas cylinderHigh pressure hydrogen

The invention discloses a fuel supplying system for a liquid-propellant rocket engine test. The fuel supplying system for the liquid-propellant rocket engine test comprises a hydrogen source system, a hydrogen conveying pipeline system and a gas distribution platform system. The hydrogen source system comprises a large high-pressure gas storage tank, a high-pressure gas cylinder, a filter, a manual adjusting and pressure reducing device, a hydrogen pump and a pipeline. The hydrogen conveying system comprises three main paths and an ignition path d, wherein the three main paths are respectively the main path a, the main path b and the main path c. The gas distribution platform system comprises three main path branch paths, an ignition path branch path, a fifth branch path and a blowdown filling gas path. The three main path branch paths are respectively the main path branch path a, the main path branch path b and the main path branch path c. According to the fuel supplying system for the liquid-propellant rocket engine test, the principle that low-pressure hydrogen and high-pressure hydrogen are used in an isolated mode is utilized, the high-pressure hydrogen is directly filled into the high-pressure gas cylinder and the low-pressure hydrogen goes through a certain pressure reducing and boosting device to have high pressure and is continuously filled into the high-pressure gas cylinder. Leftover media in the hydrogen cylinder are fully utilized and the utilization rate is improved.

Owner:BEIHANG UNIV

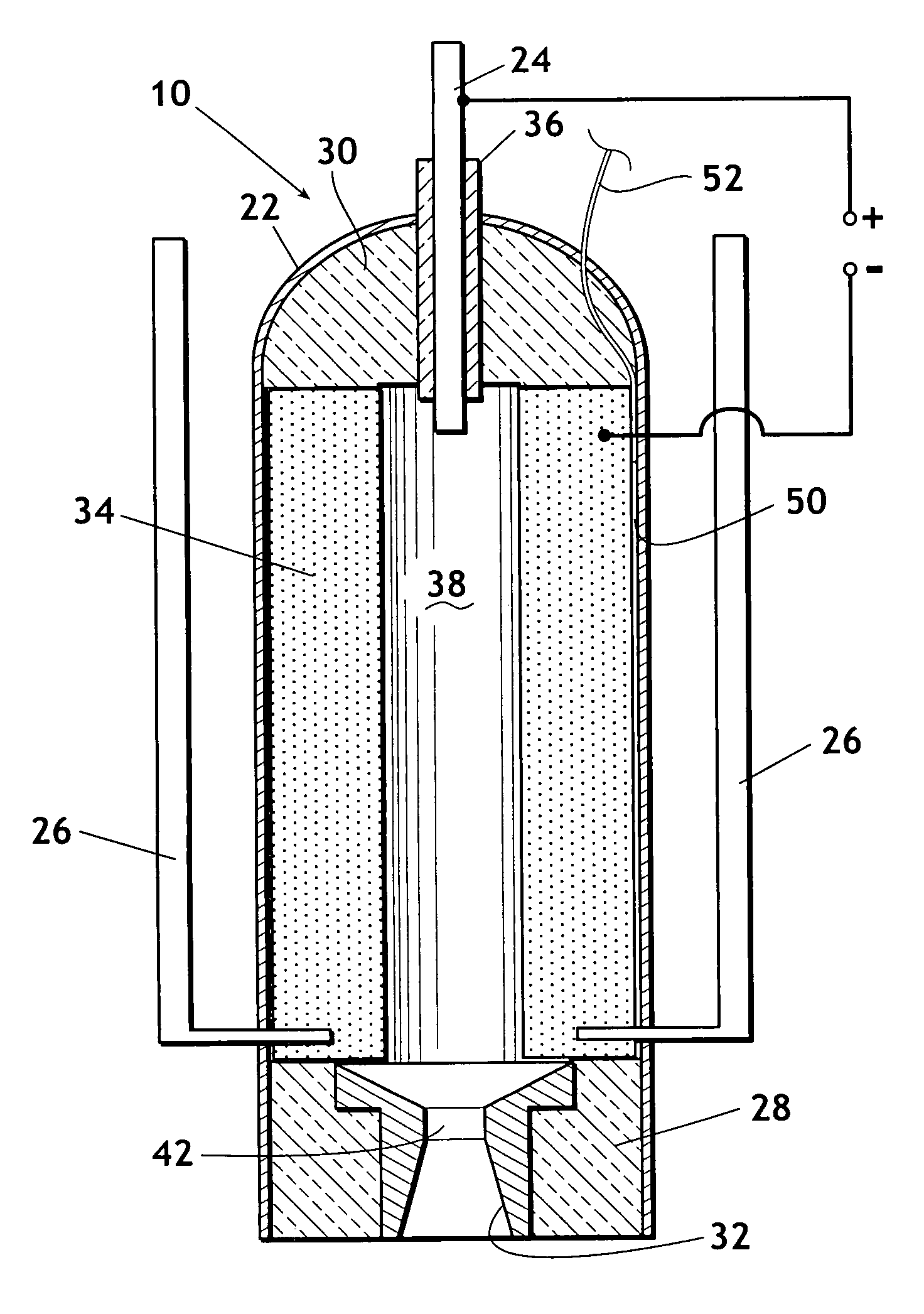

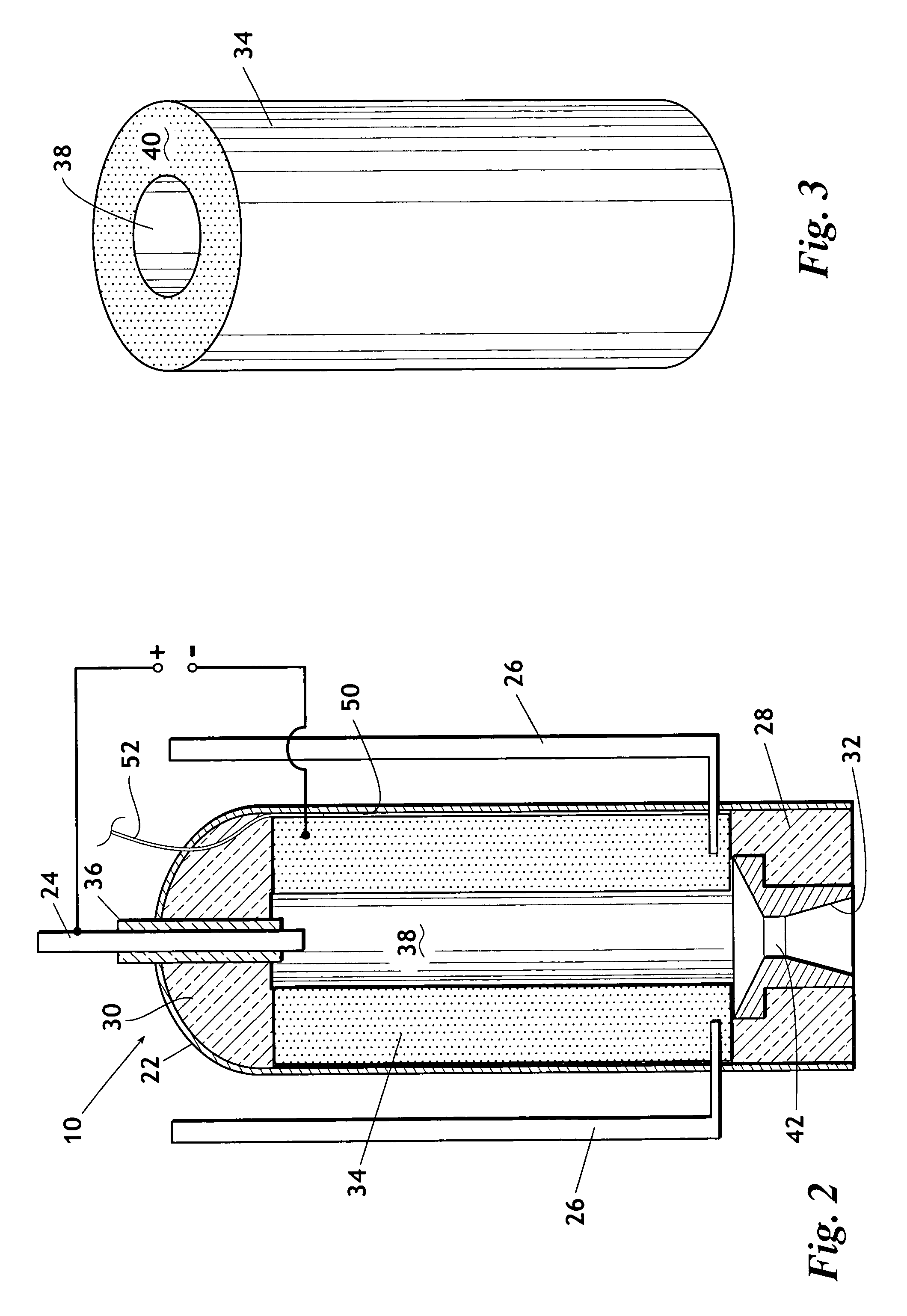

Liquid propellant rocket motor

InactiveUS6895743B1Avoid damageAvoid disassemblyEngine fuctionsGas turbine plantsLiquid fuelTranspiration

The present invention provides a transpiration cooled rocket motor which operates at low combustion pressures, inherently provides stabilized combustion, and operates over a desired range of L-star. In a preferred embodiment the inventive transpiration cooled rocket motor includes: a housing; a porous injector sleeve; a propellant injector; and a nozzle. Preferably the injector sleeve lines the inside walls of the housing such that the inside volume of the sleeve forms the chamber for the motor. Liquid fuel passes inwardly through the pores of the injector sleeve and is injected from the sleeve into the chamber, thus cooling the walls of the rocket motor.

Owner:MCELHERAN TERRY +1

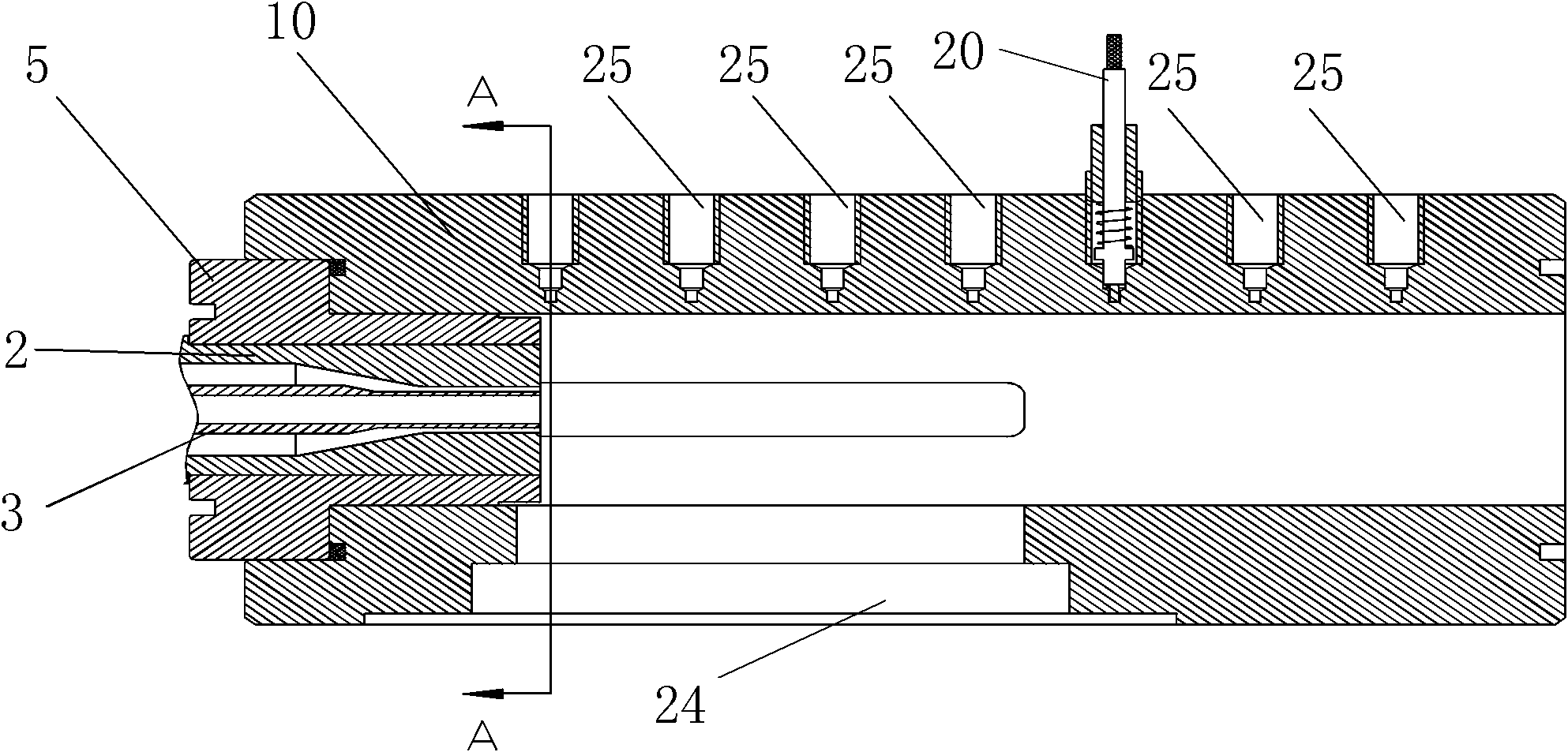

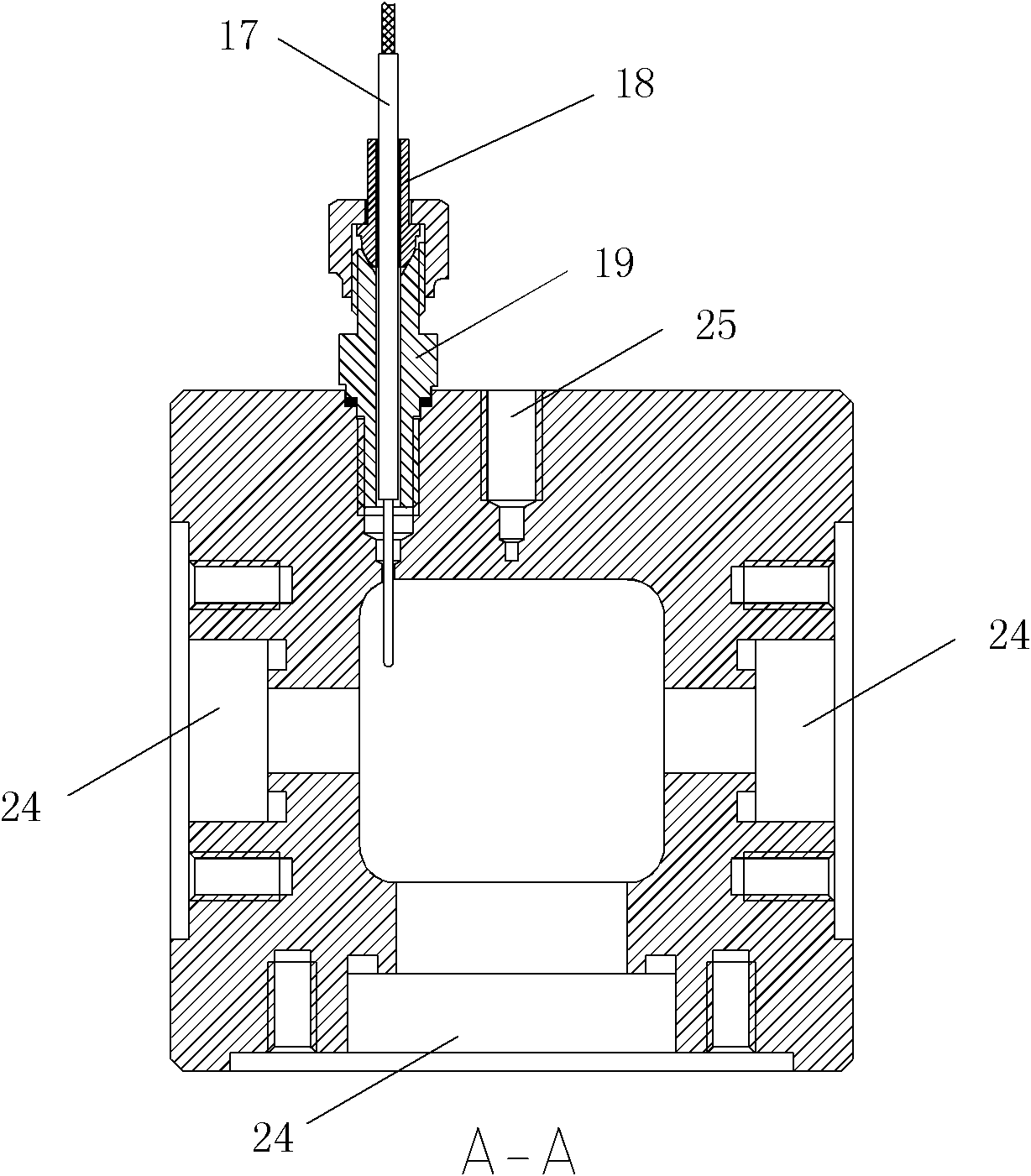

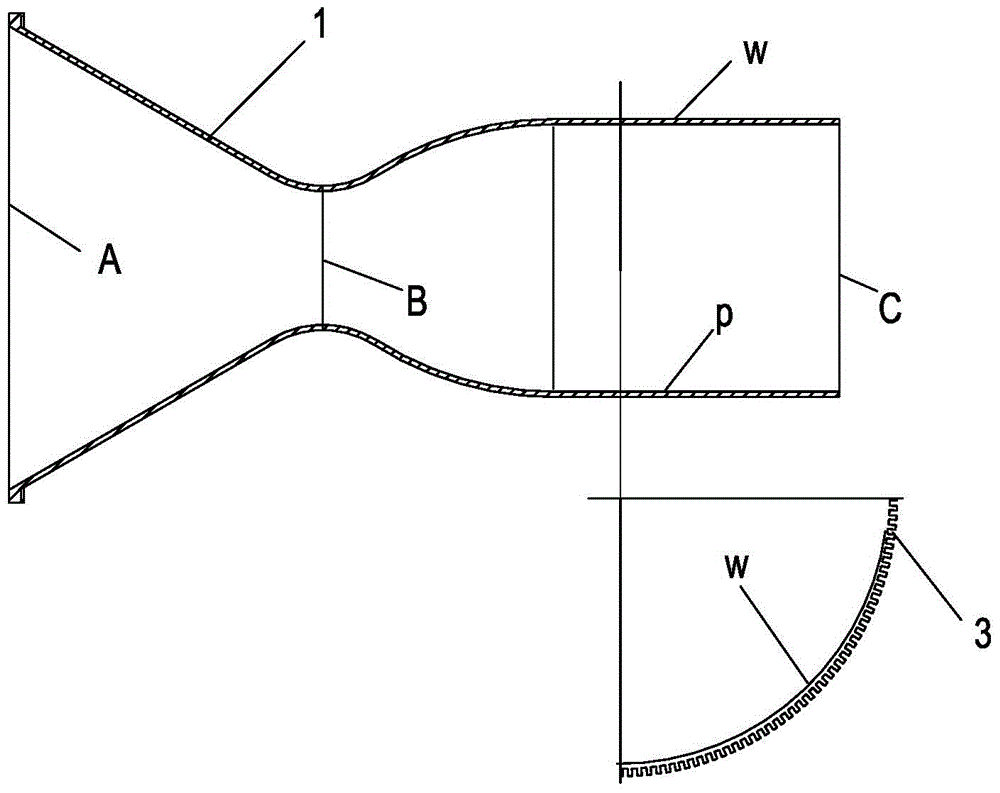

Transparent combustion chamber with square interior passage

InactiveCN102062020APromise not to touchReduce distractionsRocket engine plantsStress concentrationCombustion chamber

The invention discloses a transparent combustion chamber with a square interior passage, belonging to the field of the design of transparent combustion chambers for liquid-propellant rocket engines. The transparent combustion chamber comprises a head mechanism, a combustion chamber body mechanism, an observation window mechanism and a guiding mechanism; wherein the head mechanism comprises an oxidant cavity, a fuel nozzle, an oxygen nozzle and a fuel cavity; the combustion chamber body mechanism comprises a combustion chamber body substrate and a pressure-measuring filler neck; the observation window mechanism comprises an observation window cover plate and quartz glass; and the guiding mechanism comprises an head guiding slot and a tail guiding flange. In the invention, the observation window cover plate, the quartz glass and the combustion chamber substrate are mutually sealed with square graphite which expands to fill gaps among the observation window cover plate, the quartz glass and the combustion chamber substrate, so that glass can be ensured to be contactless with metal so as to play the role of protecting the quartz glass. The design of the square interior channel of the combustion chamber is favorable for leveling a quartz glass sheet to the inner wall surface of the combustion chamber and reducing the disturbance to an inner flow field of the combustion chamber; and four corners of the square interior channel are transitioned by adopting large circular arcs so as to prevent stress concentration.

Owner:BEIHANG UNIV

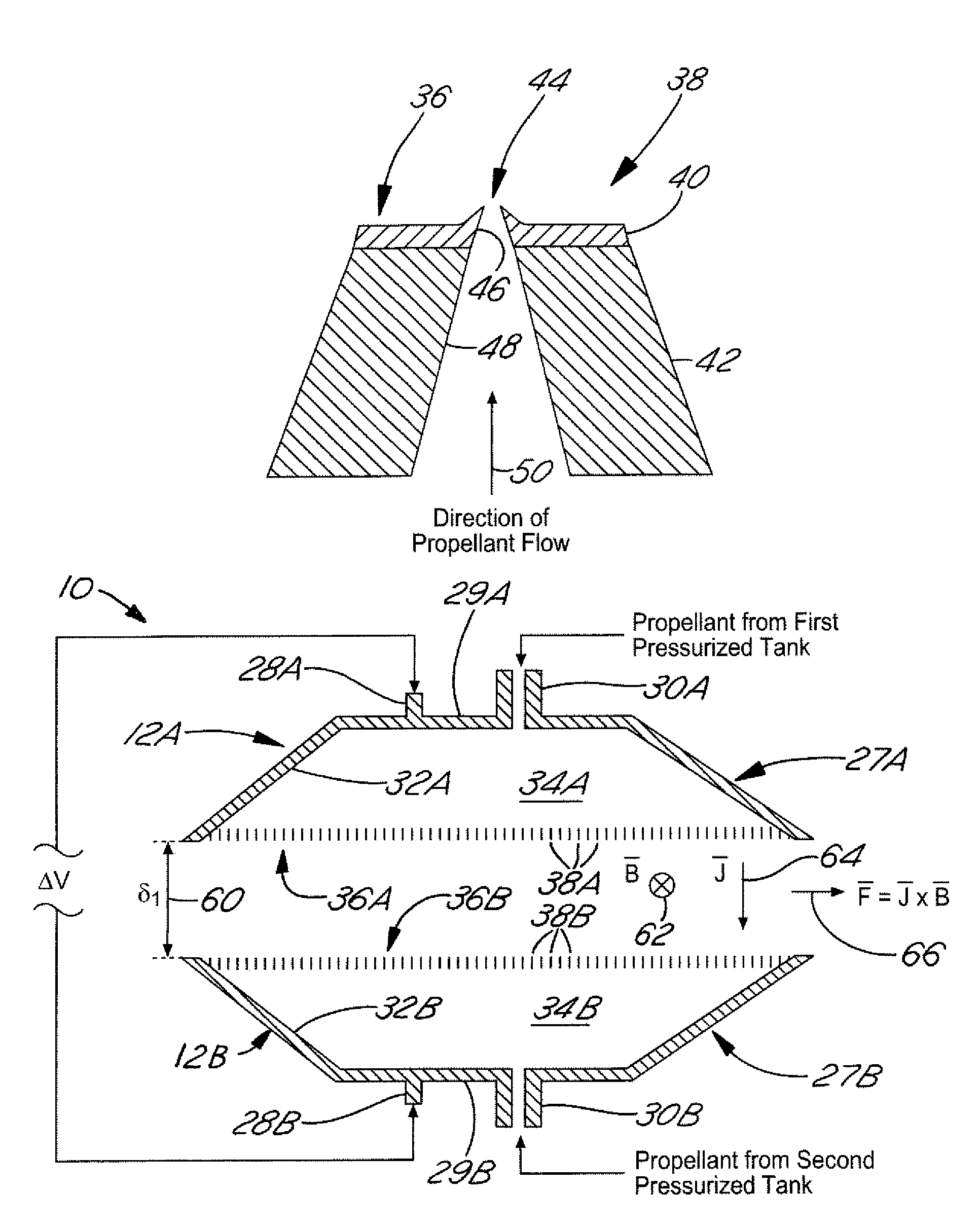

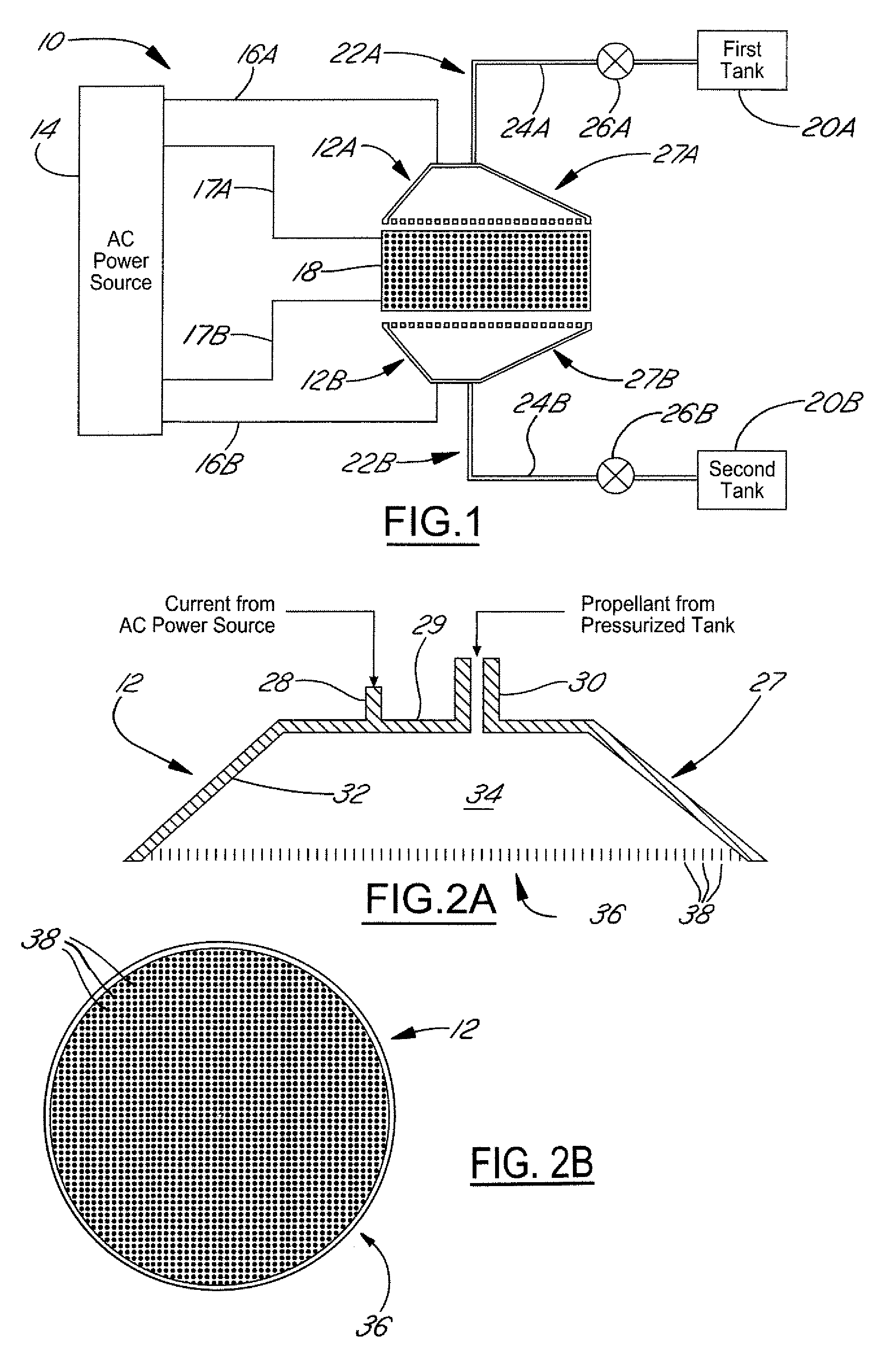

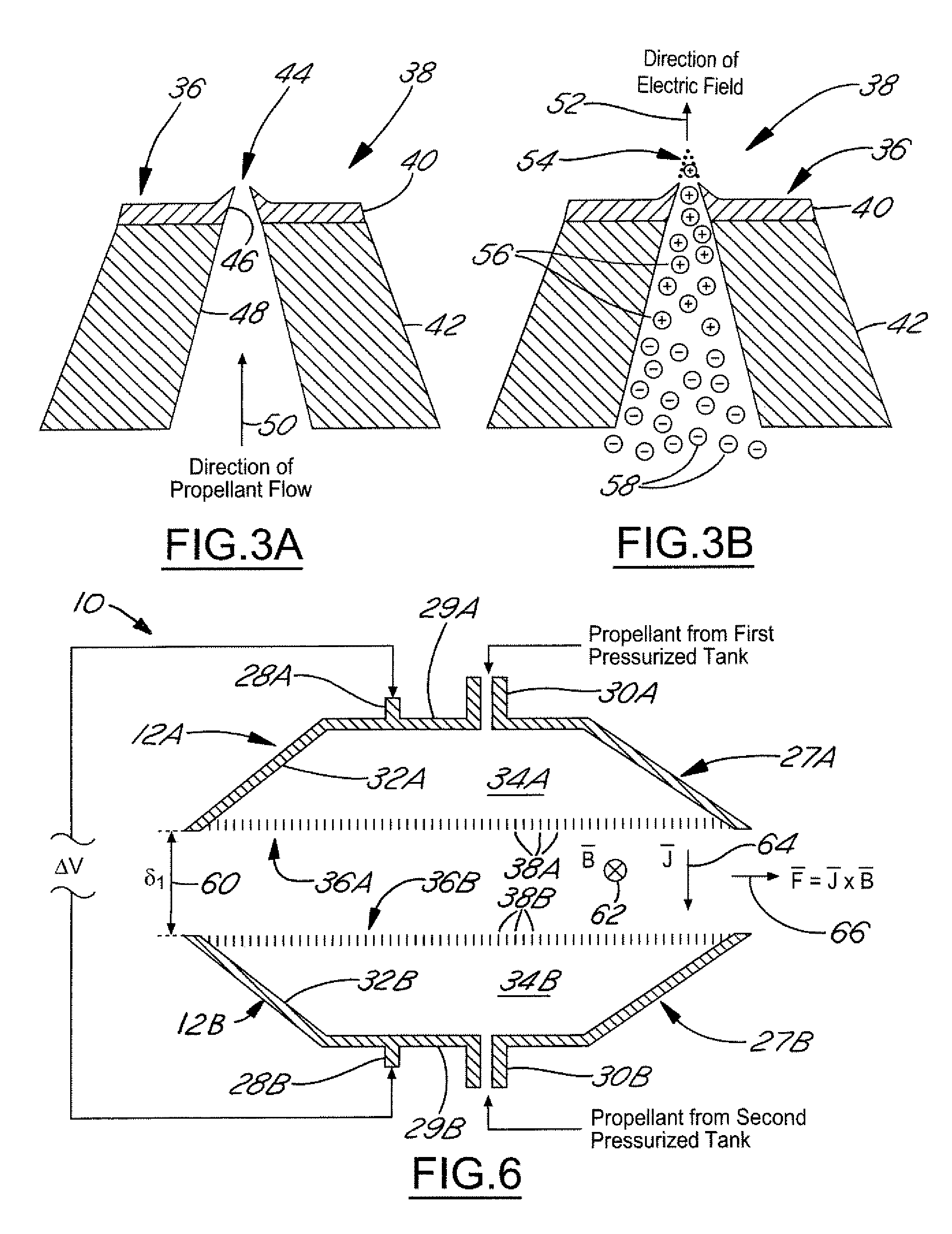

Method of ionizing a liquid propellant and an electric thruster implementing such a method

InactiveUS6996972B2Cosmonautic vehiclesCosmonautic propulsion system apparatusLiquid-propellant rocketElectrospray

A method of ionizing a liquid propellant is disclosed herein. The method includes the steps of applying an electrical charge to a showerhead, delivering a liquid propellant under pressure into a chamber defined within the showerhead, and emitting the liquid propellant under pressure through a plurality of micro-nozzles interspaced within the face of the showerhead to create a plurality of jets that collectively produce an electrospray having charged particles. An electric thruster that implements such a method is also disclosed herein. The thruster includes a showerhead having an inlet and a plurality of micro-nozzles, a reservoir for supplying propellant to the showerhead via the inlet, means for accelerating charged particles, and a power source connected to the showerhead and the accelerating means. The propellant is emitted under pressure from the micro-nozzles to produce an electrospray having charged particles. The charged particles are accelerated by the accelerating means to produce thrust.

Owner:THE BOEING CO

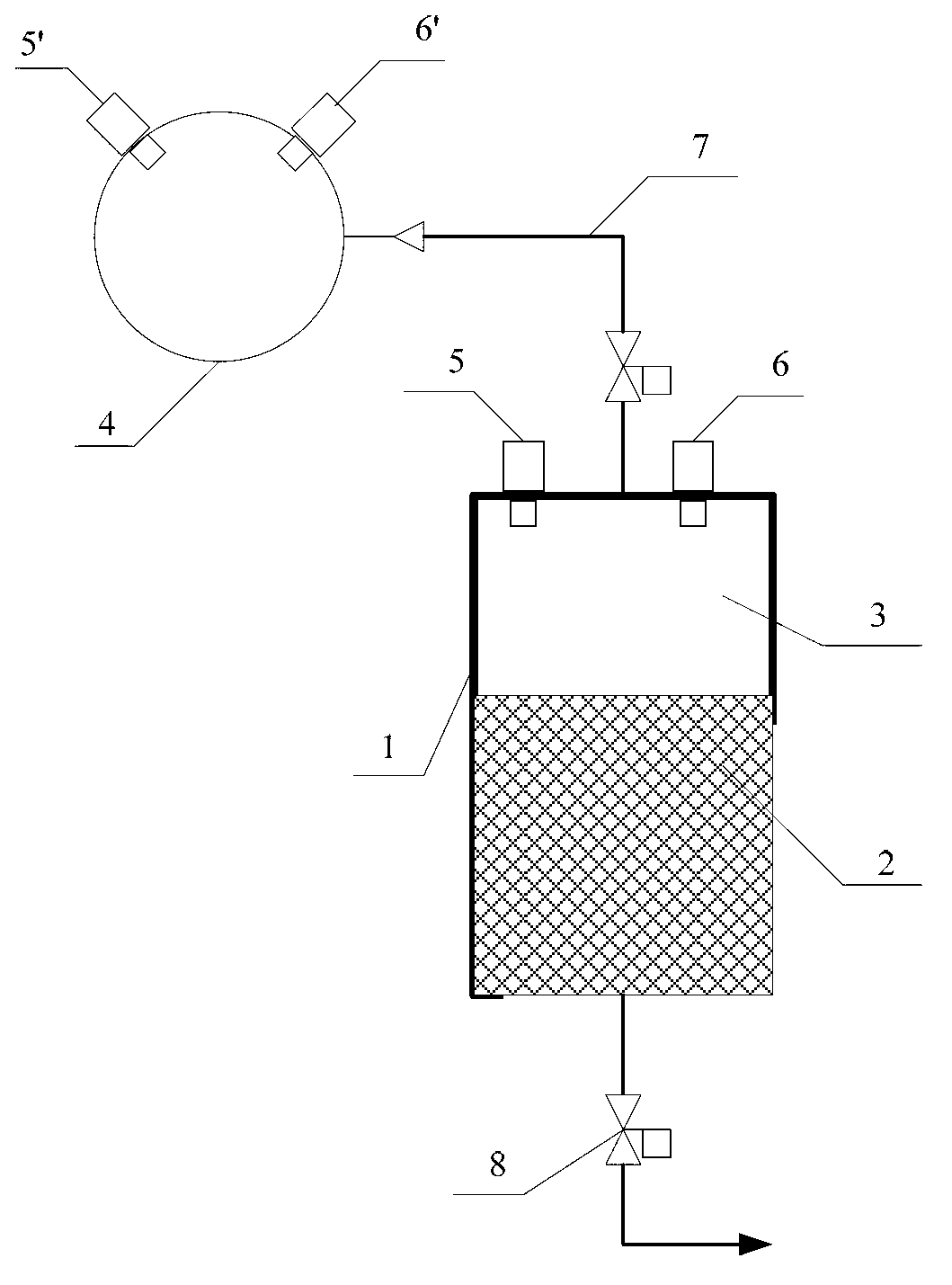

Method for measuring quantity of liquid propellant in storage tank

ActiveCN103017852AAccurate measurementHigh precisionVolume measurement apparatus/methodsGas phaseGas cylinder

The invention provides a method for measuring a quantity of a liquid propellant in a storage tank, which comprises the following steps of: step S1, measuring initial pressures and temperatures of the storage tank and a gas cylinder and forecasting an initial gas volume V0 and a quantity m10 of the residual liquid propellant in the storage tank by utilizing a propellant quantity static measurement method; step S2, establishing a heat and mass transfer mathematical model used in the pressurizing process of a storage tank open system and carrying out simulation calculation by utilizing the measured initial conditions so as to obtain a relation that a gas phase temperature and a gas phase pressure are changed with time and the propellant quantity in the storage tank; step S3, injecting pressurizing gas into the storage tank by the gas cylinder, enabling holding time to be consistent with simulation calculation time and keeping a pipeline having excellent sealing performance; step S4, measuring a gas pressure and a gas temperature of the gas part in the storage tank at a preset moment and comparing the gas pressure and the gas temperature with a simulation result; and step S5, fitting actual propellant flow according to the simulation result and an experimental result and calculating the quantity of the residual propellant in the storage tank at any moment by a formula shown in the description under the condition of the known initial propellant quantity.

Owner:NAT UNIV OF DEFENSE TECH

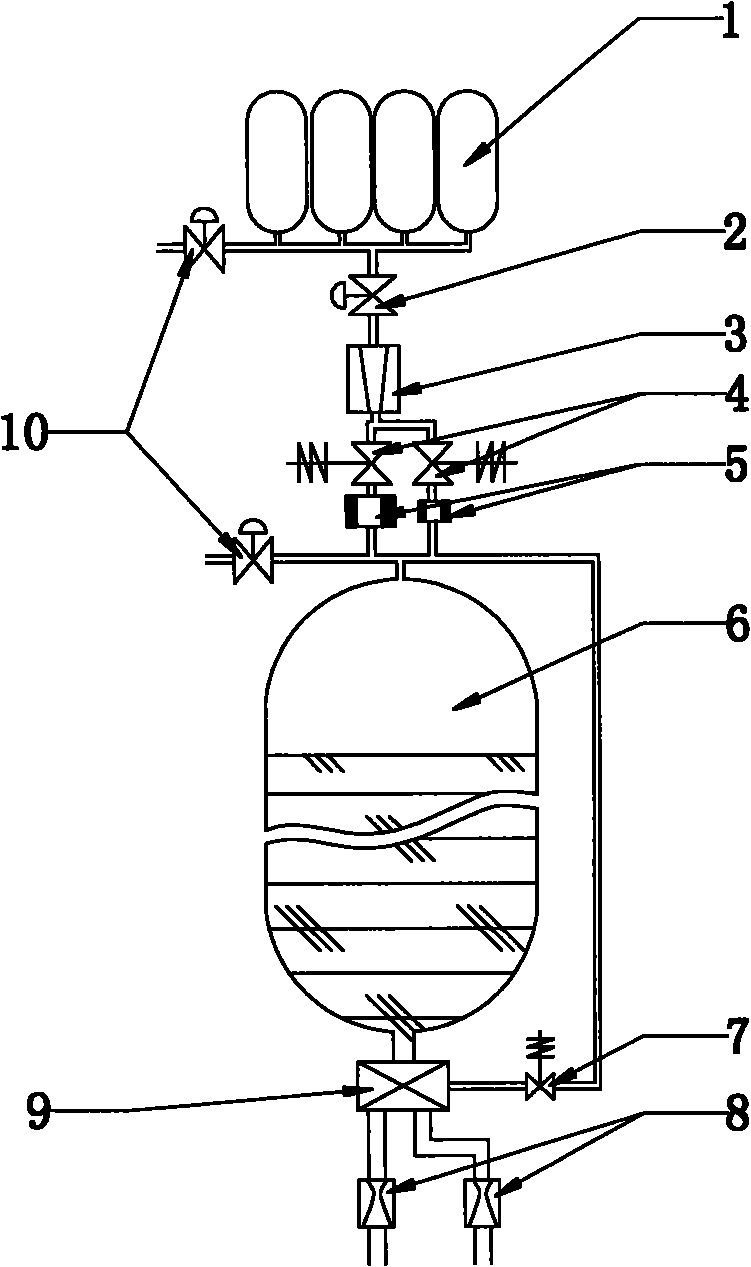

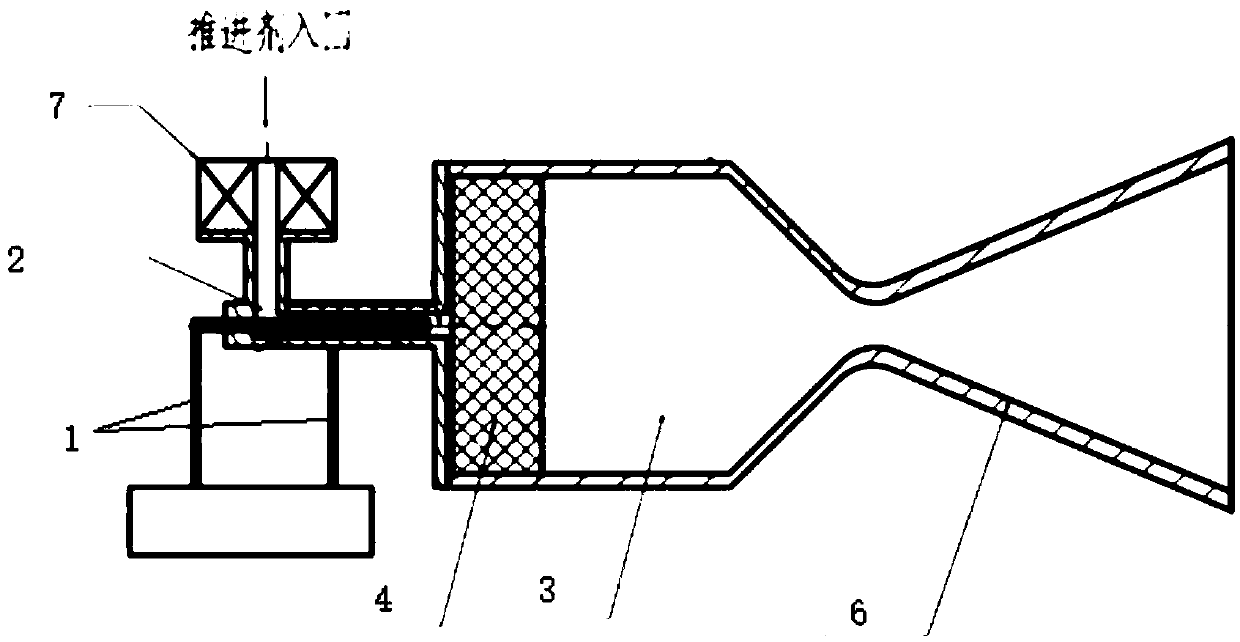

Large cryogenic liquid rocket engine test bed supply system

ActiveCN104729857ALow densityQuality impactGas-turbine engine testingJet-propulsion engine testingEngine test standPilot system

The invention discloses a large cryogenic liquid rocket engine test bed supply system. The system comprises a fuel pressurization system, an oxidizing agent pressurization system, a fuel transport system and an oxidizing agent transport system. According to the system, propellant is pressurized through a gas supercharging method, and the stability and reliability of liquid flow in the engine testing process are guaranteed; the domestic normally-used pump pressurization method is not adopted and has the defects that the output flow of liquid is in an impulse mode, vibration is strong and difficulty is caused in the testing process, so the gas supercharging method has high adaptability to the system; the function that liquid propellant is converted into gas propellant is expanded, the requirements of other testing systems for the gas propellant can be met in future, and the multifunctionality of the testing system is greatly expanded.

Owner:BEIHANG UNIV

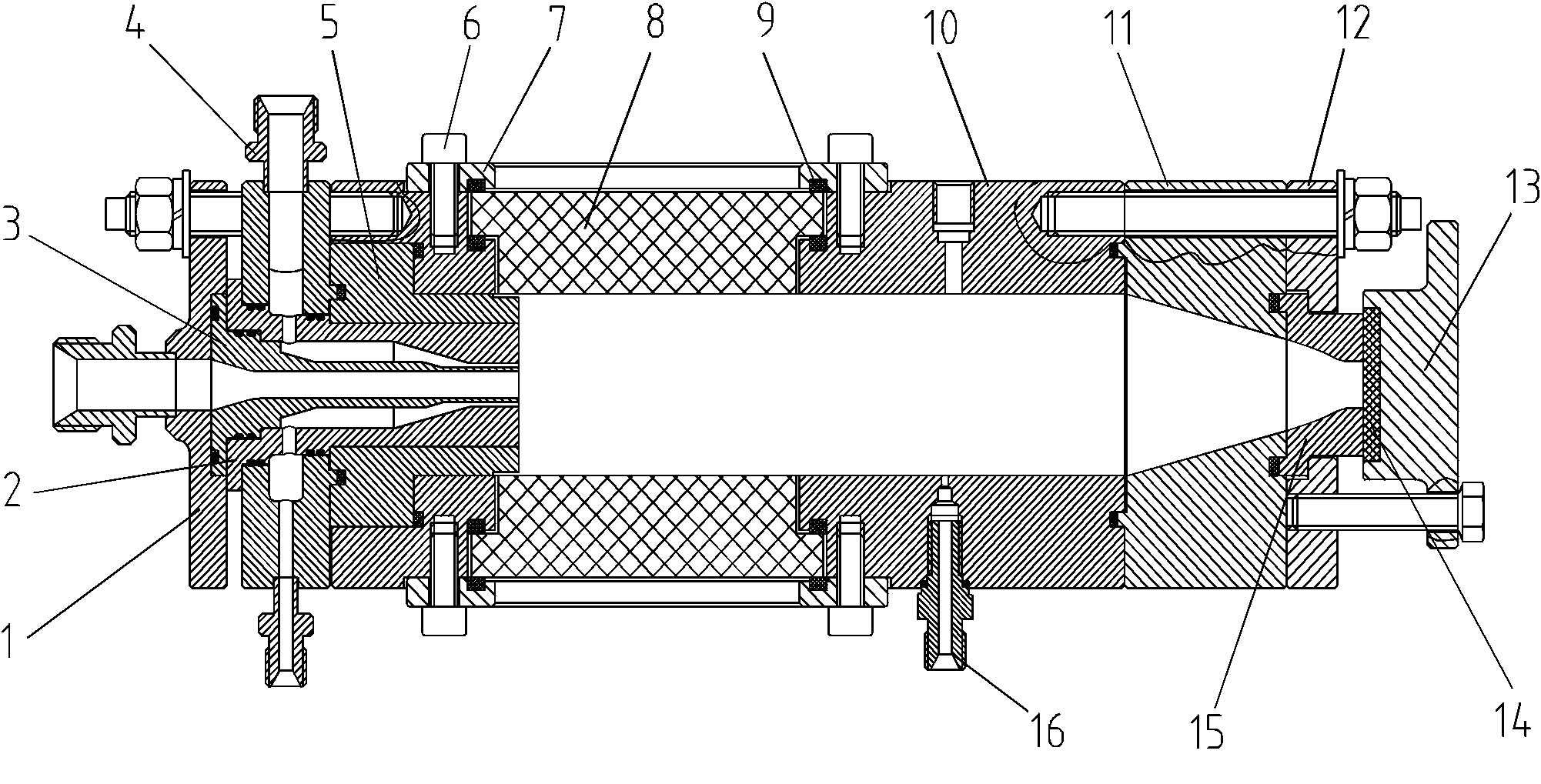

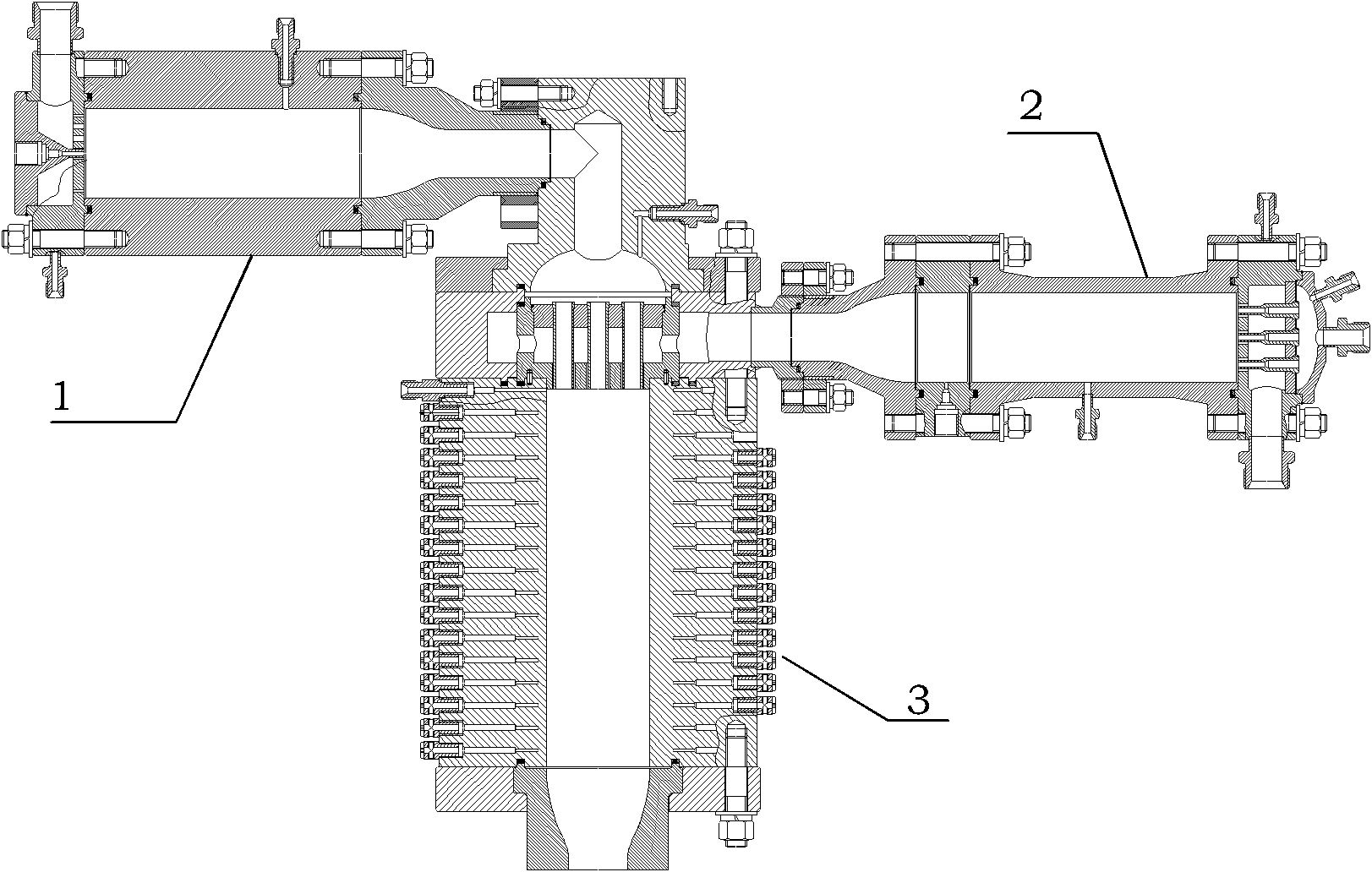

Test unit for hydrogen-rich/ oxygen-rich gas multinozzle gas-gas injector

InactiveCN102022225AImprove antioxidant capacityImprove compactnessRocket engine plantsHydrogenCombustion chamber

The invention discloses a test unit for a hydrogen-rich / oxygen-rich gas multinozzle gas-gas injector, relating to the design field of hydrogen-rich / oxygen-rich gas multinozzle combustion chambers of liquid propellant rocket engines. The test unit mainly comprises an oxygen-rich prechamber, a hydrogen-rich prechamber and a main combustion chamber. An oxygen-rich chamber outlet flange is connectedto the oxygen-rich chamber outlet section of the oxygen-rich prechamber by a thread structure, an oxygen inlet supported flange is connected to an oxygen-rich gas inlet section of the main combustionchamber, a hydrogen-rich chamber outlet flange is connected to the hydrogen-rich chamber outlet section of the hydrogen-rich prechamber by the thread structure, and a hydrogen inlet coupling flange is connected to the hydrogen-rich gas inlet section of the main combustion chamber. The flanges in an experimental facility are made of A3 carbon steel material, and thus the cost is lowered. In addition, each part of the device is convenient to connect and install, and wall surface temperature is convenient to measure.

Owner:BEIHANG UNIV

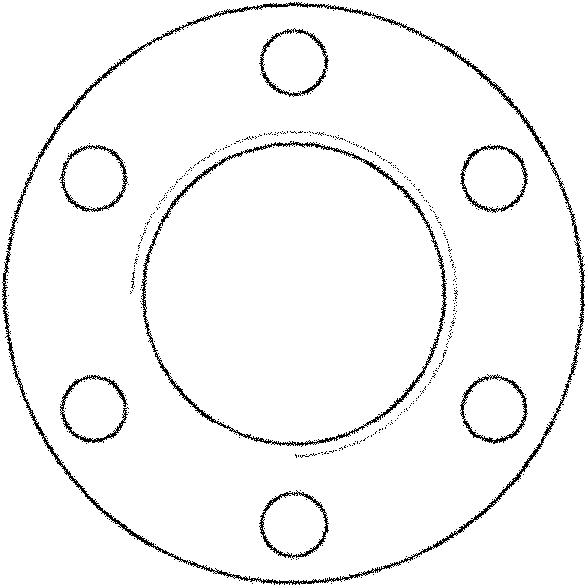

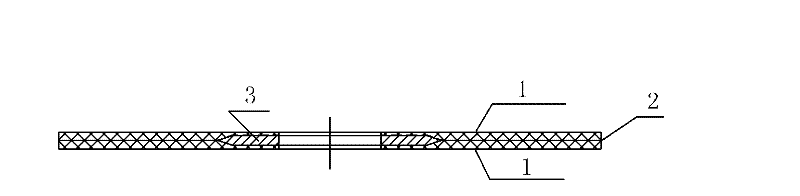

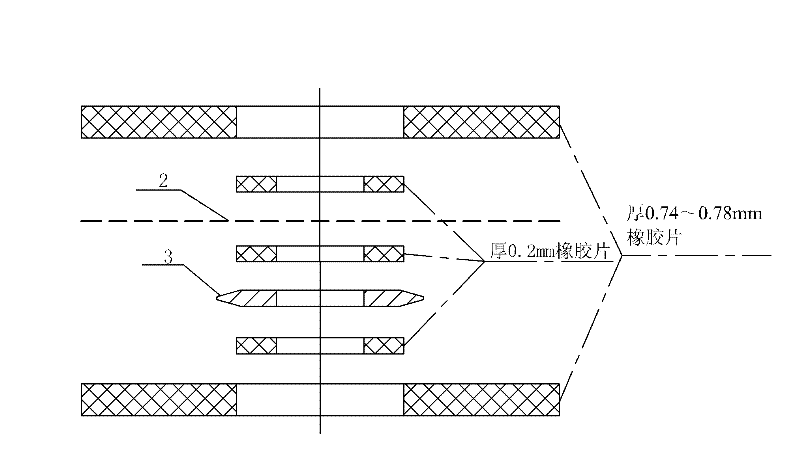

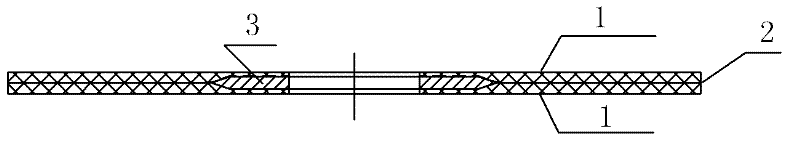

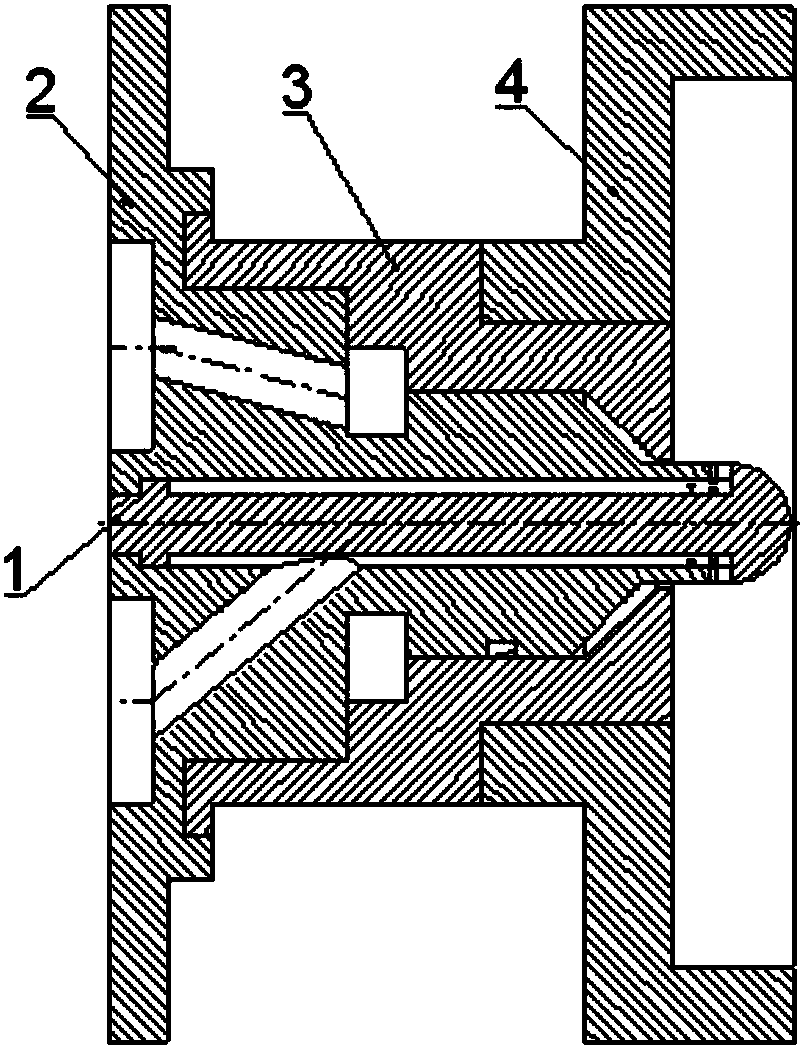

Rubber fabric clamped film sheet and manufacturing method thereof

ActiveCN102563189AImprove fatigue resistanceGood adhesionOperating means/releasing devices for valvesFibre treatmentRubber materialMetal framework

The invention relates to a rubber fabric clamped film sheet and a manufacturing method thereof. The rubber fabric clamped film sheet comprises a rubber material film sheet body which is provided with a central hole, wherein the film sheet body is internally provided with a reinforced fabric interlayer and a disc-shaped metal framework; the shape of the reinforced fabric interlayer is consistent with that of the film sheet body; the diameter of the outer circle of the metal framework is greater than the diameter of the central hole but smaller than the diameter of the outer circle of the film sheet body. The rubber fabric clamped film sheet, disclosed by the invention, solves the problem of mottled surface of the film sheet, the problem that the film sheet after being ground is difficult to separate and the problem that surface bulge and rubber layer fracture of the film sheet are resulted after the film sheet is peeled off forcibly. The rubber fabric clamped film sheet, disclosed by the invention, has the advantages of high pressure resistance, good leak tightness, high stability of pressure adjustment as well as good high-temperature and low-temperature pressure adjustment characteristics, and is particularly suitable for reducing valves of liquid-propellant rocket engines with high requirements on performance and relatively high leak tightness as well as adjustability.

Owner:NO 11 INST OF NO 6 ACADEMY OF CHINA AEROSPACE SCI & TECH

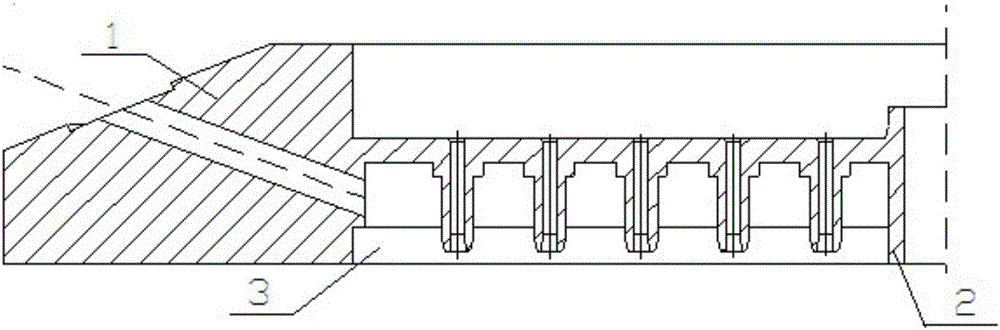

Manufacturing method of liquid-propellant rocket engine combustion chamber

ActiveCN104924036AImprove processing efficiencyEasy to operateRocket engine plantsCombustion chamberEngineering

The invention discloses a manufacturing method of a liquid-propellant rocket engine combustion chamber. The manufacturing method includes the following steps that the inner wall front sealing end face, the inner wall rear sealing end face and the inner wall outer molded surface are finely finished, and fine finish allowances are reserved on the inner wall front sealing end face, the inner wall rear sealing end face and the inner wall outer molded surface; the outer wall front sealing end face, the outer wall rear sealing end face and the outer wall inner molded surface are finely finished; fine finish allowances are reserved on the outer wall front sealing end face, the outer wall rear sealing end face and the outer wall inner molded surface; the inner wall and the outer wall are pre-treated; the inner wall which is dried and dehydrated is sleeved with the inner side of the outer wall, and then connection treatment is conducted; defect detection, fine finish, a water pressure test for strength and cleaning and airing treatment are conducted on the combustion chamber. As is proved by practice, the manufacturing method is simple in operation and high in machining efficiency, diffusion connection can be finished in one day, and efficiency is improved by more than ten times compared with that of a traditional electroforming process and a traditional brazing process.

Owner:湖北三江航天江北机械工程有限公司

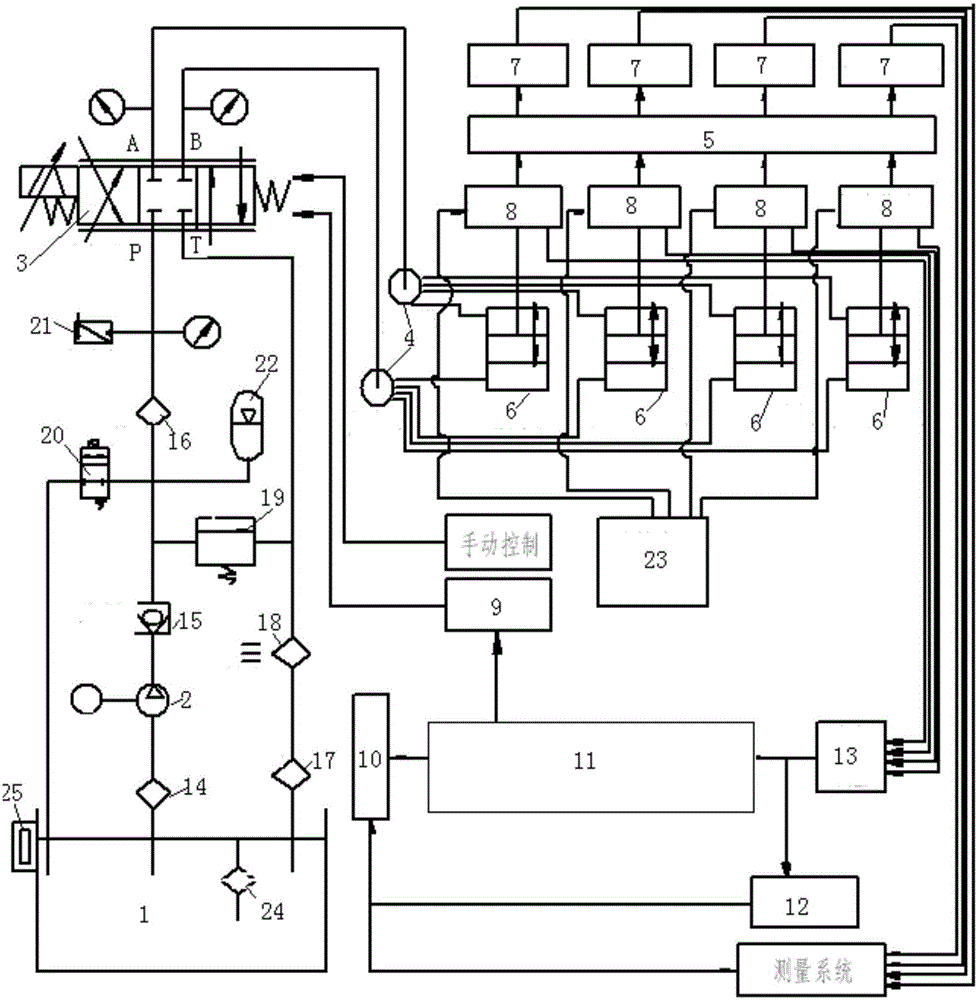

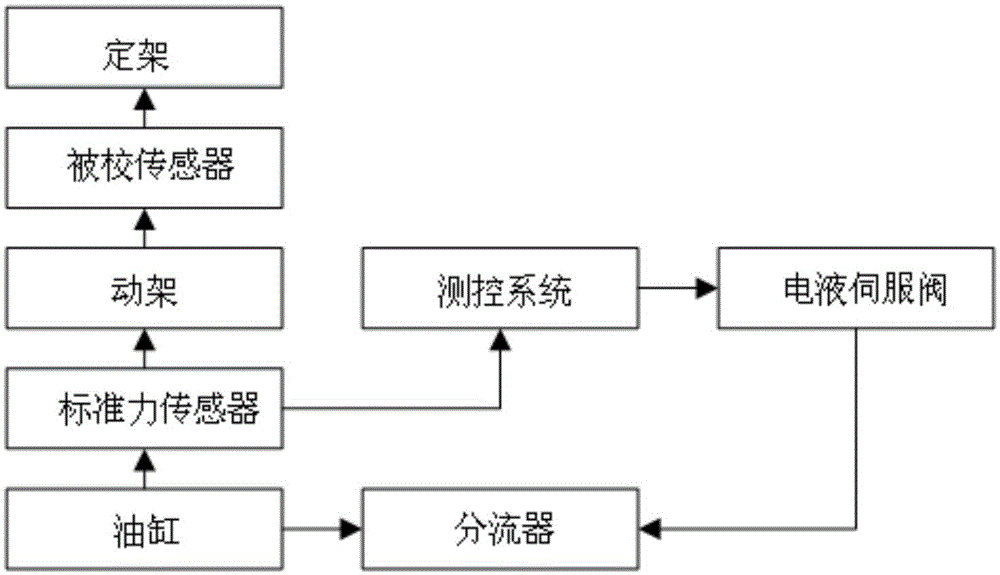

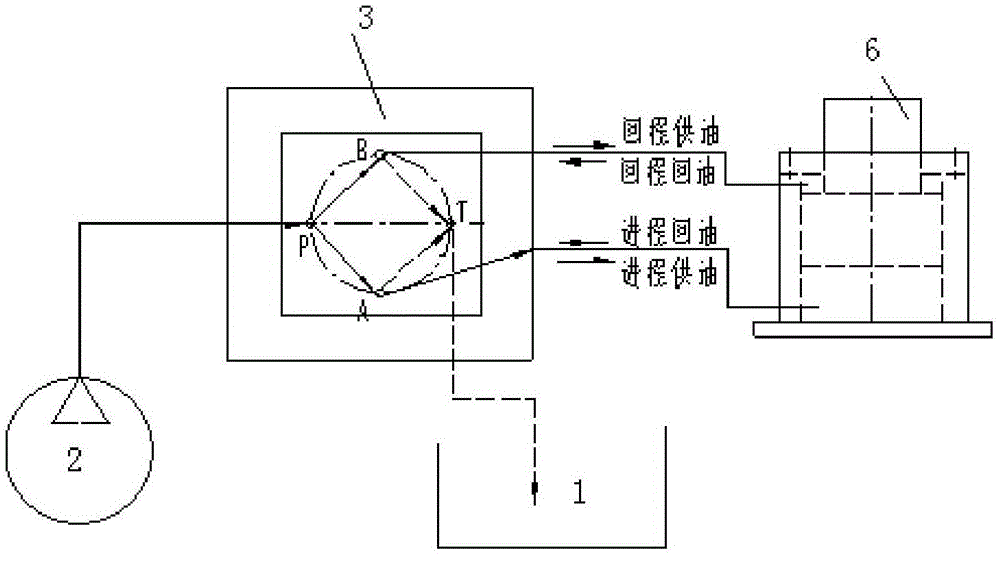

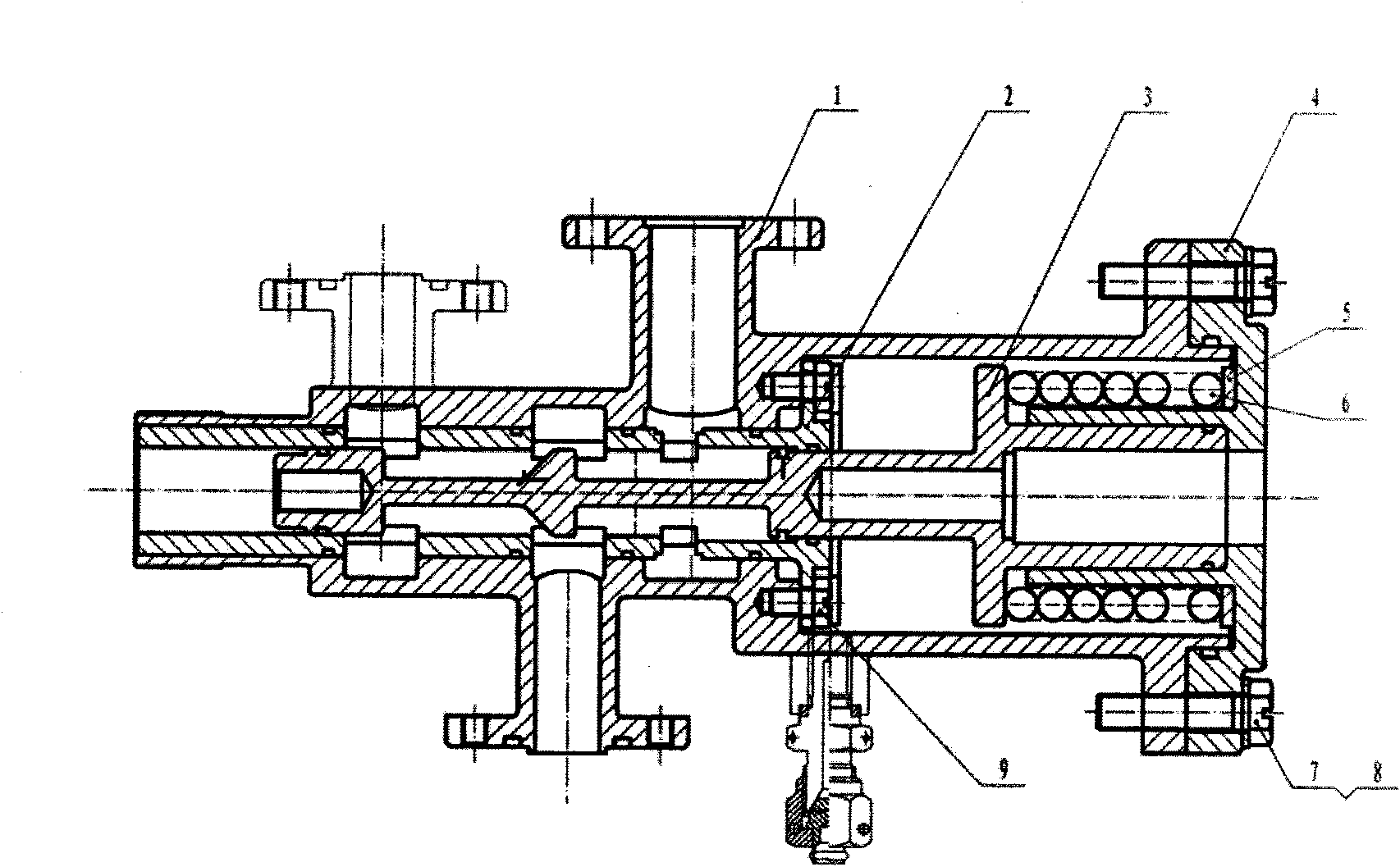

Liquid-propellant rocket engine test thrust calibration system and calibration method

InactiveCN105004525AImprove accuracyReduce the degree of impactEngine testingTransmission technologyElectro hydraulic

The invention relates to a liquid-propellant rocket engine test thrust calibration system and a calibration method. The electro-hydraulic servo control technology is employed as a core, a thrust parallel connection transmission technology is employed, Ends of two diverters are connected with a first oil outlet A and a second oil outlet B of an electro-hydraulic servo value correspondingly. A plurality of ports at the other end of one diverter are connected with oil input cavities of a plurality of double-acting oil cylinders correspondingly and respectively. A plurality of ports at the other end of the other diverter are connected with oil return cavities of the plurality of double-acting oil cylinders correspondingly and respectively. The plurality of double-acting oil cylinders are distributed under a movable rack. A fixed rack and the movable rack are connected through a spring steel plate. A plurality of calibrated sensors are located between the fixed rack and the movable rack and are pressed against the lower bottom surface of the fixed rack. A plurality of standard force sensors are located among the movable rack and the oil cylinders and are pressed against a movable rack lower bottom surface of a force transmission rack. Results show that the calibration system is advantaged by high calibration precision, good stability and short consuming time, and raises the large-thrust liquid-propellant rocket engine test thrust calibration technological level greatly.

Owner:XIAN AEROSPACE PROPULSION TESTING TECHN INST

Liquid propellant tracing impingement injector

An injector for use with the rocket thruster has a plurality of fuel ports separated from a plurality of oxidizer ports. The oxidizer and fuel ports are paired together directing their respective fluids along a path with radial and tangential components so that the two fluids impinge at a predetermined spaced apart distance from the chamber wall of the combustion chamber at an impingement track. By providing the fuel at a steeper angle relative to the chamber walls than the oxidizer, the fuel can be utilized to provide a fuel rich zone near the chamber walls to assist in cooling the chamber walls during operation.

Owner:NASA

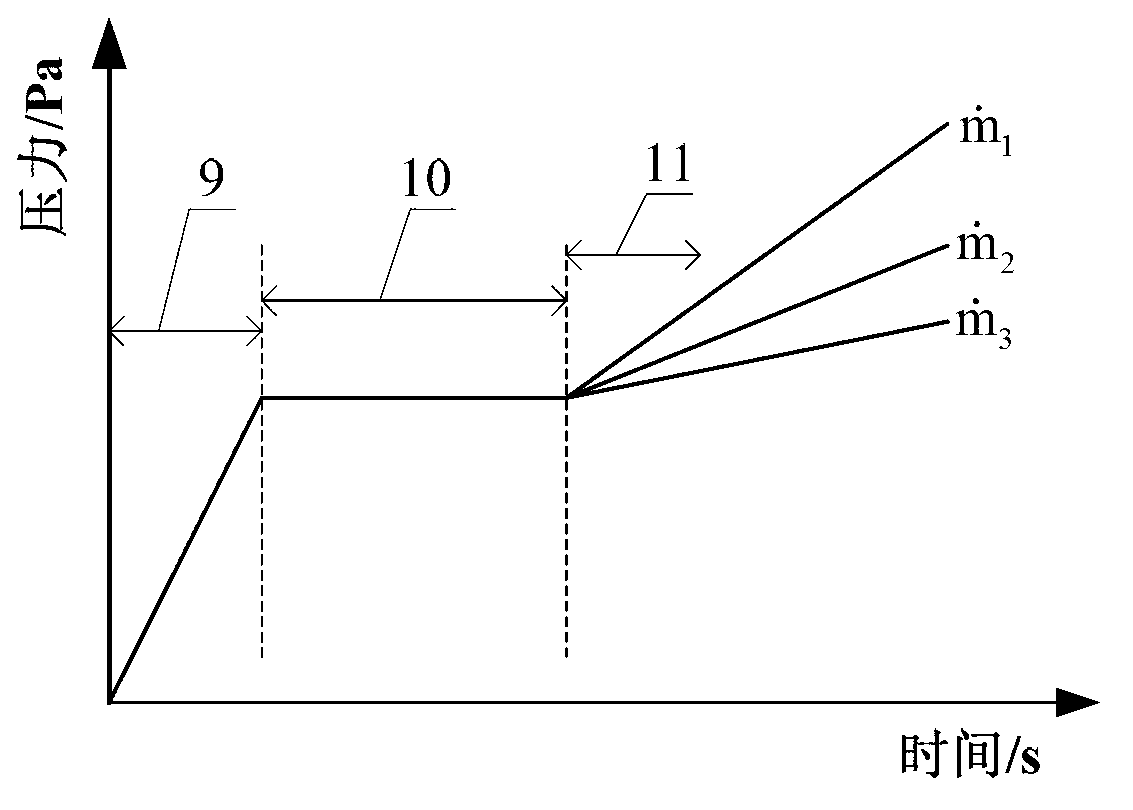

Double operating mode squeezing type conveying system and design method thereof

InactiveCN101915184ASolve the disadvantages of large lossesSimplify design difficultyRocket engine plantsGas cylinderControl system

The invention relates to a double operating mode squeezing type conveying system scheme with stepped large-range flow adjustment of a solid-liquid rocket engine, belonging to the field of liquid propellant flow control of the solid-liquid rocket engine. The conveying system of the invention comprises a gas cylinder, a supercharging gas path and a control system thereof, a storage tank, a liquid path double operating mode main valve and a flow control component. By adjusting the supercharging gas flow of the supercharging gas path, the pressure of the storage tank in the working process of theconveying system is changed, and then the liquid path double operating mode main valve senses the pressure of the storage tank and changes the operating mode, thereby adjusting the supply of the liquid propellant flow, avoiding the defect of narrow flow adjusting range caused by independently adjusting the supercharging gas path or the liquid path, and realizing large-range and stepped change of the liquid flow supply in the working process, wherein the design of the liquid path double operating mode main valve realizes the functions of the main valve and operating mode conversion, and greatly simplifies the structure and design difficulty of the liquid pipeline part of the conveying system with large-range change of flow.

Owner:BEIHANG UNIV

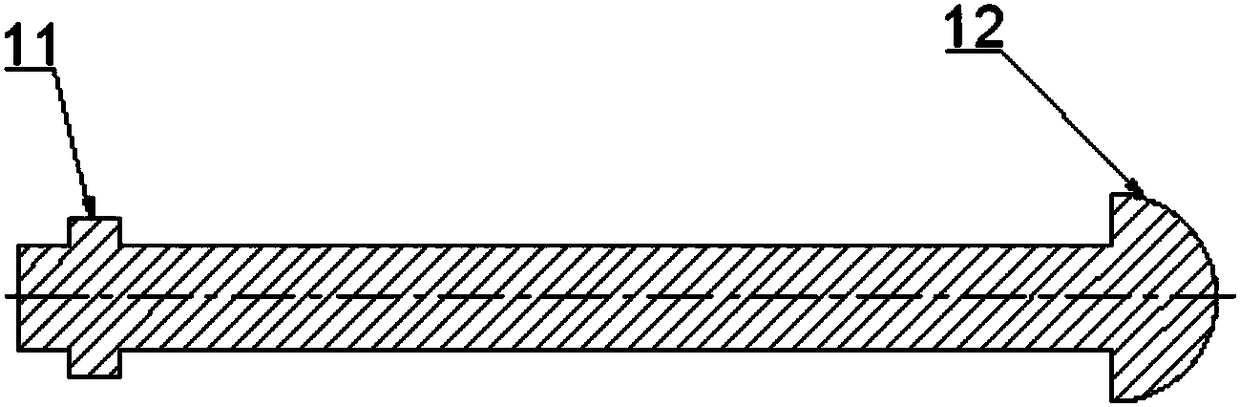

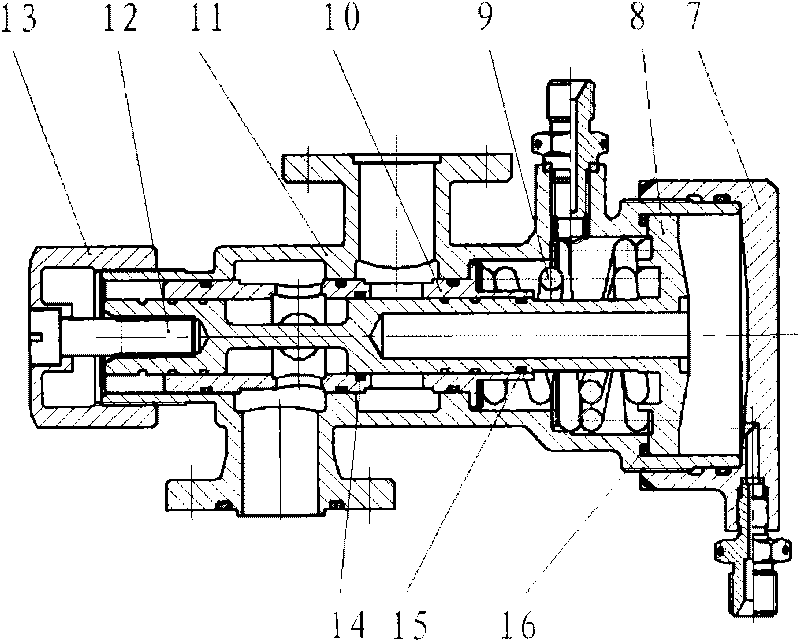

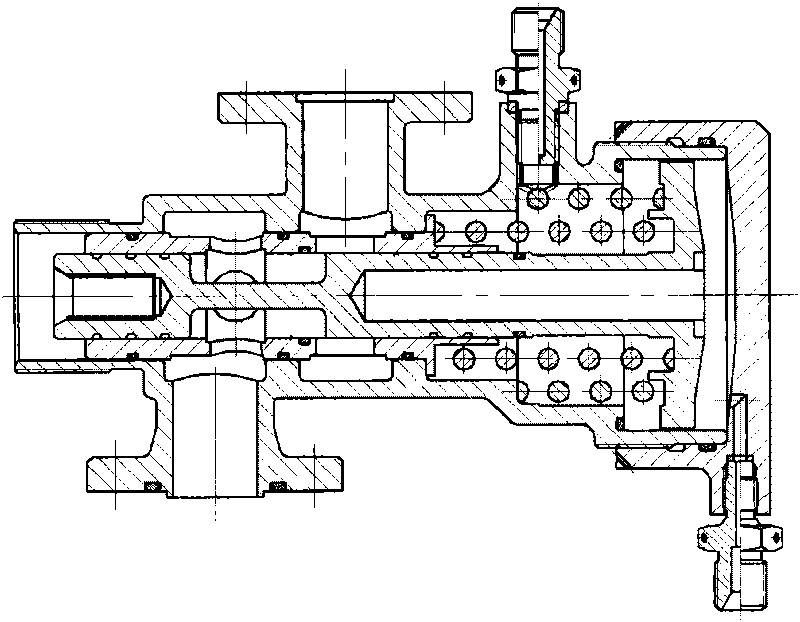

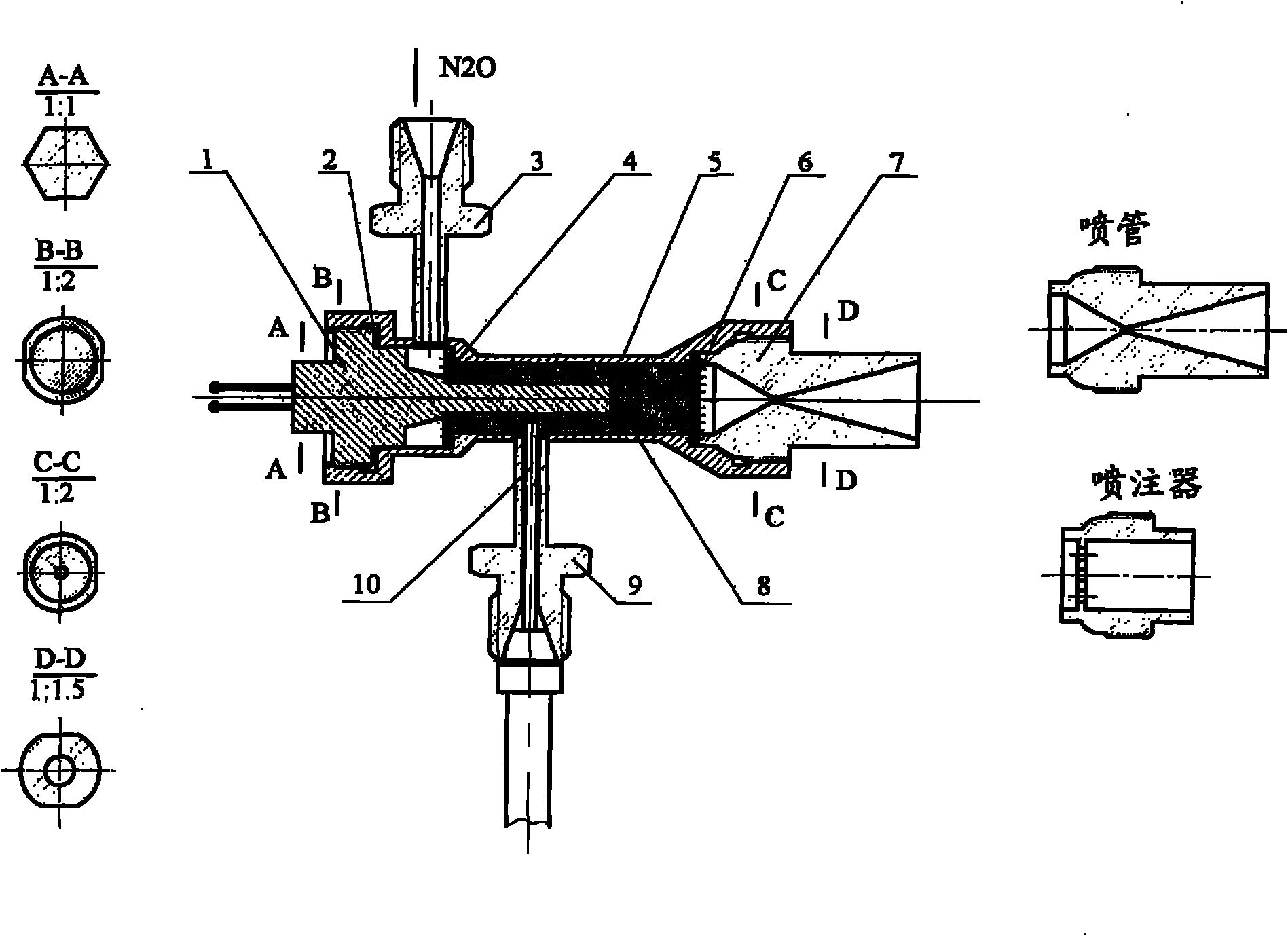

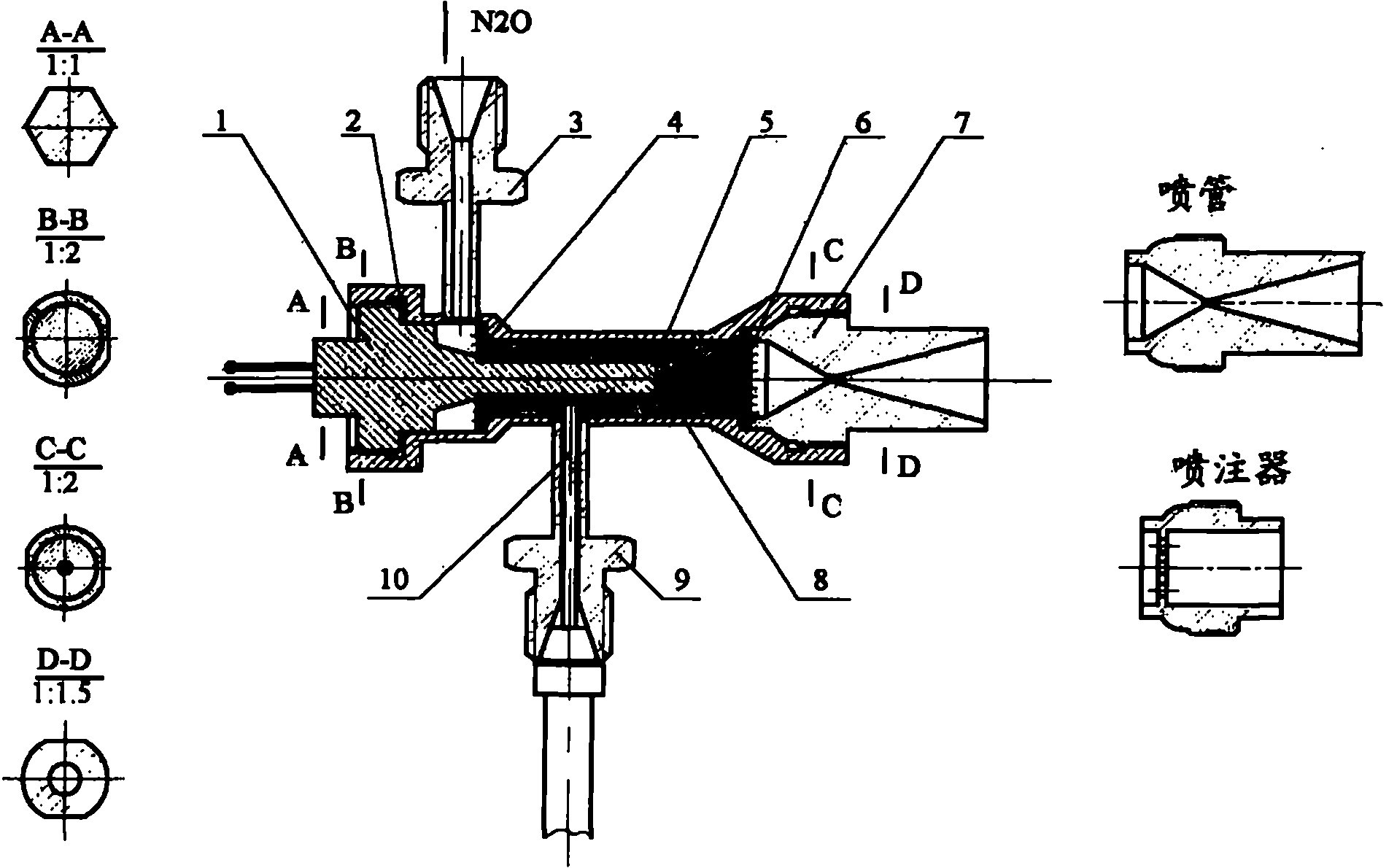

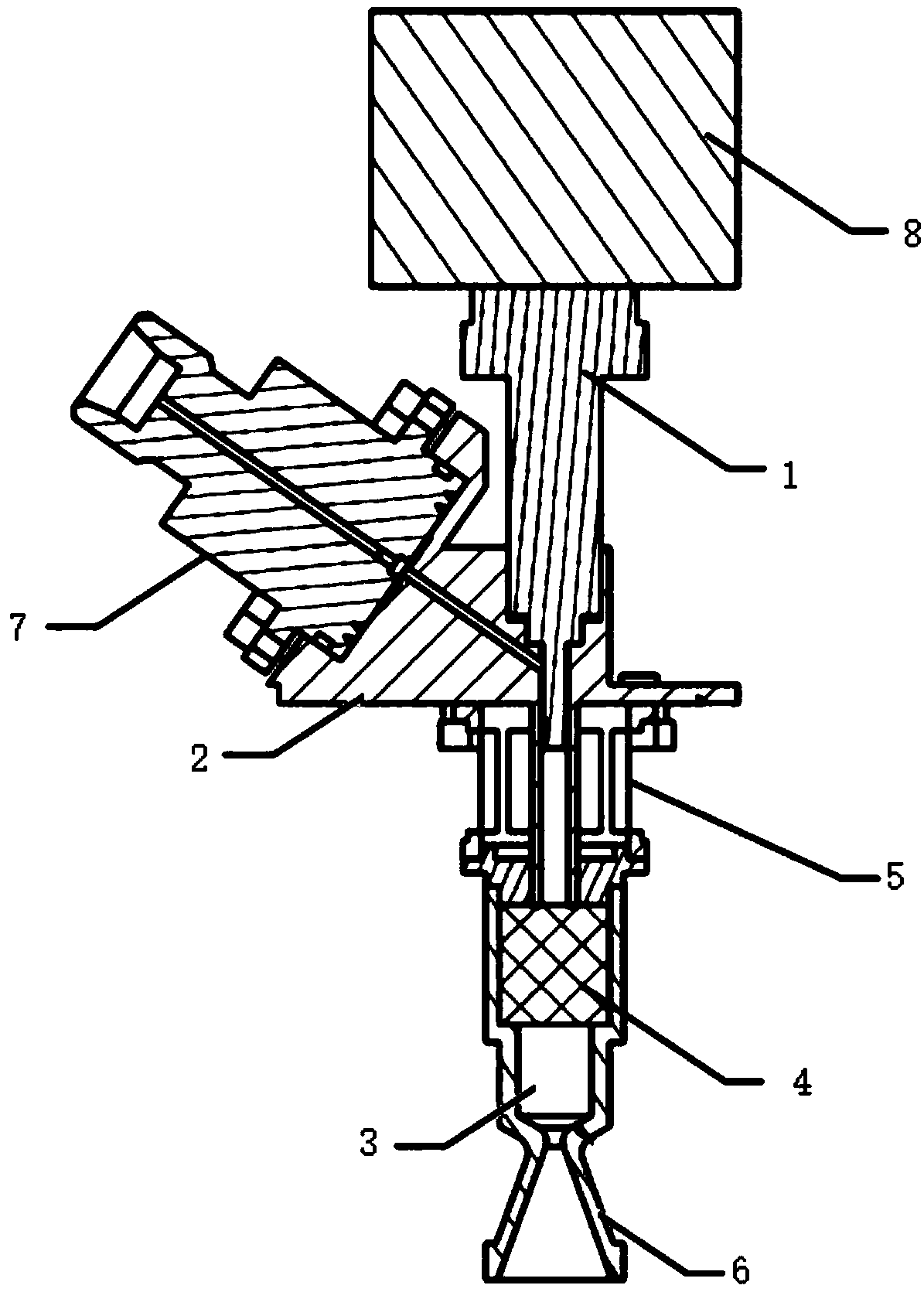

Pre-whirling type pintle injector applied to double-component liquid propellant rocket engine

ActiveCN108286478AImprove blending efficiencyImprove performanceRocket engine plantsSpray nozzleLiquid-propellant rocket

The invention discloses a pre-whirling type pintle injector applied to a double-component liquid propellant rocket engine. The pre-whirling type pintle injector applied to the double-component liquidpropellant rocket engine comprises a center rod, an inner nozzle, an outer nozzle and a connecting ring, all of which are rotation bodies. The inner nozzle coaxially sleeves the center rod, and a cavity for conveying fuel is formed by the inner nozzle and the center rod. The outer nozzle coaxially sleeves the outer nozzle, a cavity for conveying an oxidizing agent is formed by the outer nozzle andthe inner nozzle, and the connecting ring coaxially sleeves the outer nozzle. Pre-whirling treatment is conducted before oxidizing agent spraying-out, and the problem that a conventional pintle injector is not high in effective mixing efficiency is effectively solved; meanwhile, through the arrangement of two rows of fuel direct flow injection holes, cooling to a liquid film on the wall face of athrust chamber through propellant is effectively achieved; and the performance and the reliability of the double-component liquid propellant rocket engine can be obviously improved.

Owner:BEIJING INST OF CONTROL ENG

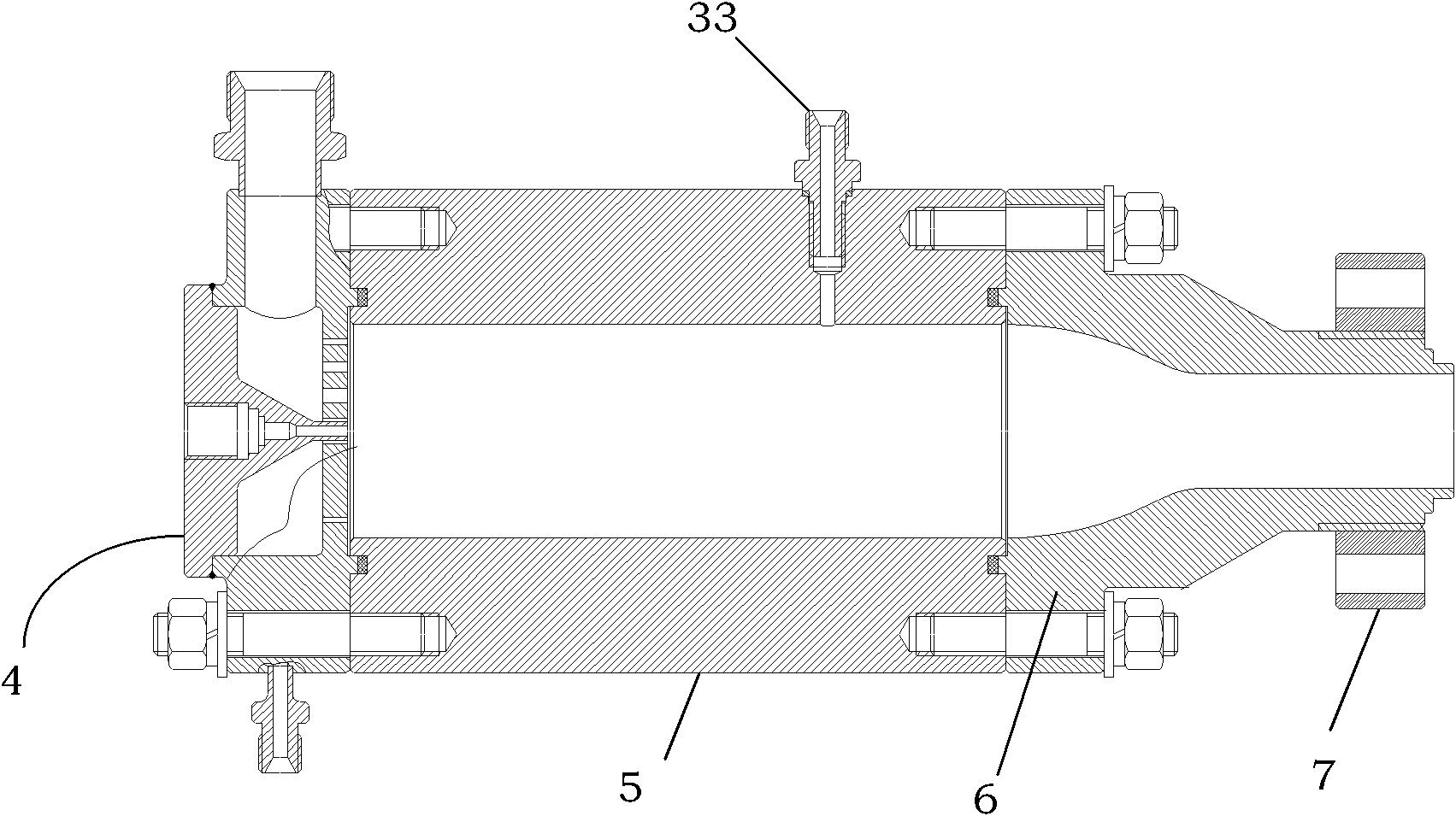

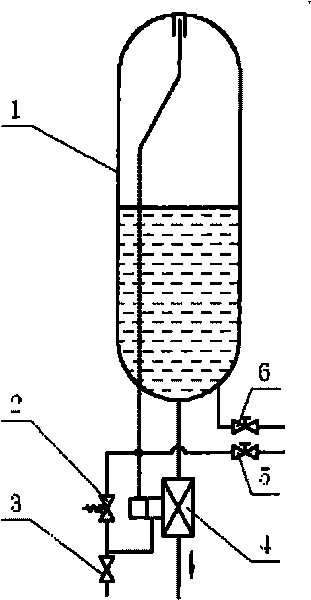

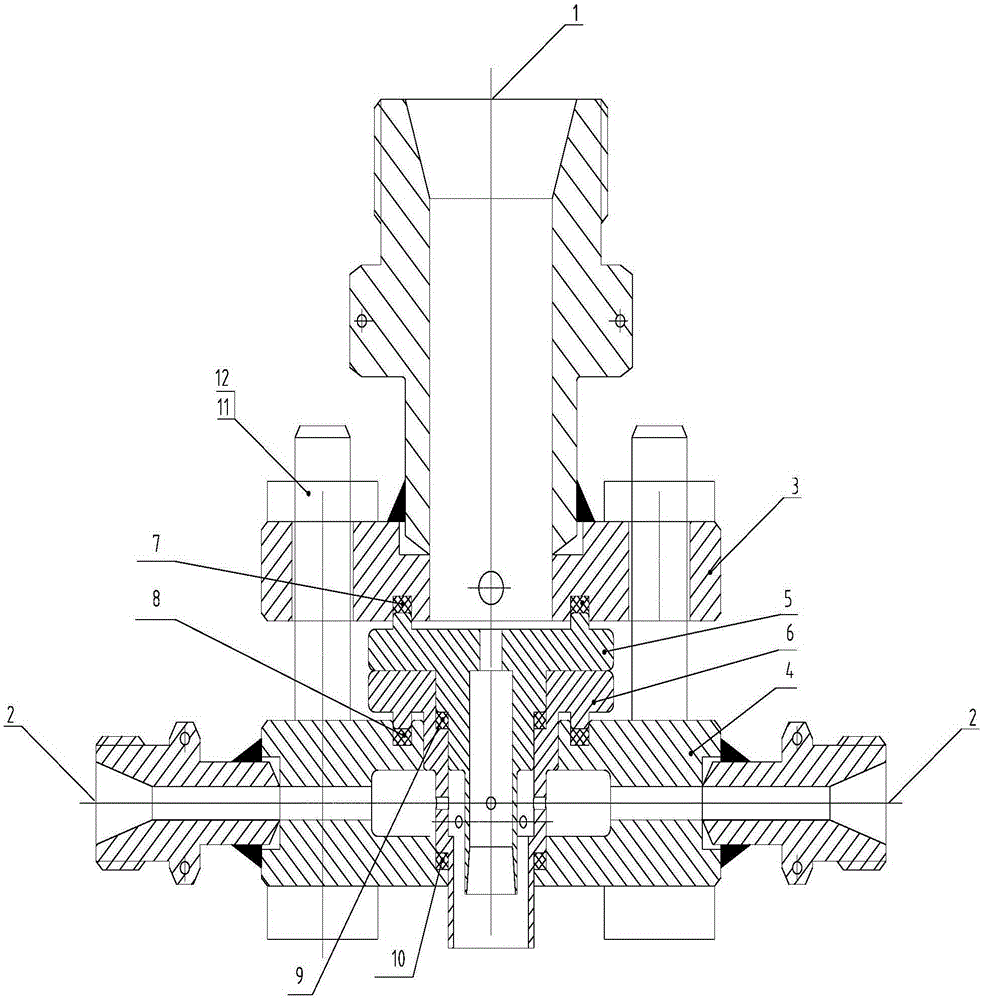

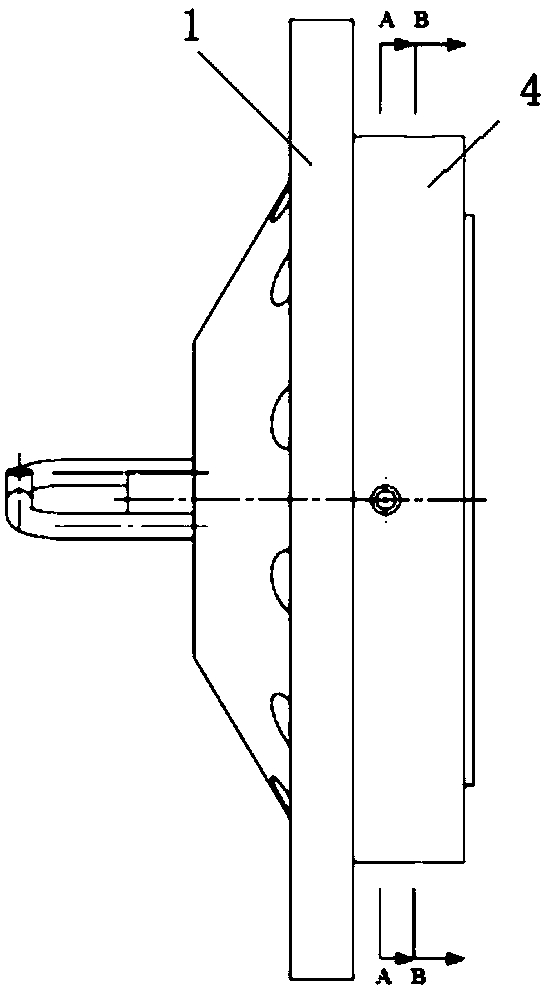

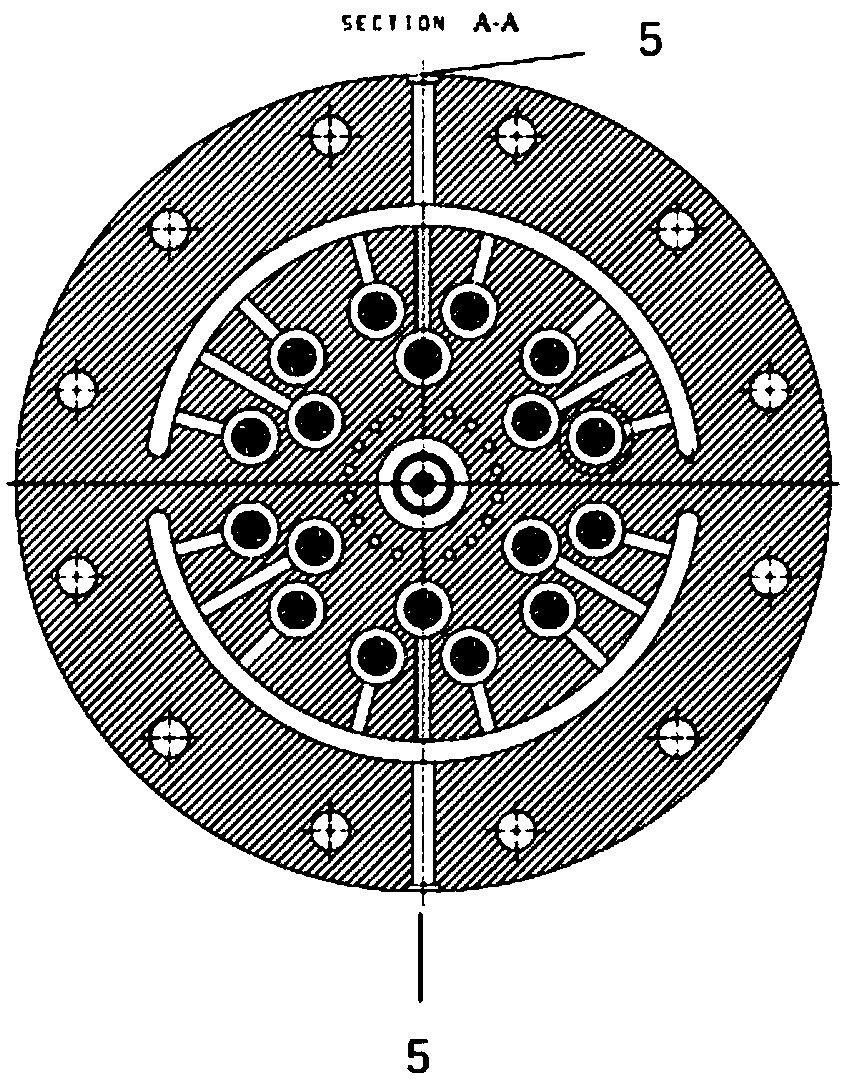

Liquid propellant conveying system of blow-down rocket engine

InactiveCN101737199APrevent accidental openingHigh sensitivityRocket engine plantsControl valvesControl circuit

The invention relates to a liquid propellant conveying system of a blow-down rocket engine, belonging to the field of the conveying system of the rocket engine. The conveying system comprises a conduit head (1), an electric explosion valve (2), an orifice (3), a flow control valve (4), a pressure increasing valve (5), a filling valve (6), a connecting pipeline and an electric explosion valve control circuit. The manipulation gas of the flow control valve (4) is the gas in the conduit head (1); the flow control valve is in the closing state before being started; the flow control valve (4) is started by the electric explosion valve (2); and the flow control valve (4) can control the flow after being started; when the pressure of the conduit head (1) falls, a valve core (8) is controlled to move by the pressure of the conduit head (1) so as to increase the valve opening and regulate the orifice size of the valves, thereby achieving the goal of flow stability; the orifice can prevent the valves from being opened, thereby improving the system reliability. The propellant conveying system has simple structure and low cost.

Owner:BEIHANG UNIV

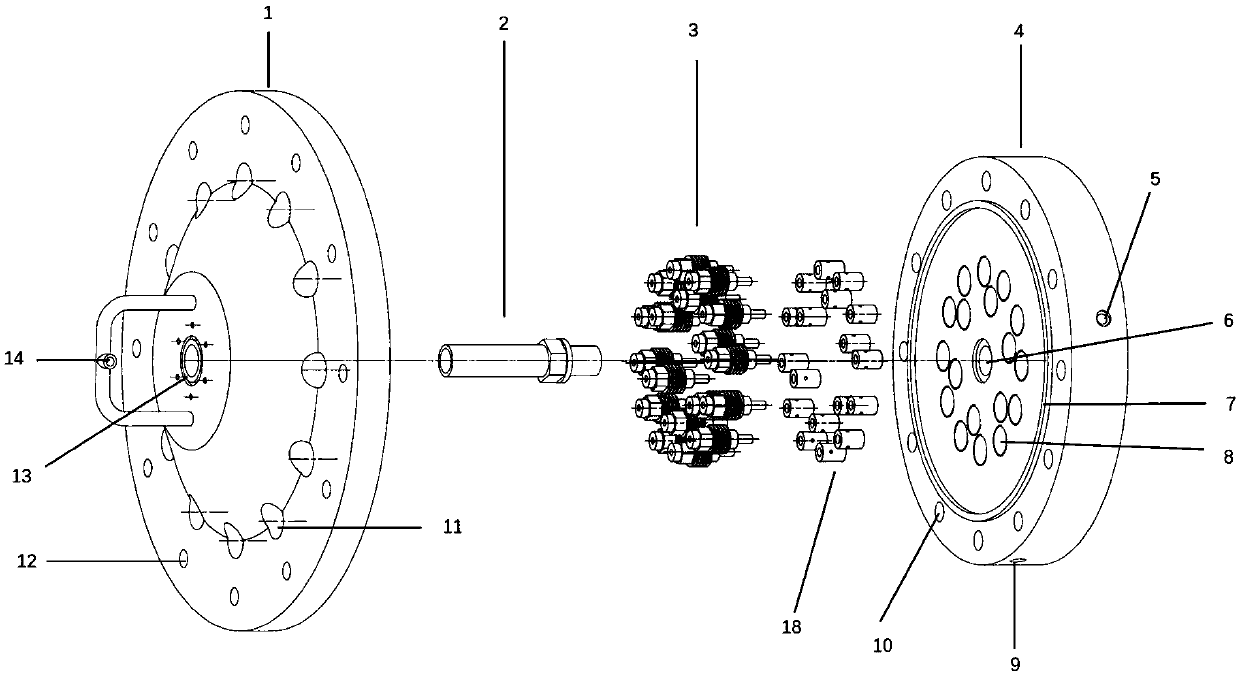

Compact single-propellant unitary propulsion system for a small satellite

InactiveUS6131858AReduce assemblyIntegrated reductionCosmonautic vehiclesCosmonautic propulsion system apparatusOrbitPropellant tank

A compact single-propellant unitary propulsion system for placing a satellite into an orbit and subsequently correcting the orbit so that the satellite is stabilized on three axes comprises a liquid propellant tank secured to a satellite platform and having a reinforced bottom wall with an outlet and filter element, a distribution block welded to the reinforced bottom wall, at least one filling / emptying value mounted on the distribution block, and a set of at least two thrusters mounted on the distribution block and fed directly from the distribution block without additional pipework. The set of at least two thrusters point substantially along the axis of the tank, which is aligned with the axis of the satellite. The propulsion system may be fully assembled before it is integrated with the satellite.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Blowing-down system and blowing-down adapting part used for low-temperature liquid-propellant rocket engine

ActiveCN109630320AImprove conversion efficiencyHigh working reliabilityRocket engine plantsSelf lockingEngineering

The invention provides a blowing-down system and a blowing-down adapting part used for a low-temperature liquid-propellant rocket engine. The blowing-down adapting part comprises a first main pipeline, a first self-locking electromagnetic valve, a third self-locking electromagnetic valve, a gas storage device and a blowing-down pipeline. The first self-locking electromagnetic valve and the third self-locking electromagnetic valve are arranged at different positions of the first main pipeline correspondingly; the gas storage device is connected with an air inlet of the first self-locking electromagnetic valve and an air outlet of the third self-locking electromagnetic valve correspondingly through a tee pipe; and the blowing-down pipeline is connected with the first main pipeline. By meansof the blowing-down adapting part, due to the fact that the self-locking electromagnetic valves are arranged at the upstream part and the downstream part of the storage device correspondingly, the electrifying time of the self-locking electromagnetic valves can be shortened, and therefore the electric quantity losses are reduced, and the work reliability of the blowing-down adapting part is improved.

Owner:SHAANXI LANDSPACE TECH CO LTD

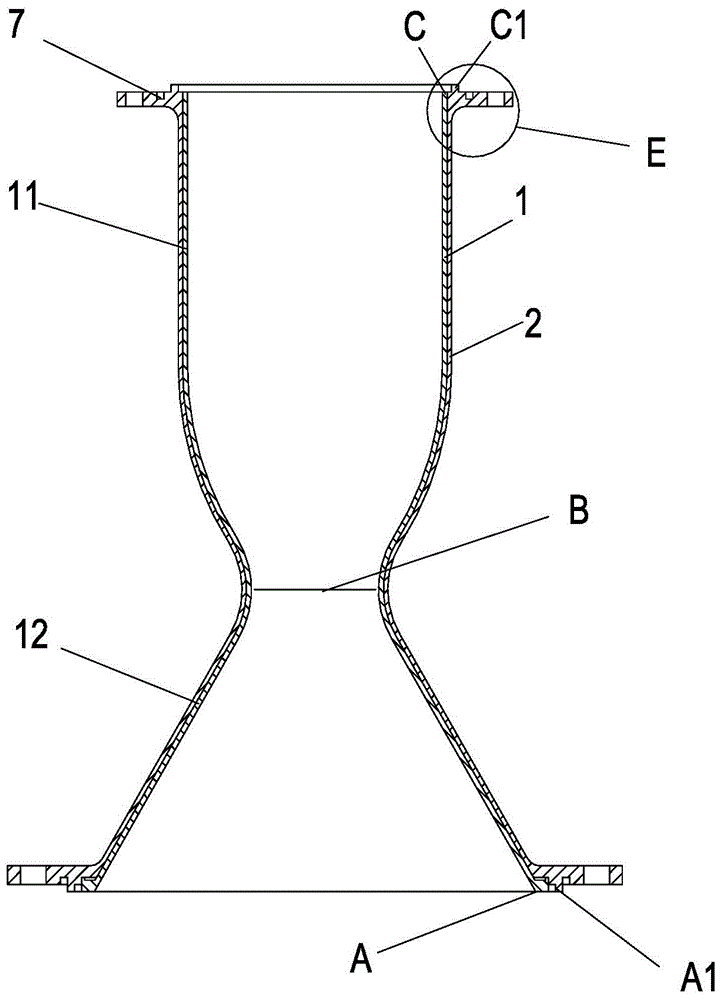

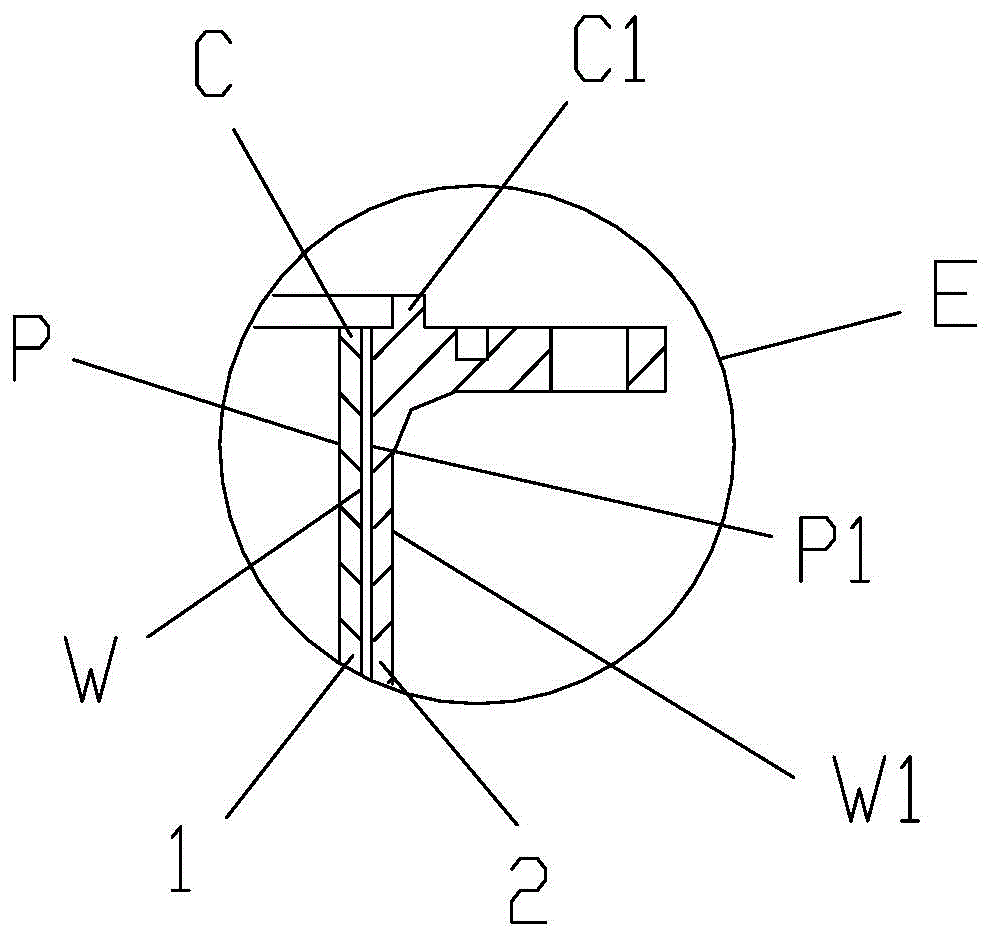

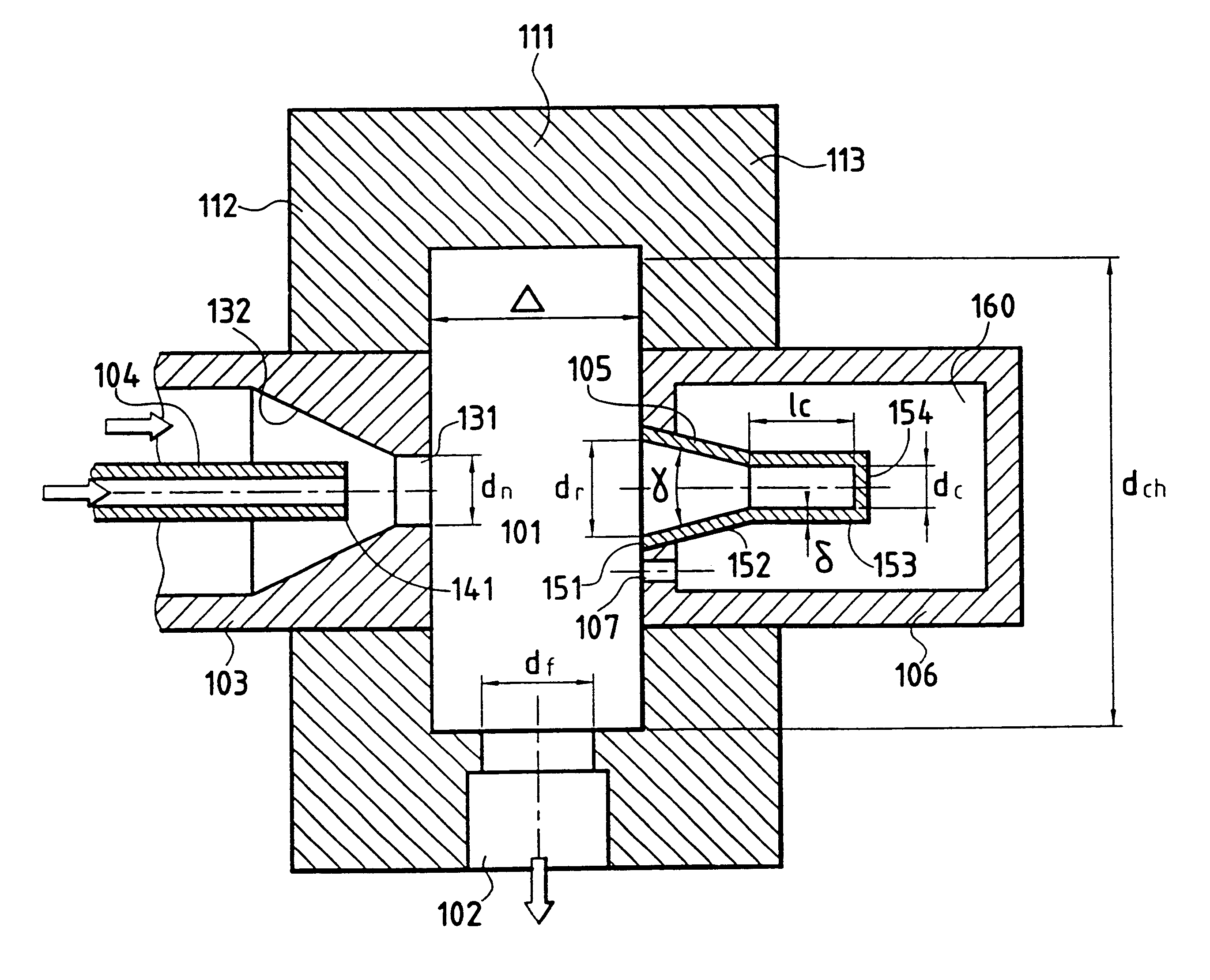

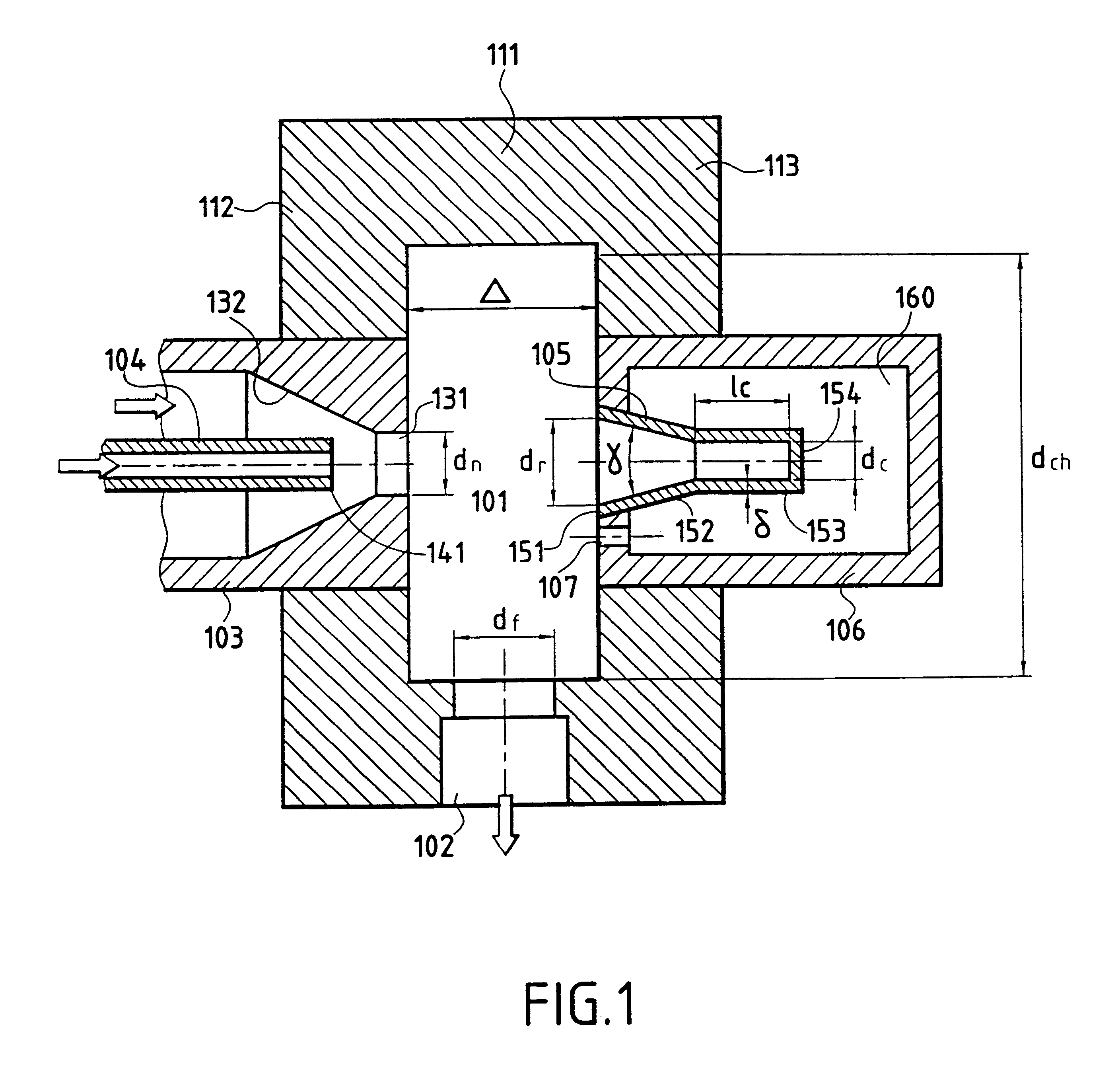

Acoustic igniter and ignition method for propellant liquid rocket engine

InactiveUS6272845B1Increase intensitySmaller thermal lossesCosmonautic vehiclesCosmonautic propulsion system apparatusCombustion chamberLiquid-propellant rocket

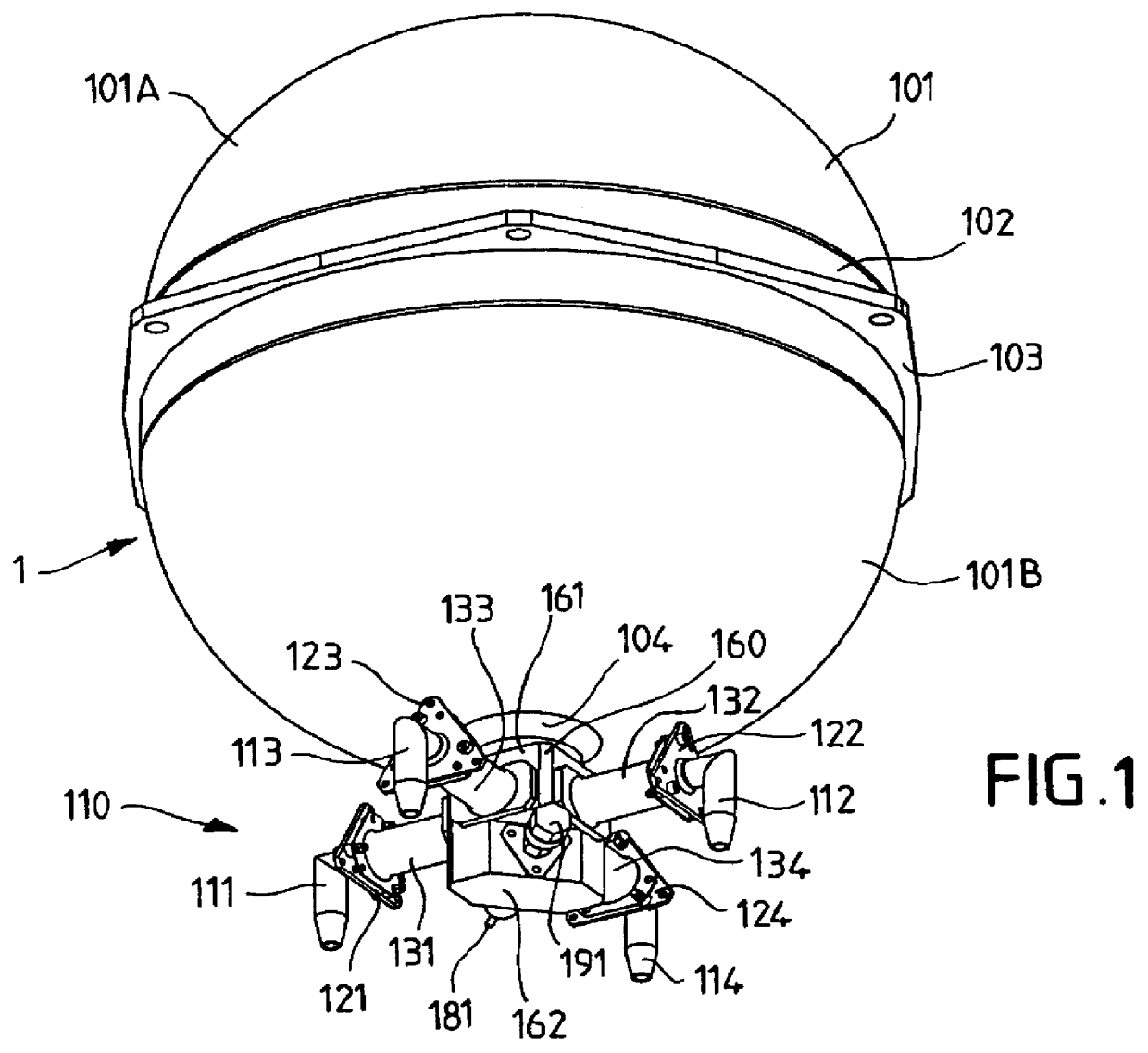

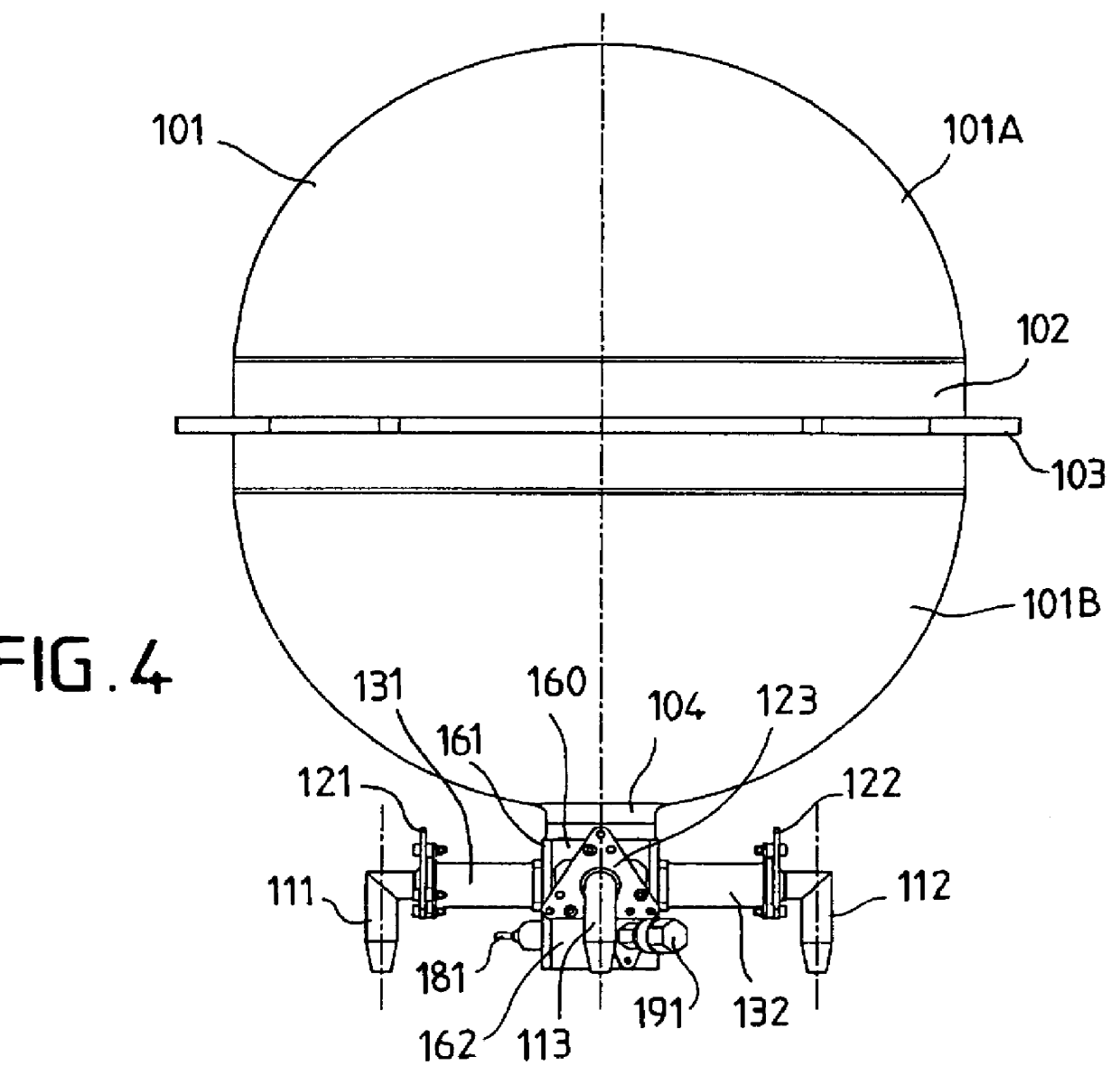

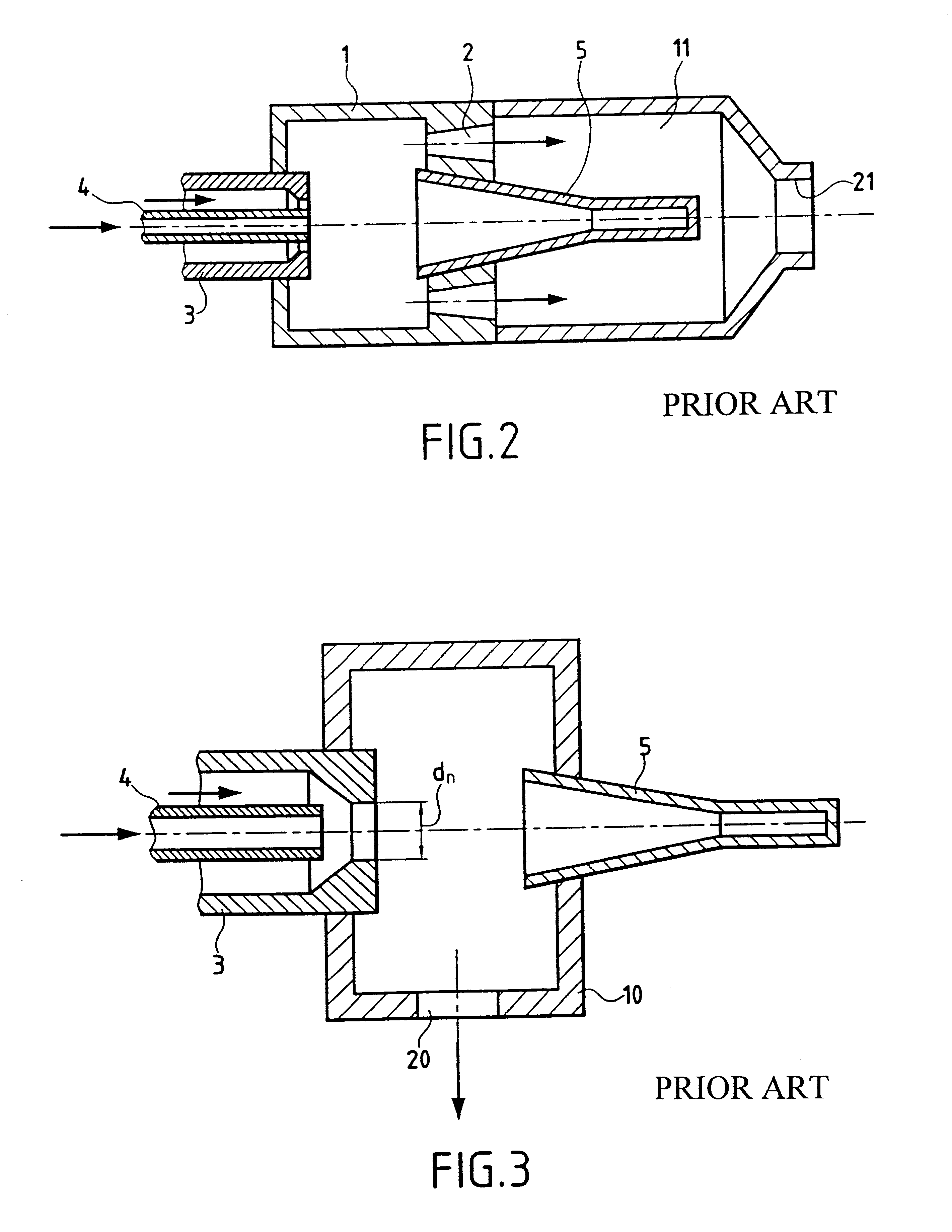

The invention concerns an acoustic igniter for igniting a mixture of rocket fuels in a liquid propellant rocket engine combustion chamber comprising a cylindrical precombustion chamber (101) including a cylindrical wall (111) and first and second end walls (112, 113), a rocket fuel injection nozzle (103) emerging into the precombustion chamber (101) through the first end wall (112) via an orifice of diameter dn, a rocket fuel injector (104) arranged inside said nozzle (103) along the axis thereof, at least an outlet orifice (102) of minimum diameter df provided in the cylindrical wall (111), an acoustic resonator (105) defining a cavity opening into the precombustion chamber (101) opposite the nozzle (103), through the second end wall (113), via an orifice (151) of diameter dr. The acoustic resonator (105) is enclosed by a housing (106) which defines around the acoustic resonator (105) a closed auxiliary chamber (160) which communicates only with the precombustion chamber (101) by at least one conduit (107).

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

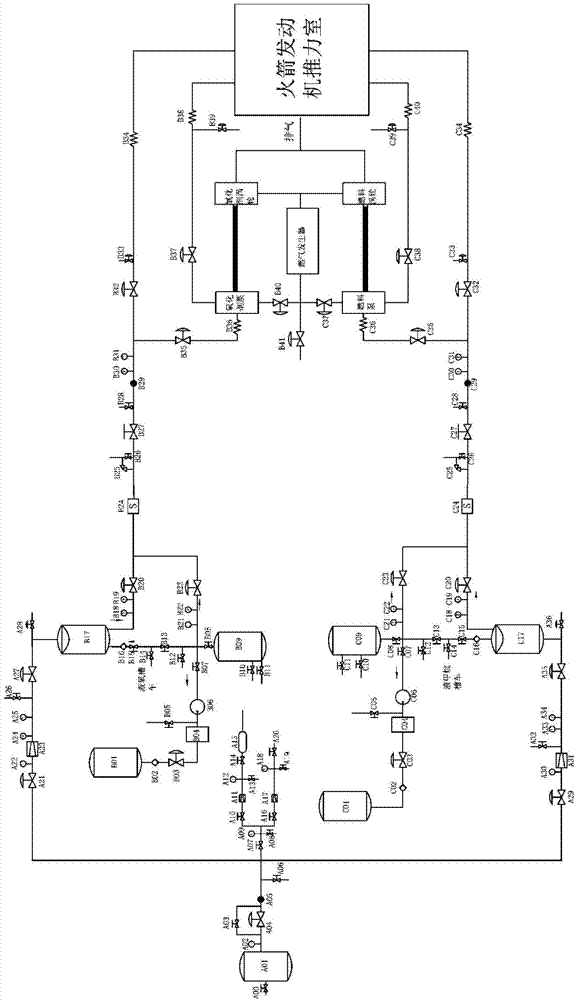

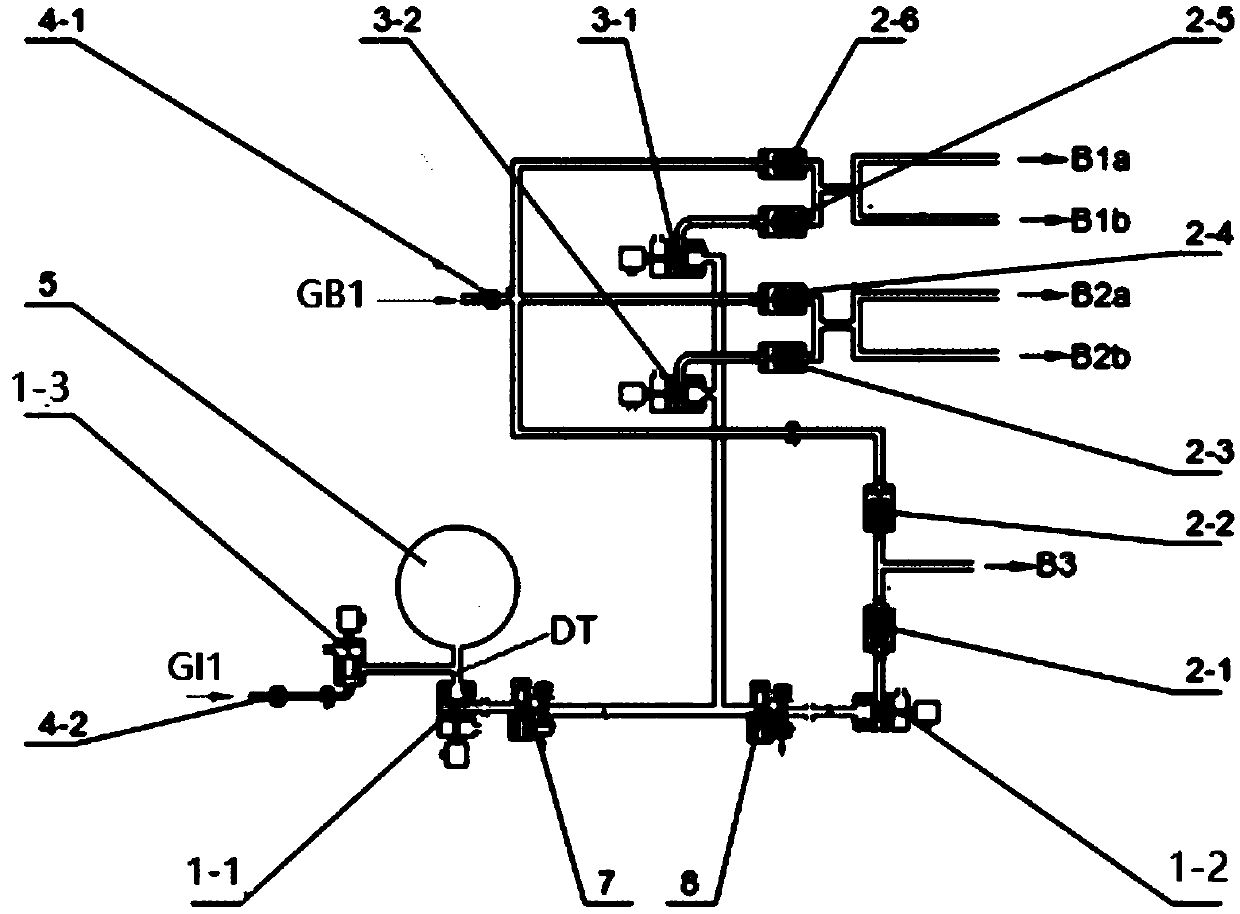

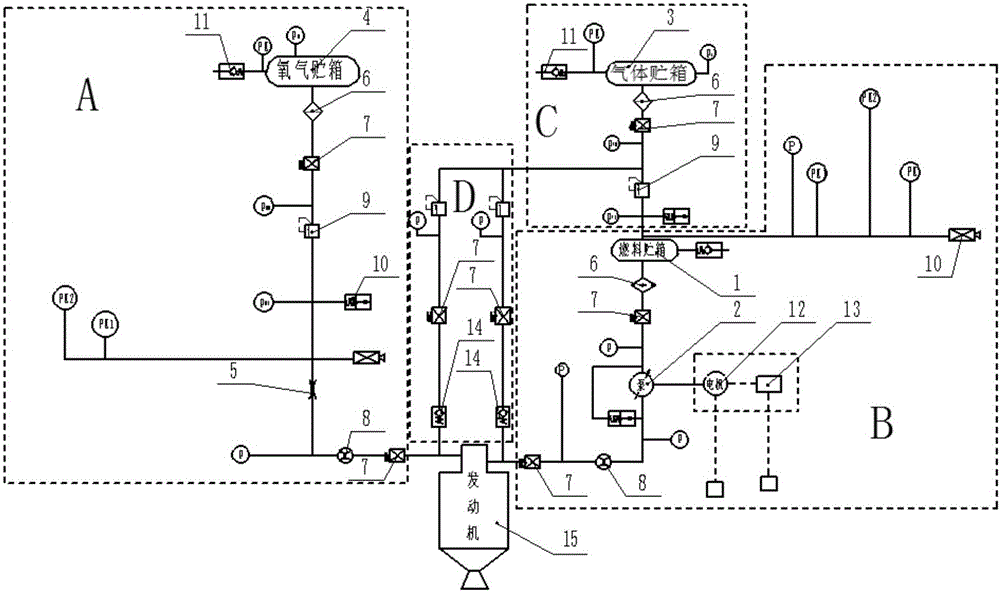

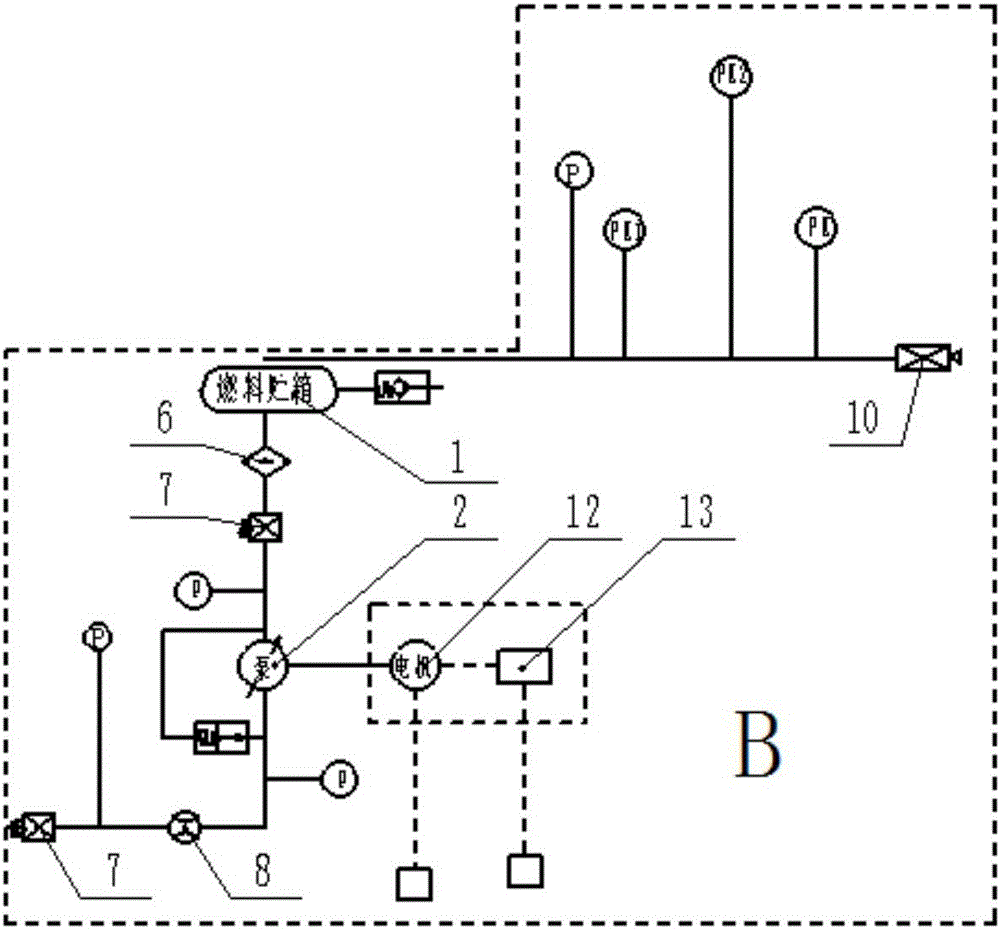

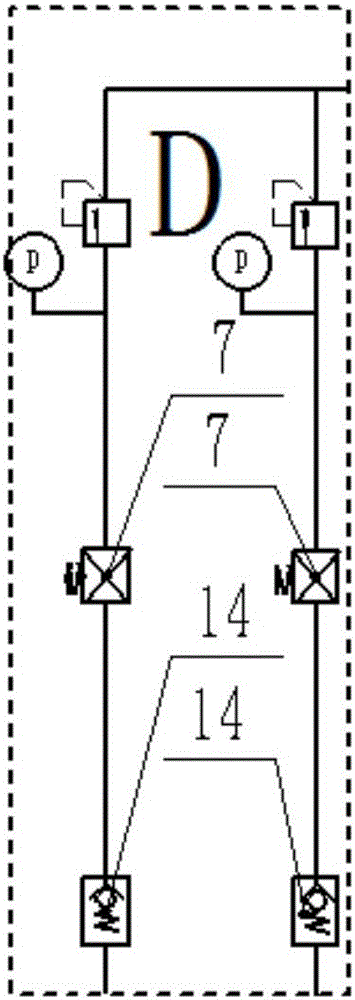

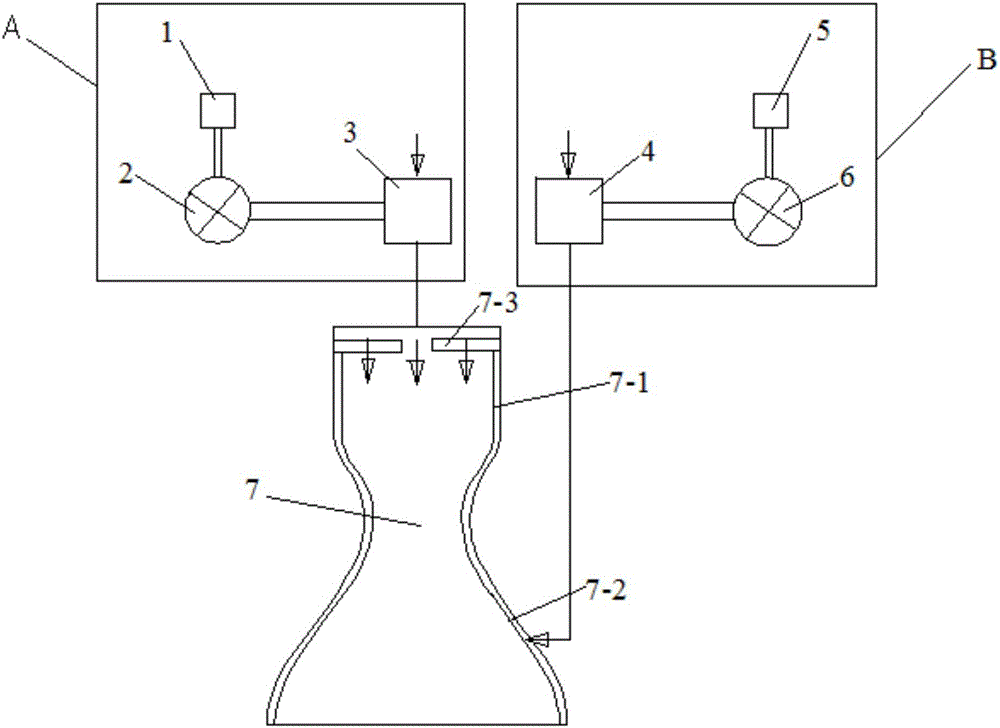

Propellant supply system for RBCC large regulating-ratio liquid-propellant rocket engine

InactiveCN105909424AReduce negative qualityMeet different needsRocket engine plantsFuel supplyOxidizing agent

The invention aims to provide a propellant supply system for an RBCC large regulating-ratio liquid-propellant rocket engine. The system comprises an oxidizing agent supply system, a fuel supply system and a gas blowing-down system, and the systems communicate with the engine respectively, wherein the fuel supply system is also connected to a fuel pressurization system. The fuel supply system comprises a fuel storage tank used to provide fuel to the engine, wherein a fuel flow regulating system used to adjust a flow rate and a mixing rate of a propellant is disposed on an output pipeline of the fuel storage tank; and the fuel flow regulating system comprises a plunger pump, and the plunger pump is connected to a motor drive device used to control actions of the engine. The system solves the problems that an existing propellant supply system cannot be integrated in an RBCC, and the flow rate and the mixing rate of the propellant cannot be adjusted within a large scope simultaneously.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

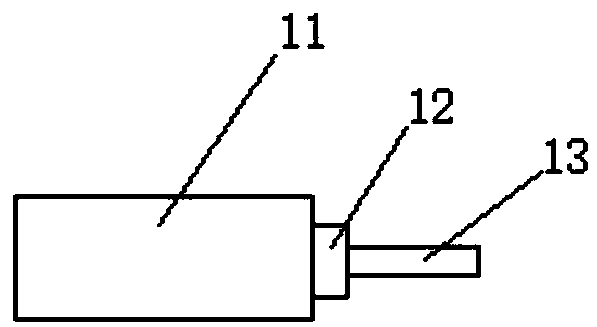

Internal heating nitrous oxide monopropellant gas generator

InactiveCN101979862AImprove heating efficiencySave energyRocket engine plantsAttitude controlPollution

The invention relates to an internal heating nitrous oxide monopropellant gas generator. A high-temperature decomposition product of nitrous oxide gas can be applied by utilizing the characteristics of nontoxicity, non-pollution, high decomposition temperature and self-sustaining decomposition reaction of the nitrous oxide gas. The internal heating nitrous oxide monopropellant gas generator can be taken as a monopropellant thruster to be applied to the attitude control of satellites, and also can be taken as an oxidant source and an ignition device to be applied to the oxidant supply and ignition of a small liquid-propellant rocket engine or a solid-liquid rocket engine. Compared with the internal heating nitrous oxide monopropellant gas generator adopting the conventional external heating preheating mode, the internal heating nitrous oxide monopropellant gas generator adopting the unique heating mode and overall layout can effectively improve heating efficiency, save energy and ensure relatively long service life.

Owner:BEIHANG UNIV

Electric drive propellant feeding system liquid-propellant rocket engine

InactiveCN106555707AEasy to controlSolve technical difficultiesRocket engine plantsElectricityThrust chamber

The invention discloses an electric drive propellant feeding system liquid-propellant rocket engine which comprises an oxidizing agent conveying system, a fuel conveying system and a thrust chamber. The oxidizing agent conveying system and the fuel conveying system are independently communicated with the thrust chamber, so that an oxidizing agent and fuel are correspondingly fed into the thrust chamber, are mixed in the thrust chamber and burn in the thrust chamber, and reaction thrust is generated. The oxidizing agent conveying system comprises an oxidizing agent battery, an oxidizing agent motor and an oxidizing agent pump which are sequentially connected, and the oxidizing agent pump is used for being connected with an oxidizing agent storage tank and a thrust chamber pipe. The electric drive propellant feeding system liquid-propellant rocket engine is simple in structure, high in reliability and miniaturized.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

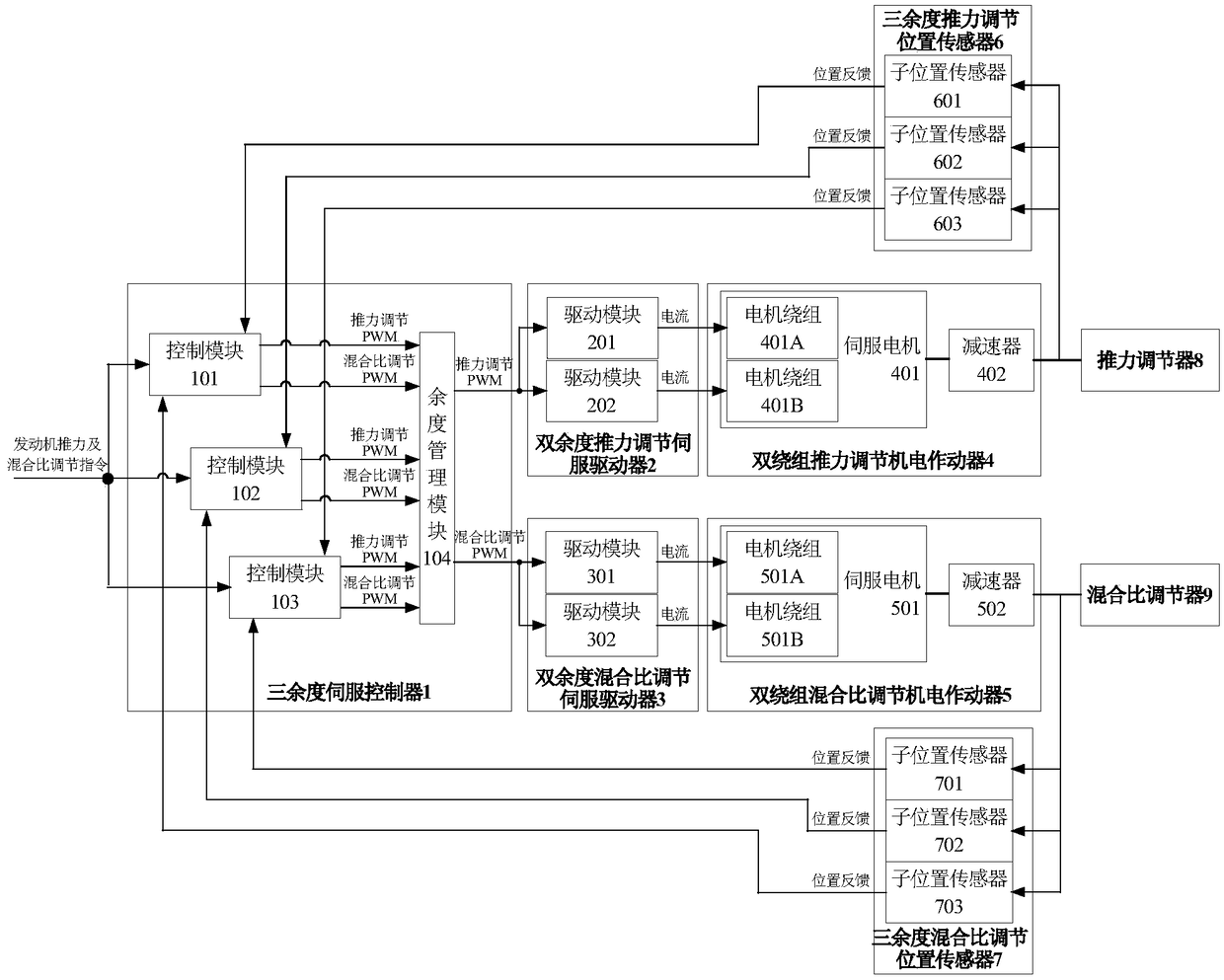

Multi-redundancy electromechanical servo system for adjusting thrust and mixing ratio of liquid-propellant rocket engine

ActiveCN108661823ASimplify gas-liquid systemsSimple control driveSafety arrangmentsError detection/correctionControl signalThree-phase

The invention discloses a multi-redundancy electromechanical servo system for adjusting the thrust and a mixing ratio of a liquid-propellant rocket engine. A three-redundancy servo controller, a double-redundancy servo driver, a double-winding electromechanical actuator, a three-redundancy position sensor, a thrust adjustor and a mixing ratio adjustor are included. An engine thrust and mixing ratio adjusting instruction and a position feedback signal of the three-redundancy position sensor are input to the three-redundancy servo controller; the three-redundancy servo controller outputs a thrust and mixing ratio adjusting PWM wave control signal to the double-redundancy servo driver; the double-redundancy servo driver outputs a three-phase frequency varying and amplitude varying sine wave current to drive the double-winding electromechanical actuator to drive the thrust adjustor and the mixing ratio adjustor to move; and adjusting of the thrust and the mixing ratio of the engine is achieved. The servo system is simple and excellent in control characteristic, has the capacity of controlling two-redundancy fault work and driving one-redundancy fault work, and the reliability of adjusting the thrust and the mixing ratio of the liquid-propellant rocket engine and the using maintenance are remarkably improved.

Owner:XIAN AEROSPACE PROPULSION INST

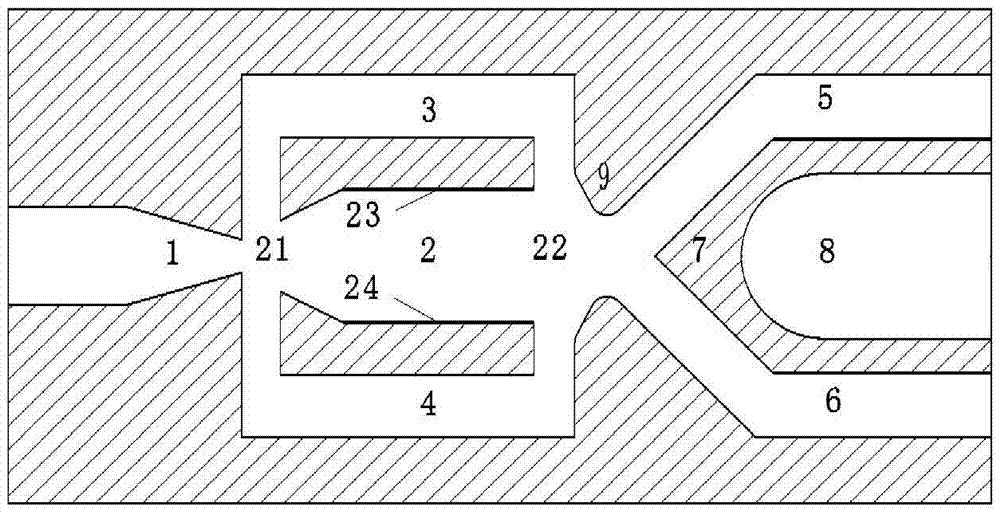

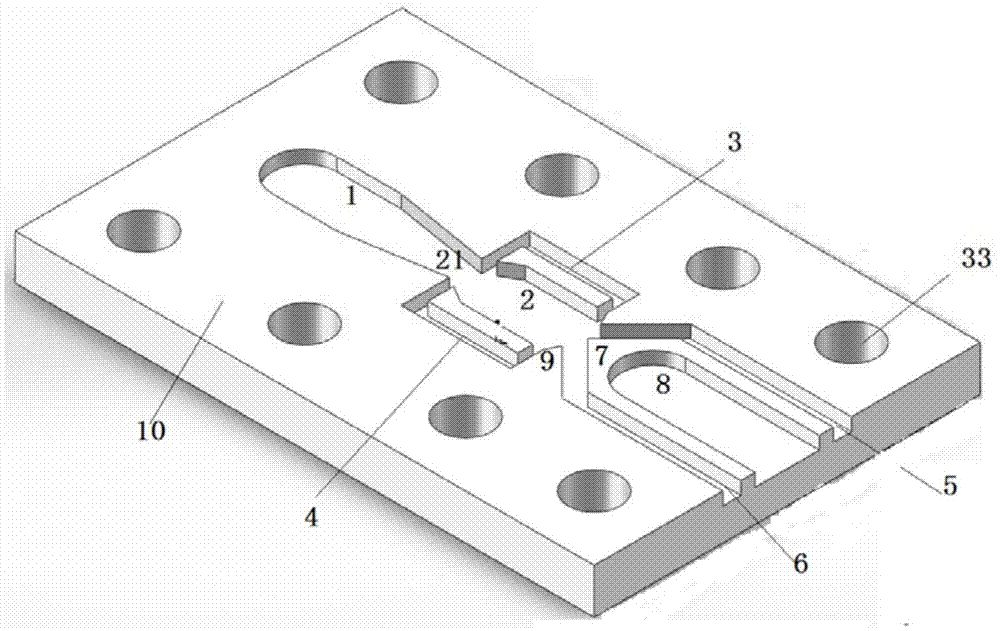

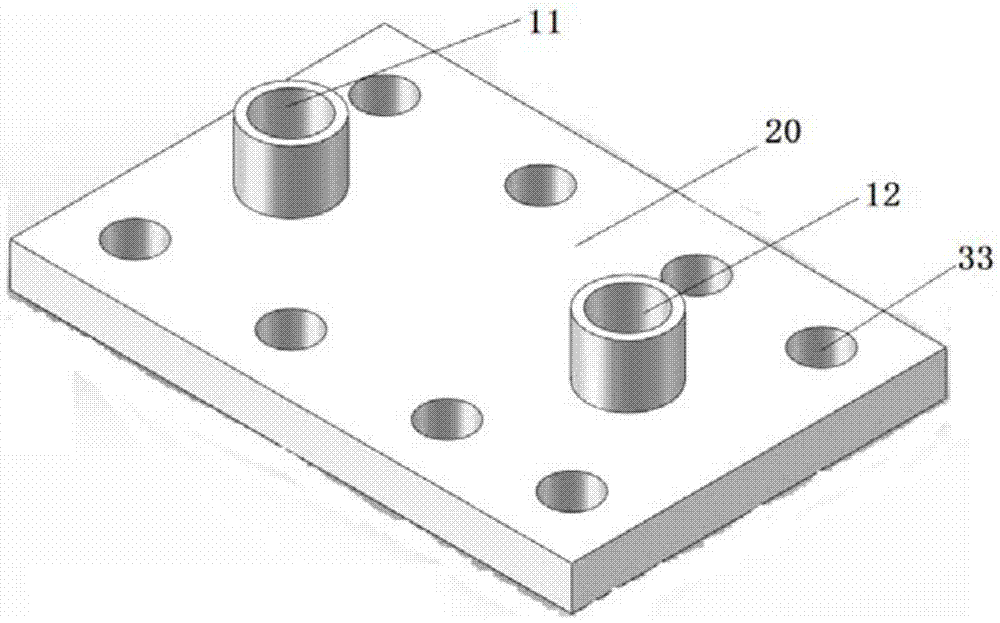

Self-oscillation gas jet auxiliary atomization device

ActiveCN105435976AImprove atomization effectImprove combustion efficiencySpray nozzlesLiquid jetCombustion

The invention discloses a self-oscillation gas jet auxiliary atomization device. The self-oscillation gas jet auxiliary atomization device is provided with an inlet, an oscillation cavity, feedback loops and a gas spraying opening which are communicated, and further provided with an independently arranged liquid spraying opening, wherein the inlet is communicated with the oscillation cavity; an outlet of the oscillation cavity is communicated with the gas spraying opening; the multiple feedback loops are arranged near the outlet of the oscillation cavity and connected back to an inlet of the oscillation cavity; the liquid spraying opening is near the gas spraying opening, independent from the above four parts structurally, and used for generating liquid jet flow which is atomized under the action of oscillation air flow. Breaking of liquid is accelerated through oscillation of gas medium, and the self-oscillation gas jet auxiliary atomization device is mainly used for the fields of liquid atomization, cleaning and the like. The self-oscillation gas jet auxiliary atomization device does not need any movable components, is convenient to use, and is simple and compact in structure. Through the self-oscillation gas jet auxiliary atomization device, the self-oscillation of the gas medium acts on the liquid jet flow, breaking of the liquid is accelerated, the atomization effect of complex fluid is further improved, and the combustion efficiency and the specific impulse of a liquid-propellant rocket engine are effectively improved.

Owner:BEIHANG UNIV

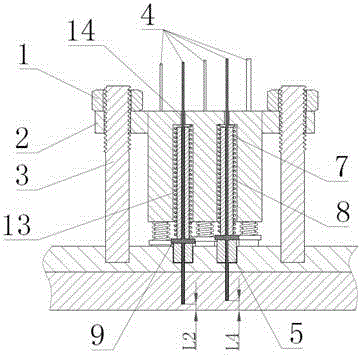

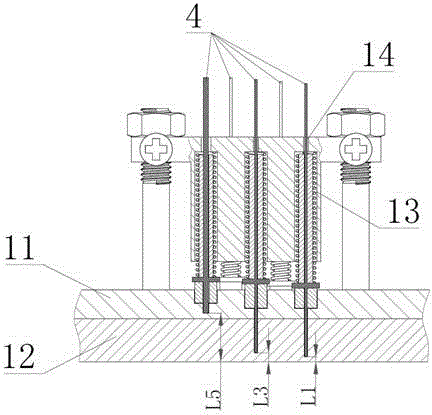

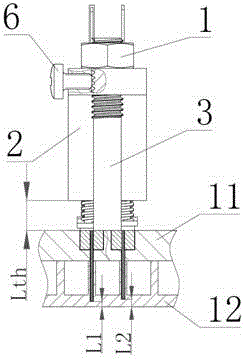

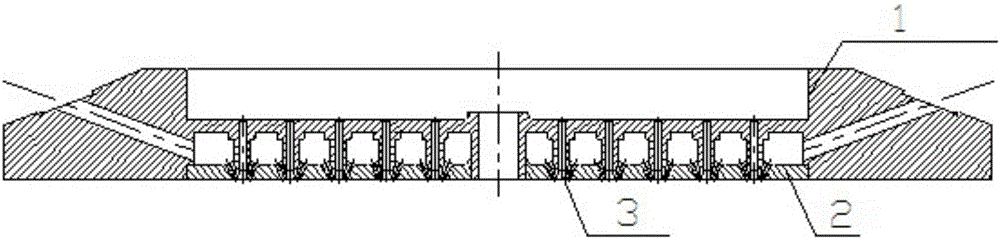

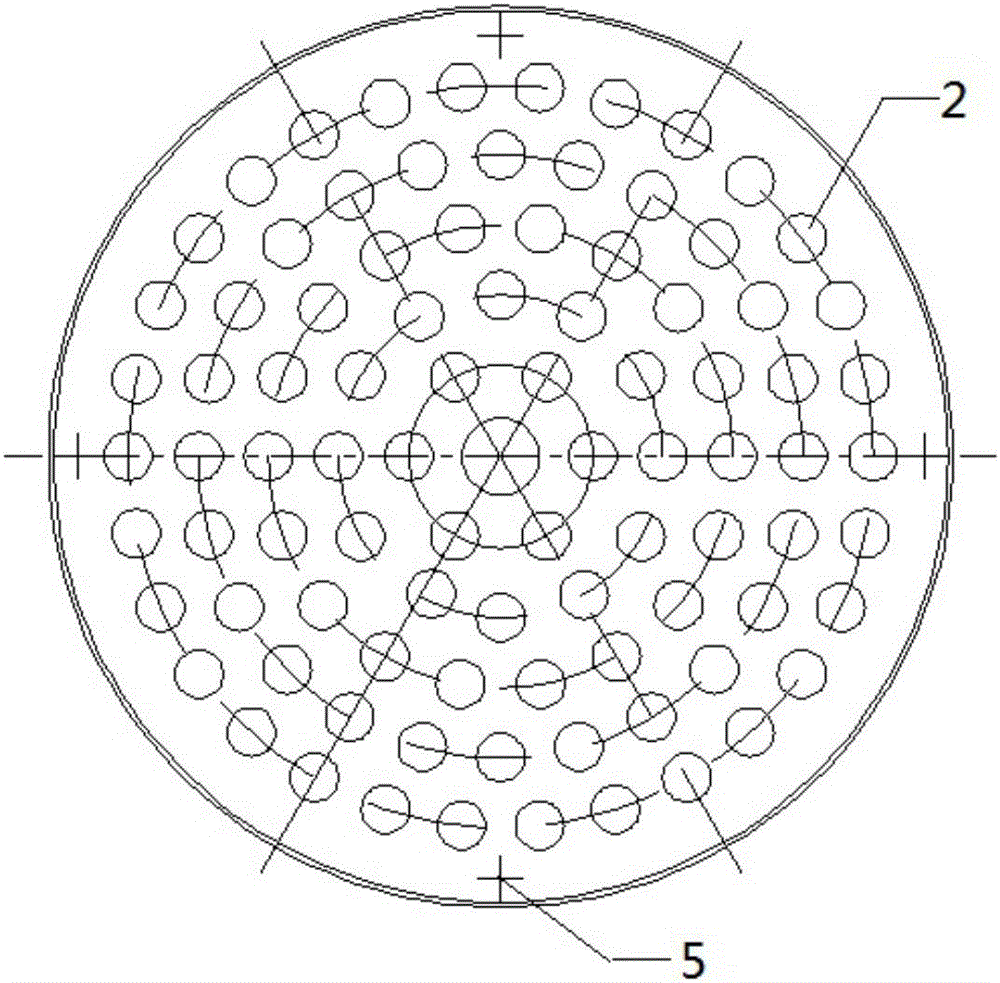

Combustion chamber wall temperature gradient measurement module

ActiveCN105277290AIncrease contactEasy to integrateThermometer detailsThermometers using electric/magnetic elementsHeat flowCombustion chamber

The present invention belongs to the field of the temperature measurement technology, and specifically relates to a cylindrical section chamber wall temperature gradient measurement module of a liquid-propellant rocket engine combustion chamber. The module provided by the invention has a flat plate structure, and comprises a planar pressure plate, five thermocouple sensors, springs, separation blades, heat insulation linings and support sleeves. A disc-shaped separation blade is welded at each thermocouple sensor, one end, at the upper portion of the separation blade, of the each thermocouple sensor passes through a support sleeve and a spring, the support sleeves are sleeved with the springs and sleeved with the planar pressure plate, and the portions, below the separation blades, of the thermocouple sensors penetrate into the heat insulation linings. According to the invention, the temperature of the inner wall structure of the cooling channel in a cylindrical section of the combustion chamber nozzle section may be measured, so that the parameters such as heat flow, gas wall temperature and outer wall temperature at the local place may be obtained.

Owner:BEIJING AEROSPACE PROPULSION INST

Welding method for multi-part structure of head injector in thrust chamber of liquid-propellant rocket engine

InactiveCN106735829AImprove reliabilityImprove welding qualityElectron beam welding apparatusThrust chamberPre treatment

The invention discloses a welding method for a multi-part structure of a head injector in a thrust chamber of a liquid-propellant rocket engine. According to the method, welding for the head injector in the thrust chamber of the liquid-propellant rocket engine is completed through welded part machining, welding reference machining for nozzle units, welded part pre-treatment, welded part assembly, welded part welding, nozzle unit welding, welding joint detection and drying. According to the method disclosed by the invention, a welding process method for a complex injector structure is optimized to be vacuum electron beam welding adopting a welding method which is more advanced, higher in reliability, higher in welding quality and lower in welding risk from traditional braze welding; and moreover, repair welding is hardly carried out once the traditional braze welding is failed, and local repair welding can be carried out in the vacuum electron beam welding, so that the product scrap risk is lowered.

Owner:湖北三江航天江北机械工程有限公司

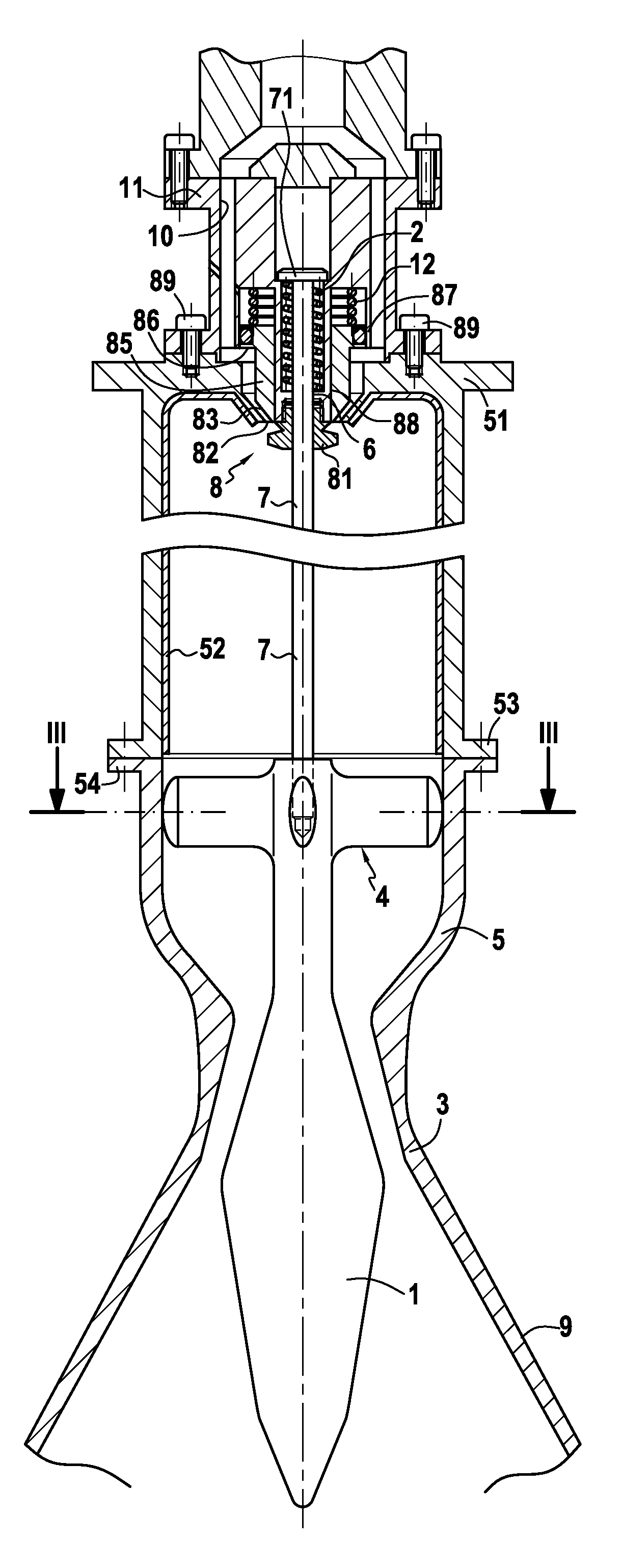

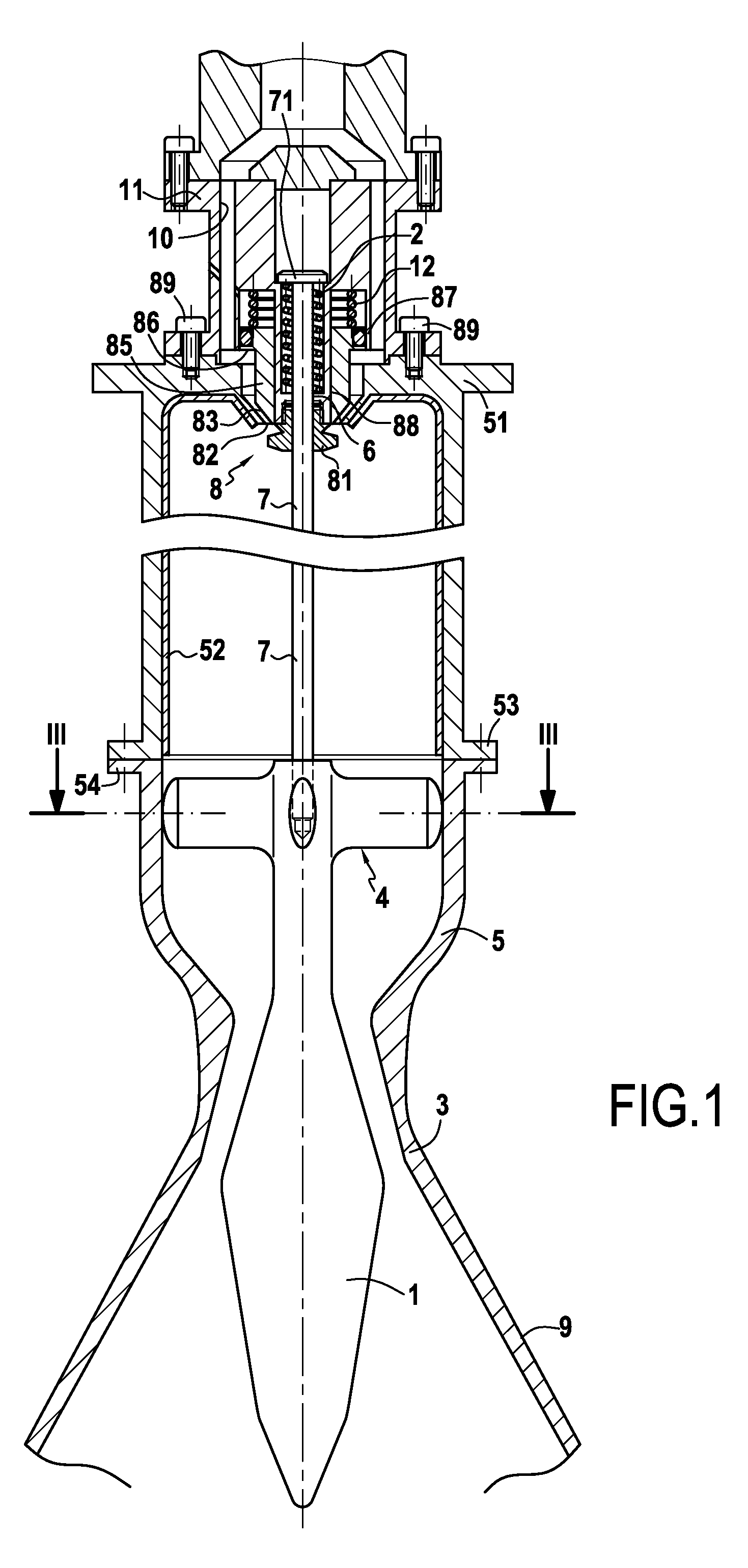

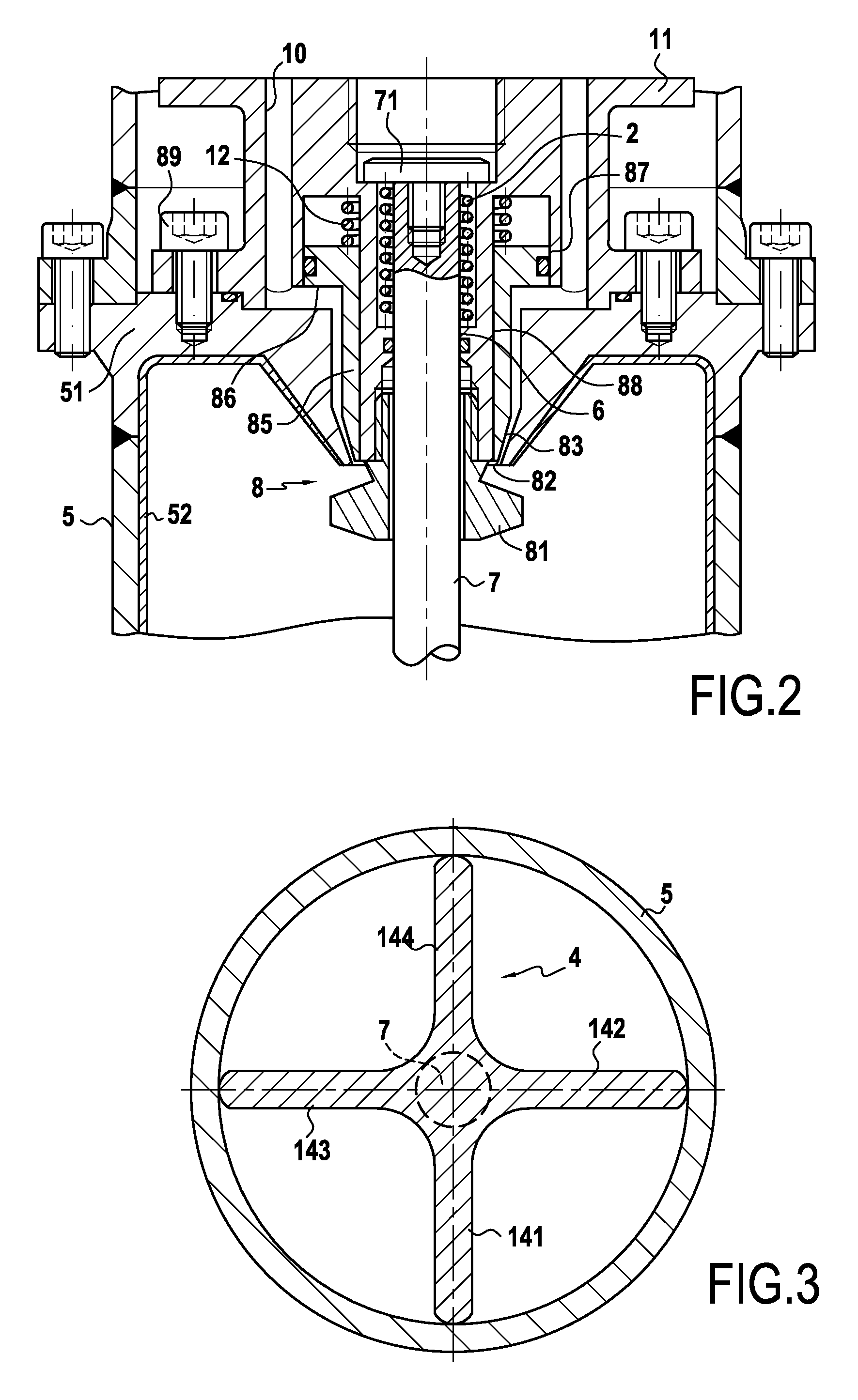

Liquid propellant rocket engine with a propulsion chamber shutter

InactiveUS20100005807A1Good effectReduce pressureRocket engine plantsRam jet enginesCombustion chamberNozzle throat

A liquid propellant rocket engine with a propulsion chamber shutter, the rocket engine comprises a combustion chamber, a propellant injector device placed at an upstream first end of the combustion chamber, a nozzle throat disposed at a downstream second end of the combustion chamber remote from the upstream first end, and a diverging portion disposed downstream from the nozzle throat. A selective shutter device for the nozzle throat comprises an axially-symmetrical shutter member placed downstream from the nozzle throat, and axial rod for controlling the shutter member, a first short centering member for the control rod situated at the upstream first end of the combustion chamber level with the propellant injector device, a second short centering member for the control rod situated in the combustion chamber in the vicinity of the nozzle throat and upstream therefrom, and a system for returning the control rod of the selective shutter device for the nozzle throat to the closed position.

Owner:ARIANEGRP SAS

Electric ignition green unit liquid propellant rocket engine structure

ActiveCN109595100AAchieving Steady State OperationOvercome the disadvantage of poor combustion self-sustainabilityRocket engine plantsElectricityCombustion chamber

The invention provides an electric ignition green unit liquid propellant rocket engine structure. The electric ignition green unit liquid propellant rocket engine structure comprises an electrode, aninjector and a combustion chamber. The electrode is connected with the injector. A propellant is fed into the injector. A cathode and an anode of the electrode are powered on to ignite the propellant.The combustion chamber communicates with the injector. The combustion chamber is internally provided with a hot bed. The ignited propellant continues burning on the hot bed. Through the electric ignition green unit liquid propellant rocket engine structure, the defect that the self-maintaining burning capability of the electrically ignited high-performance propellant is poor is overcome, and steady-state operation of an engine can be realized. The electric ignition green unit liquid propellant rocket engine structure can be applied to a high-thrust green unit engine and is suitable for aircrafts such as satellites and carrier rockets with limited electric power.

Owner:SHANGHAI INST OF SPACE PROPULSION

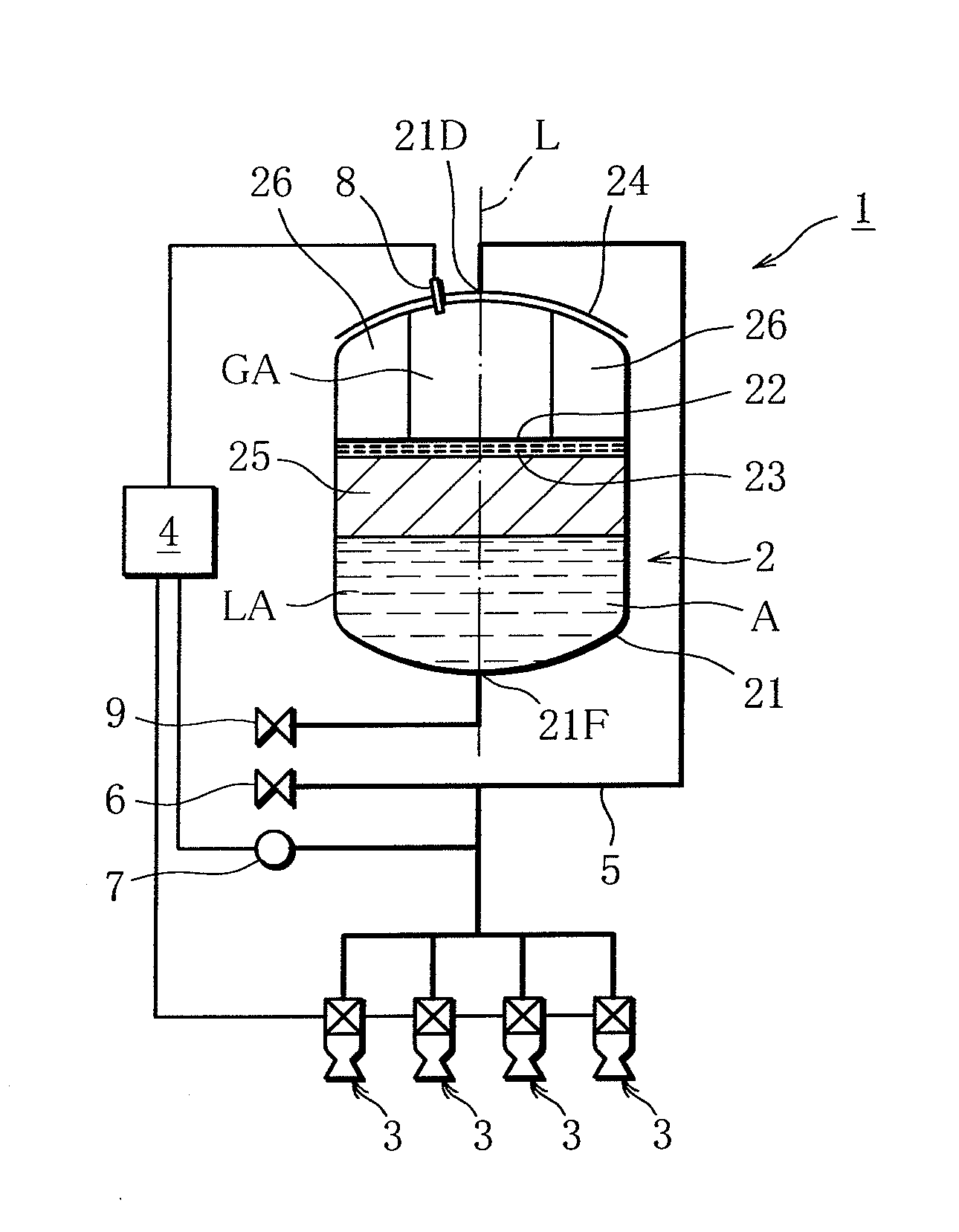

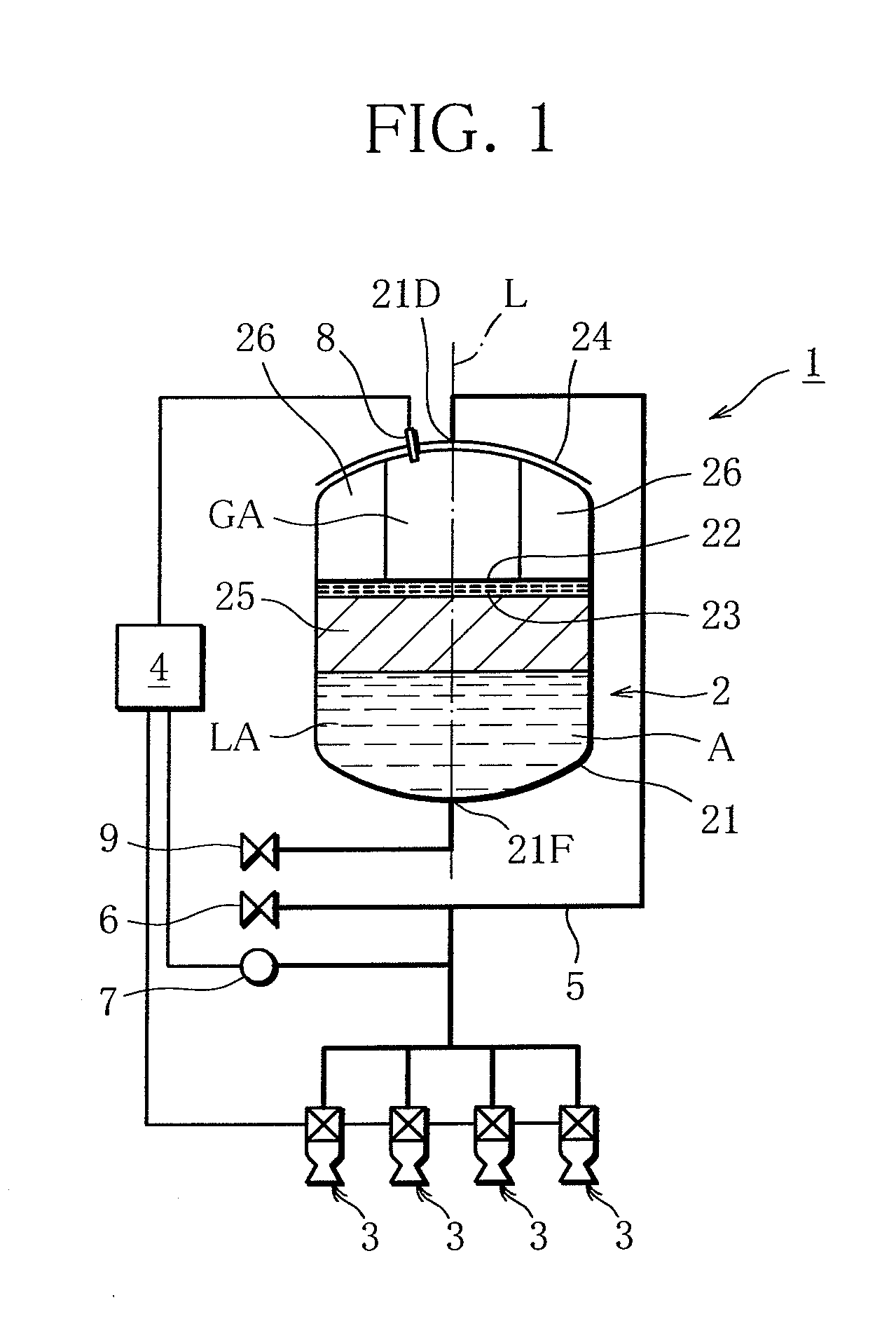

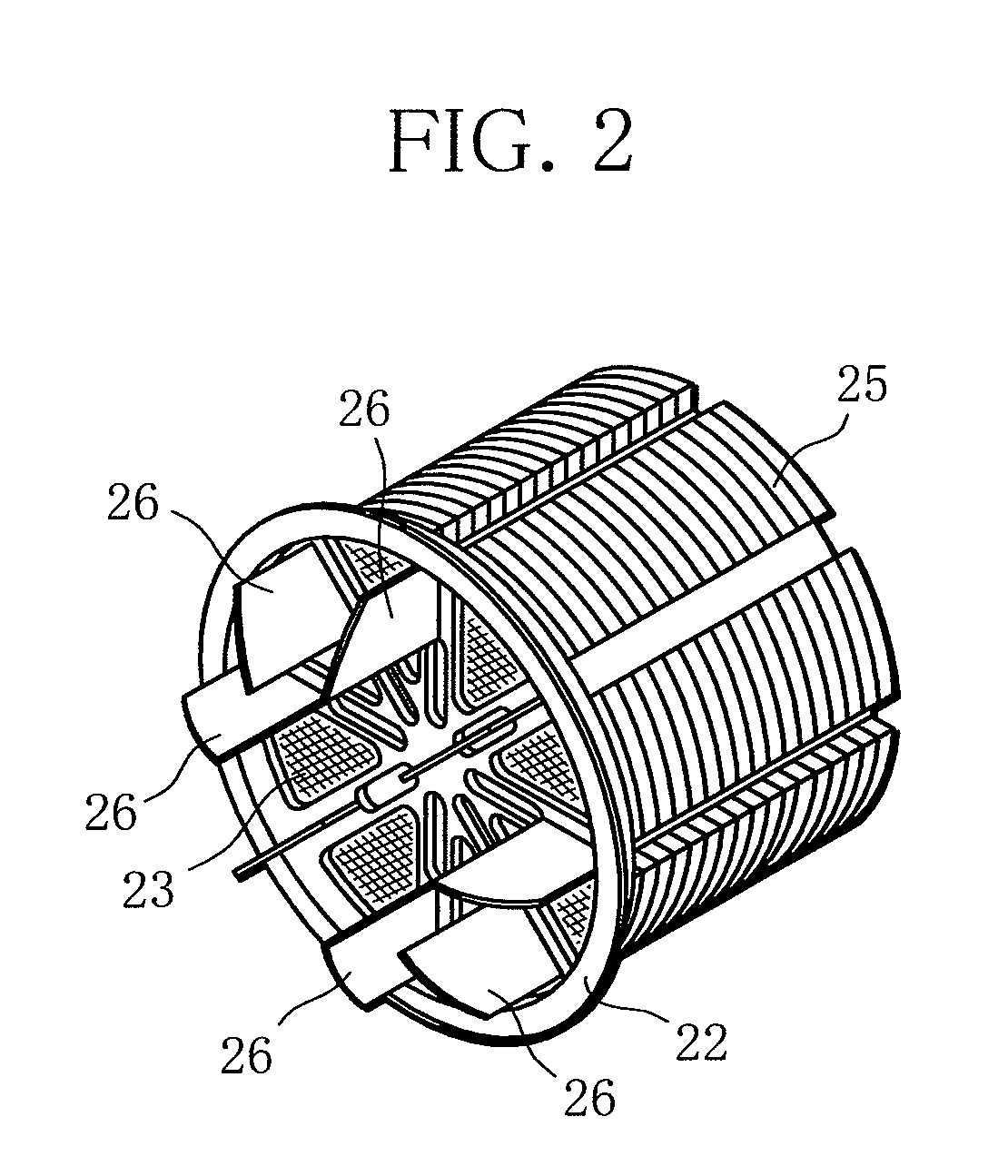

Propellant tank and vapor jet emitting device including same

InactiveUS20110214410A1Simple systemCosmonautic vehiclesDomestic cooling apparatusEvaporationPropellant tank

A propellant tank for storing a liquid propellant A and supplying vapor produced by evaporation of part of the liquid propellant A to an external location comprises a tank body for storing the liquid propellant A, a mesh member arranged inside the tank body to cover a liquid surface of the liquid propellant A to divide an interior of the tank body into a liquid propellant storing area LA and a gas storing area GA by utilizing surface tension of the liquid propellant, and a heater arranged to a gas storing area GA side of the tank body to keep the gas storing area GA at higher temperature than temperature in the liquid propellant storing area LA. The tank body has a propellant inlet open into the liquid propellant storing area LA and a gas outlet open into the gas storing area GA.

Owner:JAPAN AEROSPACE EXPLORATION AGENCY +1

Combined removable nozzle test device

The invention provides a combined removable nozzle test device, which includes a fuel path inlet collector provided internally with a cavity. Two sides of the fuel path inlet collector are provided with fuel path inlets. A fuel nozzle is disposed at the upper portion of the fuel path inlet collector. The portion, which is located in the cavity of the fuel path inlet collector, of the fuel nozzle is provided with a fuel inlet. An oxidant nozzle is disposed at the upper portion of the fuel nozzle. The lower portion of the oxidant nozzle extends into the bottom in the fuel nozzle. An oxidant path inlet collector is disposed at the upper portion of the oxidant nozzle. An oxidant inlet is disposed above the oxidant path inlet collector. The fuel enters from the fuel path inlets at the two sides, and an oxidant enters from the oxidant inlet. The structure of the invention is easy to install and remove, reliable sealing of high pressure low temperature media can be achieved, the increase in test efficiency is facilitated. The invention is excellent in sealing and short in test cycle when used for an atomization test of high pressure low temperature liquid-propellant rocket engine materials and an oxidant nozzle.

Owner:BEIJING AEROSPACE PROPULSION INST

Modular rocket engine propellant offset jetting panel capable of achieving threaded connection

ActiveCN107676194AReduce processing difficultyEasy to assembleRocket engine plantsScale modelKerosene

The invention discloses a modular rocket engine propellant offset jetting panel capable of achieving threaded connection. Center direct-current pieces, periphery rotational flow pieces and a propellant flow guide panel of a coaxial centrifugal nozzle are subjected to modular design, the processing difficulty can be lowered, and assembling and maintaining are facilitated. Based on the modular design of the nozzle assembly, the center direct-current pieces are designed to be in two types with center through holes and without center through holes, the periphery rotational flow pieces are also designed to be in two types with rotational flow holes and without rotational flow holes, and thus four types of different jetting modes can be realized when the nozzle assembly is assembled. The nozzlecan be combined by users according to the actual demands, the difference of all the nozzle jetting modes of the jetting panel can be achieved, and therefore uneven propellant distribution can be realized. When being used for studying the instable mechanism of liquid-propellant rocket engine combustion, the modular rocket engine propellant offset jetting panel solves the problem of low probabilityhappening to high-frequency instable combustion of a scale model gaseous oxygen / kerosene rocket engine.

Owner:PLA PEOPLES LIBERATION ARMY OF CHINA STRATEGIC SUPPORT FORCE AEROSPACE ENG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com