Double operating mode squeezing type conveying system and design method thereof

A technology of conveying system and dual working conditions, which is used in mechanical equipment, jet propulsion devices, rocket engine devices, etc., can solve the problems of narrow flow change range, inability to practically use, and inability to adjust propellant flow, and achieves the design difficulty of solving problems. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below with reference to the accompanying drawings.

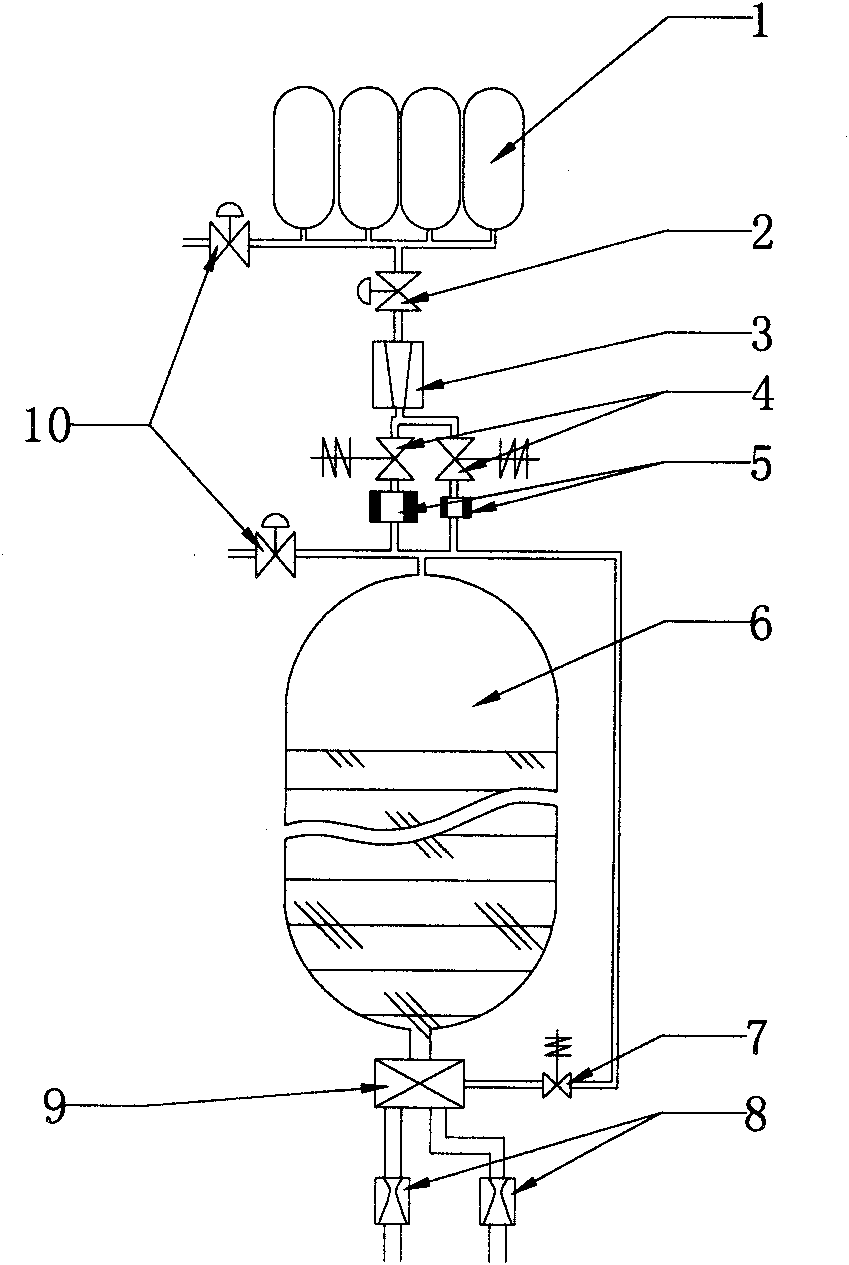

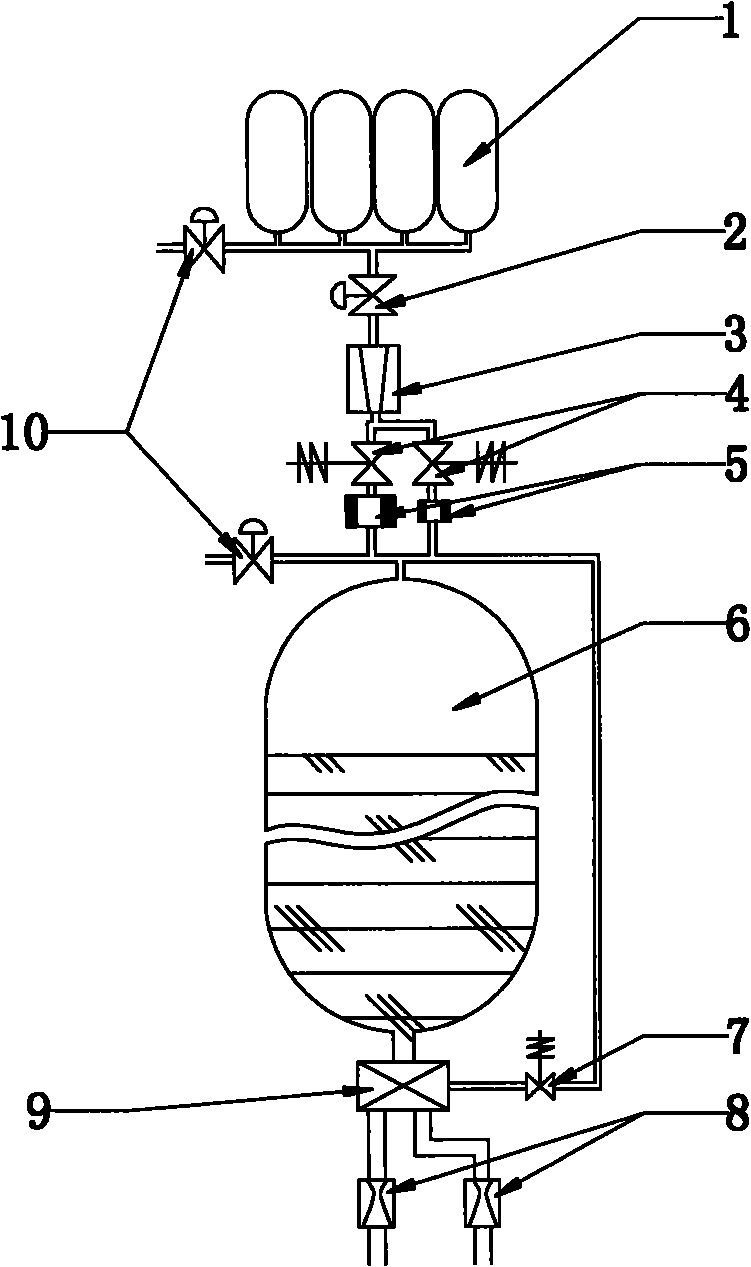

[0010] Such as figure 1 As shown, the delivery system scheme consists of pressurized gas cylinder group (1), hand valve (2, 10), pressure reducer (3), solenoid valve (4, 7), orifice (5), storage tank ( 6), consisting of a main valve with dual operating conditions in the liquid path (9), and a venturi tube (8) in the liquid path.

[0011] The design process of the conveying system is as follows:

[0012] 1. Determine the working pressure P under the two working conditions of the combustion chamber c1 and P c2 ;

[0013] 2. By calculating the pipeline loss between the storage tank and the combustion chamber, determine the storage tank pressure P under the two working conditions t1 and P t2 ;

[0014] 3. Calculate the pressurized gas volume P required to maintain the tank pressure and corresponding working hours under the two working conditions pg and pressure V pg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com