Liquid-propellant rocket engine test thrust calibration system and calibration method

A liquid rocket and calibration system technology, which is applied in the direction of engine testing, machine/structural component testing, measuring devices, etc., can solve problems such as interference mixed with unreliable data, difficult adjustment of the force loading system, and poor stability, etc., to improve Measurement accuracy, high degree of automation, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0046] 1. System composition

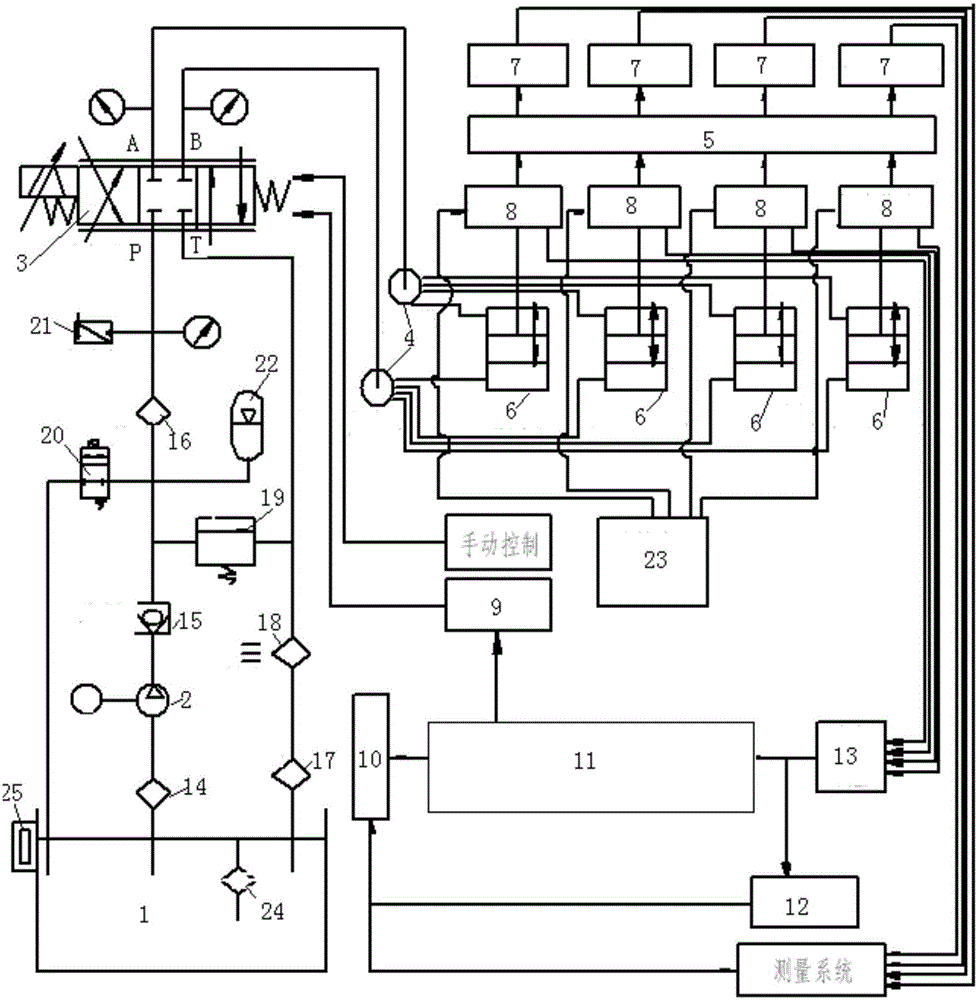

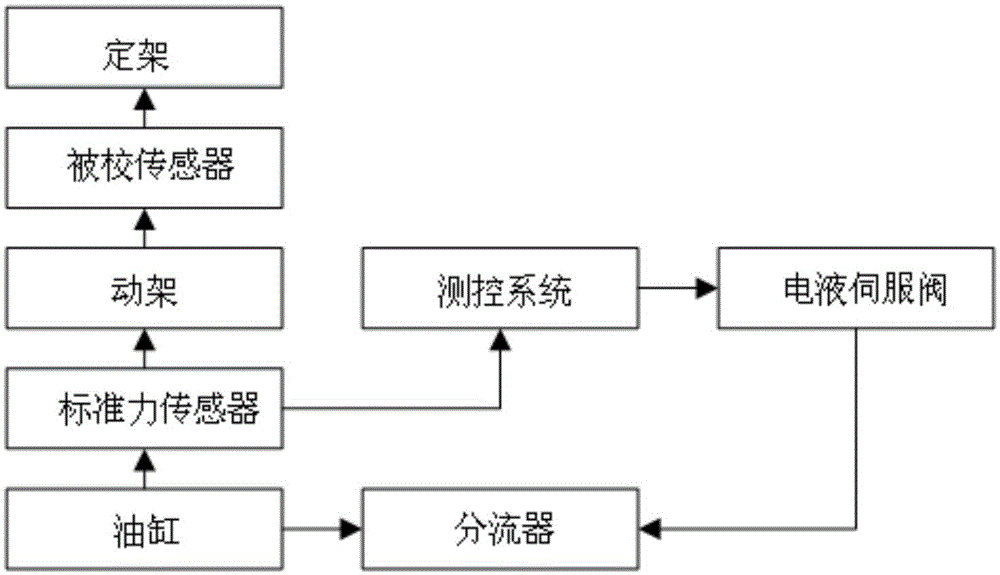

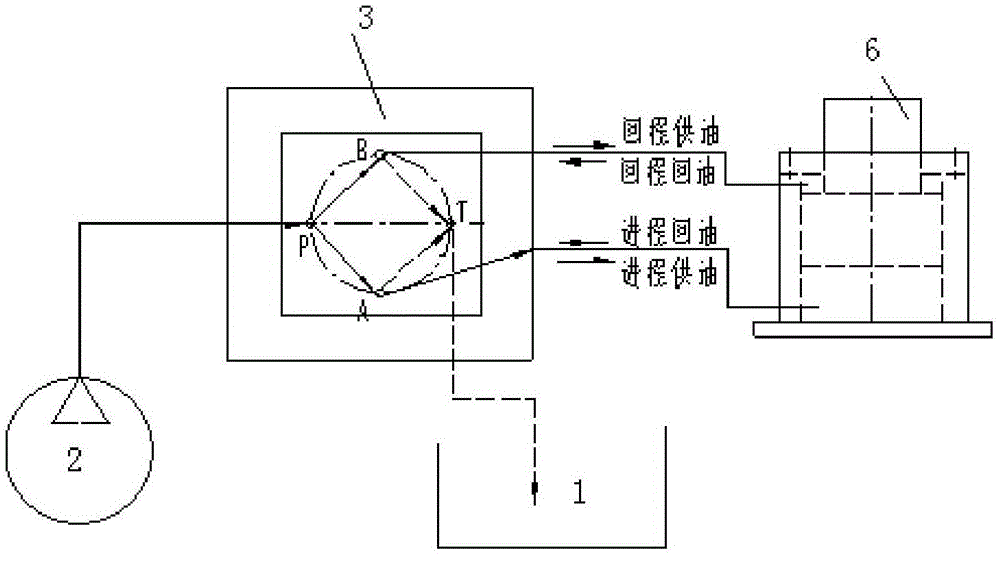

[0047] Such as figure 1 As shown, the thrust automatic calibration system of the present invention is mainly composed of a hydraulic source system, a hydraulic actuator - a jet pipe electro-hydraulic servo valve, a measurement and control system, and a force transmission system for performing calibration. The hydraulic source system is mainly composed of a fuel tank 1 and a fine filter 16 , oil return filter 17, air cooler 18, oil pump 2, overflow valve 19, one-way valve 15, two-position two-way valve 20, pressure relay 21, accumulator 22, pressure gauge, etc.; the measurement and control system is mainly composed of Computer 10, multipurpose digital meter 12, measurement and control circuit, linear power supply 23, etc.;

[0048]The hydraulic source system includes an oil pump, an oil tank, and an electro-hydraulic servo valve. The e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com